Self-Powered Sensors' Impact on Minimizing Industrial Waste

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensing Technology Background and Objectives

Self-powered sensing technology has evolved significantly over the past decade, transitioning from theoretical concepts to practical applications across various industrial sectors. The fundamental principle behind this technology lies in harvesting ambient energy from the environment—such as mechanical vibrations, thermal gradients, or electromagnetic radiation—to power sensing devices without the need for external power sources or battery replacements. This technological approach emerged from the convergence of energy harvesting techniques, low-power electronics, and advanced sensor miniaturization.

The evolution trajectory of self-powered sensors began with simple piezoelectric energy harvesters in the early 2000s and has now expanded to include triboelectric nanogenerators, thermoelectric generators, and photovoltaic cells integrated directly with sensing elements. This progression has been driven by advancements in nanomaterials, microfabrication techniques, and power management circuits that enable efficient energy conversion at increasingly smaller scales.

In the context of industrial waste minimization, self-powered sensors represent a paradigm shift in monitoring and control capabilities. Traditional industrial monitoring systems often rely on wired networks or battery-powered sensors that generate significant electronic waste through regular replacements and maintenance. The environmental impact of battery disposal, containing toxic chemicals and heavy metals, presents a growing concern as IoT deployments expand globally.

The primary technical objectives for self-powered sensing in waste reduction applications include achieving energy autonomy in harsh industrial environments, extending operational lifetimes beyond ten years without maintenance, and developing closed-loop systems that can detect, analyze, and respond to waste-generating processes in real-time. These objectives align with broader industrial sustainability goals and circular economy principles.

Current research focuses on improving energy conversion efficiency, reducing sensor power requirements, and developing robust packaging solutions that can withstand industrial conditions. The integration of machine learning algorithms directly at the sensor level—often referred to as edge computing—further enhances the capability of these systems to identify inefficiencies and reduce waste without requiring constant communication with centralized systems.

The technological trend is moving toward self-powered sensor networks that can form the backbone of smart manufacturing systems, enabling precise resource management and waste reduction through continuous monitoring of material flows, energy usage, and process parameters. These systems aim to achieve a dual environmental benefit: eliminating the waste associated with conventional sensing infrastructure while simultaneously providing the data necessary to optimize industrial processes and minimize operational waste.

The evolution trajectory of self-powered sensors began with simple piezoelectric energy harvesters in the early 2000s and has now expanded to include triboelectric nanogenerators, thermoelectric generators, and photovoltaic cells integrated directly with sensing elements. This progression has been driven by advancements in nanomaterials, microfabrication techniques, and power management circuits that enable efficient energy conversion at increasingly smaller scales.

In the context of industrial waste minimization, self-powered sensors represent a paradigm shift in monitoring and control capabilities. Traditional industrial monitoring systems often rely on wired networks or battery-powered sensors that generate significant electronic waste through regular replacements and maintenance. The environmental impact of battery disposal, containing toxic chemicals and heavy metals, presents a growing concern as IoT deployments expand globally.

The primary technical objectives for self-powered sensing in waste reduction applications include achieving energy autonomy in harsh industrial environments, extending operational lifetimes beyond ten years without maintenance, and developing closed-loop systems that can detect, analyze, and respond to waste-generating processes in real-time. These objectives align with broader industrial sustainability goals and circular economy principles.

Current research focuses on improving energy conversion efficiency, reducing sensor power requirements, and developing robust packaging solutions that can withstand industrial conditions. The integration of machine learning algorithms directly at the sensor level—often referred to as edge computing—further enhances the capability of these systems to identify inefficiencies and reduce waste without requiring constant communication with centralized systems.

The technological trend is moving toward self-powered sensor networks that can form the backbone of smart manufacturing systems, enabling precise resource management and waste reduction through continuous monitoring of material flows, energy usage, and process parameters. These systems aim to achieve a dual environmental benefit: eliminating the waste associated with conventional sensing infrastructure while simultaneously providing the data necessary to optimize industrial processes and minimize operational waste.

Market Demand for Waste Reduction Solutions

The global market for industrial waste reduction solutions is experiencing significant growth, driven by increasing environmental regulations, corporate sustainability initiatives, and economic pressures to optimize resource utilization. According to recent market analyses, the global waste management market was valued at approximately $423 billion in 2020 and is projected to reach $542 billion by 2025, with waste reduction technologies representing a substantial segment of this growth.

