Predictive Maintenance Approaches for Battery Management Systems Using Big Data

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Predictive Maintenance Background and Objectives

Predictive maintenance for Battery Management Systems (BMS) using big data has emerged as a critical area of focus in the rapidly evolving landscape of energy storage technologies. The development of this field can be traced back to the early 2000s when the proliferation of lithium-ion batteries in consumer electronics and electric vehicles necessitated more sophisticated management systems. As battery technologies advanced, so did the need for more accurate and reliable methods to monitor, predict, and optimize battery performance and lifespan.

The evolution of BMS predictive maintenance has been closely tied to advancements in sensor technologies, data analytics, and machine learning algorithms. Early systems relied on simple voltage and temperature measurements, but modern BMS incorporate a wide array of sensors that capture detailed information on battery health, usage patterns, and environmental conditions. This wealth of data, combined with the increasing computational power available, has paved the way for more sophisticated predictive maintenance approaches.

The primary objective of BMS predictive maintenance using big data is to enhance the reliability, efficiency, and longevity of battery systems while minimizing downtime and maintenance costs. This is achieved through real-time monitoring, accurate prediction of potential failures, and optimization of battery usage and charging strategies. By leveraging big data analytics, these systems aim to identify subtle patterns and anomalies that may indicate impending issues, allowing for proactive maintenance interventions before failures occur.

Another key goal is to improve the overall performance and lifespan of battery systems. By analyzing vast amounts of historical and real-time data, predictive maintenance approaches can optimize charging and discharging cycles, manage thermal conditions, and balance cell voltages more effectively. This not only extends the useful life of batteries but also ensures they operate at peak efficiency throughout their lifecycle.

As the adoption of electric vehicles and renewable energy storage solutions continues to grow, the importance of advanced BMS predictive maintenance becomes increasingly apparent. The technology aims to address critical challenges such as range anxiety in electric vehicles, grid stability in renewable energy systems, and the overall reliability of energy storage solutions in various applications. By continuously refining predictive models and incorporating new data sources, researchers and industry professionals strive to develop more accurate, robust, and adaptable BMS predictive maintenance solutions.

The evolution of BMS predictive maintenance has been closely tied to advancements in sensor technologies, data analytics, and machine learning algorithms. Early systems relied on simple voltage and temperature measurements, but modern BMS incorporate a wide array of sensors that capture detailed information on battery health, usage patterns, and environmental conditions. This wealth of data, combined with the increasing computational power available, has paved the way for more sophisticated predictive maintenance approaches.

The primary objective of BMS predictive maintenance using big data is to enhance the reliability, efficiency, and longevity of battery systems while minimizing downtime and maintenance costs. This is achieved through real-time monitoring, accurate prediction of potential failures, and optimization of battery usage and charging strategies. By leveraging big data analytics, these systems aim to identify subtle patterns and anomalies that may indicate impending issues, allowing for proactive maintenance interventions before failures occur.

Another key goal is to improve the overall performance and lifespan of battery systems. By analyzing vast amounts of historical and real-time data, predictive maintenance approaches can optimize charging and discharging cycles, manage thermal conditions, and balance cell voltages more effectively. This not only extends the useful life of batteries but also ensures they operate at peak efficiency throughout their lifecycle.

As the adoption of electric vehicles and renewable energy storage solutions continues to grow, the importance of advanced BMS predictive maintenance becomes increasingly apparent. The technology aims to address critical challenges such as range anxiety in electric vehicles, grid stability in renewable energy systems, and the overall reliability of energy storage solutions in various applications. By continuously refining predictive models and incorporating new data sources, researchers and industry professionals strive to develop more accurate, robust, and adaptable BMS predictive maintenance solutions.

Market Demand for Advanced BMS Solutions

The market demand for advanced Battery Management Systems (BMS) solutions has been experiencing significant growth, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. As the global shift towards electrification accelerates, the need for more sophisticated BMS technologies becomes increasingly critical to ensure optimal battery performance, longevity, and safety.

In the automotive sector, the surge in EV adoption has created a substantial market for advanced BMS solutions. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups within the next decade. This transition has intensified the demand for BMS that can accurately predict battery health, optimize charging cycles, and extend overall battery life. The ability to provide real-time diagnostics and predictive maintenance capabilities has become a key differentiator for EV manufacturers, as it directly impacts vehicle range, performance, and consumer confidence.

