Self-Powered Sensors in Advanced Manufacturing Processes

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past decade, transforming from theoretical concepts to practical applications in manufacturing environments. The development trajectory began with basic energy harvesting mechanisms in the early 2000s, progressing through miniaturization phases and integration with wireless communication systems. Recent advancements have focused on improving energy conversion efficiency, reducing form factors, and enhancing durability in harsh industrial environments.

The technological evolution has been driven by the convergence of several fields, including materials science, microelectronics, and energy harvesting techniques. Particularly noteworthy is the shift from traditional battery-dependent sensors to autonomous systems capable of harvesting energy from their immediate environment—whether through vibration, temperature differentials, electromagnetic fields, or light sources present in manufacturing settings.

Current trends indicate accelerating development in multifunctional self-powered sensors that can simultaneously harvest energy from multiple sources, thereby increasing reliability and operational uptime. The integration of advanced materials such as piezoelectric nanostructures, triboelectric nanogenerators, and thermoelectric compounds has significantly expanded the application scope and efficiency of these systems.

The primary technical objective for self-powered sensors in advanced manufacturing is to achieve complete energy autonomy while maintaining or exceeding the performance metrics of conventional powered sensors. This includes developing sensors with sufficient sensitivity, accuracy, and response time to monitor critical manufacturing parameters without external power sources or maintenance interventions.

Secondary objectives include enhancing the sensors' ability to function reliably in challenging manufacturing environments characterized by extreme temperatures, high vibration levels, electromagnetic interference, and potentially corrosive atmospheres. The development of robust encapsulation techniques and adaptive power management systems represents critical pathways toward achieving these goals.

Long-term technical aspirations focus on creating self-powered sensor networks capable of not only monitoring manufacturing processes but also participating in closed-loop control systems. This evolution requires significant improvements in energy storage capabilities, power management efficiency, and data processing capabilities at the edge, allowing sensors to make autonomous decisions based on collected data.

The ultimate technological vision encompasses the development of self-healing, self-calibrating sensor systems that can adapt to changing manufacturing conditions while maintaining energy independence. This represents the convergence point where self-powered sensor technology could fundamentally transform manufacturing processes from periodic monitoring paradigms to continuous, real-time optimization frameworks with minimal human intervention.

The technological evolution has been driven by the convergence of several fields, including materials science, microelectronics, and energy harvesting techniques. Particularly noteworthy is the shift from traditional battery-dependent sensors to autonomous systems capable of harvesting energy from their immediate environment—whether through vibration, temperature differentials, electromagnetic fields, or light sources present in manufacturing settings.

Current trends indicate accelerating development in multifunctional self-powered sensors that can simultaneously harvest energy from multiple sources, thereby increasing reliability and operational uptime. The integration of advanced materials such as piezoelectric nanostructures, triboelectric nanogenerators, and thermoelectric compounds has significantly expanded the application scope and efficiency of these systems.

The primary technical objective for self-powered sensors in advanced manufacturing is to achieve complete energy autonomy while maintaining or exceeding the performance metrics of conventional powered sensors. This includes developing sensors with sufficient sensitivity, accuracy, and response time to monitor critical manufacturing parameters without external power sources or maintenance interventions.

Secondary objectives include enhancing the sensors' ability to function reliably in challenging manufacturing environments characterized by extreme temperatures, high vibration levels, electromagnetic interference, and potentially corrosive atmospheres. The development of robust encapsulation techniques and adaptive power management systems represents critical pathways toward achieving these goals.

Long-term technical aspirations focus on creating self-powered sensor networks capable of not only monitoring manufacturing processes but also participating in closed-loop control systems. This evolution requires significant improvements in energy storage capabilities, power management efficiency, and data processing capabilities at the edge, allowing sensors to make autonomous decisions based on collected data.

The ultimate technological vision encompasses the development of self-healing, self-calibrating sensor systems that can adapt to changing manufacturing conditions while maintaining energy independence. This represents the convergence point where self-powered sensor technology could fundamentally transform manufacturing processes from periodic monitoring paradigms to continuous, real-time optimization frameworks with minimal human intervention.