Self-powered sensors are emerging as a critical component in this market landscape, offering unprecedented capabilities for real-time monitoring and optimization of industrial processes. The demand for these sensors is particularly strong in manufacturing sectors where waste generation directly impacts operational costs and environmental compliance. Industries such as chemical processing, food and beverage, pharmaceuticals, and electronics manufacturing have shown the highest adoption rates for advanced sensing technologies.

Market research indicates that companies implementing comprehensive waste monitoring solutions typically achieve 15-30% reduction in material waste within the first year of deployment. This translates to significant cost savings, with large manufacturers reporting annual savings between $2 million and $10 million through optimized resource utilization and reduced waste disposal costs.

The regulatory landscape is also driving market demand, with increasingly stringent environmental regulations in major industrial economies. The European Union's Circular Economy Action Plan, China's aggressive industrial pollution control measures, and the United States' tightening EPA standards all create market pull for advanced waste reduction technologies. Companies face potential fines and operational restrictions for non-compliance, making investment in waste reduction solutions a strategic priority.

Consumer and investor pressure represents another significant market driver. Studies show that 73% of global consumers expect businesses to ensure their supply chain does not harm the environment, while 78% of institutional investors now consider sustainability performance in their investment decisions. This has created a corporate imperative to demonstrate measurable waste reduction achievements.

The market for self-powered sensing solutions specifically is projected to grow at a compound annual growth rate of 19% through 2027, outpacing the broader industrial IoT market. This accelerated growth reflects the unique value proposition of energy-autonomous sensors in waste reduction applications, where traditional wired or battery-powered solutions face significant limitations in deployment scale and maintenance requirements.

Regional analysis reveals that while North America and Europe currently lead in adoption of advanced waste reduction technologies, the fastest growth is occurring in Asia-Pacific industrial centers, particularly in China, South Korea, and Singapore, where government initiatives are actively promoting smart manufacturing and environmental technology adoption.

Self-powered sensors are emerging as a critical component in this market landscape, offering unprecedented capabilities for real-time monitoring and optimization of industrial processes. The demand for these sensors is particularly strong in manufacturing sectors where waste generation directly impacts operational costs and environmental compliance. Industries such as chemical processing, food and beverage, pharmaceuticals, and electronics manufacturing have shown the highest adoption rates for advanced sensing technologies.

Market research indicates that companies implementing comprehensive waste monitoring solutions typically achieve 15-30% reduction in material waste within the first year of deployment. This translates to significant cost savings, with large manufacturers reporting annual savings between $2 million and $10 million through optimized resource utilization and reduced waste disposal costs.

The regulatory landscape is also driving market demand, with increasingly stringent environmental regulations in major industrial economies. The European Union's Circular Economy Action Plan, China's aggressive industrial pollution control measures, and the United States' tightening EPA standards all create market pull for advanced waste reduction technologies. Companies face potential fines and operational restrictions for non-compliance, making investment in waste reduction solutions a strategic priority.

Consumer and investor pressure represents another significant market driver. Studies show that 73% of global consumers expect businesses to ensure their supply chain does not harm the environment, while 78% of institutional investors now consider sustainability performance in their investment decisions. This has created a corporate imperative to demonstrate measurable waste reduction achievements.

The market for self-powered sensing solutions specifically is projected to grow at a compound annual growth rate of 19% through 2027, outpacing the broader industrial IoT market. This accelerated growth reflects the unique value proposition of energy-autonomous sensors in waste reduction applications, where traditional wired or battery-powered solutions face significant limitations in deployment scale and maintenance requirements.

Regional analysis reveals that while North America and Europe currently lead in adoption of advanced waste reduction technologies, the fastest growth is occurring in Asia-Pacific industrial centers, particularly in China, South Korea, and Singapore, where government initiatives are actively promoting smart manufacturing and environmental technology adoption.

Current State and Challenges in Self-Powered Sensor Technology

Self-powered sensor technology has witnessed significant advancements globally, yet faces substantial challenges in achieving widespread industrial adoption. Currently, these sensors primarily utilize energy harvesting mechanisms including piezoelectric, triboelectric, thermoelectric, and photovoltaic technologies to generate power from ambient environmental sources. The global market for self-powered sensors reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 18.5% through 2028, indicating strong commercial interest despite technical limitations.

