Exploring Resource Conservation through Self-Powered Sensors

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensing Technology Background and Objectives

Self-powered sensing technology has evolved significantly over the past two decades, transforming from laboratory curiosities to practical solutions addressing real-world challenges. The fundamental concept behind this technology lies in harvesting ambient energy from the environment—such as mechanical vibrations, thermal gradients, solar radiation, or RF signals—to power sensing devices without external power sources or battery replacements.

The evolution of this field traces back to early energy harvesting research in the 1990s, but gained substantial momentum in the early 2000s with advancements in low-power electronics and nanomaterials. The convergence of miniaturized sensors, efficient energy harvesting mechanisms, and ultra-low-power electronics has created a technological ecosystem where self-powered sensing has become increasingly viable.

Current technological trends indicate a shift toward integrated systems that combine multiple energy harvesting methods to ensure reliable operation across varying environmental conditions. Additionally, there is growing emphasis on developing sensors with adaptive power management capabilities that can dynamically adjust their operation based on available energy and application requirements.

The primary objective of self-powered sensing technology is to enable sustainable, maintenance-free monitoring solutions that can operate indefinitely in remote or inaccessible locations. This aligns perfectly with global resource conservation efforts by eliminating battery waste, reducing maintenance requirements, and enabling new applications that were previously impractical due to power constraints.

From an environmental perspective, self-powered sensors represent a significant advancement in sustainable technology. By eliminating the need for battery replacements and associated maintenance visits, these systems substantially reduce the carbon footprint associated with traditional sensing networks. Conservative estimates suggest that widespread adoption could prevent millions of batteries from entering waste streams annually.

Technical objectives in this field include improving energy conversion efficiency, reducing sensor power requirements, enhancing energy storage capabilities, and developing more robust power management systems. Researchers are particularly focused on increasing the power density of harvesting mechanisms while simultaneously decreasing the power consumption of sensing and communication components.

The ultimate goal is to develop completely autonomous sensing systems capable of perpetual operation across diverse applications—from environmental monitoring and infrastructure health assessment to industrial process control and healthcare. As this technology matures, it promises to fundamentally change our approach to sensing networks, enabling truly pervasive monitoring while minimizing resource consumption and environmental impact.

The evolution of this field traces back to early energy harvesting research in the 1990s, but gained substantial momentum in the early 2000s with advancements in low-power electronics and nanomaterials. The convergence of miniaturized sensors, efficient energy harvesting mechanisms, and ultra-low-power electronics has created a technological ecosystem where self-powered sensing has become increasingly viable.

Current technological trends indicate a shift toward integrated systems that combine multiple energy harvesting methods to ensure reliable operation across varying environmental conditions. Additionally, there is growing emphasis on developing sensors with adaptive power management capabilities that can dynamically adjust their operation based on available energy and application requirements.

The primary objective of self-powered sensing technology is to enable sustainable, maintenance-free monitoring solutions that can operate indefinitely in remote or inaccessible locations. This aligns perfectly with global resource conservation efforts by eliminating battery waste, reducing maintenance requirements, and enabling new applications that were previously impractical due to power constraints.

From an environmental perspective, self-powered sensors represent a significant advancement in sustainable technology. By eliminating the need for battery replacements and associated maintenance visits, these systems substantially reduce the carbon footprint associated with traditional sensing networks. Conservative estimates suggest that widespread adoption could prevent millions of batteries from entering waste streams annually.

Technical objectives in this field include improving energy conversion efficiency, reducing sensor power requirements, enhancing energy storage capabilities, and developing more robust power management systems. Researchers are particularly focused on increasing the power density of harvesting mechanisms while simultaneously decreasing the power consumption of sensing and communication components.

The ultimate goal is to develop completely autonomous sensing systems capable of perpetual operation across diverse applications—from environmental monitoring and infrastructure health assessment to industrial process control and healthcare. As this technology matures, it promises to fundamentally change our approach to sensing networks, enabling truly pervasive monitoring while minimizing resource consumption and environmental impact.

Market Demand Analysis for Energy-Autonomous Sensors

The global market for energy-autonomous sensors is experiencing unprecedented growth, driven by the convergence of Internet of Things (IoT) expansion, sustainability imperatives, and advancements in energy harvesting technologies. Current market projections indicate that the self-powered sensor market will reach approximately $8.5 billion by 2026, with a compound annual growth rate of 12.5% from 2021. This growth trajectory reflects the increasing demand for maintenance-free sensing solutions across multiple industries.

Industrial applications represent the largest market segment, accounting for nearly 35% of the total demand. Manufacturing facilities are increasingly adopting self-powered sensors for condition monitoring, predictive maintenance, and process optimization. The ability to deploy sensors in hard-to-reach locations without power infrastructure concerns has proven particularly valuable in legacy industrial environments where retrofitting conventional wired sensors would be prohibitively expensive.

Smart building applications constitute the second-largest market segment, with building automation systems increasingly incorporating energy-autonomous sensors for occupancy detection, environmental monitoring, and energy management. The cost savings from eliminating wiring and battery replacement has significantly improved the return on investment calculations for large-scale deployments.

