Battery Management Systems in Operational Safety and Risk Management

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Safety Objectives

Battery Management Systems (BMS) play a crucial role in ensuring the operational safety and risk management of battery-powered systems. The primary safety objectives of BMS are multifaceted, encompassing various aspects of battery operation and protection.

One of the key safety objectives is to prevent thermal runaway, a potentially catastrophic event where the battery's temperature rises uncontrollably. BMS achieves this by continuously monitoring cell temperatures and implementing cooling strategies when necessary. It also includes mechanisms to detect and isolate faulty cells, preventing the spread of thermal issues to adjacent cells.

Overcharge and over-discharge protection form another critical safety objective. BMS monitors individual cell voltages and controls the charging and discharging processes to ensure that cells operate within their safe voltage ranges. This not only extends battery life but also prevents dangerous situations that could lead to cell damage or fire.

Short circuit protection is an essential safety feature implemented by BMS. It involves rapid detection of abnormal current flows and immediate disconnection of the battery from the load or charging source. This quick response prevents potential fire hazards and protects both the battery and the connected equipment.

BMS also aims to maintain cell balancing, ensuring that all cells in a battery pack have similar voltage levels. This objective is crucial for preventing localized stress on individual cells, which could lead to premature aging or safety issues. Advanced BMS implementations use active balancing techniques to redistribute energy between cells, optimizing overall battery performance and safety.

Another important safety objective is the management of battery state-of-charge (SOC) and state-of-health (SOH). By accurately estimating these parameters, BMS can predict potential issues before they occur and adjust operating conditions accordingly. This proactive approach significantly enhances the overall safety profile of the battery system.

BMS safety objectives also extend to external communication and integration with other vehicle or system safety features. This includes providing real-time data to external systems, enabling emergency shutdown procedures, and ensuring compatibility with broader safety protocols.

Lastly, BMS aims to provide comprehensive diagnostics and logging capabilities. This objective supports not only immediate safety management but also long-term risk assessment and improvement of battery systems. By analyzing historical data, manufacturers and operators can identify patterns, refine safety algorithms, and enhance overall system reliability.

One of the key safety objectives is to prevent thermal runaway, a potentially catastrophic event where the battery's temperature rises uncontrollably. BMS achieves this by continuously monitoring cell temperatures and implementing cooling strategies when necessary. It also includes mechanisms to detect and isolate faulty cells, preventing the spread of thermal issues to adjacent cells.

Overcharge and over-discharge protection form another critical safety objective. BMS monitors individual cell voltages and controls the charging and discharging processes to ensure that cells operate within their safe voltage ranges. This not only extends battery life but also prevents dangerous situations that could lead to cell damage or fire.

Short circuit protection is an essential safety feature implemented by BMS. It involves rapid detection of abnormal current flows and immediate disconnection of the battery from the load or charging source. This quick response prevents potential fire hazards and protects both the battery and the connected equipment.

BMS also aims to maintain cell balancing, ensuring that all cells in a battery pack have similar voltage levels. This objective is crucial for preventing localized stress on individual cells, which could lead to premature aging or safety issues. Advanced BMS implementations use active balancing techniques to redistribute energy between cells, optimizing overall battery performance and safety.

Another important safety objective is the management of battery state-of-charge (SOC) and state-of-health (SOH). By accurately estimating these parameters, BMS can predict potential issues before they occur and adjust operating conditions accordingly. This proactive approach significantly enhances the overall safety profile of the battery system.

BMS safety objectives also extend to external communication and integration with other vehicle or system safety features. This includes providing real-time data to external systems, enabling emergency shutdown procedures, and ensuring compatibility with broader safety protocols.

Lastly, BMS aims to provide comprehensive diagnostics and logging capabilities. This objective supports not only immediate safety management but also long-term risk assessment and improvement of battery systems. By analyzing historical data, manufacturers and operators can identify patterns, refine safety algorithms, and enhance overall system reliability.