In developed regions such as North America and Europe, research institutions and technology companies have achieved notable breakthroughs in miniaturization and efficiency optimization. Asian markets, particularly China, Japan, and South Korea, have demonstrated rapid advancement in manufacturing capabilities and cost reduction strategies. However, significant geographical disparities exist in technology adoption rates, with developing regions showing limited implementation due to infrastructure constraints.

The primary technical challenges currently impeding broader adoption include limited power generation capacity, with most self-powered sensors generating only microwatts to milliwatts of power. This restricts their application in high-energy-demand industrial monitoring scenarios. Energy storage integration remains problematic, as existing battery and supercapacitor technologies often compromise the size advantages and maintenance-free benefits of self-powered systems.

Reliability under harsh industrial conditions presents another significant obstacle. Temperature fluctuations, chemical exposure, and mechanical stress in industrial environments can severely impact energy harvesting efficiency and sensor longevity. Additionally, signal processing capabilities are constrained by power limitations, forcing compromises between sensing accuracy, transmission frequency, and power consumption.

Standardization issues further complicate industrial integration, as the lack of unified protocols and interfaces creates compatibility challenges with existing industrial systems. The cost-effectiveness equation remains unfavorable for many applications, with initial implementation expenses often outweighing short-term waste reduction benefits despite promising long-term ROI projections.

From a waste reduction perspective, current self-powered sensor technologies face limitations in detection range and sensitivity when monitoring industrial processes. Many waste-generating events require continuous high-resolution monitoring that exceeds current power generation capabilities. Furthermore, the environmental impact of sensor materials themselves presents a paradox, as some energy harvesting components contain rare earth elements or toxic materials that create disposal challenges at end-of-life.

Despite these challenges, recent innovations show promise, including hybrid energy harvesting approaches that combine multiple generation mechanisms, advanced low-power electronics that operate effectively with minimal energy input, and novel materials with enhanced energy conversion efficiencies. These developments suggest pathways toward overcoming current limitations and enabling self-powered sensors to fulfill their potential in industrial waste minimization applications.

In developed regions such as North America and Europe, research institutions and technology companies have achieved notable breakthroughs in miniaturization and efficiency optimization. Asian markets, particularly China, Japan, and South Korea, have demonstrated rapid advancement in manufacturing capabilities and cost reduction strategies. However, significant geographical disparities exist in technology adoption rates, with developing regions showing limited implementation due to infrastructure constraints.

The primary technical challenges currently impeding broader adoption include limited power generation capacity, with most self-powered sensors generating only microwatts to milliwatts of power. This restricts their application in high-energy-demand industrial monitoring scenarios. Energy storage integration remains problematic, as existing battery and supercapacitor technologies often compromise the size advantages and maintenance-free benefits of self-powered systems.

Reliability under harsh industrial conditions presents another significant obstacle. Temperature fluctuations, chemical exposure, and mechanical stress in industrial environments can severely impact energy harvesting efficiency and sensor longevity. Additionally, signal processing capabilities are constrained by power limitations, forcing compromises between sensing accuracy, transmission frequency, and power consumption.

Standardization issues further complicate industrial integration, as the lack of unified protocols and interfaces creates compatibility challenges with existing industrial systems. The cost-effectiveness equation remains unfavorable for many applications, with initial implementation expenses often outweighing short-term waste reduction benefits despite promising long-term ROI projections.

From a waste reduction perspective, current self-powered sensor technologies face limitations in detection range and sensitivity when monitoring industrial processes. Many waste-generating events require continuous high-resolution monitoring that exceeds current power generation capabilities. Furthermore, the environmental impact of sensor materials themselves presents a paradox, as some energy harvesting components contain rare earth elements or toxic materials that create disposal challenges at end-of-life.

Despite these challenges, recent innovations show promise, including hybrid energy harvesting approaches that combine multiple generation mechanisms, advanced low-power electronics that operate effectively with minimal energy input, and novel materials with enhanced energy conversion efficiencies. These developments suggest pathways toward overcoming current limitations and enabling self-powered sensors to fulfill their potential in industrial waste minimization applications.

