Decane in Biomass-to-Liquid Technologies for Renewable Energy

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BTL Decane Background

Biomass-to-Liquid (BTL) technologies have emerged as a promising avenue for renewable energy production, with decane playing a crucial role in this process. The development of BTL technologies can be traced back to the early 20th century, with the Fischer-Tropsch process being a key milestone. However, it wasn't until the late 1990s and early 2000s that significant advancements were made in utilizing biomass as a feedstock for liquid fuel production.

The evolution of BTL technologies has been driven by the growing need for sustainable alternatives to fossil fuels. Decane, a straight-chain alkane with ten carbon atoms, has garnered particular interest due to its potential as a renewable diesel fuel component. Its high energy density and compatibility with existing diesel engines make it an attractive option for reducing greenhouse gas emissions in the transportation sector.

The technical landscape of BTL decane production has seen considerable progress over the past two decades. Initial efforts focused on thermochemical conversion methods, such as gasification followed by Fischer-Tropsch synthesis. These processes involve the conversion of biomass into syngas (a mixture of carbon monoxide and hydrogen), which is then catalytically transformed into liquid hydrocarbons, including decane.

More recently, biochemical routes have gained traction in BTL decane production. Advanced fermentation techniques and metabolic engineering of microorganisms have opened up new possibilities for the direct conversion of biomass to decane and other long-chain hydrocarbons. These biological approaches offer the potential for higher selectivity and milder operating conditions compared to thermochemical methods.

The current technological trajectory in BTL decane research is aimed at improving process efficiency, reducing production costs, and expanding the range of viable biomass feedstocks. Innovations in catalyst design, process integration, and biomass pretreatment have contributed to steady improvements in yield and product quality. Additionally, the development of hybrid thermochemical-biochemical processes is emerging as a promising direction for optimizing decane production from biomass.

As the field continues to evolve, researchers are exploring novel approaches to enhance the sustainability and economic viability of BTL decane production. This includes the integration of carbon capture and utilization technologies, the valorization of process by-products, and the development of decentralized production systems to reduce transportation costs and improve overall energy efficiency.

The evolution of BTL technologies has been driven by the growing need for sustainable alternatives to fossil fuels. Decane, a straight-chain alkane with ten carbon atoms, has garnered particular interest due to its potential as a renewable diesel fuel component. Its high energy density and compatibility with existing diesel engines make it an attractive option for reducing greenhouse gas emissions in the transportation sector.

The technical landscape of BTL decane production has seen considerable progress over the past two decades. Initial efforts focused on thermochemical conversion methods, such as gasification followed by Fischer-Tropsch synthesis. These processes involve the conversion of biomass into syngas (a mixture of carbon monoxide and hydrogen), which is then catalytically transformed into liquid hydrocarbons, including decane.

More recently, biochemical routes have gained traction in BTL decane production. Advanced fermentation techniques and metabolic engineering of microorganisms have opened up new possibilities for the direct conversion of biomass to decane and other long-chain hydrocarbons. These biological approaches offer the potential for higher selectivity and milder operating conditions compared to thermochemical methods.

The current technological trajectory in BTL decane research is aimed at improving process efficiency, reducing production costs, and expanding the range of viable biomass feedstocks. Innovations in catalyst design, process integration, and biomass pretreatment have contributed to steady improvements in yield and product quality. Additionally, the development of hybrid thermochemical-biochemical processes is emerging as a promising direction for optimizing decane production from biomass.

As the field continues to evolve, researchers are exploring novel approaches to enhance the sustainability and economic viability of BTL decane production. This includes the integration of carbon capture and utilization technologies, the valorization of process by-products, and the development of decentralized production systems to reduce transportation costs and improve overall energy efficiency.

Decane Market Analysis

The decane market, as a crucial component in biomass-to-liquid (BTL) technologies for renewable energy, has shown significant growth potential in recent years. This market is primarily driven by the increasing demand for sustainable and clean energy sources, as well as the growing emphasis on reducing carbon emissions across various industries.