The renewable energy sector is another major driver of BMS market growth. As grid-scale energy storage systems become more prevalent, the need for sophisticated BMS solutions to manage large battery arrays has increased dramatically. These systems require advanced predictive maintenance approaches to ensure reliable operation and maximize the return on investment for utility companies and renewable energy providers.

Consumer electronics represent another significant market segment for advanced BMS solutions. With the proliferation of smartphones, laptops, and other portable devices, consumers are increasingly demanding longer battery life and faster charging times. This has led to a growing interest in BMS technologies that can optimize battery performance and provide accurate predictions of battery health and remaining lifespan.

The industrial sector is also showing increased demand for advanced BMS solutions, particularly in applications such as robotics, automated guided vehicles, and uninterruptible power supplies. These applications require highly reliable power sources, making predictive maintenance capabilities essential for minimizing downtime and ensuring operational efficiency.

Market analysts project that the global BMS market will continue to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is fueled not only by the increasing adoption of electric vehicles and renewable energy systems but also by the integration of artificial intelligence and machine learning technologies into BMS solutions. These advanced technologies enable more accurate predictions of battery health and performance, leading to improved maintenance schedules and reduced operational costs.

As environmental regulations become more stringent and sustainability initiatives gain momentum, the demand for efficient energy storage solutions will continue to rise. This trend is expected to further drive the market for advanced BMS solutions that can maximize the lifespan and performance of battery systems across various applications.

In the automotive sector, the surge in EV adoption has created a substantial market for advanced BMS solutions. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups within the next decade. This transition has intensified the demand for BMS that can accurately predict battery health, optimize charging cycles, and extend overall battery life. The ability to provide real-time diagnostics and predictive maintenance capabilities has become a key differentiator for EV manufacturers, as it directly impacts vehicle range, performance, and consumer confidence.

The renewable energy sector is another major driver of BMS market growth. As grid-scale energy storage systems become more prevalent, the need for sophisticated BMS solutions to manage large battery arrays has increased dramatically. These systems require advanced predictive maintenance approaches to ensure reliable operation and maximize the return on investment for utility companies and renewable energy providers.

Consumer electronics represent another significant market segment for advanced BMS solutions. With the proliferation of smartphones, laptops, and other portable devices, consumers are increasingly demanding longer battery life and faster charging times. This has led to a growing interest in BMS technologies that can optimize battery performance and provide accurate predictions of battery health and remaining lifespan.

The industrial sector is also showing increased demand for advanced BMS solutions, particularly in applications such as robotics, automated guided vehicles, and uninterruptible power supplies. These applications require highly reliable power sources, making predictive maintenance capabilities essential for minimizing downtime and ensuring operational efficiency.

Market analysts project that the global BMS market will continue to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is fueled not only by the increasing adoption of electric vehicles and renewable energy systems but also by the integration of artificial intelligence and machine learning technologies into BMS solutions. These advanced technologies enable more accurate predictions of battery health and performance, leading to improved maintenance schedules and reduced operational costs.

As environmental regulations become more stringent and sustainability initiatives gain momentum, the demand for efficient energy storage solutions will continue to rise. This trend is expected to further drive the market for advanced BMS solutions that can maximize the lifespan and performance of battery systems across various applications.

Current BMS Technologies and Challenges

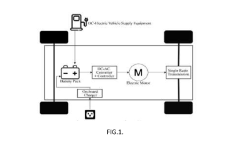

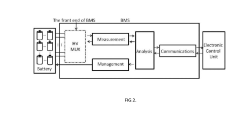

Battery Management Systems (BMS) have become increasingly sophisticated in recent years, yet they still face significant challenges in accurately predicting battery health and performance. Current BMS technologies primarily rely on voltage, current, and temperature measurements to estimate the state of charge (SOC) and state of health (SOH) of batteries. These systems often employ algorithms such as Coulomb counting, open-circuit voltage (OCV) estimation, and various filtering techniques to process sensor data.

One of the main challenges in BMS is the accurate estimation of SOC and SOH, which is crucial for optimizing battery performance and longevity. Traditional methods often struggle with the complex, non-linear behavior of batteries, especially as they age. This can lead to inaccurate predictions of remaining battery life and potential failures, impacting the reliability of electric vehicles and energy storage systems.

Another significant challenge is the management of thermal issues in battery packs. Uneven temperature distribution can lead to accelerated degradation and, in extreme cases, thermal runaway. Current BMS technologies often lack the capability to predict and prevent these thermal issues proactively, relying instead on reactive measures once problems are detected.