Current Technical Solutions for Industrial Waste Minimization

01 Energy harvesting technologies for self-powered sensors

Various energy harvesting technologies can be integrated into self-powered sensors for industrial waste monitoring. These technologies convert ambient energy sources such as vibration, thermal gradients, and fluid flow into electrical energy to power sensing devices. By eliminating the need for battery replacement, these self-powered sensors can operate continuously in harsh industrial environments, providing real-time monitoring of waste parameters with minimal maintenance requirements.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors in industrial waste monitoring applications. These include piezoelectric generators that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differentials, and photovoltaic cells that harvest solar energy. These self-powered sensors eliminate the need for battery replacement and enable continuous monitoring in harsh industrial environments.

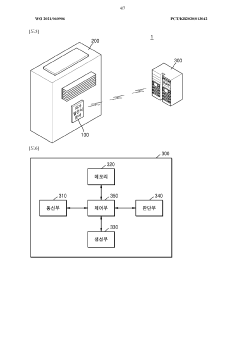

- Wireless sensor networks for industrial waste monitoring: Wireless sensor networks consisting of self-powered sensors can be deployed for comprehensive monitoring of industrial waste. These networks enable real-time data collection from multiple points, facilitating efficient waste management and environmental compliance. The sensors can communicate with central systems using various wireless protocols, allowing for remote monitoring and automated alert systems when waste parameters exceed predefined thresholds.

- Smart sensors for chemical and biological waste detection: Advanced self-powered sensors can detect and analyze chemical and biological contaminants in industrial waste streams. These sensors incorporate specialized sensing elements that respond to specific pollutants, heavy metals, or biological agents. The integration of microfluidic systems and nanomaterials enhances detection sensitivity while maintaining low power consumption, making them suitable for long-term deployment in waste management facilities.

- IoT integration for industrial waste management: Self-powered sensors can be integrated with Internet of Things (IoT) platforms to create comprehensive waste management systems. These systems collect, analyze, and visualize data from multiple sensors, enabling predictive maintenance and optimization of waste treatment processes. The IoT integration allows for automated decision-making based on sensor data, reducing response time to potential environmental hazards and improving overall waste management efficiency.

- Sustainable materials and circular economy applications: Self-powered sensors for industrial waste monitoring can be manufactured using sustainable materials and designed for circular economy applications. These sensors may incorporate biodegradable components or be designed for easy disassembly and recycling at end-of-life. Additionally, some sensors can be specifically designed to monitor and optimize resource recovery processes, supporting the transformation of waste streams into valuable resources through recycling and upcycling initiatives.

02 Waste monitoring sensor networks

Sensor networks specifically designed for industrial waste monitoring utilize multiple self-powered sensors distributed across waste management facilities. These networks can detect various parameters including chemical composition, temperature, pH levels, and contaminant concentrations. The interconnected nature of these systems allows for comprehensive data collection and analysis, enabling more efficient waste management practices and early detection of potential environmental hazards.Expand Specific Solutions03 Piezoelectric-based waste monitoring systems

Piezoelectric materials can be utilized in self-powered sensors for industrial waste monitoring by converting mechanical stress or vibration from waste processing equipment into electrical energy. These systems can be strategically placed in waste treatment facilities to harvest energy from machinery vibrations while simultaneously monitoring operational parameters. The generated electricity powers sensors that measure waste characteristics, flow rates, and equipment performance metrics.Expand Specific Solutions04 Biodegradable self-powered sensors

Environmentally friendly self-powered sensors made from biodegradable materials offer sustainable solutions for industrial waste monitoring. These sensors can be deployed in large numbers across waste sites without creating additional waste concerns. The biodegradable components break down naturally after their operational lifetime, while still providing reliable monitoring of waste parameters during their active period. Some designs incorporate biofuel cells that generate power from organic waste materials themselves.Expand Specific Solutions05 Wireless data transmission for waste monitoring

Self-powered sensor systems for industrial waste incorporate wireless data transmission capabilities to relay collected information to central monitoring stations. These systems utilize low-power communication protocols to transmit data while maintaining energy efficiency. The wireless nature eliminates the need for complex wiring in hazardous waste environments and allows for flexible deployment across large industrial sites. Some advanced systems include edge computing capabilities to process data locally before transmission, further reducing power requirements.Expand Specific Solutions

