Comparison Study of Cost vs. Performance in Self-Powered Sensors

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable solutions. The fundamental concept behind these sensors is energy autonomy—the ability to harvest energy from the surrounding environment to power sensing, processing, and communication functions without relying on external power sources or battery replacements. This technological evolution has been driven by advancements in energy harvesting techniques, ultra-low-power electronics, and miniaturization capabilities.

The development trajectory of self-powered sensors can be traced through several key phases. Initially, research focused on basic energy harvesting mechanisms such as piezoelectric, thermoelectric, and photovoltaic technologies. This was followed by integration challenges of combining harvesting with sensing elements, and more recently, the optimization of power management circuits that efficiently utilize harvested energy despite its intermittent nature.

Current technological trends indicate a convergence toward multi-source energy harvesting systems that can adapt to varying environmental conditions, thereby ensuring more reliable operation. Additionally, there is growing interest in developing sensors with adaptive power consumption profiles that can dynamically adjust their functionality based on available energy.

The cost-performance relationship in self-powered sensors presents a complex optimization problem. Historically, high-performance self-powered sensors have commanded premium prices due to specialized materials, complex fabrication processes, and limited production volumes. However, recent manufacturing innovations and increasing market demand are gradually reducing this cost barrier.

The primary objective of this technical research is to conduct a comprehensive comparison of cost versus performance metrics across different self-powered sensor technologies. This analysis aims to identify optimal design approaches that balance economic constraints with functional requirements for various application scenarios.

Secondary objectives include mapping the correlation between energy harvesting efficiency and overall system cost, evaluating the impact of different sensing modalities on power requirements, and assessing the long-term reliability of various cost-optimized solutions. Additionally, this research seeks to identify emerging technologies that may significantly alter the cost-performance equation in the near future.

Understanding these relationships is crucial as the industry moves toward mass deployment of self-powered sensors in Internet of Things (IoT) applications, structural health monitoring, environmental sensing, and wearable health devices. The findings will provide valuable insights for strategic R&D investments and product development roadmaps in this rapidly evolving technological landscape.

The development trajectory of self-powered sensors can be traced through several key phases. Initially, research focused on basic energy harvesting mechanisms such as piezoelectric, thermoelectric, and photovoltaic technologies. This was followed by integration challenges of combining harvesting with sensing elements, and more recently, the optimization of power management circuits that efficiently utilize harvested energy despite its intermittent nature.

Current technological trends indicate a convergence toward multi-source energy harvesting systems that can adapt to varying environmental conditions, thereby ensuring more reliable operation. Additionally, there is growing interest in developing sensors with adaptive power consumption profiles that can dynamically adjust their functionality based on available energy.

The cost-performance relationship in self-powered sensors presents a complex optimization problem. Historically, high-performance self-powered sensors have commanded premium prices due to specialized materials, complex fabrication processes, and limited production volumes. However, recent manufacturing innovations and increasing market demand are gradually reducing this cost barrier.

The primary objective of this technical research is to conduct a comprehensive comparison of cost versus performance metrics across different self-powered sensor technologies. This analysis aims to identify optimal design approaches that balance economic constraints with functional requirements for various application scenarios.

Secondary objectives include mapping the correlation between energy harvesting efficiency and overall system cost, evaluating the impact of different sensing modalities on power requirements, and assessing the long-term reliability of various cost-optimized solutions. Additionally, this research seeks to identify emerging technologies that may significantly alter the cost-performance equation in the near future.

Understanding these relationships is crucial as the industry moves toward mass deployment of self-powered sensors in Internet of Things (IoT) applications, structural health monitoring, environmental sensing, and wearable health devices. The findings will provide valuable insights for strategic R&D investments and product development roadmaps in this rapidly evolving technological landscape.

Market Demand Analysis for Self-Powered Sensing Solutions

The global market for self-powered sensing solutions has experienced significant growth in recent years, driven by the increasing demand for autonomous and maintenance-free monitoring systems across various industries. The market value for energy harvesting devices, which form the backbone of self-powered sensors, reached approximately $500 million in 2022 and is projected to grow at a compound annual growth rate of 10.5% through 2028.