Data management and processing present another hurdle for BMS. As the number of sensors and the frequency of data collection increase, BMS must handle and analyze vast amounts of data in real-time. This requires significant computational resources and efficient algorithms, which can be challenging to implement in cost-sensitive applications.

The variability in battery chemistry and design also poses a challenge for BMS. Different battery types exhibit unique characteristics and aging patterns, making it difficult to develop a one-size-fits-all solution. This variability necessitates adaptive algorithms that can learn and adjust to specific battery behaviors over time.

Lastly, the integration of BMS with other vehicle or grid systems remains a challenge. Effective communication and coordination between BMS and other components, such as power electronics and energy management systems, are crucial for optimal performance but can be complex to implement.

These challenges highlight the need for more advanced, data-driven approaches in BMS technology. The integration of big data analytics and machine learning techniques offers promising avenues for addressing these issues, potentially leading to more accurate, adaptive, and predictive battery management systems.

One of the main challenges in BMS is the accurate estimation of SOC and SOH, which is crucial for optimizing battery performance and longevity. Traditional methods often struggle with the complex, non-linear behavior of batteries, especially as they age. This can lead to inaccurate predictions of remaining battery life and potential failures, impacting the reliability of electric vehicles and energy storage systems.

Another significant challenge is the management of thermal issues in battery packs. Uneven temperature distribution can lead to accelerated degradation and, in extreme cases, thermal runaway. Current BMS technologies often lack the capability to predict and prevent these thermal issues proactively, relying instead on reactive measures once problems are detected.

Data management and processing present another hurdle for BMS. As the number of sensors and the frequency of data collection increase, BMS must handle and analyze vast amounts of data in real-time. This requires significant computational resources and efficient algorithms, which can be challenging to implement in cost-sensitive applications.

The variability in battery chemistry and design also poses a challenge for BMS. Different battery types exhibit unique characteristics and aging patterns, making it difficult to develop a one-size-fits-all solution. This variability necessitates adaptive algorithms that can learn and adjust to specific battery behaviors over time.

Lastly, the integration of BMS with other vehicle or grid systems remains a challenge. Effective communication and coordination between BMS and other components, such as power electronics and energy management systems, are crucial for optimal performance but can be complex to implement.

These challenges highlight the need for more advanced, data-driven approaches in BMS technology. The integration of big data analytics and machine learning techniques offers promising avenues for addressing these issues, potentially leading to more accurate, adaptive, and predictive battery management systems.

Existing Predictive Maintenance Solutions for BMS

01 Remote monitoring and diagnostics

Battery Management Systems (BMS) can be equipped with remote monitoring capabilities, allowing for real-time diagnostics and maintenance. This feature enables technicians to identify and address issues promptly, reducing downtime and improving overall system efficiency. Remote monitoring also facilitates predictive maintenance, helping to prevent potential failures before they occur.- Battery monitoring and diagnostics: Battery Management Systems (BMS) incorporate advanced monitoring and diagnostic capabilities to assess battery health, performance, and potential issues. This includes real-time tracking of voltage, current, temperature, and state of charge. Diagnostic algorithms analyze this data to detect anomalies, predict failures, and optimize battery life.

- Thermal management and safety features: BMS maintenance involves managing thermal conditions and implementing safety features. This includes active cooling systems, temperature sensors, and safety protocols to prevent overheating, thermal runaway, and other hazardous conditions. Regular checks and calibration of these systems are crucial for maintaining battery safety and longevity.

- Software updates and calibration: Maintaining BMS involves regular software updates and calibration procedures. This ensures that the system operates with the latest algorithms for battery management, incorporates new safety features, and maintains accurate measurements. Over-the-air updates and remote diagnostics capabilities are becoming increasingly common in modern BMS.

- Cell balancing and charge management: A critical aspect of BMS maintenance is ensuring proper cell balancing and charge management. This involves equalizing the charge across all cells in a battery pack to prevent overcharging or undercharging of individual cells. Regular maintenance checks and adjustments to balancing algorithms help optimize battery performance and lifespan.

- Data logging and performance analysis: BMS maintenance includes regular data logging and performance analysis. This involves collecting and analyzing historical data on battery usage, charging cycles, and performance metrics. Advanced analytics tools help identify trends, optimize charging strategies, and inform predictive maintenance schedules to enhance overall battery system reliability.