Key Industry Players in Self-Powered Sensor Development

Self-powered sensors are emerging as a transformative technology in industrial waste reduction, currently in the early growth phase with an estimated market size of $1.5-2 billion and projected annual growth of 15-20%. The technology is approaching maturity with key players driving innovation across different specializations: EnOcean and Gentle Energy Corp. lead in energy harvesting solutions, Texas Instruments and Pepperl+Fuchs excel in sensor development, while academic institutions like University of Michigan and Case Western Reserve University contribute fundamental research. Companies like Rockwell Automation and ABB Group are integrating these technologies into comprehensive industrial systems, creating a competitive landscape where specialized expertise and system integration capabilities determine market position.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced self-powered sensor solutions for industrial applications that significantly reduce waste through their MEMS (Micro-Electro-Mechanical Systems) technology platform. Their self-powered sensors incorporate piezoelectric energy harvesting elements that convert mechanical vibrations from industrial machinery into electrical energy, powering wireless sensor nodes that monitor equipment health and performance. Bosch's sensors feature ultra-low power consumption microcontrollers and proprietary power management ICs that can operate on harvested energy as low as 10μW. Their industrial waste reduction approach integrates predictive maintenance capabilities, where self-powered sensors detect early signs of equipment failure, preventing catastrophic breakdowns that generate substantial waste. Bosch's self-powered sensor networks have demonstrated up to 30% reduction in unplanned downtime and associated waste generation in manufacturing environments, with sensor lifespans exceeding 10 years without battery replacement.

Strengths: Extensive industrial expertise and established market presence; highly integrated solutions combining sensors with sophisticated analytics; robust design for harsh industrial environments. Weaknesses: Solutions often tied to broader Bosch ecosystem, potentially limiting flexibility; higher complexity requiring more technical support; customization may be needed for specific industrial applications.

EnOcean GmbH

Technical Solution: EnOcean has pioneered energy harvesting wireless technology for self-powered sensors that eliminate battery waste in industrial environments. Their patented technology harvests energy from ambient sources (motion, light, temperature differentials) to power wireless sensors and switches. Their self-powered sensors utilize electromagnetic energy converters that generate electricity from mechanical motion, miniaturized solar cells that work efficiently even in low light conditions, and thermoelectric generators that convert temperature differences into electrical energy. EnOcean's sensors communicate using ultra-low-power radio protocols specifically optimized for energy harvesting applications, with transmission ranges up to 30 meters indoors and 300 meters outdoors. Their solutions have been deployed in over 500,000 buildings worldwide, significantly reducing battery waste while providing reliable monitoring capabilities for industrial applications.

Strengths: Industry leader in energy harvesting with patented technologies; comprehensive ecosystem with interoperable products; proven reliability with millions of installations. Weaknesses: Higher initial cost compared to battery-powered alternatives; performance limitations in environments with insufficient ambient energy sources; requires specialized knowledge for optimal deployment.

Core Innovations in Energy Harvesting Sensor Technologies

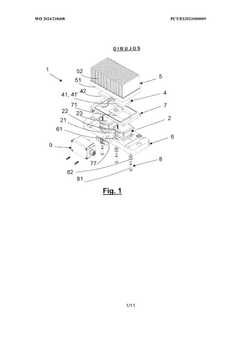

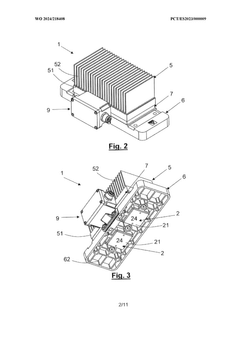

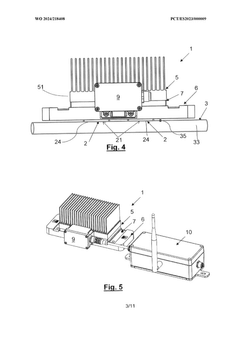

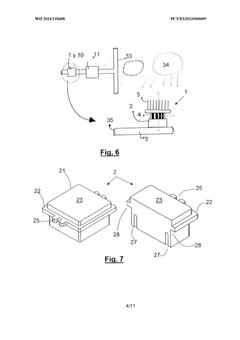

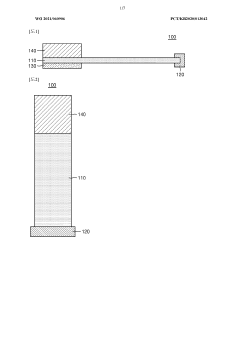

Self-powered monitoring system

PatentWO2024218408A1

Innovation

- A self-powered monitoring system utilizing a thermoelectric module that converts residual heat from industrial pipes into electrical energy to power sensors and components, eliminating the need for external energy sources or installations.