Consumer electronics manufacturers are also showing growing interest in self-powered sensor technologies, particularly for wearable devices and smart home applications. The elimination of charging requirements represents a significant competitive advantage in consumer markets where convenience is paramount.

Market research indicates that end-users are primarily motivated by three factors when considering energy-autonomous sensors: total cost of ownership reduction, deployment flexibility, and environmental sustainability. The elimination of battery replacement costs can reduce lifetime operational expenses by up to 70% for certain applications, making self-powered sensors increasingly economically viable despite higher initial acquisition costs.

Regional analysis reveals that North America currently leads in adoption, followed closely by Europe and East Asia. However, the fastest growth is projected in emerging economies where infrastructure limitations make self-powered solutions particularly attractive. Countries like India and Brazil are expected to see adoption rates exceeding 18% annually through 2025.

Key market challenges include performance consistency concerns, particularly in environments with variable energy harvesting potential, and integration complexities with existing systems. Despite these challenges, market surveys indicate that 78% of industrial IoT decision-makers plan to incorporate energy-autonomous sensors into their deployment strategies within the next three years, signaling strong continued market momentum.

Industrial applications represent the largest market segment, accounting for nearly 35% of the total demand. Manufacturing facilities are increasingly adopting self-powered sensors for condition monitoring, predictive maintenance, and process optimization. The ability to deploy sensors in hard-to-reach locations without power infrastructure concerns has proven particularly valuable in legacy industrial environments where retrofitting conventional wired sensors would be prohibitively expensive.

Smart building applications constitute the second-largest market segment, with building automation systems increasingly incorporating energy-autonomous sensors for occupancy detection, environmental monitoring, and energy management. The cost savings from eliminating wiring and battery replacement has significantly improved the return on investment calculations for large-scale deployments.

Consumer electronics manufacturers are also showing growing interest in self-powered sensor technologies, particularly for wearable devices and smart home applications. The elimination of charging requirements represents a significant competitive advantage in consumer markets where convenience is paramount.

Market research indicates that end-users are primarily motivated by three factors when considering energy-autonomous sensors: total cost of ownership reduction, deployment flexibility, and environmental sustainability. The elimination of battery replacement costs can reduce lifetime operational expenses by up to 70% for certain applications, making self-powered sensors increasingly economically viable despite higher initial acquisition costs.

Regional analysis reveals that North America currently leads in adoption, followed closely by Europe and East Asia. However, the fastest growth is projected in emerging economies where infrastructure limitations make self-powered solutions particularly attractive. Countries like India and Brazil are expected to see adoption rates exceeding 18% annually through 2025.

Key market challenges include performance consistency concerns, particularly in environments with variable energy harvesting potential, and integration complexities with existing systems. Despite these challenges, market surveys indicate that 78% of industrial IoT decision-makers plan to incorporate energy-autonomous sensors into their deployment strategies within the next three years, signaling strong continued market momentum.

Current State and Challenges in Self-Powered Sensing

Self-powered sensing technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. The current landscape reveals a diverse ecosystem of energy harvesting mechanisms including piezoelectric, triboelectric, thermoelectric, photovoltaic, and RF energy harvesting technologies. Each approach demonstrates unique advantages in specific application scenarios while facing distinct limitations.

Piezoelectric energy harvesters have achieved power densities of 10-100 μW/cm³ in laboratory settings, but commercial implementations typically deliver only 1-10 μW/cm³ under real-world conditions. Similarly, triboelectric nanogenerators (TENGs) show promising theoretical performance but struggle with durability issues, with most devices experiencing 30-50% performance degradation after 10,000 operational cycles.

A significant challenge facing self-powered sensors is the power gap between energy generation and consumption. While energy harvesting technologies continue to improve, most can only generate power in the microwatt range, whereas conventional sensors often require milliwatts for continuous operation. This fundamental mismatch necessitates innovative approaches to power management and ultra-low-power sensing techniques.

Environmental adaptability represents another critical challenge. Self-powered sensors deployed in industrial settings must withstand harsh conditions including extreme temperatures, humidity, vibration, and potentially corrosive environments. Current energy harvesting materials often exhibit significant performance degradation under such conditions, limiting their practical deployment.

Miniaturization presents additional technical hurdles. As sensors shrink to accommodate space-constrained applications, the available surface area for energy harvesting diminishes proportionally. This inverse relationship between device size and energy harvesting capability creates fundamental design constraints that require novel material science and engineering solutions.

Integration complexity further complicates development efforts. Creating fully functional self-powered sensing systems requires seamless integration of energy harvesters, power management circuits, energy storage elements, sensing components, and communication modules. Current manufacturing processes struggle to achieve this integration cost-effectively at scale.

Standardization remains notably absent in the self-powered sensing domain. Unlike established sensor technologies with well-defined protocols and interfaces, self-powered sensing lacks industry-wide standards for performance metrics, testing methodologies, and interoperability frameworks. This fragmentation impedes widespread adoption and creates market uncertainty for potential implementers.