02 Thermal management and cooling systems

Effective thermal management is crucial for maintaining optimal battery performance and longevity. BMS maintenance includes regular inspection and cleaning of cooling systems, ensuring proper heat dissipation. Advanced thermal management techniques may involve active cooling systems, phase change materials, or intelligent temperature control algorithms to prevent overheating and extend battery life.Expand Specific Solutions03 Software updates and calibration

Regular software updates are essential for maintaining and improving BMS performance. These updates can include enhancements to battery state estimation algorithms, safety protocols, and overall system efficiency. Periodic calibration of sensors and measurement systems ensures accurate data collection and analysis, contributing to better battery health management and performance optimization.Expand Specific Solutions04 Cell balancing and capacity optimization

Maintenance of cell balancing systems is crucial for maximizing battery pack capacity and lifespan. Regular checks and adjustments to balancing circuits ensure uniform charge distribution across cells, preventing overcharging or undercharging of individual cells. This process helps maintain overall pack health and optimizes energy utilization, contributing to improved system performance and longevity.Expand Specific Solutions05 Safety systems and fault detection

Maintenance of BMS safety systems involves regular testing and calibration of fault detection mechanisms, such as short circuit protection, over-current detection, and temperature monitoring. This includes verifying the proper functioning of emergency shutdown procedures and ensuring that all safety interlocks are operational. Regular maintenance of these systems is critical for preventing accidents and ensuring the overall reliability of the battery system.Expand Specific Solutions

Key Players in BMS and Big Data Analytics

The predictive maintenance market for battery management systems using big data is in a growth phase, driven by increasing adoption of electric vehicles and renewable energy storage solutions. The market size is expanding rapidly, with projections indicating significant growth over the next decade. Technologically, the field is advancing quickly but still maturing, with companies like TWAICE Technologies, Samsung Electronics, and LG Energy Solution leading innovation. Established automotive players such as Hyundai, Kia, and Volkswagen are also investing heavily in this area. The competitive landscape is diverse, including both specialized battery analytics firms and large technology conglomerates, indicating a dynamic and evolving market with substantial potential for further development and consolidation.

TWAICE Technologies GmbH

Technical Solution: TWAICE has developed an advanced predictive maintenance approach for battery management systems using big data analytics. Their solution combines physics-based modeling with machine learning algorithms to create digital twins of battery systems. These digital twins continuously analyze real-time sensor data and historical performance data to predict battery health, remaining useful life, and potential failure modes. The system utilizes cloud computing to process vast amounts of data from connected battery systems across various applications, enabling fleet-wide insights and optimizations[1][3]. TWAICE's approach also incorporates adaptive algorithms that improve prediction accuracy over time as more data is collected and analyzed.

Strengths: Highly accurate predictive capabilities, scalable across large fleets, adaptable to various battery types and applications. Weaknesses: Requires significant initial data collection and model training, may have higher implementation costs for smaller operations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive predictive maintenance system for battery management using big data and AI. Their approach integrates data from multiple sources, including battery sensors, usage patterns, and environmental factors. The system employs advanced machine learning algorithms, particularly deep learning neural networks, to analyze this data in real-time. Samsung's solution can predict battery degradation, estimate remaining useful life, and identify potential safety issues before they occur. The company has also implemented edge computing capabilities in their battery management systems, allowing for faster response times and reduced data transmission costs[2][5]. Additionally, Samsung has developed proprietary algorithms for battery state estimation that can adapt to different battery chemistries and form factors.

Strengths: Robust AI capabilities, integration with Samsung's ecosystem of devices, strong focus on safety prediction. Weaknesses: May be less flexible for non-Samsung battery systems, potential for vendor lock-in.

Core Innovations in BMS Predictive Analytics

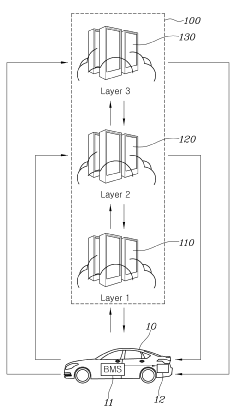

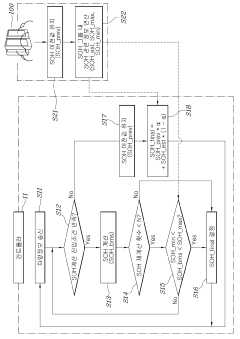

System for estimating state of health of battery using big data

PatentPendingKR1020210136496A

Innovation

- A system utilizing a big data server to collect and process vehicle driving data, employing a hierarchical cloud structure to classify and group vehicles based on battery life factors, and a controller to calculate SOH using algorithms and data from similar groups, ensuring accurate predictions regardless of specific conditions.