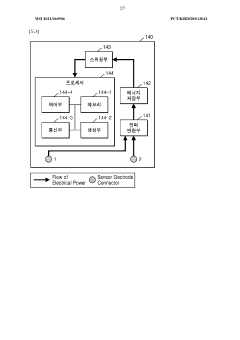

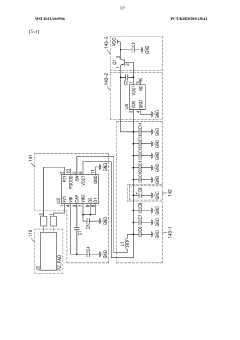

Self-powered sensor, and monitoring system including same

PatentWO2021060906A1

Innovation

- A self-powered sensor that converts external physical stimulation into electrical energy, integrating power generation and sensing units to transmit signals wirelessly without a battery or wiring, using a power management unit to switch between energized and power-saving states based on energy storage levels.

Environmental Impact Assessment Methodologies

Environmental impact assessment methodologies for self-powered sensors require systematic approaches to evaluate their contribution to industrial waste reduction. Traditional assessment methods often fail to capture the unique characteristics of these autonomous sensing technologies, necessitating specialized frameworks that consider their entire lifecycle.

Life Cycle Assessment (LCA) serves as a foundational methodology, examining environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. For self-powered sensors, this approach must be modified to account for the absence of battery replacement cycles and reduced maintenance requirements, which significantly alters their environmental footprint compared to conventional sensors.

Material Flow Analysis (MFA) provides crucial insights by tracking resource flows throughout industrial systems. When applied to self-powered sensing networks, MFA can quantify waste reduction through improved process efficiency, predictive maintenance, and resource optimization. Studies indicate that energy-harvesting sensors can reduce material waste by 15-30% in manufacturing environments through real-time monitoring and adaptive control systems.

Carbon footprint analysis methodologies have been adapted specifically for self-powered sensor networks, incorporating both embodied carbon (from manufacturing) and avoided emissions (from waste reduction). Recent research demonstrates that energy-autonomous monitoring systems in chemical processing can reduce carbon emissions by up to 22% through optimization of resource utilization and prevention of batch failures.

Waste Reduction Model (WARM) frameworks, originally developed by environmental agencies, have been modified to evaluate how sensor-driven process optimization contributes to waste minimization. These models now incorporate parameters specific to self-powered sensing technologies, including energy harvesting efficiency, data transmission protocols, and system longevity.

Economic Input-Output Life Cycle Assessment (EIO-LCA) methods help quantify broader environmental impacts across supply chains. For industrial applications of self-powered sensors, these assessments reveal significant upstream and downstream waste reduction potential beyond the immediate manufacturing environment, particularly in resource extraction and transportation sectors.

Standardization efforts are underway to develop industry-specific environmental impact metrics for self-powered sensing technologies. The International Organization for Standardization (ISO) is currently developing guidelines that will establish consistent methodologies for evaluating how these technologies contribute to industrial sustainability goals and waste reduction targets across diverse manufacturing contexts.

Life Cycle Assessment (LCA) serves as a foundational methodology, examining environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. For self-powered sensors, this approach must be modified to account for the absence of battery replacement cycles and reduced maintenance requirements, which significantly alters their environmental footprint compared to conventional sensors.

Material Flow Analysis (MFA) provides crucial insights by tracking resource flows throughout industrial systems. When applied to self-powered sensing networks, MFA can quantify waste reduction through improved process efficiency, predictive maintenance, and resource optimization. Studies indicate that energy-harvesting sensors can reduce material waste by 15-30% in manufacturing environments through real-time monitoring and adaptive control systems.

Carbon footprint analysis methodologies have been adapted specifically for self-powered sensor networks, incorporating both embodied carbon (from manufacturing) and avoided emissions (from waste reduction). Recent research demonstrates that energy-autonomous monitoring systems in chemical processing can reduce carbon emissions by up to 22% through optimization of resource utilization and prevention of batch failures.