Market Demand Analysis for Self-Powered Sensing Solutions

The global market for self-powered sensing solutions in advanced manufacturing is experiencing robust growth, driven by the increasing adoption of Industry 4.0 technologies and the growing need for autonomous monitoring systems. Current market valuations indicate that the self-powered sensor market reached approximately 2.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 14.7% through 2030, potentially reaching 8.5 billion USD by the end of the forecast period.

Manufacturing environments present unique challenges that have created specific market demands for self-powered sensors. The harsh operating conditions in factories, including high temperatures, vibration, and electromagnetic interference, necessitate robust sensing solutions that can operate reliably without frequent maintenance or battery replacement. This has led to a significant demand pull from automotive, aerospace, and heavy machinery manufacturing sectors, where downtime costs can exceed thousands of dollars per minute.

Energy harvesting technologies integrated with sensors address a critical pain point in industrial settings: the high cost and logistical challenges of wiring and powering thousands of sensors throughout a manufacturing facility. Market research indicates that approximately 67% of manufacturing companies cite power supply and wiring as major obstacles to implementing comprehensive sensor networks. Self-powered solutions eliminate these barriers, driving adoption across various industrial applications.

The market segmentation reveals distinct demand patterns across different manufacturing verticals. Predictive maintenance applications currently represent the largest market share at 38%, followed by process optimization (27%), quality control (21%), and safety monitoring (14%). This distribution reflects the immediate ROI potential of preventing equipment failures and optimizing production processes.

Geographically, the demand for self-powered sensing solutions shows regional variations. North America and Europe currently lead in adoption rates due to their advanced manufacturing infrastructure and higher labor costs, which increase the value proposition of automation. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 16.8% annually, driven by rapid industrial modernization initiatives and government support for smart manufacturing.

Customer requirements analysis reveals that manufacturing end-users prioritize several key features in self-powered sensors: long operational lifetime (10+ years), reliable performance in harsh environments, seamless integration with existing industrial IoT platforms, and competitive cost structures that enable large-scale deployment. The market is increasingly demanding solutions that combine multiple sensing modalities in a single self-powered package to maximize the value proposition and reduce the total number of deployed devices.

Manufacturing environments present unique challenges that have created specific market demands for self-powered sensors. The harsh operating conditions in factories, including high temperatures, vibration, and electromagnetic interference, necessitate robust sensing solutions that can operate reliably without frequent maintenance or battery replacement. This has led to a significant demand pull from automotive, aerospace, and heavy machinery manufacturing sectors, where downtime costs can exceed thousands of dollars per minute.

Energy harvesting technologies integrated with sensors address a critical pain point in industrial settings: the high cost and logistical challenges of wiring and powering thousands of sensors throughout a manufacturing facility. Market research indicates that approximately 67% of manufacturing companies cite power supply and wiring as major obstacles to implementing comprehensive sensor networks. Self-powered solutions eliminate these barriers, driving adoption across various industrial applications.

The market segmentation reveals distinct demand patterns across different manufacturing verticals. Predictive maintenance applications currently represent the largest market share at 38%, followed by process optimization (27%), quality control (21%), and safety monitoring (14%). This distribution reflects the immediate ROI potential of preventing equipment failures and optimizing production processes.

Geographically, the demand for self-powered sensing solutions shows regional variations. North America and Europe currently lead in adoption rates due to their advanced manufacturing infrastructure and higher labor costs, which increase the value proposition of automation. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 16.8% annually, driven by rapid industrial modernization initiatives and government support for smart manufacturing.

Customer requirements analysis reveals that manufacturing end-users prioritize several key features in self-powered sensors: long operational lifetime (10+ years), reliable performance in harsh environments, seamless integration with existing industrial IoT platforms, and competitive cost structures that enable large-scale deployment. The market is increasingly demanding solutions that combine multiple sensing modalities in a single self-powered package to maximize the value proposition and reduce the total number of deployed devices.

Current Status and Challenges in Self-Powered Sensor Development

Self-powered sensors represent a significant advancement in manufacturing technology, with global research efforts intensifying over the past decade. Currently, these sensors primarily utilize energy harvesting mechanisms including piezoelectric, triboelectric, thermoelectric, and photovoltaic technologies. Each approach has achieved varying degrees of commercial readiness, with piezoelectric and photovoltaic solutions being the most mature while triboelectric nanogenerators remain predominantly in research phases.