Ai-driven predictive strategies for enhancing electric vehicle battery charging life cycle sustainability

PatentPendingIN202411035163A

Innovation

- AI-driven predictive strategies that integrate machine learning algorithms with battery management systems to anticipate usage patterns and adjust charging and discharging cycles, optimizing battery life and energy management through real-time data analysis and smart energy distribution from renewable sources.

Data Privacy and Security in BMS Analytics

Data privacy and security are paramount concerns in the implementation of Battery Management System (BMS) analytics, especially when leveraging big data for predictive maintenance. As BMS collect and process vast amounts of sensitive information, including battery performance data, usage patterns, and potentially user-specific details, robust security measures are essential to protect against unauthorized access and data breaches.

Encryption plays a crucial role in safeguarding BMS data. Advanced encryption algorithms are employed to secure data both at rest and in transit. This includes encrypting data stored in databases and cloud storage systems, as well as securing communication channels between BMS components and central analytics platforms. Implementing end-to-end encryption ensures that even if data is intercepted, it remains unreadable to unauthorized parties.

Access control mechanisms are another critical aspect of BMS data security. Multi-factor authentication, role-based access control, and least privilege principles are implemented to ensure that only authorized personnel can access sensitive BMS data. Regular audits and access logs help monitor and track data access patterns, enabling quick detection of any suspicious activities.

Data anonymization techniques are employed to protect individual privacy while still allowing for meaningful analytics. Personal identifiers are removed or obfuscated, and aggregation methods are used to analyze trends without exposing individual battery or user data. Differential privacy techniques can be applied to add controlled noise to datasets, further protecting individual privacy while maintaining the overall statistical validity of the data.

Compliance with data protection regulations, such as GDPR in Europe or CCPA in California, is a key consideration in BMS analytics. This involves implementing data governance frameworks, conducting regular privacy impact assessments, and ensuring transparent data handling practices. Clear data retention policies are established to define how long data is stored and when it should be securely deleted.

As BMS often operate in distributed environments, including edge computing scenarios, securing data at the edge is crucial. This involves implementing robust security measures on individual BMS units, including secure boot processes, firmware integrity checks, and tamper-resistant hardware designs. Edge-to-cloud security protocols ensure that data remains protected as it moves from individual battery units to centralized analytics platforms.

Continuous monitoring and threat detection systems are deployed to identify and respond to potential security breaches in real-time. This includes implementing intrusion detection systems, security information and event management (SIEM) solutions, and regular vulnerability assessments. Incident response plans are developed and regularly tested to ensure rapid and effective responses to any security incidents.

Encryption plays a crucial role in safeguarding BMS data. Advanced encryption algorithms are employed to secure data both at rest and in transit. This includes encrypting data stored in databases and cloud storage systems, as well as securing communication channels between BMS components and central analytics platforms. Implementing end-to-end encryption ensures that even if data is intercepted, it remains unreadable to unauthorized parties.

Access control mechanisms are another critical aspect of BMS data security. Multi-factor authentication, role-based access control, and least privilege principles are implemented to ensure that only authorized personnel can access sensitive BMS data. Regular audits and access logs help monitor and track data access patterns, enabling quick detection of any suspicious activities.

Data anonymization techniques are employed to protect individual privacy while still allowing for meaningful analytics. Personal identifiers are removed or obfuscated, and aggregation methods are used to analyze trends without exposing individual battery or user data. Differential privacy techniques can be applied to add controlled noise to datasets, further protecting individual privacy while maintaining the overall statistical validity of the data.

Compliance with data protection regulations, such as GDPR in Europe or CCPA in California, is a key consideration in BMS analytics. This involves implementing data governance frameworks, conducting regular privacy impact assessments, and ensuring transparent data handling practices. Clear data retention policies are established to define how long data is stored and when it should be securely deleted.

As BMS often operate in distributed environments, including edge computing scenarios, securing data at the edge is crucial. This involves implementing robust security measures on individual BMS units, including secure boot processes, firmware integrity checks, and tamper-resistant hardware designs. Edge-to-cloud security protocols ensure that data remains protected as it moves from individual battery units to centralized analytics platforms.