Market Demand Analysis

The market demand for advanced Battery Management Systems (BMS) in operational safety and risk management has been experiencing significant growth in recent years. This surge is primarily driven by the rapid expansion of the electric vehicle (EV) market and the increasing adoption of large-scale energy storage systems. As batteries become more integral to various industries, the need for sophisticated BMS solutions that can effectively manage safety and mitigate risks has become paramount.

In the automotive sector, the global shift towards electrification has created a substantial market for BMS. Major automakers are investing heavily in electric vehicle technology, with many committing to phase out internal combustion engines in favor of electric powertrains. This transition has led to a growing demand for BMS that can ensure the safety, longevity, and optimal performance of EV batteries.

The energy storage sector is another key driver of BMS market growth. As renewable energy sources become more prevalent, the need for efficient and safe energy storage solutions has increased. Large-scale battery systems used in grid stabilization and renewable energy integration require sophisticated BMS to manage complex battery arrays and ensure their safe operation.

Industrial applications, including robotics, aerospace, and marine industries, are also contributing to the expanding BMS market. These sectors require reliable and safe power sources, often in challenging environments, making advanced BMS crucial for their operations.

The market demand for BMS is further fueled by stringent safety regulations and standards imposed by governments and regulatory bodies worldwide. These regulations aim to minimize the risks associated with battery usage, such as thermal runaway, overcharging, and short circuits. As a result, manufacturers across various industries are compelled to implement robust BMS solutions to comply with these safety requirements.

Consumer electronics represent another significant market segment for BMS. With the increasing power demands of smartphones, laptops, and other portable devices, manufacturers are focusing on developing more efficient and safer battery systems. This has led to a growing need for advanced BMS that can optimize battery performance while ensuring user safety.

The global BMS market is expected to continue its upward trajectory in the coming years. Factors such as the ongoing electrification of transportation, the expansion of renewable energy infrastructure, and the increasing emphasis on energy efficiency across industries will likely sustain this growth. Additionally, emerging technologies such as artificial intelligence and machine learning are expected to further enhance BMS capabilities, creating new opportunities for innovation and market expansion in the field of operational safety and risk management.

In the automotive sector, the global shift towards electrification has created a substantial market for BMS. Major automakers are investing heavily in electric vehicle technology, with many committing to phase out internal combustion engines in favor of electric powertrains. This transition has led to a growing demand for BMS that can ensure the safety, longevity, and optimal performance of EV batteries.

The energy storage sector is another key driver of BMS market growth. As renewable energy sources become more prevalent, the need for efficient and safe energy storage solutions has increased. Large-scale battery systems used in grid stabilization and renewable energy integration require sophisticated BMS to manage complex battery arrays and ensure their safe operation.

Industrial applications, including robotics, aerospace, and marine industries, are also contributing to the expanding BMS market. These sectors require reliable and safe power sources, often in challenging environments, making advanced BMS crucial for their operations.

The market demand for BMS is further fueled by stringent safety regulations and standards imposed by governments and regulatory bodies worldwide. These regulations aim to minimize the risks associated with battery usage, such as thermal runaway, overcharging, and short circuits. As a result, manufacturers across various industries are compelled to implement robust BMS solutions to comply with these safety requirements.

Consumer electronics represent another significant market segment for BMS. With the increasing power demands of smartphones, laptops, and other portable devices, manufacturers are focusing on developing more efficient and safer battery systems. This has led to a growing need for advanced BMS that can optimize battery performance while ensuring user safety.

The global BMS market is expected to continue its upward trajectory in the coming years. Factors such as the ongoing electrification of transportation, the expansion of renewable energy infrastructure, and the increasing emphasis on energy efficiency across industries will likely sustain this growth. Additionally, emerging technologies such as artificial intelligence and machine learning are expected to further enhance BMS capabilities, creating new opportunities for innovation and market expansion in the field of operational safety and risk management.