The integration of these sensors into manufacturing environments faces several critical challenges. Power generation capacity remains insufficient for many industrial applications, with most self-powered sensors currently generating only microwatts to milliwatts of power. This limitation restricts their functionality to simple, low-power operations rather than supporting comprehensive data processing or wireless transmission capabilities required in modern smart manufacturing systems.

Reliability issues present another significant hurdle, particularly in harsh manufacturing environments characterized by extreme temperatures, vibrations, and electromagnetic interference. Current self-powered sensor technologies often demonstrate performance degradation under these conditions, with mean time between failures significantly lower than traditional powered sensors. This reliability gap creates hesitation among industrial adopters who prioritize consistent operation above all else.

Standardization represents a third major challenge, with the absence of unified protocols and interfaces hampering widespread integration. The self-powered sensor ecosystem currently features proprietary solutions with limited interoperability, creating implementation barriers for manufacturing systems that require seamless communication across multiple platforms and protocols.

Cost-effectiveness remains problematic despite progress in manufacturing techniques. The specialized materials and fabrication processes required for energy harvesting components typically result in unit costs 3-5 times higher than conventional sensors. This cost premium has limited adoption primarily to high-value applications where the elimination of wiring and battery maintenance justifies the investment.

Geographically, research leadership in self-powered sensor technology shows distinct patterns. North America and Europe lead in fundamental research and intellectual property development, while Asian countries, particularly China, Japan, and South Korea, demonstrate advantages in manufacturing scale and application-specific implementations. This distribution has created competitive dynamics in both technology development and market applications.

Recent technological breakthroughs in nanomaterials and hybrid energy harvesting approaches show promise for addressing these limitations, but significant engineering challenges remain before self-powered sensors can achieve the reliability, power output, and cost metrics necessary for widespread adoption in advanced manufacturing processes.

The integration of these sensors into manufacturing environments faces several critical challenges. Power generation capacity remains insufficient for many industrial applications, with most self-powered sensors currently generating only microwatts to milliwatts of power. This limitation restricts their functionality to simple, low-power operations rather than supporting comprehensive data processing or wireless transmission capabilities required in modern smart manufacturing systems.

Reliability issues present another significant hurdle, particularly in harsh manufacturing environments characterized by extreme temperatures, vibrations, and electromagnetic interference. Current self-powered sensor technologies often demonstrate performance degradation under these conditions, with mean time between failures significantly lower than traditional powered sensors. This reliability gap creates hesitation among industrial adopters who prioritize consistent operation above all else.

Standardization represents a third major challenge, with the absence of unified protocols and interfaces hampering widespread integration. The self-powered sensor ecosystem currently features proprietary solutions with limited interoperability, creating implementation barriers for manufacturing systems that require seamless communication across multiple platforms and protocols.

Cost-effectiveness remains problematic despite progress in manufacturing techniques. The specialized materials and fabrication processes required for energy harvesting components typically result in unit costs 3-5 times higher than conventional sensors. This cost premium has limited adoption primarily to high-value applications where the elimination of wiring and battery maintenance justifies the investment.

Geographically, research leadership in self-powered sensor technology shows distinct patterns. North America and Europe lead in fundamental research and intellectual property development, while Asian countries, particularly China, Japan, and South Korea, demonstrate advantages in manufacturing scale and application-specific implementations. This distribution has created competitive dynamics in both technology development and market applications.

Recent technological breakthroughs in nanomaterials and hybrid energy harvesting approaches show promise for addressing these limitations, but significant engineering challenges remain before self-powered sensors can achieve the reliability, power output, and cost metrics necessary for widespread adoption in advanced manufacturing processes.

Current Technical Solutions for Self-Powered Sensors

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric, thermoelectric, and electromagnetic energy conversion techniques that transform ambient energy (mechanical vibrations, temperature gradients, or electromagnetic fields) into electrical energy to power sensing devices. These self-sustaining power solutions enable sensors to operate in remote or inaccessible locations without battery replacement.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric, thermoelectric, and electromagnetic energy conversion techniques that transform ambient energy (such as vibration, heat, or motion) into electrical energy to power sensing devices. These self-sustaining power solutions enable sensors to operate autonomously in remote or inaccessible locations without battery replacement.