Geographic distribution of technological expertise shows concentration patterns, with piezoelectric technologies predominantly advanced in Japan and South Korea, triboelectric research centered in China, and integrated system design leadership in North America and Western Europe. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

Piezoelectric energy harvesters have achieved power densities of 10-100 μW/cm³ in laboratory settings, but commercial implementations typically deliver only 1-10 μW/cm³ under real-world conditions. Similarly, triboelectric nanogenerators (TENGs) show promising theoretical performance but struggle with durability issues, with most devices experiencing 30-50% performance degradation after 10,000 operational cycles.

A significant challenge facing self-powered sensors is the power gap between energy generation and consumption. While energy harvesting technologies continue to improve, most can only generate power in the microwatt range, whereas conventional sensors often require milliwatts for continuous operation. This fundamental mismatch necessitates innovative approaches to power management and ultra-low-power sensing techniques.

Environmental adaptability represents another critical challenge. Self-powered sensors deployed in industrial settings must withstand harsh conditions including extreme temperatures, humidity, vibration, and potentially corrosive environments. Current energy harvesting materials often exhibit significant performance degradation under such conditions, limiting their practical deployment.

Miniaturization presents additional technical hurdles. As sensors shrink to accommodate space-constrained applications, the available surface area for energy harvesting diminishes proportionally. This inverse relationship between device size and energy harvesting capability creates fundamental design constraints that require novel material science and engineering solutions.

Integration complexity further complicates development efforts. Creating fully functional self-powered sensing systems requires seamless integration of energy harvesters, power management circuits, energy storage elements, sensing components, and communication modules. Current manufacturing processes struggle to achieve this integration cost-effectively at scale.

Standardization remains notably absent in the self-powered sensing domain. Unlike established sensor technologies with well-defined protocols and interfaces, self-powered sensing lacks industry-wide standards for performance metrics, testing methodologies, and interoperability frameworks. This fragmentation impedes widespread adoption and creates market uncertainty for potential implementers.

Geographic distribution of technological expertise shows concentration patterns, with piezoelectric technologies predominantly advanced in Japan and South Korea, triboelectric research centered in China, and integrated system design leadership in North America and Western Europe. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