BMS Tech Challenges

Battery Management Systems (BMS) face several significant technical challenges in ensuring operational safety and effective risk management. One of the primary concerns is the accurate estimation of the State of Charge (SOC) and State of Health (SOH) of battery cells. These parameters are crucial for predicting battery performance and preventing potential safety hazards, yet their precise determination remains complex due to the dynamic nature of battery chemistry and varying operational conditions.

Another major challenge lies in thermal management. Lithium-ion batteries, which are widely used in electric vehicles and energy storage systems, are sensitive to temperature fluctuations. Overheating can lead to thermal runaway, potentially resulting in fires or explosions. Developing efficient cooling systems and implementing accurate temperature monitoring and control mechanisms are ongoing challenges for BMS designers.

Cell balancing presents another technical hurdle. In large battery packs, individual cells can develop voltage imbalances over time, leading to reduced overall capacity and potential safety risks. Implementing effective cell balancing techniques without compromising system efficiency or adding significant complexity to the BMS architecture remains a challenge.

The detection and mitigation of internal short circuits pose a significant safety concern. These faults can occur due to manufacturing defects or physical damage and may lead to catastrophic failures if not detected early. Developing reliable methods for early detection of internal short circuits, especially in large-scale battery systems, is an area of active research and development.

Cybersecurity has emerged as a critical challenge for BMS, particularly in connected and smart energy systems. As BMS become more integrated with digital networks, they become potential targets for cyber attacks. Ensuring the integrity and security of BMS data and control systems while maintaining functionality and performance is a complex task that requires ongoing attention and innovation.

Long-term reliability and degradation prediction represent another set of challenges. BMS must accurately forecast battery life and performance over extended periods, considering various usage patterns and environmental conditions. This requires sophisticated algorithms and models that can adapt to changing battery characteristics over time.

Finally, the integration of BMS with other vehicle or grid systems presents interoperability challenges. Ensuring seamless communication and coordination between the BMS and other control systems, such as power electronics and energy management systems, is crucial for optimal performance and safety. This integration becomes increasingly complex as systems grow in scale and sophistication.

Another major challenge lies in thermal management. Lithium-ion batteries, which are widely used in electric vehicles and energy storage systems, are sensitive to temperature fluctuations. Overheating can lead to thermal runaway, potentially resulting in fires or explosions. Developing efficient cooling systems and implementing accurate temperature monitoring and control mechanisms are ongoing challenges for BMS designers.

Cell balancing presents another technical hurdle. In large battery packs, individual cells can develop voltage imbalances over time, leading to reduced overall capacity and potential safety risks. Implementing effective cell balancing techniques without compromising system efficiency or adding significant complexity to the BMS architecture remains a challenge.

The detection and mitigation of internal short circuits pose a significant safety concern. These faults can occur due to manufacturing defects or physical damage and may lead to catastrophic failures if not detected early. Developing reliable methods for early detection of internal short circuits, especially in large-scale battery systems, is an area of active research and development.

Cybersecurity has emerged as a critical challenge for BMS, particularly in connected and smart energy systems. As BMS become more integrated with digital networks, they become potential targets for cyber attacks. Ensuring the integrity and security of BMS data and control systems while maintaining functionality and performance is a complex task that requires ongoing attention and innovation.

Long-term reliability and degradation prediction represent another set of challenges. BMS must accurately forecast battery life and performance over extended periods, considering various usage patterns and environmental conditions. This requires sophisticated algorithms and models that can adapt to changing battery characteristics over time.

Finally, the integration of BMS with other vehicle or grid systems presents interoperability challenges. Ensuring seamless communication and coordination between the BMS and other control systems, such as power electronics and energy management systems, is crucial for optimal performance and safety. This integration becomes increasingly complex as systems grow in scale and sophistication.