- Wireless self-powered sensor networks: Self-powered sensors can be integrated into wireless sensor networks that collect and transmit data without requiring external power connections. These networks utilize energy-efficient communication protocols and power management systems to extend operational lifetimes. Applications include environmental monitoring, structural health monitoring, and industrial automation where traditional wired power is impractical or cost-prohibitive.

- Triboelectric and piezoelectric sensing technologies: Triboelectric and piezoelectric materials can simultaneously generate power and serve as sensing elements, creating truly self-powered sensor systems. These materials generate electrical signals in response to mechanical stimuli, enabling the development of pressure sensors, motion detectors, and vibration monitors that operate without batteries. This dual functionality reduces system complexity and size while improving reliability in harsh environments.

- Solar and light-powered sensing systems: Photovoltaic technology enables the development of light-powered sensors that can operate continuously in illuminated environments. These systems may incorporate energy storage components to maintain operation during periods of low light. Applications include outdoor environmental monitoring, smart agriculture, and building automation where ambient light provides a reliable energy source for long-term deployment without maintenance.

- Thermal energy harvesting for sensor applications: Temperature differentials can be exploited to power sensors through thermoelectric generators. These systems convert heat gradients into electrical energy, making them suitable for industrial environments, body-worn devices, and other applications where temperature differences naturally occur. Thermal energy harvesting enables continuous monitoring in environments where other energy sources may be unavailable or unreliable.

02 Wireless self-powered sensor networks

Self-powered sensors can be integrated into wireless sensor networks that collect and transmit data without requiring external power connections. These networks utilize energy-efficient communication protocols and power management systems to optimize energy usage. The sensors harvest ambient energy to power both the sensing elements and wireless communication modules, enabling distributed monitoring systems for various applications including environmental monitoring, structural health monitoring, and industrial automation.Expand Specific Solutions03 Triboelectric and piezoelectric self-powered sensing systems

Triboelectric and piezoelectric materials can generate electrical charges in response to mechanical stimuli, making them ideal for self-powered sensing applications. These materials can simultaneously act as both energy harvesters and sensing elements, creating truly self-powered sensors. Applications include wearable health monitors, structural vibration sensors, and touch-sensitive interfaces that generate their own power through movement or pressure, eliminating the need for batteries.Expand Specific Solutions04 Solar and light-powered sensing technologies

Photovoltaic cells can be integrated with sensors to create light-powered sensing systems. These sensors utilize ambient light or dedicated light sources to generate sufficient power for sensing and data transmission operations. Advanced power management circuits and energy storage components enable operation during low-light conditions. Applications include outdoor environmental monitoring, smart agriculture, and building automation systems where light is readily available as an energy source.Expand Specific Solutions05 Thermal energy harvesting for sensor applications

Thermal energy harvesting technologies utilize temperature differentials to generate electrical power for sensors. These systems employ thermoelectric materials that convert heat gradients into electrical energy through the Seebeck effect. Self-powered thermal sensors can monitor temperature-critical environments while drawing power from the very temperature differences they are designed to measure. Applications include industrial equipment monitoring, HVAC systems, and wearable health monitors that harvest body heat.Expand Specific Solutions

Key Industry Players in Self-Powered Sensor Manufacturing

The self-powered sensor market in advanced manufacturing is currently in a growth phase, with increasing adoption driven by Industry 4.0 initiatives. The competitive landscape features established semiconductor giants like TSMC, Applied Materials, and Texas Instruments focusing on integration capabilities, while specialized players such as Gentle Energy Corp. and Tegway are developing innovative energy harvesting technologies. Major industrial automation companies including Siemens, Rockwell Automation, and Infineon are leveraging their manufacturing expertise to incorporate self-powered sensing into smart factory solutions. Academic institutions like KAIST and Zhejiang University are contributing significant research advancements, particularly in flexible thermoelectric modules and wireless monitoring systems. The technology is approaching commercial maturity in certain applications, though widespread implementation across all manufacturing sectors remains in development.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced self-powered sensor networks for their semiconductor fabrication facilities, focusing on process optimization and equipment monitoring. Their proprietary system combines multiple energy harvesting technologies, with particular emphasis on RF energy harvesting from the abundant electromagnetic fields present in semiconductor manufacturing environments. TSMC's sensors can harvest power from RF sources in the 900MHz-2.4GHz range with specialized rectennas achieving conversion efficiencies of up to 70% at optimal power levels. The system incorporates ultra-low-power CMOS circuits fabricated using their own advanced process nodes (7nm and below), enabling extremely efficient operation with power consumption as low as 100nW in sleep mode. Their sensors feature adaptive duty cycling based on available energy and event importance, with specialized wake-up receivers that can activate the main sensor circuitry only when specific trigger conditions are met. Data is processed using edge computing techniques to minimize transmission requirements, with AI algorithms running directly on the sensor nodes to identify anomalies before transmission.