Continuous monitoring and threat detection systems are deployed to identify and respond to potential security breaches in real-time. This includes implementing intrusion detection systems, security information and event management (SIEM) solutions, and regular vulnerability assessments. Incident response plans are developed and regularly tested to ensure rapid and effective responses to any security incidents.

Environmental Impact of Improved Battery Lifecycle Management

The environmental impact of improved battery lifecycle management through predictive maintenance approaches using big data is significant and multifaceted. By leveraging advanced analytics and machine learning techniques, battery management systems can optimize the performance and longevity of batteries, leading to substantial environmental benefits.

Firstly, predictive maintenance strategies can significantly extend battery life, reducing the frequency of battery replacements. This decrease in battery turnover directly translates to a reduction in raw material extraction, manufacturing processes, and associated carbon emissions. The mining of lithium, cobalt, and other materials used in battery production often has severe environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions. By prolonging battery life, these impacts are mitigated over time.

Moreover, optimized battery performance through predictive maintenance leads to improved energy efficiency. Batteries operating at peak efficiency consume less energy during charging cycles and provide more consistent power output. This increased efficiency reduces overall energy consumption, potentially lowering the demand on power grids and, by extension, decreasing reliance on fossil fuel-based energy sources.

The implementation of big data analytics in battery management systems also enables more accurate state-of-health assessments. This precision allows for better-informed decisions regarding battery replacement, preventing premature disposal of batteries that still have useful life remaining. Consequently, this approach minimizes electronic waste, a growing environmental concern due to the hazardous materials present in batteries.

Furthermore, predictive maintenance can enhance the safety of battery systems by identifying potential failure modes before they occur. This proactive approach reduces the risk of battery-related accidents, such as fires or explosions, which can have severe environmental consequences, including the release of toxic chemicals and air pollution.

The use of big data in battery management also facilitates more efficient recycling processes. By providing detailed information on battery composition and usage history, recycling facilities can optimize their procedures, increasing the recovery rate of valuable materials and reducing waste. This closed-loop approach contributes to a more circular economy, reducing the need for virgin material extraction.

Lastly, improved battery lifecycle management through predictive maintenance can accelerate the adoption of renewable energy storage solutions. As batteries become more reliable and cost-effective over their lifespan, they become increasingly viable for large-scale energy storage applications. This development supports the integration of intermittent renewable energy sources into power grids, potentially displacing fossil fuel-based power generation and further reducing carbon emissions.

Firstly, predictive maintenance strategies can significantly extend battery life, reducing the frequency of battery replacements. This decrease in battery turnover directly translates to a reduction in raw material extraction, manufacturing processes, and associated carbon emissions. The mining of lithium, cobalt, and other materials used in battery production often has severe environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions. By prolonging battery life, these impacts are mitigated over time.

Moreover, optimized battery performance through predictive maintenance leads to improved energy efficiency. Batteries operating at peak efficiency consume less energy during charging cycles and provide more consistent power output. This increased efficiency reduces overall energy consumption, potentially lowering the demand on power grids and, by extension, decreasing reliance on fossil fuel-based energy sources.

The implementation of big data analytics in battery management systems also enables more accurate state-of-health assessments. This precision allows for better-informed decisions regarding battery replacement, preventing premature disposal of batteries that still have useful life remaining. Consequently, this approach minimizes electronic waste, a growing environmental concern due to the hazardous materials present in batteries.

Furthermore, predictive maintenance can enhance the safety of battery systems by identifying potential failure modes before they occur. This proactive approach reduces the risk of battery-related accidents, such as fires or explosions, which can have severe environmental consequences, including the release of toxic chemicals and air pollution.

The use of big data in battery management also facilitates more efficient recycling processes. By providing detailed information on battery composition and usage history, recycling facilities can optimize their procedures, increasing the recovery rate of valuable materials and reducing waste. This closed-loop approach contributes to a more circular economy, reducing the need for virgin material extraction.

Lastly, improved battery lifecycle management through predictive maintenance can accelerate the adoption of renewable energy storage solutions. As batteries become more reliable and cost-effective over their lifespan, they become increasingly viable for large-scale energy storage applications. This development supports the integration of intermittent renewable energy sources into power grids, potentially displacing fossil fuel-based power generation and further reducing carbon emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!