Current BMS Solutions

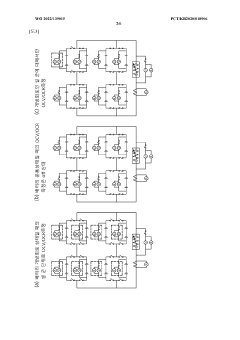

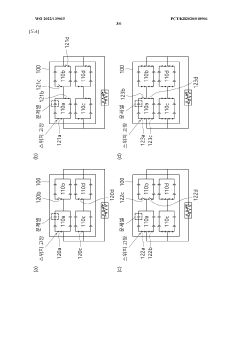

01 Battery Management System (BMS) Safety Monitoring

BMS continuously monitors battery parameters such as voltage, current, and temperature to ensure safe operation. It detects abnormal conditions and implements protective measures to prevent thermal runaway, overcharging, or other safety hazards. Advanced algorithms are used to predict potential failures and trigger preventive actions.- Battery Management System (BMS) Safety Monitoring: Battery Management Systems incorporate advanced safety monitoring features to detect and mitigate potential risks. These systems continuously monitor battery parameters such as temperature, voltage, and current to identify abnormal conditions. When deviations are detected, the BMS can initiate protective measures like disconnecting the battery or adjusting charging rates to prevent accidents and ensure operational safety.

- Risk Assessment and Management in BMS: Implementing comprehensive risk assessment and management strategies is crucial for Battery Management Systems. This involves identifying potential hazards, evaluating their likelihood and impact, and developing mitigation plans. Advanced algorithms and machine learning techniques are employed to predict and prevent failures, enhancing overall system reliability and safety.

- Thermal Management and Fire Prevention: Effective thermal management is essential for battery safety. BMS incorporates sophisticated cooling systems and temperature control mechanisms to prevent overheating. Additionally, fire prevention measures such as flame-retardant materials and isolation techniques are integrated to minimize the risk of thermal runaway and contain potential fires.

- Data Analytics and Predictive Maintenance: Utilizing data analytics and predictive maintenance techniques enhances the operational safety of Battery Management Systems. By analyzing historical data and real-time information, BMS can predict potential failures and schedule maintenance activities proactively. This approach helps in preventing unexpected breakdowns and extends the lifespan of battery systems.

- Regulatory Compliance and Standardization: Ensuring compliance with safety regulations and industry standards is crucial for BMS operational safety. This includes adhering to guidelines set by regulatory bodies, implementing standardized safety protocols, and conducting regular audits. Standardization efforts also focus on interoperability and communication protocols to enhance overall system reliability and safety across different battery technologies and applications.

02 Risk Assessment and Mitigation Strategies

Comprehensive risk assessment methodologies are employed to identify potential hazards in battery systems. This includes analyzing failure modes, evaluating environmental factors, and assessing operational risks. Mitigation strategies are developed based on these assessments, involving hardware safeguards, software controls, and operational procedures to minimize risks.Expand Specific Solutions03 Predictive Maintenance and Diagnostics

Advanced diagnostic tools and predictive maintenance techniques are integrated into BMS to anticipate potential issues before they occur. Machine learning algorithms analyze historical data and real-time performance metrics to forecast battery health and identify maintenance needs, thereby enhancing operational safety and reliability.Expand Specific Solutions04 Emergency Response and Fail-Safe Mechanisms

BMS incorporates fail-safe mechanisms and emergency response protocols to handle critical situations. This includes automatic shutdown procedures, isolation of faulty cells, and rapid discharge mechanisms in case of severe anomalies. Integration with broader safety systems ensures coordinated response to battery-related emergencies.Expand Specific Solutions05 Regulatory Compliance and Safety Standards

BMS design and operation adhere to stringent regulatory requirements and industry safety standards. This involves compliance with electrical safety codes, transportation regulations for battery-powered vehicles, and specific standards for energy storage systems. Regular audits and certifications ensure ongoing compliance and safety performance.Expand Specific Solutions