Current Technical Solutions for Energy Autonomous Sensing

01 Energy harvesting technologies for self-powered sensors

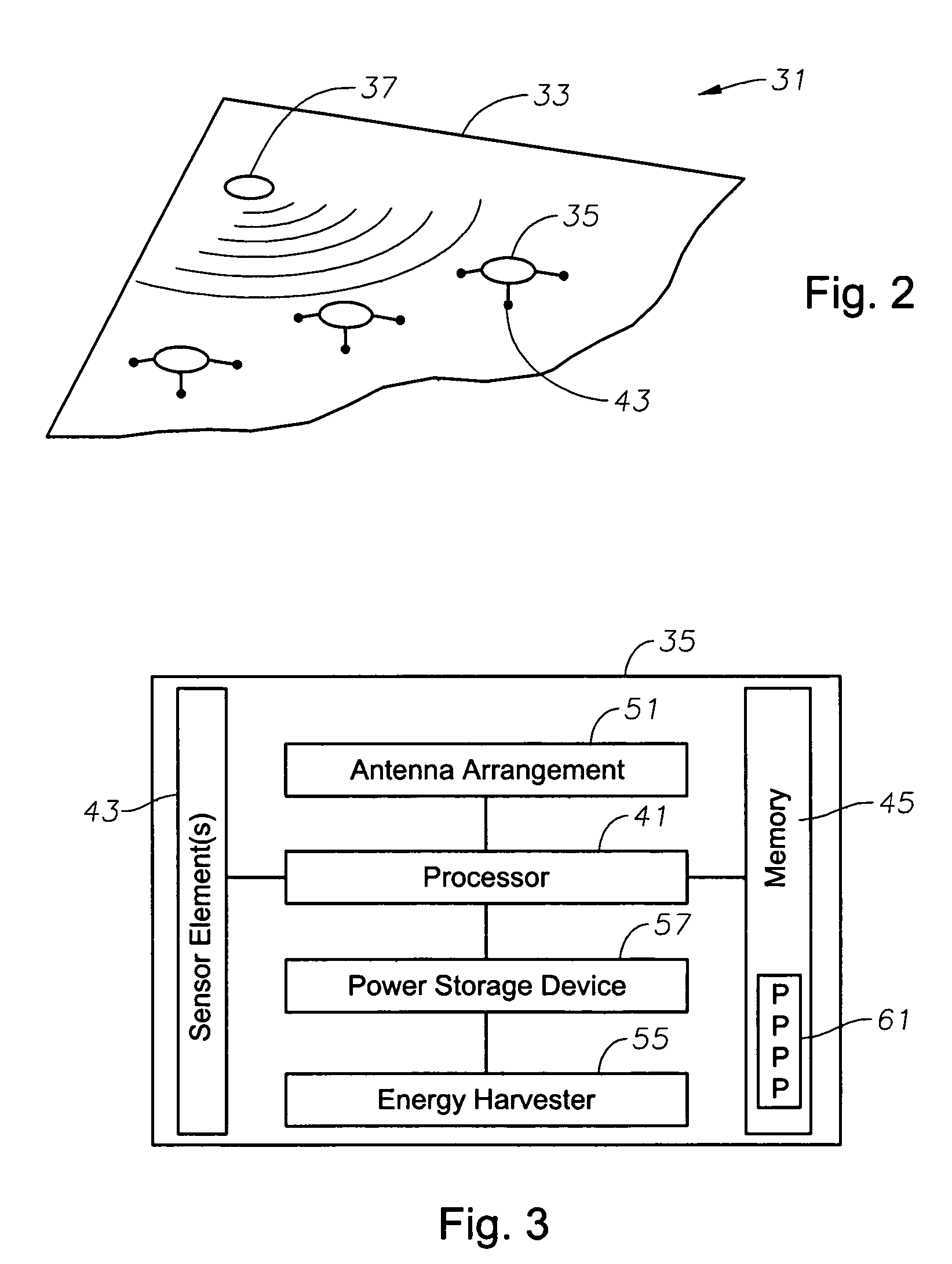

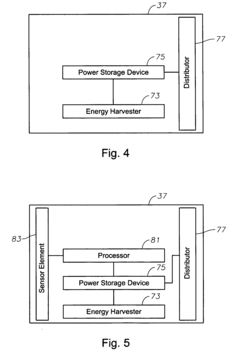

Various energy harvesting technologies can be integrated into sensor systems to make them self-powered, reducing or eliminating the need for battery replacements. These technologies convert ambient energy sources such as vibration, motion, light, or thermal gradients into electrical energy to power sensors. This approach significantly extends operational lifetimes and reduces maintenance requirements, making sensors more sustainable and resource-efficient for long-term deployments.- Energy harvesting technologies for self-powered sensors: Various energy harvesting technologies can be integrated into sensor systems to make them self-powered, reducing or eliminating the need for battery replacements. These technologies convert ambient energy sources such as vibration, motion, light, and thermal gradients into electrical energy to power sensors. This approach significantly extends operational lifetimes and reduces maintenance requirements, making sensors more sustainable and resource-efficient for long-term deployments in remote or hard-to-access locations.

- Power management and optimization techniques: Advanced power management techniques are essential for conserving resources in self-powered sensor systems. These include intelligent duty cycling, adaptive sampling rates, and low-power sleep modes that activate sensors only when necessary. By optimizing power consumption through efficient microcontroller operations, data processing algorithms, and transmission protocols, these systems can operate longer on limited energy resources, maximizing the utility of harvested energy and extending functional lifetimes in field deployments.