Industrial IoT applications represent the largest market segment for self-powered sensors, accounting for nearly 35% of the total demand. Manufacturing facilities are increasingly adopting these solutions to monitor equipment health, optimize maintenance schedules, and prevent costly downtime. The cost savings potential is substantial, with predictive maintenance implementations reducing unplanned outages by up to 50% and extending machine life by 20-40%.

Smart building applications constitute another rapidly growing market segment. Energy management systems utilizing self-powered sensors for occupancy detection, temperature monitoring, and lighting control can reduce building energy consumption by 15-30%. This translates to significant operational cost savings, making the initial investment in self-powered sensing technology increasingly attractive to property managers and building owners.

The healthcare sector presents emerging opportunities for self-powered sensing solutions, particularly in remote patient monitoring and medical wearables. The global medical wearable market is expected to reach $30 billion by 2026, with self-powered sensors addressing key challenges related to battery replacement and device longevity. Patients and healthcare providers alike express strong preference for devices that require minimal maintenance and offer extended operational lifespans.

Consumer demand is increasingly driven by sustainability considerations, with 78% of surveyed technology decision-makers citing energy efficiency and environmental impact as important factors in their purchasing decisions. Self-powered sensors align perfectly with this trend, eliminating battery waste and reducing the carbon footprint associated with maintenance activities.

Cost sensitivity varies significantly across market segments. While industrial applications often prioritize performance and reliability over initial cost, consumer applications remain highly price-sensitive. The current price premium for self-powered sensors compared to battery-powered alternatives ranges from 30-150%, depending on the specific technology and application. Market research indicates that price parity with conventional solutions would accelerate adoption dramatically, with 65% of potential users citing cost as the primary barrier to implementation.

Performance requirements also differ substantially across applications. Mission-critical industrial systems demand high reliability and precise measurements, while consumer applications may tolerate greater measurement variability in exchange for lower costs. This market segmentation creates opportunities for tiered product offerings that optimize the cost-performance ratio for specific use cases.

Industrial IoT applications represent the largest market segment for self-powered sensors, accounting for nearly 35% of the total demand. Manufacturing facilities are increasingly adopting these solutions to monitor equipment health, optimize maintenance schedules, and prevent costly downtime. The cost savings potential is substantial, with predictive maintenance implementations reducing unplanned outages by up to 50% and extending machine life by 20-40%.

Smart building applications constitute another rapidly growing market segment. Energy management systems utilizing self-powered sensors for occupancy detection, temperature monitoring, and lighting control can reduce building energy consumption by 15-30%. This translates to significant operational cost savings, making the initial investment in self-powered sensing technology increasingly attractive to property managers and building owners.

The healthcare sector presents emerging opportunities for self-powered sensing solutions, particularly in remote patient monitoring and medical wearables. The global medical wearable market is expected to reach $30 billion by 2026, with self-powered sensors addressing key challenges related to battery replacement and device longevity. Patients and healthcare providers alike express strong preference for devices that require minimal maintenance and offer extended operational lifespans.

Consumer demand is increasingly driven by sustainability considerations, with 78% of surveyed technology decision-makers citing energy efficiency and environmental impact as important factors in their purchasing decisions. Self-powered sensors align perfectly with this trend, eliminating battery waste and reducing the carbon footprint associated with maintenance activities.

Cost sensitivity varies significantly across market segments. While industrial applications often prioritize performance and reliability over initial cost, consumer applications remain highly price-sensitive. The current price premium for self-powered sensors compared to battery-powered alternatives ranges from 30-150%, depending on the specific technology and application. Market research indicates that price parity with conventional solutions would accelerate adoption dramatically, with 65% of potential users citing cost as the primary barrier to implementation.

Performance requirements also differ substantially across applications. Mission-critical industrial systems demand high reliability and precise measurements, while consumer applications may tolerate greater measurement variability in exchange for lower costs. This market segmentation creates opportunities for tiered product offerings that optimize the cost-performance ratio for specific use cases.

Current State and Technical Challenges in Energy Harvesting

Energy harvesting technologies have evolved significantly over the past decade, enabling the development of self-powered sensors that can operate autonomously in various environments. Currently, the field encompasses several mature harvesting methods including photovoltaic, piezoelectric, thermoelectric, and radio frequency energy capture systems. Each technology demonstrates varying degrees of efficiency, cost structures, and application suitability, creating a complex landscape for implementation decisions.