Waste Reduction Model (WARM) frameworks, originally developed by environmental agencies, have been modified to evaluate how sensor-driven process optimization contributes to waste minimization. These models now incorporate parameters specific to self-powered sensing technologies, including energy harvesting efficiency, data transmission protocols, and system longevity.

Economic Input-Output Life Cycle Assessment (EIO-LCA) methods help quantify broader environmental impacts across supply chains. For industrial applications of self-powered sensors, these assessments reveal significant upstream and downstream waste reduction potential beyond the immediate manufacturing environment, particularly in resource extraction and transportation sectors.

Standardization efforts are underway to develop industry-specific environmental impact metrics for self-powered sensing technologies. The International Organization for Standardization (ISO) is currently developing guidelines that will establish consistent methodologies for evaluating how these technologies contribute to industrial sustainability goals and waste reduction targets across diverse manufacturing contexts.

Circular Economy Integration Strategies

The integration of self-powered sensors into circular economy frameworks represents a transformative approach to industrial waste minimization. These autonomous sensing technologies can be strategically embedded within production systems to create closed-loop material flows that significantly reduce resource consumption and waste generation. By implementing real-time monitoring of material streams, self-powered sensors enable precise identification of reusable components and recyclable materials, facilitating their recovery before they enter waste streams.

A key integration strategy involves designing industrial processes with sensor-enabled sorting systems that automatically categorize materials based on their potential for reuse or recycling. This approach creates intelligent material recovery loops where components are directed to appropriate reprocessing channels without human intervention, dramatically increasing resource efficiency while reducing sorting errors and contamination rates.

Self-powered sensors also enable the implementation of predictive maintenance systems that extend equipment lifespan through early detection of performance degradation. By continuously monitoring operational parameters, these sensors help prevent catastrophic failures that result in scrapped machinery and components. The data collected supports refurbishment decisions that keep valuable materials in circulation rather than being prematurely discarded.

Product lifecycle tracking represents another powerful integration strategy, where embedded self-powered sensors maintain digital material passports throughout a product's useful life. These passports contain critical information about material composition, usage history, and optimal end-of-life processing methods, ensuring that products can be efficiently disassembled and their materials properly reclaimed when they reach obsolescence.

Manufacturing facilities can implement sensor networks that monitor energy and material flows to identify inefficiencies and waste sources in real-time. This continuous feedback enables dynamic process optimization that progressively reduces waste generation while maintaining or improving production quality. The autonomous nature of self-powered sensors makes this monitoring sustainable over extended periods without creating additional energy demands.

For industries with complex supply chains, distributed sensor networks can coordinate material exchanges between different production facilities, creating industrial symbiosis networks where one facility's waste becomes another's raw material. These sensor-enabled material marketplaces optimize resource allocation across multiple stakeholders, maximizing the economic and environmental benefits of circular material flows while minimizing transportation impacts.

A key integration strategy involves designing industrial processes with sensor-enabled sorting systems that automatically categorize materials based on their potential for reuse or recycling. This approach creates intelligent material recovery loops where components are directed to appropriate reprocessing channels without human intervention, dramatically increasing resource efficiency while reducing sorting errors and contamination rates.

Self-powered sensors also enable the implementation of predictive maintenance systems that extend equipment lifespan through early detection of performance degradation. By continuously monitoring operational parameters, these sensors help prevent catastrophic failures that result in scrapped machinery and components. The data collected supports refurbishment decisions that keep valuable materials in circulation rather than being prematurely discarded.

Product lifecycle tracking represents another powerful integration strategy, where embedded self-powered sensors maintain digital material passports throughout a product's useful life. These passports contain critical information about material composition, usage history, and optimal end-of-life processing methods, ensuring that products can be efficiently disassembled and their materials properly reclaimed when they reach obsolescence.

Manufacturing facilities can implement sensor networks that monitor energy and material flows to identify inefficiencies and waste sources in real-time. This continuous feedback enables dynamic process optimization that progressively reduces waste generation while maintaining or improving production quality. The autonomous nature of self-powered sensors makes this monitoring sustainable over extended periods without creating additional energy demands.

For industries with complex supply chains, distributed sensor networks can coordinate material exchanges between different production facilities, creating industrial symbiosis networks where one facility's waste becomes another's raw material. These sensor-enabled material marketplaces optimize resource allocation across multiple stakeholders, maximizing the economic and environmental benefits of circular material flows while minimizing transportation impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!