Key BMS Players

The battery management systems (BMS) market for operational safety and risk management in electric vehicles is experiencing rapid growth, driven by increasing EV adoption and stringent safety regulations. The market is in its growth phase, with a projected size reaching billions of dollars by 2030. Technologically, BMS solutions are advancing quickly, with key players like Contemporary Amperex Technology, LG Energy Solution, and Samsung SDI leading innovation. These companies are developing more sophisticated systems integrating AI and cloud connectivity for improved safety and performance. Emerging players such as Dukosi and BattGenie are also contributing novel approaches, focusing on distributed BMS architectures and advanced simulation tools, respectively. The competitive landscape is dynamic, with both established automotive suppliers and specialized tech firms vying for market share.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced Battery Management System (BMS) that incorporates AI algorithms for real-time monitoring and predictive maintenance. Their system utilizes cloud-based data analytics to process vast amounts of battery performance data, enabling early detection of potential safety issues[1]. The BMS employs a multi-layered approach to operational safety, including thermal management, state-of-charge balancing, and fault diagnosis. CATL's system also features a unique cell-to-pack technology that enhances energy density while maintaining safety standards[2]. In terms of risk management, CATL's BMS incorporates adaptive control strategies that adjust battery performance based on environmental conditions and usage patterns, significantly reducing the risk of thermal runaway and other critical failures[3].

Strengths: Industry-leading AI integration, comprehensive data analytics, and innovative cell-to-pack technology. Weaknesses: High implementation costs and potential over-reliance on cloud connectivity for some features.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated Battery Management System that focuses on enhancing operational safety through precise cell monitoring and advanced diagnostics. Their BMS utilizes high-resolution voltage and current sensors to monitor individual cells with exceptional accuracy[4]. The system employs proprietary algorithms for state-of-charge and state-of-health estimation, providing real-time insights into battery performance and degradation. Bosch's BMS also features an intelligent thermal management system that optimizes battery temperature across various operating conditions, crucial for maintaining safety and extending battery life[5]. In the realm of risk management, Bosch has implemented a multi-tiered safety architecture, including redundant measurement channels and fail-safe mechanisms to ensure system reliability even in the event of component failures[6].

Strengths: High-precision cell monitoring, robust safety architecture, and extensive automotive industry experience. Weaknesses: Potentially higher cost due to premium components and complexity in system integration.

Core BMS Innovations

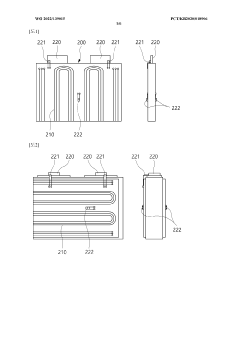

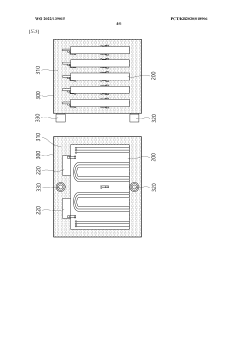

Battery safety system comprising battery cooling apparatus

PatentWO2022139015A1

Innovation

- A battery safety system that includes a measuring unit for individual cell-level monitoring of voltage, current, resistance, temperature, and volume changes, along with a control unit to block external power to problematic cells and a cooling unit for enhanced cooling efficiency through direct contact with a cooling solution, allowing for precise identification and mitigation of safety issues.

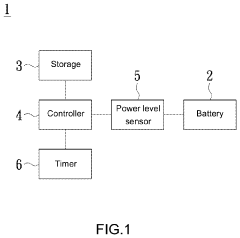

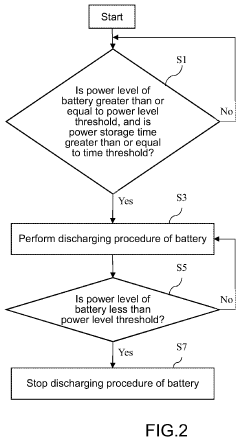

Battery safety management system and procedure thereof

PatentActiveUS20230246468A1

Innovation

- A battery safety management system that includes a controller, storage, and power level sensor, which executes a procedure to determine if the battery power level and storage time exceed thresholds, initiating a discharging process to prevent prolonged high power states and subsequently reducing the risk of swelling and damage.