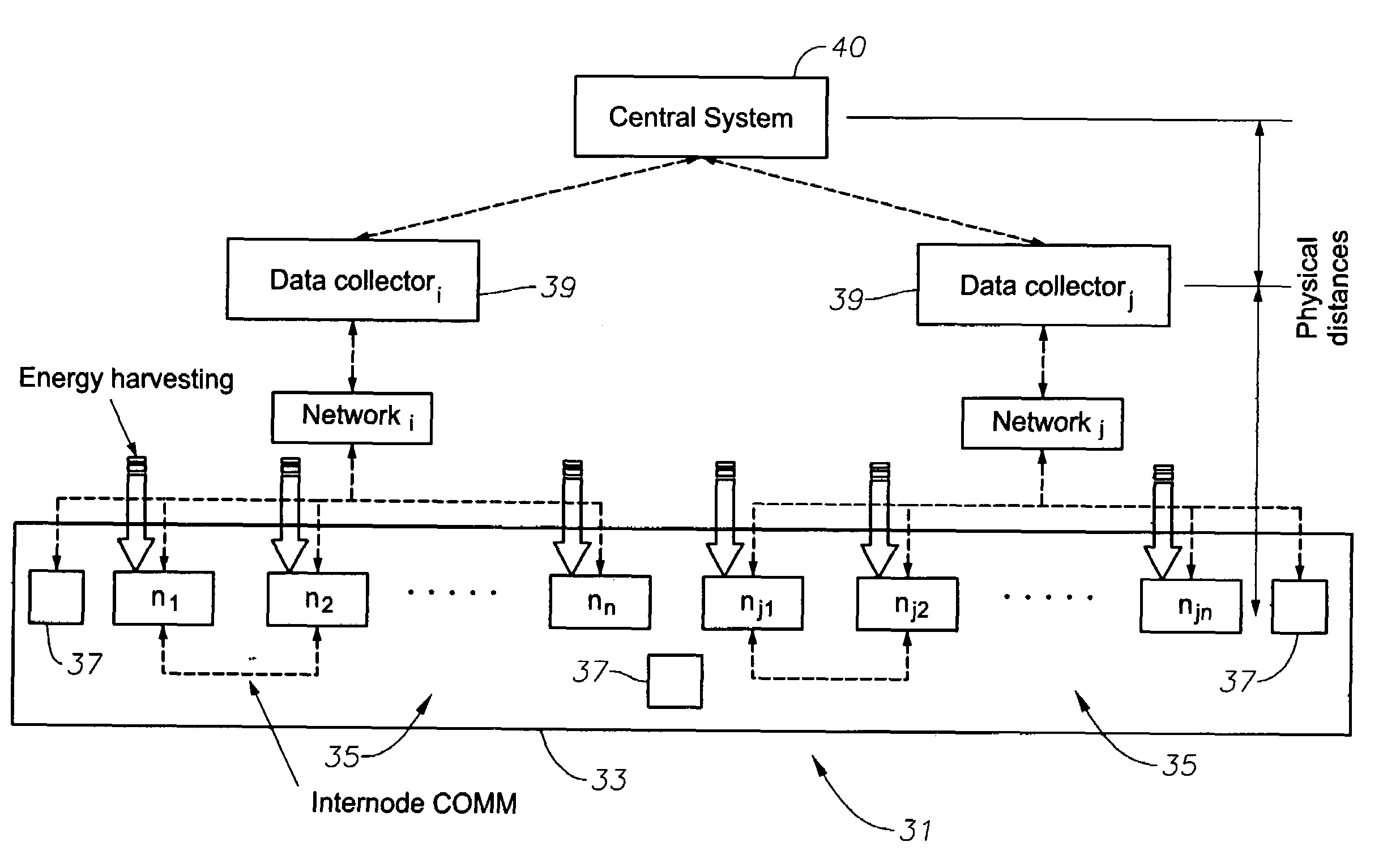

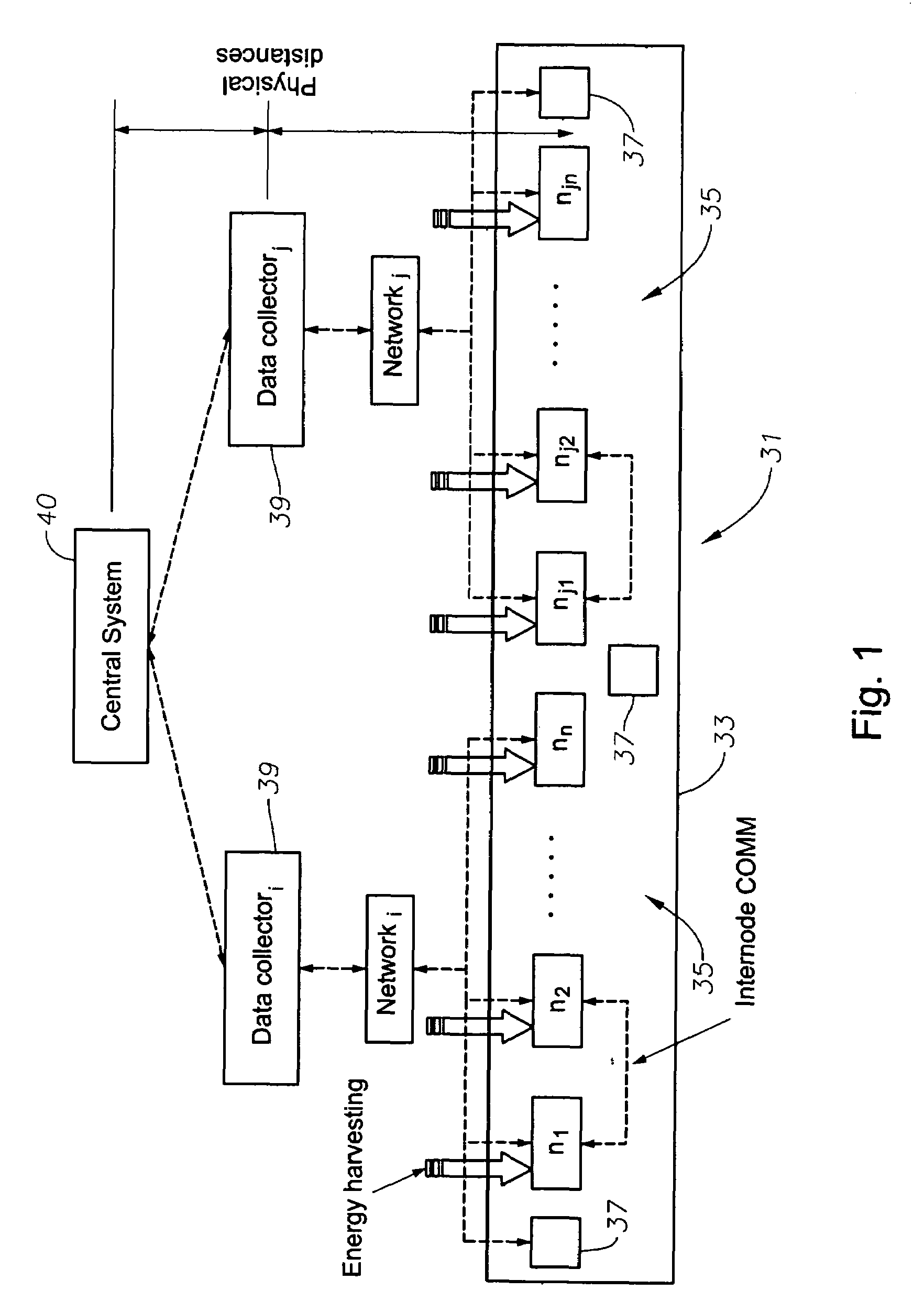

- Wireless sensor networks for resource monitoring: Self-powered wireless sensor networks enable efficient monitoring and conservation of natural resources such as water, energy, and agricultural inputs. These networks collect and transmit environmental data to central systems for analysis, allowing for precise resource allocation and reduced waste. By providing real-time monitoring capabilities without requiring grid power or frequent maintenance, these systems support sustainable resource management practices across various applications including smart agriculture, water management, and environmental protection.

- Smart building and infrastructure monitoring systems: Self-powered sensors are increasingly deployed in smart buildings and infrastructure to monitor energy usage, occupancy, and environmental conditions. These systems help optimize heating, ventilation, air conditioning, and lighting systems based on real-time data, significantly reducing energy consumption. By operating independently of building power systems and requiring minimal maintenance, these sensor networks provide continuous monitoring capabilities that support resource conservation efforts and contribute to more sustainable built environments.

- Data management and analytics for resource optimization: Advanced data management and analytics platforms process information from self-powered sensor networks to enable resource optimization. These systems employ machine learning algorithms and predictive analytics to identify patterns, detect anomalies, and generate actionable insights from sensor data. By transforming raw data into meaningful information, these platforms support decision-making processes that lead to more efficient resource allocation, reduced waste, and improved conservation outcomes across various applications and industries.

02 Power management and optimization techniques

Advanced power management systems optimize energy consumption in self-powered sensors through intelligent duty cycling, adaptive sampling rates, and low-power operating modes. These techniques ensure sensors only activate when needed and operate at minimum required power levels. By implementing sophisticated power optimization algorithms, sensor networks can significantly extend their operational lifetime while maintaining effective monitoring capabilities, thus conserving both energy resources and reducing maintenance requirements.Expand Specific Solutions03 Wireless sensor networks for resource monitoring

Self-powered wireless sensor networks enable efficient monitoring and management of natural resources, utilities, and infrastructure. These networks collect and transmit data about resource usage patterns, environmental conditions, and system performance without requiring wired power connections. By providing real-time insights into resource consumption and environmental parameters, these systems help identify inefficiencies, detect leaks or failures, and optimize resource allocation, leading to significant conservation of water, energy, and other valuable resources.Expand Specific Solutions04 Smart monitoring systems with resource-efficient data processing