Strengths: Extremely low power consumption; high integration density; leverages TSMC's advanced semiconductor manufacturing capabilities; sophisticated power management algorithms. Weaknesses: Highly customized for semiconductor manufacturing environments; significant engineering expertise required for deployment; limited applicability outside of controlled fab environments.

Applied Materials, Inc.

Technical Solution: Applied Materials has pioneered self-powered sensor technology for semiconductor manufacturing environments through their SmartFactory® platform. Their solution utilizes advanced thin-film thermoelectric generators (TEGs) that harvest energy from temperature gradients inherently present in semiconductor processing equipment. These custom-designed TEGs can generate power from temperature differences as small as 5°C, producing 1-10mW of continuous power depending on conditions. The sensors incorporate proprietary ultra-low-power MEMS technology that can operate on sub-milliwatt power budgets while monitoring critical parameters like pressure, temperature, gas flow, and vibration. Applied Materials' system features specialized power conditioning circuits with 90%+ efficiency and energy storage using advanced thin-film solid-state batteries or supercapacitors that can operate in high-temperature environments (up to 200°C). Their sensors communicate using custom RF protocols optimized for the challenging RF environments of semiconductor fabs, with mesh networking capabilities to ensure reliable data transmission.

Strengths: Specifically designed for harsh semiconductor manufacturing environments; extremely high reliability (>99.99%); seamless integration with existing fab monitoring systems; minimal maintenance requirements. Weaknesses: Higher cost compared to conventional powered sensors; limited to applications with sufficient temperature gradients; requires specialized installation procedures.

Core Patents and Innovations in Energy Harvesting Sensors

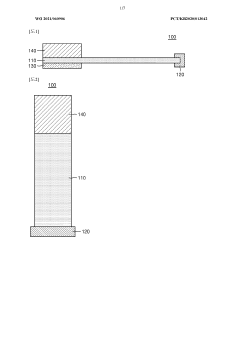

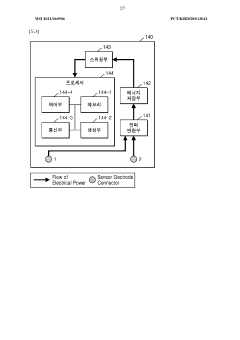

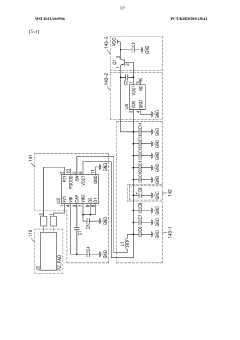

Self-powered sensor, and monitoring system including same

PatentWO2021060906A1

Innovation

- A self-powered sensor that converts external physical stimulation into electrical energy, integrating power generation and sensing units to transmit signals wirelessly without a battery or wiring, using a power management unit to switch between energized and power-saving states based on energy storage levels.