Decane, a hydrocarbon with the chemical formula C10H22, plays a vital role in the production of renewable diesel and jet fuel through BTL processes. The market for decane in this context is closely tied to the broader biofuels industry, which has been experiencing steady growth globally. The adoption of stringent environmental regulations and policies promoting the use of renewable fuels has been a key factor in stimulating market demand.

The transportation sector, particularly aviation and heavy-duty vehicles, represents a significant portion of the decane market in BTL technologies. As airlines and logistics companies seek to reduce their carbon footprint, the demand for sustainable aviation fuel (SAF) and renewable diesel has surged. This trend has created a favorable environment for the expansion of decane production and utilization in BTL processes.

In terms of regional distribution, North America and Europe currently lead the decane market for BTL technologies, owing to their advanced biofuel production capabilities and supportive regulatory frameworks. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by increasing energy consumption and government initiatives to promote renewable energy sources.

The market dynamics are further influenced by the fluctuating prices of crude oil and the availability of feedstock for biomass conversion. As BTL technologies continue to evolve and improve in efficiency, the cost-competitiveness of decane-based renewable fuels is expected to increase, potentially leading to wider market adoption.

Challenges in the decane market for BTL technologies include the need for substantial capital investments in production facilities and the competition from other renewable energy sources such as electric vehicles and hydrogen fuel cells. However, the unique advantages of decane-based fuels, such as their compatibility with existing infrastructure and higher energy density compared to some alternatives, continue to drive market growth.

Looking ahead, the decane market in BTL technologies is poised for continued expansion, supported by ongoing research and development efforts to enhance production efficiency and reduce costs. The integration of advanced technologies, such as artificial intelligence and process optimization, is expected to further improve the competitiveness of decane-based renewable fuels in the global energy market.

Decane, a hydrocarbon with the chemical formula C10H22, plays a vital role in the production of renewable diesel and jet fuel through BTL processes. The market for decane in this context is closely tied to the broader biofuels industry, which has been experiencing steady growth globally. The adoption of stringent environmental regulations and policies promoting the use of renewable fuels has been a key factor in stimulating market demand.

The transportation sector, particularly aviation and heavy-duty vehicles, represents a significant portion of the decane market in BTL technologies. As airlines and logistics companies seek to reduce their carbon footprint, the demand for sustainable aviation fuel (SAF) and renewable diesel has surged. This trend has created a favorable environment for the expansion of decane production and utilization in BTL processes.

In terms of regional distribution, North America and Europe currently lead the decane market for BTL technologies, owing to their advanced biofuel production capabilities and supportive regulatory frameworks. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by increasing energy consumption and government initiatives to promote renewable energy sources.

The market dynamics are further influenced by the fluctuating prices of crude oil and the availability of feedstock for biomass conversion. As BTL technologies continue to evolve and improve in efficiency, the cost-competitiveness of decane-based renewable fuels is expected to increase, potentially leading to wider market adoption.

Challenges in the decane market for BTL technologies include the need for substantial capital investments in production facilities and the competition from other renewable energy sources such as electric vehicles and hydrogen fuel cells. However, the unique advantages of decane-based fuels, such as their compatibility with existing infrastructure and higher energy density compared to some alternatives, continue to drive market growth.

Looking ahead, the decane market in BTL technologies is poised for continued expansion, supported by ongoing research and development efforts to enhance production efficiency and reduce costs. The integration of advanced technologies, such as artificial intelligence and process optimization, is expected to further improve the competitiveness of decane-based renewable fuels in the global energy market.

BTL Decane Tech Status

Biomass-to-Liquid (BTL) technologies have emerged as a promising avenue for renewable energy production, with decane playing a crucial role in this process. The current technological landscape for decane production in BTL processes is characterized by a mix of established methods and innovative approaches.