Resource-efficient data processing techniques for self-powered sensors include edge computing, data compression, and selective transmission protocols. These approaches minimize energy consumption by processing data locally before transmission, reducing the volume of data sent wirelessly, and implementing intelligent algorithms that prioritize critical information. By optimizing the data handling process, these systems extend battery life, reduce network congestion, and ensure that energy is conserved while maintaining monitoring effectiveness.Expand Specific Solutions05 Resource management platforms and IoT integration

Integrated platforms combine self-powered sensors with IoT technologies to create comprehensive resource management systems. These platforms collect data from distributed sensor networks, analyze consumption patterns, and provide actionable insights through user-friendly interfaces. By leveraging cloud computing, artificial intelligence, and mobile applications, these systems enable automated resource optimization, predictive maintenance, and behavior-changing feedback loops that promote conservation across industrial, commercial, and residential applications.Expand Specific Solutions

Key Industry Players in Self-Powered Sensor Development

The self-powered sensor market is currently in a growth phase, with increasing adoption across industrial, commercial, and smart infrastructure applications. The competitive landscape features a mix of established players and emerging innovators. Major corporations like Texas Instruments, Bosch, and Honeywell are leveraging their extensive R&D capabilities to develop commercial solutions, while specialized companies such as EnOcean and Gentle Energy Corp. have established leadership in energy harvesting technologies. Academic institutions including University of Michigan and Case Western Reserve University are driving fundamental research innovations. The technology is approaching maturity for simple applications but remains in development for more complex sensing scenarios, with companies like Zolitron Technology and Sunna Design pioneering integrated solutions that combine energy harvesting with advanced analytics capabilities.

Robert Bosch GmbH

Technical Solution: Bosch has developed an extensive portfolio of self-powered sensor technologies under their MEMS and IoT divisions. Their Cross Domain Development Kit (XDK) platform incorporates multiple energy harvesting technologies including high-efficiency photovoltaic cells (22% conversion efficiency), thermoelectric generators (operating with temperature differentials as low as 2°C), and piezoelectric vibration harvesters. Bosch's proprietary ultra-low-power MEMS sensors feature power consumption as low as 270 nA in standby mode while maintaining rapid wake-up capabilities. Their BHI260AP self-learning AI sensor hub combines motion sensing with edge AI processing, consuming only 790 μA while performing complex activity recognition. For industrial applications, Bosch has developed self-powered wireless sensor nodes that integrate with their IoT Suite, enabling predictive maintenance and process optimization. Their energy-autonomous sensors utilize a hierarchical architecture with tiered power modes and adaptive sampling rates based on detected events and available energy. Bosch has demonstrated these technologies in automotive, industrial, and smart building applications, with field tests showing operational lifetimes exceeding 10 years without maintenance[3][6][8].