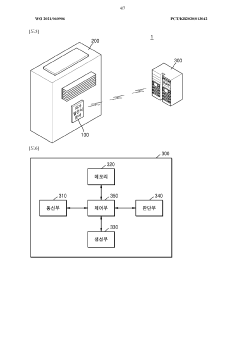

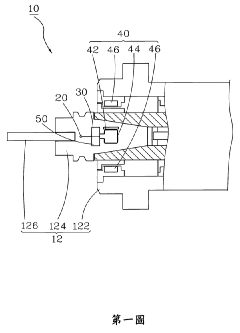

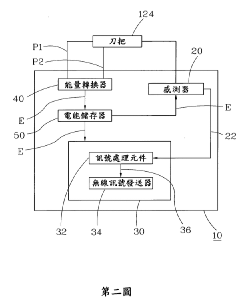

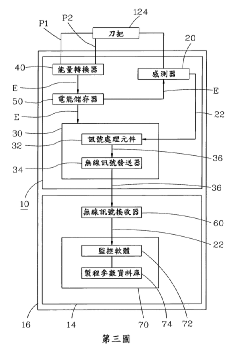

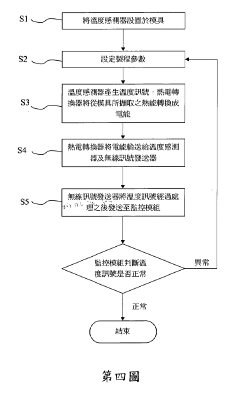

Self-power-generating sensing module for machining equipment, monitoring system having the same, and operation method of the monitoring system

PatentActiveTW201412453A

Innovation

- A self-generating sensing module that harnesses kinetic energy from machining processes to power itself, using piezoelectric materials or induction coils with magnets to convert vibration and rotation energy into electrical energy, eliminating the need for batteries.

Integration Strategies in Advanced Manufacturing Processes

The integration of self-powered sensors into advanced manufacturing processes requires strategic approaches that balance technological capabilities with practical implementation considerations. Manufacturing environments present unique challenges including harsh conditions, space constraints, and the need for reliable, continuous operation without disrupting existing workflows.

A key integration strategy involves modular sensor deployment, where self-powered sensors are designed as plug-and-play units that can be incorporated into existing machinery with minimal modifications. This approach reduces implementation costs and downtime while allowing for gradual adoption across manufacturing lines. Companies like Siemens and ABB have pioneered such modular systems that combine energy harvesting with wireless communication capabilities.

Layered architecture implementation represents another effective strategy, separating the energy harvesting components, sensing elements, and communication modules into distinct but interconnected layers. This design philosophy enables manufacturers to upgrade individual components without replacing entire sensor systems, extending the technology lifecycle and improving return on investment.

Real-time data integration frameworks must be established to handle the continuous stream of information from self-powered sensor networks. These frameworks typically incorporate edge computing capabilities to process data near its source, reducing latency and bandwidth requirements while enabling immediate response to manufacturing anomalies or quality issues.

Retrofitting strategies have emerged as a practical approach for integrating self-powered sensors into legacy manufacturing equipment. These strategies involve developing sensor packages specifically designed to attach to existing machinery, harvesting energy from the operational vibrations, heat, or motion already present in the manufacturing process.

Scalability considerations must guide integration planning, as manufacturing environments typically require hundreds or thousands of sensing points. Successful integration strategies incorporate hierarchical network architectures that can expand without exponential increases in complexity or management overhead.

Cross-functional implementation teams have proven essential for successful integration projects. These teams combine expertise from manufacturing engineering, IT infrastructure, data analytics, and operational technology domains to address the multidisciplinary challenges of sensor integration across the manufacturing ecosystem.

A key integration strategy involves modular sensor deployment, where self-powered sensors are designed as plug-and-play units that can be incorporated into existing machinery with minimal modifications. This approach reduces implementation costs and downtime while allowing for gradual adoption across manufacturing lines. Companies like Siemens and ABB have pioneered such modular systems that combine energy harvesting with wireless communication capabilities.

Layered architecture implementation represents another effective strategy, separating the energy harvesting components, sensing elements, and communication modules into distinct but interconnected layers. This design philosophy enables manufacturers to upgrade individual components without replacing entire sensor systems, extending the technology lifecycle and improving return on investment.

Real-time data integration frameworks must be established to handle the continuous stream of information from self-powered sensor networks. These frameworks typically incorporate edge computing capabilities to process data near its source, reducing latency and bandwidth requirements while enabling immediate response to manufacturing anomalies or quality issues.

Retrofitting strategies have emerged as a practical approach for integrating self-powered sensors into legacy manufacturing equipment. These strategies involve developing sensor packages specifically designed to attach to existing machinery, harvesting energy from the operational vibrations, heat, or motion already present in the manufacturing process.

Scalability considerations must guide integration planning, as manufacturing environments typically require hundreds or thousands of sensing points. Successful integration strategies incorporate hierarchical network architectures that can expand without exponential increases in complexity or management overhead.