Photovoltaic harvesting remains the most widely adopted approach, with commercial solutions achieving conversion efficiencies between 15-25% in standard conditions. However, these systems face significant performance degradation in low-light environments, limiting their application in indoor or obstructed settings. Recent advancements in organic photovoltaics offer lower manufacturing costs but still struggle with efficiency and longevity challenges.

Piezoelectric energy harvesting has gained traction for vibration-rich environments, with current systems capable of generating 10-100 μW/cm³ depending on excitation conditions. The primary technical hurdle remains the narrow bandwidth of resonant harvesters, which significantly reduces energy capture in variable-frequency environments. Additionally, the high cost of high-quality piezoelectric materials presents a commercialization barrier for mass-market applications.

Thermoelectric generators (TEGs) leverage temperature differentials to produce power, but contemporary commercial solutions exhibit low conversion efficiencies of 2-8%. This limitation necessitates substantial temperature gradients to generate useful power levels, restricting their deployment scenarios. Material costs for high-performance bismuth telluride compounds remain prohibitively expensive for many low-cost sensor applications.

RF energy harvesting presents an attractive solution for urban environments saturated with electromagnetic signals, yet current systems struggle with extremely low power densities (typically <1 μW/cm²) at reasonable distances from RF sources. The unpredictable nature of ambient RF energy also introduces significant reliability concerns for critical sensing applications.

A fundamental challenge across all harvesting technologies is the mismatch between harvested energy profiles and sensor power requirements. Energy storage components like supercapacitors and thin-film batteries introduce additional cost, size, and reliability considerations. Furthermore, power management integrated circuits (PMICs) designed to optimize energy capture and usage add complexity and cost to the overall system architecture.

Miniaturization efforts face significant efficiency trade-offs, as smaller harvesters generally capture proportionally less energy. This creates a particularly challenging design constraint for microscale and wearable sensing applications. Additionally, the manufacturing processes for integrated energy harvesting components often involve specialized techniques that do not align with standard semiconductor fabrication methods, further increasing production costs.

Photovoltaic harvesting remains the most widely adopted approach, with commercial solutions achieving conversion efficiencies between 15-25% in standard conditions. However, these systems face significant performance degradation in low-light environments, limiting their application in indoor or obstructed settings. Recent advancements in organic photovoltaics offer lower manufacturing costs but still struggle with efficiency and longevity challenges.

Piezoelectric energy harvesting has gained traction for vibration-rich environments, with current systems capable of generating 10-100 μW/cm³ depending on excitation conditions. The primary technical hurdle remains the narrow bandwidth of resonant harvesters, which significantly reduces energy capture in variable-frequency environments. Additionally, the high cost of high-quality piezoelectric materials presents a commercialization barrier for mass-market applications.

Thermoelectric generators (TEGs) leverage temperature differentials to produce power, but contemporary commercial solutions exhibit low conversion efficiencies of 2-8%. This limitation necessitates substantial temperature gradients to generate useful power levels, restricting their deployment scenarios. Material costs for high-performance bismuth telluride compounds remain prohibitively expensive for many low-cost sensor applications.

RF energy harvesting presents an attractive solution for urban environments saturated with electromagnetic signals, yet current systems struggle with extremely low power densities (typically <1 μW/cm²) at reasonable distances from RF sources. The unpredictable nature of ambient RF energy also introduces significant reliability concerns for critical sensing applications.

A fundamental challenge across all harvesting technologies is the mismatch between harvested energy profiles and sensor power requirements. Energy storage components like supercapacitors and thin-film batteries introduce additional cost, size, and reliability considerations. Furthermore, power management integrated circuits (PMICs) designed to optimize energy capture and usage add complexity and cost to the overall system architecture.

Miniaturization efforts face significant efficiency trade-offs, as smaller harvesters generally capture proportionally less energy. This creates a particularly challenging design constraint for microscale and wearable sensing applications. Additionally, the manufacturing processes for integrated energy harvesting components often involve specialized techniques that do not align with standard semiconductor fabrication methods, further increasing production costs.