Strengths: Comprehensive vertical integration from sensor manufacturing to cloud platforms; extensive automotive and industrial qualification testing ensures reliability; advanced AI capabilities enable intelligent power management. Weaknesses: Complex implementation may require specialized expertise; higher cost compared to simpler solutions; some components optimized for specific Bosch ecosystems with limited third-party support.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive energy harvesting solutions centered around their ultra-low-power microcontrollers and power management ICs. Their MSP430 microcontroller family operates at voltages as low as 1.8V with power consumption under 100μA/MHz in active mode and less than 1μA in standby mode. TI's BQ25570 power management IC is specifically designed for harvesting microwatts to milliwatts from various sources including solar, thermal, and vibration. It features a highly efficient boost converter that can start with input voltages as low as 330mV, achieving up to 90% conversion efficiency. The integrated maximum power point tracking (MPPT) optimizes energy extraction from variable sources. TI's CC2650 wireless MCU combines ultra-low-power operation with multi-protocol support (Bluetooth, ZigBee, 6LoWPAN) for flexible connectivity options. Their reference designs demonstrate complete self-powered sensor systems that can operate perpetually from ambient energy sources while monitoring environmental parameters, industrial equipment conditions, or building occupancy[2][5].

Strengths: Comprehensive component ecosystem from energy harvesting to processing and communication; industry-leading power efficiency metrics; extensive documentation and reference designs accelerate development. Weaknesses: Individual components require significant integration effort; solutions may be overengineered for simple applications; higher component cost compared to simpler alternatives.

Core Innovations in Energy Harvesting Mechanisms

System to monitor the health of a structure, sensor nodes, program product, and related methods

PatentActiveUS7276703B2

Innovation

- A self-powered health monitoring system that combines energy harvesting and radiated power distribution, using energy distributing nodes to convert and redistribute excess energy to sensor nodes in areas of low environmental energy, utilizing mechanical, chemical, heat, solar, or other forms of energy harvesting.

Environmental Impact Assessment of Self-Powered Technologies

The environmental impact of self-powered sensor technologies extends far beyond their immediate energy-saving benefits. When evaluating these technologies from a lifecycle perspective, they demonstrate significant advantages over conventional battery-powered alternatives. The elimination of battery replacement and disposal represents a substantial reduction in electronic waste, addressing a growing environmental concern as IoT deployments scale globally.

Manufacturing processes for self-powered sensors typically require fewer raw materials and generate less pollution compared to traditional sensing systems. Energy harvesting components such as piezoelectric materials, photovoltaic cells, and thermoelectric generators often utilize abundant materials that can be sourced with relatively low environmental impact. However, certain specialized materials like rare earth elements in some energy harvesters may present sustainability challenges that warrant careful consideration.

Carbon footprint analyses reveal that self-powered sensors can reduce greenhouse gas emissions by 60-85% over their operational lifetime compared to battery-powered equivalents. This reduction stems primarily from eliminating the energy-intensive processes of battery manufacturing and the transportation logistics associated with maintenance and replacement activities.

Water conservation benefits emerge as another critical environmental advantage. Traditional sensor networks in applications such as agricultural monitoring or industrial systems often require maintenance activities that consume water resources. Self-powered alternatives minimize these requirements while simultaneously enabling more efficient water management through continuous, maintenance-free monitoring capabilities.

Biodiversity protection represents an often-overlooked benefit of self-powered sensing technologies. Their minimal maintenance requirements reduce human disturbance in sensitive ecosystems where environmental monitoring is crucial. Additionally, their potential for miniaturization and integration into natural surroundings creates less habitat disruption than conventional monitoring equipment.

End-of-life considerations reveal both challenges and opportunities. While many energy harvesting components are recyclable, the integration of multiple materials in compact designs can complicate disassembly processes. Emerging design approaches focusing on modular construction and material selection are addressing these concerns, potentially enabling circular economy principles in future generations of self-powered sensing technologies.

Quantitative environmental impact assessments indicate that widespread adoption of self-powered sensors could reduce electronic waste by millions of tons annually while significantly decreasing the mining demand for battery materials like lithium, cobalt, and nickel—resources associated with substantial environmental and social impacts in extraction regions.

Manufacturing processes for self-powered sensors typically require fewer raw materials and generate less pollution compared to traditional sensing systems. Energy harvesting components such as piezoelectric materials, photovoltaic cells, and thermoelectric generators often utilize abundant materials that can be sourced with relatively low environmental impact. However, certain specialized materials like rare earth elements in some energy harvesters may present sustainability challenges that warrant careful consideration.

Carbon footprint analyses reveal that self-powered sensors can reduce greenhouse gas emissions by 60-85% over their operational lifetime compared to battery-powered equivalents. This reduction stems primarily from eliminating the energy-intensive processes of battery manufacturing and the transportation logistics associated with maintenance and replacement activities.