Regulatory Framework

The regulatory framework surrounding Battery Management Systems (BMS) in operational safety and risk management is a critical aspect of the electric vehicle (EV) and energy storage industries. As the adoption of lithium-ion batteries continues to grow, governments and international organizations have developed comprehensive regulations to ensure the safe operation and management of these systems.

At the forefront of BMS regulations is the United Nations Economic Commission for Europe (UNECE) Regulation No. 100, which outlines specific requirements for the safety of rechargeable energy storage systems in electric vehicles. This regulation addresses various aspects of BMS, including thermal management, overcharge protection, and cell balancing. It also mandates the implementation of safety mechanisms to prevent thermal runaway and other potential hazards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include provisions for BMS in electric vehicles. These standards focus on crash safety, electrical isolation, and thermal management to minimize the risk of battery-related incidents during vehicle operation and in the event of a collision.

The European Union has implemented the General Safety Regulation (EU) 2019/2144, which includes specific requirements for BMS in electric and hybrid vehicles. This regulation emphasizes the importance of real-time monitoring and diagnostics to detect potential battery failures and ensure timely intervention.

In addition to vehicle-specific regulations, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619 and IEC 62660, which provide guidelines for the design and testing of BMS in various applications. These standards address issues such as cell voltage monitoring, temperature control, and state-of-charge estimation, all of which are crucial for maintaining battery health and safety.

The regulatory landscape also extends to the transportation and storage of lithium-ion batteries. The International Air Transport Association (IATA) has established strict guidelines for the air shipment of batteries, including requirements for BMS to prevent thermal events during transit. Similarly, the International Maritime Organization (IMO) has implemented regulations for the safe transport of batteries by sea, emphasizing the role of BMS in mitigating risks associated with maritime transportation.

As the technology evolves, regulatory bodies are continuously updating their frameworks to address emerging challenges in BMS. For instance, there is an increasing focus on cybersecurity regulations to protect BMS from potential hacking attempts that could compromise battery safety. The UN Regulation No. 155 on Cyber Security and Cyber Security Management System sets requirements for vehicle manufacturers to implement robust cybersecurity measures, including those related to BMS.

At the forefront of BMS regulations is the United Nations Economic Commission for Europe (UNECE) Regulation No. 100, which outlines specific requirements for the safety of rechargeable energy storage systems in electric vehicles. This regulation addresses various aspects of BMS, including thermal management, overcharge protection, and cell balancing. It also mandates the implementation of safety mechanisms to prevent thermal runaway and other potential hazards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include provisions for BMS in electric vehicles. These standards focus on crash safety, electrical isolation, and thermal management to minimize the risk of battery-related incidents during vehicle operation and in the event of a collision.

The European Union has implemented the General Safety Regulation (EU) 2019/2144, which includes specific requirements for BMS in electric and hybrid vehicles. This regulation emphasizes the importance of real-time monitoring and diagnostics to detect potential battery failures and ensure timely intervention.

In addition to vehicle-specific regulations, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619 and IEC 62660, which provide guidelines for the design and testing of BMS in various applications. These standards address issues such as cell voltage monitoring, temperature control, and state-of-charge estimation, all of which are crucial for maintaining battery health and safety.

The regulatory landscape also extends to the transportation and storage of lithium-ion batteries. The International Air Transport Association (IATA) has established strict guidelines for the air shipment of batteries, including requirements for BMS to prevent thermal events during transit. Similarly, the International Maritime Organization (IMO) has implemented regulations for the safe transport of batteries by sea, emphasizing the role of BMS in mitigating risks associated with maritime transportation.

As the technology evolves, regulatory bodies are continuously updating their frameworks to address emerging challenges in BMS. For instance, there is an increasing focus on cybersecurity regulations to protect BMS from potential hacking attempts that could compromise battery safety. The UN Regulation No. 155 on Cyber Security and Cyber Security Management System sets requirements for vehicle manufacturers to implement robust cybersecurity measures, including those related to BMS.