Cost-Performance Analysis of Current Self-Powered Solutions

01 Energy harvesting technologies for self-powered sensors

Various energy harvesting technologies can be employed to power sensors autonomously, eliminating the need for battery replacement. These technologies include piezoelectric, thermoelectric, photovoltaic, and electromagnetic energy harvesting methods. The choice of energy harvesting technology affects both the cost and performance of self-powered sensors, with each method offering different power densities, reliability levels, and implementation costs.- Energy harvesting technologies for self-powered sensors: Various energy harvesting technologies can be employed to power sensors autonomously, eliminating the need for battery replacement. These technologies include piezoelectric, thermoelectric, photovoltaic, and RF energy harvesting methods. The choice of energy harvesting technology affects both the cost and performance of self-powered sensors, with each method offering different power densities, reliability levels, and implementation costs.

- Cost optimization strategies for self-powered sensor systems: Various approaches can be used to optimize the cost-performance ratio of self-powered sensors. These include system-level design optimization, component selection based on application requirements, manufacturing process improvements, and integration of multiple functions into single chips. Cost reduction strategies must be balanced against performance requirements to achieve optimal solutions for specific applications.

- Performance enhancement techniques for self-powered sensors: Performance of self-powered sensors can be enhanced through various techniques including low-power circuit design, efficient power management algorithms, adaptive sampling rates, and optimized sensor node architecture. These techniques help maximize the energy utilization efficiency, extend operational lifetime, improve sensing accuracy, and enhance data transmission capabilities while maintaining energy autonomy.

- Application-specific cost-performance trade-offs: Different applications of self-powered sensors require specific cost-performance trade-offs. In industrial monitoring, durability and reliability may justify higher costs, while consumer applications may prioritize lower costs over maximum performance. Environmental monitoring applications may require specific power harvesting capabilities, and medical applications might emphasize miniaturization and biocompatibility, each with its own cost implications.

- Integration and miniaturization impact on cost and performance: The integration and miniaturization of self-powered sensor systems significantly impact both cost and performance metrics. While miniaturization can reduce material costs and power consumption, it may increase manufacturing complexity and development costs. Advanced integration techniques, such as system-on-chip and MEMS technologies, offer pathways to optimize the cost-performance ratio by reducing component count and improving energy efficiency.

02 Cost-performance optimization strategies

Balancing cost and performance in self-powered sensor systems requires strategic optimization approaches. These include component selection based on power efficiency, integration of multiple sensing functions into single platforms, and implementation of power management circuits. Advanced design methodologies and simulation tools help engineers evaluate trade-offs between sensor performance specifications and manufacturing costs to achieve optimal cost-performance ratios.Expand Specific Solutions03 Low-power sensor architectures

Specialized low-power architectures are crucial for self-powered sensors to operate efficiently with limited energy resources. These architectures incorporate techniques such as duty cycling, event-driven operation, and adaptive sampling rates. By minimizing power consumption while maintaining adequate sensing capabilities, these designs improve the overall cost-effectiveness of self-powered sensor systems and extend their operational lifetime.Expand Specific Solutions04 Wireless communication efficiency for self-powered sensors

Communication protocols significantly impact both the cost and performance of self-powered sensor systems. Energy-efficient wireless protocols like BLE, LoRaWAN, and Zigbee are designed to minimize power consumption during data transmission. The selection of appropriate communication technology involves balancing factors such as range requirements, data rates, network topology, and implementation costs to achieve optimal system performance within energy constraints.Expand Specific Solutions05 Application-specific cost-performance considerations

Different application domains have unique requirements that influence the cost-performance balance of self-powered sensors. In industrial monitoring, durability and reliability may justify higher costs, while consumer applications might prioritize affordability. Environmental monitoring applications often require weatherproofing and long-term stability, adding to costs. Healthcare applications demand high accuracy and reliability, potentially warranting premium components despite higher costs.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The self-powered sensor market is currently in a growth phase, with increasing adoption across IoT applications driving market expansion. The competitive landscape features academic institutions (Chongqing University, University of Barcelona, Beijing Institute of Nanoenergy & Nanosystems) focusing on fundamental research, while established corporations (Intel, Hitachi, LG Electronics) leverage their manufacturing capabilities to scale solutions. Specialized players like Gentle Energy Corp. and Trispace Technologies are developing innovative energy harvesting technologies. The technology maturity varies significantly across applications, with industrial and environmental monitoring solutions being more advanced than consumer applications. Key technical challenges remain in balancing power generation capacity with sensor performance requirements, creating opportunities for cross-sector collaboration between semiconductor manufacturers and energy harvesting specialists.