The Fischer-Tropsch (FT) synthesis remains the cornerstone of BTL decane production. This well-established process converts syngas derived from biomass into a range of hydrocarbons, including decane. Recent advancements in FT catalysts have significantly improved selectivity towards decane and other middle distillates, enhancing overall process efficiency.

Hydroprocessing techniques have also seen substantial progress in recent years. Catalytic hydrocracking and hydrotreating of bio-oils and FT products have been optimized to increase decane yields. These processes effectively remove oxygen and other impurities, resulting in high-quality decane suitable for use as a renewable fuel or chemical feedstock.

Innovative approaches in biomass pretreatment and gasification have addressed longstanding challenges in feedstock variability and syngas quality. Advanced torrefaction methods and fluidized bed gasifiers have improved the consistency of syngas composition, leading to more stable decane production in downstream processes.

The integration of membrane technology for gas separation and purification has emerged as a key innovation in BTL decane production. These systems enhance the efficiency of syngas cleaning and conditioning, resulting in higher-quality feedstock for FT synthesis and, consequently, improved decane yields.

Catalytic fast pyrolysis has gained traction as an alternative route for decane production. This process directly converts biomass into bio-oil with a higher proportion of long-chain hydrocarbons, including decane. Subsequent upgrading steps further refine the product to meet fuel specifications.

Microbial fermentation pathways for decane production represent a cutting-edge approach in BTL technologies. Engineered microorganisms capable of producing decane from biomass-derived sugars have shown promise in laboratory settings, though scaling challenges persist.

Process intensification efforts have led to the development of compact, modular BTL systems. These units integrate multiple process steps, reducing capital costs and improving overall energy efficiency in decane production.

Despite these advancements, challenges remain in scaling up BTL decane production to commercial levels. Issues such as catalyst deactivation, process stability over extended periods, and the need for more efficient carbon utilization continue to be active areas of research and development in the field.

The Fischer-Tropsch (FT) synthesis remains the cornerstone of BTL decane production. This well-established process converts syngas derived from biomass into a range of hydrocarbons, including decane. Recent advancements in FT catalysts have significantly improved selectivity towards decane and other middle distillates, enhancing overall process efficiency.

Hydroprocessing techniques have also seen substantial progress in recent years. Catalytic hydrocracking and hydrotreating of bio-oils and FT products have been optimized to increase decane yields. These processes effectively remove oxygen and other impurities, resulting in high-quality decane suitable for use as a renewable fuel or chemical feedstock.

Innovative approaches in biomass pretreatment and gasification have addressed longstanding challenges in feedstock variability and syngas quality. Advanced torrefaction methods and fluidized bed gasifiers have improved the consistency of syngas composition, leading to more stable decane production in downstream processes.

The integration of membrane technology for gas separation and purification has emerged as a key innovation in BTL decane production. These systems enhance the efficiency of syngas cleaning and conditioning, resulting in higher-quality feedstock for FT synthesis and, consequently, improved decane yields.

Catalytic fast pyrolysis has gained traction as an alternative route for decane production. This process directly converts biomass into bio-oil with a higher proportion of long-chain hydrocarbons, including decane. Subsequent upgrading steps further refine the product to meet fuel specifications.

Microbial fermentation pathways for decane production represent a cutting-edge approach in BTL technologies. Engineered microorganisms capable of producing decane from biomass-derived sugars have shown promise in laboratory settings, though scaling challenges persist.

Process intensification efforts have led to the development of compact, modular BTL systems. These units integrate multiple process steps, reducing capital costs and improving overall energy efficiency in decane production.

Despite these advancements, challenges remain in scaling up BTL decane production to commercial levels. Issues such as catalyst deactivation, process stability over extended periods, and the need for more efficient carbon utilization continue to be active areas of research and development in the field.