Cross-functional implementation teams have proven essential for successful integration projects. These teams combine expertise from manufacturing engineering, IT infrastructure, data analytics, and operational technology domains to address the multidisciplinary challenges of sensor integration across the manufacturing ecosystem.

Sustainability Impact and Resource Efficiency Analysis

The integration of self-powered sensors in advanced manufacturing processes represents a significant advancement in sustainable industrial practices. These autonomous sensing systems contribute substantially to environmental sustainability by eliminating the need for external power sources and reducing electronic waste associated with battery disposal. The energy harvesting mechanisms employed—whether piezoelectric, triboelectric, thermoelectric, or photovoltaic—utilize ambient energy that would otherwise be wasted, creating a circular energy ecosystem within manufacturing environments.

From a resource efficiency perspective, self-powered sensors optimize manufacturing processes through real-time monitoring capabilities that enable precise resource allocation. Studies indicate that implementation of these sensors can reduce energy consumption in manufacturing operations by 15-30% through improved process control and predictive maintenance. Additionally, the reduction in raw material waste achieved through more accurate quality control and process optimization contributes to significant resource conservation across production lifecycles.

The carbon footprint reduction associated with self-powered sensor networks is noteworthy. By eliminating battery replacement requirements and associated maintenance operations, these systems reduce transportation emissions and operational disruptions. Quantitative assessments demonstrate that large-scale industrial deployments can achieve carbon emission reductions equivalent to removing hundreds of vehicles from roadways annually, depending on facility size and production volume.

Water conservation represents another critical sustainability benefit. Self-powered sensors enable precise monitoring of water usage in manufacturing processes, with documented case studies showing reductions of 20-25% in water consumption through leak detection and optimized cleaning cycles. This aspect is particularly valuable in water-intensive industries such as semiconductor manufacturing, food processing, and textile production.

The economic sustainability dimension cannot be overlooked. While initial implementation costs may exceed traditional sensing solutions, lifecycle cost analyses reveal favorable long-term economics. The elimination of battery replacement costs, reduced maintenance requirements, and extended operational lifespans create compelling total cost of ownership advantages. Furthermore, the resource efficiency gains translate directly to operational cost reductions, with payback periods typically ranging from 18-36 months depending on application specifics.

Looking forward, the sustainability impact of self-powered sensors will likely expand as energy harvesting efficiencies improve and material innovations reduce environmental footprints of the sensors themselves. Emerging biodegradable and recyclable sensor components promise to further enhance end-of-life sustainability considerations, creating truly circular technology solutions for advanced manufacturing environments.

From a resource efficiency perspective, self-powered sensors optimize manufacturing processes through real-time monitoring capabilities that enable precise resource allocation. Studies indicate that implementation of these sensors can reduce energy consumption in manufacturing operations by 15-30% through improved process control and predictive maintenance. Additionally, the reduction in raw material waste achieved through more accurate quality control and process optimization contributes to significant resource conservation across production lifecycles.

The carbon footprint reduction associated with self-powered sensor networks is noteworthy. By eliminating battery replacement requirements and associated maintenance operations, these systems reduce transportation emissions and operational disruptions. Quantitative assessments demonstrate that large-scale industrial deployments can achieve carbon emission reductions equivalent to removing hundreds of vehicles from roadways annually, depending on facility size and production volume.

Water conservation represents another critical sustainability benefit. Self-powered sensors enable precise monitoring of water usage in manufacturing processes, with documented case studies showing reductions of 20-25% in water consumption through leak detection and optimized cleaning cycles. This aspect is particularly valuable in water-intensive industries such as semiconductor manufacturing, food processing, and textile production.

The economic sustainability dimension cannot be overlooked. While initial implementation costs may exceed traditional sensing solutions, lifecycle cost analyses reveal favorable long-term economics. The elimination of battery replacement costs, reduced maintenance requirements, and extended operational lifespans create compelling total cost of ownership advantages. Furthermore, the resource efficiency gains translate directly to operational cost reductions, with payback periods typically ranging from 18-36 months depending on application specifics.

Looking forward, the sustainability impact of self-powered sensors will likely expand as energy harvesting efficiencies improve and material innovations reduce environmental footprints of the sensors themselves. Emerging biodegradable and recyclable sensor components promise to further enhance end-of-life sustainability considerations, creating truly circular technology solutions for advanced manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!