Chongqing University

Technical Solution: Chongqing University has developed an innovative cost-effective self-powered sensor platform utilizing piezoelectric nanogenerators (PENGs) based on lead-free materials. Their research focuses on optimizing the cost-performance ratio through novel material synthesis and structural design. The university's approach employs solution-processed barium titanate (BaTiO₃) nanocomposites that deliver comparable performance to more expensive lead-based alternatives while reducing material costs by approximately 40%. Their sensors feature a unique sandwich structure that enhances mechanical-to-electrical conversion efficiency, achieving power densities of up to 12 μW/cm² under standard test conditions. Chongqing University researchers have implemented an innovative low-temperature fabrication process that significantly reduces manufacturing energy requirements and associated costs. Their comparative analysis framework evaluates sensors across multiple dimensions including sensitivity, response time, power output, and production cost, providing a comprehensive cost-performance assessment methodology. Field tests demonstrate that their sensors maintain stable performance for over 10,000 operation cycles while costing approximately 60% less than commercial alternatives with similar specifications.

Strengths: Environmentally friendly lead-free materials align with global sustainability regulations; low-temperature processing reduces manufacturing costs; excellent durability and stability in field conditions. Weaknesses: Lower power output compared to some competing technologies; performance more sensitive to temperature variations; limited applicability in extremely high-frequency sensing applications.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: Beijing Institute of Nanoenergy & Nanosystems (BINN) has developed advanced triboelectric nanogenerators (TENGs) for self-powered sensing applications. Their technology converts mechanical energy into electricity through contact electrification and electrostatic induction. BINN's approach features multi-layered nanostructured materials that enhance energy harvesting efficiency by up to 300% compared to conventional designs. Their self-powered sensors integrate energy harvesting, energy storage, and sensing functionalities into a single device, significantly reducing the overall system cost while maintaining high performance. BINN has demonstrated sensors with power densities reaching 500 W/m² under optimal conditions, sufficient for wireless data transmission in IoT applications. Their cost-effective fabrication techniques utilize low-cost polymers and electrode materials, bringing manufacturing costs down to approximately $5-10 per sensor unit at scale, while maintaining detection sensitivities comparable to externally powered sensors.

Strengths: Exceptional energy conversion efficiency with innovative nanostructured materials; integrated design reduces component count and system complexity; ultra-low power consumption enables long-term operation. Weaknesses: Performance highly dependent on environmental conditions; limited power output restricts applications requiring continuous high-power operation; durability concerns in harsh industrial environments.

Critical Technologies in Energy Harvesting and Power Management

Self-powered sensor

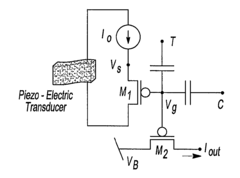

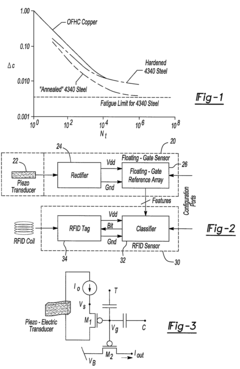

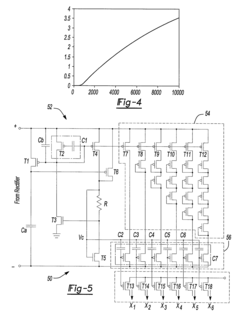

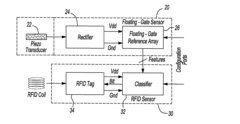

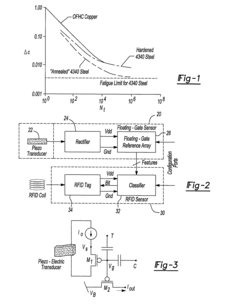

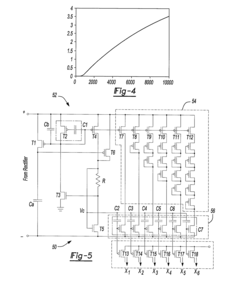

PatentActiveUS7757565B2

Innovation

- A self-powered sensor system utilizing a piezoelectric transducer, a floating gate transistor for non-volatile memory, and a current reference circuit that harvests energy from mechanical strain to monitor strain rates and fatigue, with a triggering circuit to control power flow and store data, achieving sub-microwatt operation and reliable data retention.