Environmental Impact

Battery Management Systems (BMS) play a crucial role in ensuring the operational safety and risk management of battery systems. However, their environmental impact is an increasingly important consideration in the development and deployment of these systems. The production, use, and disposal of BMS components contribute to various environmental concerns that must be addressed to ensure sustainable energy storage solutions.

The manufacturing process of BMS components, including printed circuit boards, sensors, and microcontrollers, involves the use of rare earth metals and other materials that can have significant environmental implications. The extraction and processing of these materials often lead to habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the energy-intensive production of electronic components contributes to the overall carbon footprint of BMS.

During the operational phase, BMS contribute to the efficient use of battery systems, which can indirectly reduce environmental impact by optimizing energy consumption and extending battery life. However, the continuous operation of BMS requires energy, which, depending on the power source, may contribute to ongoing emissions. The environmental benefits of BMS in terms of improved battery efficiency and longevity must be weighed against the energy consumed by the system itself.

End-of-life considerations for BMS present another set of environmental challenges. As electronic waste, BMS components contain hazardous materials that require proper disposal to prevent soil and water contamination. The complexity of BMS often makes recycling difficult, leading to potential resource waste and environmental pollution if not managed correctly. Developing more easily recyclable BMS designs and implementing effective e-waste management strategies are crucial steps in mitigating these impacts.

The environmental impact of BMS extends beyond their direct effects, influencing the overall sustainability of battery-powered systems. By enabling more efficient and longer-lasting batteries, BMS indirectly contribute to reducing the frequency of battery replacements, thereby decreasing the demand for new battery production and associated environmental costs. This positive impact is particularly significant in applications such as electric vehicles and renewable energy storage systems, where BMS play a key role in enhancing the viability and environmental benefits of these technologies.

As the adoption of battery technologies continues to grow, addressing the environmental impact of BMS becomes increasingly important. Research and development efforts are focusing on creating more sustainable BMS solutions, including the use of bio-based materials, design for recyclability, and improved energy efficiency. These advancements aim to minimize the environmental footprint of BMS while maintaining or enhancing their critical role in battery safety and performance management.

The manufacturing process of BMS components, including printed circuit boards, sensors, and microcontrollers, involves the use of rare earth metals and other materials that can have significant environmental implications. The extraction and processing of these materials often lead to habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the energy-intensive production of electronic components contributes to the overall carbon footprint of BMS.

During the operational phase, BMS contribute to the efficient use of battery systems, which can indirectly reduce environmental impact by optimizing energy consumption and extending battery life. However, the continuous operation of BMS requires energy, which, depending on the power source, may contribute to ongoing emissions. The environmental benefits of BMS in terms of improved battery efficiency and longevity must be weighed against the energy consumed by the system itself.

End-of-life considerations for BMS present another set of environmental challenges. As electronic waste, BMS components contain hazardous materials that require proper disposal to prevent soil and water contamination. The complexity of BMS often makes recycling difficult, leading to potential resource waste and environmental pollution if not managed correctly. Developing more easily recyclable BMS designs and implementing effective e-waste management strategies are crucial steps in mitigating these impacts.

The environmental impact of BMS extends beyond their direct effects, influencing the overall sustainability of battery-powered systems. By enabling more efficient and longer-lasting batteries, BMS indirectly contribute to reducing the frequency of battery replacements, thereby decreasing the demand for new battery production and associated environmental costs. This positive impact is particularly significant in applications such as electric vehicles and renewable energy storage systems, where BMS play a key role in enhancing the viability and environmental benefits of these technologies.

As the adoption of battery technologies continues to grow, addressing the environmental impact of BMS becomes increasingly important. Research and development efforts are focusing on creating more sustainable BMS solutions, including the use of bio-based materials, design for recyclability, and improved energy efficiency. These advancements aim to minimize the environmental footprint of BMS while maintaining or enhancing their critical role in battery safety and performance management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!