Water conservation benefits emerge as another critical environmental advantage. Traditional sensor networks in applications such as agricultural monitoring or industrial systems often require maintenance activities that consume water resources. Self-powered alternatives minimize these requirements while simultaneously enabling more efficient water management through continuous, maintenance-free monitoring capabilities.

Biodiversity protection represents an often-overlooked benefit of self-powered sensing technologies. Their minimal maintenance requirements reduce human disturbance in sensitive ecosystems where environmental monitoring is crucial. Additionally, their potential for miniaturization and integration into natural surroundings creates less habitat disruption than conventional monitoring equipment.

End-of-life considerations reveal both challenges and opportunities. While many energy harvesting components are recyclable, the integration of multiple materials in compact designs can complicate disassembly processes. Emerging design approaches focusing on modular construction and material selection are addressing these concerns, potentially enabling circular economy principles in future generations of self-powered sensing technologies.

Quantitative environmental impact assessments indicate that widespread adoption of self-powered sensors could reduce electronic waste by millions of tons annually while significantly decreasing the mining demand for battery materials like lithium, cobalt, and nickel—resources associated with substantial environmental and social impacts in extraction regions.

Standardization and Certification Requirements

The standardization and certification landscape for self-powered sensors represents a critical framework for ensuring reliability, interoperability, and market acceptance of these resource-conserving technologies. Currently, several international bodies are actively developing standards specific to energy harvesting and self-powered sensing technologies, including the IEEE P2100 series for energy harvesting, storage, and transfer, and IEC TC 47's standards for semiconductor devices used in energy harvesting applications. These standards address crucial aspects such as performance metrics, testing methodologies, and safety requirements.

For self-powered sensors to gain widespread adoption across industries, they must comply with industry-specific certifications that vary significantly by application domain. Medical applications require FDA approval in the United States and CE marking in Europe, with additional compliance to IEC 60601 for medical electrical equipment. Industrial implementations must adhere to industrial safety standards like IEC 61508 for functional safety and various explosion-proof certifications for hazardous environments.

Environmental durability certifications present another layer of requirements, with IP ratings (IEC 60529) specifying protection against dust and water ingress, and MIL-STD-810 addressing environmental design considerations for military applications. These certifications are particularly relevant for self-powered sensors deployed in harsh or remote environments where maintenance access is limited.

The electromagnetic compatibility (EMC) standards, including IEC 61000 series and CISPR 22/32, ensure that self-powered sensors neither cause nor are susceptible to electromagnetic interference. This is especially important as these devices often operate in environments with multiple electronic systems.

A significant gap in current standardization efforts relates to the long-term reliability assessment of energy harvesting mechanisms. The industry lacks standardized methodologies for predicting the operational lifespan of various harvesting technologies under real-world conditions. This gap creates uncertainty for potential adopters and may impede market growth.

Looking forward, emerging certification needs include sustainability metrics that quantify the environmental benefits of self-powered sensors compared to traditional powered devices. These metrics would assess factors such as reduced battery waste, lower carbon footprint from eliminated power infrastructure, and overall resource conservation throughout the product lifecycle.

For manufacturers and developers, navigating this complex certification landscape requires early integration of compliance considerations into the design process. Creating products that meet global standards from inception rather than retrofitting compliance features later significantly reduces time-to-market and development costs while ensuring broader market acceptance.

For self-powered sensors to gain widespread adoption across industries, they must comply with industry-specific certifications that vary significantly by application domain. Medical applications require FDA approval in the United States and CE marking in Europe, with additional compliance to IEC 60601 for medical electrical equipment. Industrial implementations must adhere to industrial safety standards like IEC 61508 for functional safety and various explosion-proof certifications for hazardous environments.

Environmental durability certifications present another layer of requirements, with IP ratings (IEC 60529) specifying protection against dust and water ingress, and MIL-STD-810 addressing environmental design considerations for military applications. These certifications are particularly relevant for self-powered sensors deployed in harsh or remote environments where maintenance access is limited.

The electromagnetic compatibility (EMC) standards, including IEC 61000 series and CISPR 22/32, ensure that self-powered sensors neither cause nor are susceptible to electromagnetic interference. This is especially important as these devices often operate in environments with multiple electronic systems.

A significant gap in current standardization efforts relates to the long-term reliability assessment of energy harvesting mechanisms. The industry lacks standardized methodologies for predicting the operational lifespan of various harvesting technologies under real-world conditions. This gap creates uncertainty for potential adopters and may impede market growth.

Looking forward, emerging certification needs include sustainability metrics that quantify the environmental benefits of self-powered sensors compared to traditional powered devices. These metrics would assess factors such as reduced battery waste, lower carbon footprint from eliminated power infrastructure, and overall resource conservation throughout the product lifecycle.

For manufacturers and developers, navigating this complex certification landscape requires early integration of compliance considerations into the design process. Creating products that meet global standards from inception rather than retrofitting compliance features later significantly reduces time-to-market and development costs while ensuring broader market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!