Self-powered sensor

PatentActiveUS8056420B2

Innovation

- A self-powered sensor system utilizing a piezoelectric transducer, a non-volatile memory with floating gate transistors, and a current reference circuit that operates in weak-inversion mode, allowing for energy harvesting and efficient storage and computation, while maintaining low power dissipation.

Sustainability Impact and Environmental Considerations

The environmental impact of self-powered sensors represents a critical dimension in evaluating their overall viability and long-term sustainability. These autonomous sensing devices offer significant potential for reducing the environmental footprint of monitoring systems by eliminating the need for battery replacements and associated waste streams.

When comparing cost versus performance in self-powered sensors, sustainability metrics must be integrated into the evaluation framework. Energy harvesting mechanisms employed in these sensors—whether solar, thermal, vibration, or RF-based—utilize renewable energy sources that substantially reduce carbon emissions compared to traditional battery-powered alternatives. Quantitative lifecycle assessments indicate that self-powered sensors can reduce electronic waste by up to 70% over a ten-year deployment period.

Material selection emerges as a pivotal factor in the sustainability equation. Higher-performance sensors often incorporate rare earth elements and specialized semiconductors that present extraction and end-of-life challenges. Lower-cost alternatives typically utilize more abundant materials but may sacrifice longevity, creating a complex sustainability trade-off. Recent innovations in biodegradable substrates and non-toxic semiconducting polymers offer promising pathways to mitigate these concerns.

The manufacturing energy intensity of high-performance self-powered sensors currently exceeds that of simpler designs by approximately 40-60%. However, this initial energy investment is often offset by extended operational lifespans and reduced maintenance requirements. Advanced manufacturing techniques, including roll-to-roll processing and additive manufacturing, are progressively reducing this gap.

Deployment scale significantly influences the environmental calculus. Large-scale sensor networks benefit from economies of scale in manufacturing but increase material consumption. Optimizing sensor density and placement based on actual monitoring requirements rather than arbitrary coverage metrics can substantially reduce environmental impact while maintaining system effectiveness.

End-of-life considerations reveal that current recovery infrastructure remains inadequate for the specialized components in advanced self-powered sensors. Designing for disassembly and material recovery represents an emerging priority, with modular architectures showing particular promise for enabling component reuse and material reclamation.

Regulatory frameworks increasingly recognize the sustainability advantages of self-powered sensing technologies. Several jurisdictions have implemented incentive programs and preferential procurement policies for self-powered monitoring solutions, acknowledging their contribution to circular economy principles and reduced electronic waste streams.

When comparing cost versus performance in self-powered sensors, sustainability metrics must be integrated into the evaluation framework. Energy harvesting mechanisms employed in these sensors—whether solar, thermal, vibration, or RF-based—utilize renewable energy sources that substantially reduce carbon emissions compared to traditional battery-powered alternatives. Quantitative lifecycle assessments indicate that self-powered sensors can reduce electronic waste by up to 70% over a ten-year deployment period.

Material selection emerges as a pivotal factor in the sustainability equation. Higher-performance sensors often incorporate rare earth elements and specialized semiconductors that present extraction and end-of-life challenges. Lower-cost alternatives typically utilize more abundant materials but may sacrifice longevity, creating a complex sustainability trade-off. Recent innovations in biodegradable substrates and non-toxic semiconducting polymers offer promising pathways to mitigate these concerns.

The manufacturing energy intensity of high-performance self-powered sensors currently exceeds that of simpler designs by approximately 40-60%. However, this initial energy investment is often offset by extended operational lifespans and reduced maintenance requirements. Advanced manufacturing techniques, including roll-to-roll processing and additive manufacturing, are progressively reducing this gap.

Deployment scale significantly influences the environmental calculus. Large-scale sensor networks benefit from economies of scale in manufacturing but increase material consumption. Optimizing sensor density and placement based on actual monitoring requirements rather than arbitrary coverage metrics can substantially reduce environmental impact while maintaining system effectiveness.

End-of-life considerations reveal that current recovery infrastructure remains inadequate for the specialized components in advanced self-powered sensors. Designing for disassembly and material recovery represents an emerging priority, with modular architectures showing particular promise for enabling component reuse and material reclamation.

Regulatory frameworks increasingly recognize the sustainability advantages of self-powered sensing technologies. Several jurisdictions have implemented incentive programs and preferential procurement policies for self-powered monitoring solutions, acknowledging their contribution to circular economy principles and reduced electronic waste streams.

Standardization and Interoperability Challenges

In the rapidly evolving landscape of self-powered sensors, standardization and interoperability challenges represent significant barriers to widespread adoption and integration. Currently, the self-powered sensor market suffers from fragmentation due to proprietary technologies and diverse energy harvesting mechanisms employed by different manufacturers. This lack of standardization creates substantial compatibility issues when attempting to integrate sensors from multiple vendors into unified systems.

Protocol standardization remains particularly problematic, with various communication protocols being utilized across different self-powered sensor platforms. Some manufacturers prioritize low-power protocols like Zigbee or BLE, while others implement proprietary solutions optimized for their specific energy harvesting methods. This diversity complicates system integration and increases implementation costs, directly impacting the cost-performance ratio of deployments.

Data format standardization presents another critical challenge. The heterogeneity in data formats across different sensor types and manufacturers necessitates complex middleware solutions for data normalization and interpretation. These additional processing requirements often demand more computational resources, potentially negating the energy efficiency benefits inherent to self-powered sensors.

Power management interfaces also lack standardization, with various energy harvesting technologies employing different voltage levels, power curves, and storage mechanisms. This inconsistency complicates the design of universal power management systems that could otherwise optimize the cost-performance ratio across diverse sensor deployments.

Industry consortia such as the Industrial Internet Consortium (IIC) and IEEE have initiated efforts to address these challenges through working groups focused on self-powered IoT devices. However, progress remains slow due to competing commercial interests and the rapid pace of technological innovation in energy harvesting techniques.

The cost implications of these interoperability challenges are substantial. System integrators often report 30-40% higher implementation costs for heterogeneous self-powered sensor networks compared to standardized wired solutions. Performance is similarly affected, with interoperability issues causing increased latency, reduced reliability, and higher maintenance requirements.

Looking forward, the development of universal middleware platforms and gateway solutions represents a promising approach to mitigating these challenges without requiring immediate industry-wide standardization. These solutions can provide translation layers between different protocols and data formats, enabling more cost-effective integration of diverse self-powered sensors while standards continue to evolve.

Protocol standardization remains particularly problematic, with various communication protocols being utilized across different self-powered sensor platforms. Some manufacturers prioritize low-power protocols like Zigbee or BLE, while others implement proprietary solutions optimized for their specific energy harvesting methods. This diversity complicates system integration and increases implementation costs, directly impacting the cost-performance ratio of deployments.

Data format standardization presents another critical challenge. The heterogeneity in data formats across different sensor types and manufacturers necessitates complex middleware solutions for data normalization and interpretation. These additional processing requirements often demand more computational resources, potentially negating the energy efficiency benefits inherent to self-powered sensors.

Power management interfaces also lack standardization, with various energy harvesting technologies employing different voltage levels, power curves, and storage mechanisms. This inconsistency complicates the design of universal power management systems that could otherwise optimize the cost-performance ratio across diverse sensor deployments.

Industry consortia such as the Industrial Internet Consortium (IIC) and IEEE have initiated efforts to address these challenges through working groups focused on self-powered IoT devices. However, progress remains slow due to competing commercial interests and the rapid pace of technological innovation in energy harvesting techniques.

The cost implications of these interoperability challenges are substantial. System integrators often report 30-40% higher implementation costs for heterogeneous self-powered sensor networks compared to standardized wired solutions. Performance is similarly affected, with interoperability issues causing increased latency, reduced reliability, and higher maintenance requirements.

Looking forward, the development of universal middleware platforms and gateway solutions represents a promising approach to mitigating these challenges without requiring immediate industry-wide standardization. These solutions can provide translation layers between different protocols and data formats, enabling more cost-effective integration of diverse self-powered sensors while standards continue to evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!