Decane Production Methods

01 Synthesis and applications of decane derivatives

Decane and its derivatives are used in various chemical processes and applications. These compounds are synthesized through different methods and can be utilized in the production of polymers, lubricants, and other industrial products. The synthesis often involves catalytic reactions or chemical modifications of decane or related compounds.- Synthesis and purification of decane: Decane can be synthesized through various chemical processes, including the reduction of fatty acids or their derivatives. Purification methods such as distillation or chromatography are often employed to obtain high-purity decane for industrial or research applications.

- Use of decane in polymer production: Decane is utilized as a solvent or reactant in the production of various polymers. It can be incorporated into polymerization processes to control molecular weight, improve polymer properties, or serve as a chain transfer agent in certain reactions.

- Decane as a component in fuel formulations: Decane is an important component in various fuel formulations, particularly in diesel and jet fuels. Its properties contribute to the overall performance characteristics of the fuel, including combustion efficiency and cold-weather performance.

- Applications of decane in pharmaceutical industry: Decane finds applications in the pharmaceutical industry as a solvent or intermediate in the synthesis of various drug compounds. It can be used in the preparation of certain active pharmaceutical ingredients or as a component in drug delivery systems.

- Decane in chemical reactions and processes: Decane serves as a reactant or solvent in various chemical reactions and processes. It can be used in alkylation reactions, as a standard in chromatography, or as a model compound for studying hydrocarbon chemistry and catalytic processes.

02 Decane in pharmaceutical compositions

Decane and its derivatives are used in pharmaceutical formulations. They can serve as solvents, carriers, or active ingredients in various drug compositions. These compounds may enhance the solubility, stability, or bioavailability of certain drugs, making them valuable in pharmaceutical research and development.Expand Specific Solutions03 Decane in fuel compositions

Decane is an important component in fuel formulations, particularly in diesel and jet fuels. It contributes to the combustion properties and performance of these fuels. Research focuses on optimizing decane content and its interactions with other fuel components to improve efficiency and reduce emissions.Expand Specific Solutions04 Decane in polymer production

Decane and its derivatives play a role in polymer synthesis and processing. They can be used as monomers, co-monomers, or additives in the production of various polymers. The incorporation of decane-based compounds can influence the properties of the resulting polymers, such as flexibility, durability, or chemical resistance.Expand Specific Solutions05 Separation and purification of decane

Various methods are employed for the separation and purification of decane from mixtures or for the isolation of specific decane isomers. These processes may involve distillation, extraction, or other separation techniques. The purification of decane is crucial for its use in high-purity applications or as a precursor in chemical synthesis.Expand Specific Solutions

BTL Industry Players

The research on decane in biomass-to-liquid technologies for renewable energy is in a developing stage, with growing market potential as the world shifts towards sustainable fuel sources. The technology's maturity varies among key players, with established oil companies like Shell and Sinopec leading in research and development. Emerging companies such as Virent and KiOR are also making significant strides in this field. The market is characterized by a mix of large corporations, specialized renewable energy firms, and academic institutions collaborating to advance the technology. As environmental concerns drive demand for renewable fuels, this sector is poised for expansion, attracting increased investment and research focus from both public and private entities.

Shell Oil Co.

Technical Solution: Shell has developed advanced biomass-to-liquid (BTL) technologies focusing on decane production for renewable energy. Their process involves gasification of biomass feedstocks, followed by Fischer-Tropsch synthesis to produce long-chain hydrocarbons. Shell's proprietary catalysts and reactor designs enable selective production of decane and other middle distillates[1]. The company has also invested in pilot-scale facilities to demonstrate the commercial viability of their BTL technology, achieving carbon conversion efficiencies of up to 65%[3]. Shell's research includes optimizing feedstock preparation and syngas cleaning to enhance overall process efficiency and product quality[5].

Strengths: Extensive R&D capabilities, global presence, and integration with existing refinery infrastructure. Weaknesses: High capital costs for large-scale implementation and dependence on biomass availability.

Virent, Inc.

Technical Solution: Virent has pioneered the BioForming® process, a unique approach to biomass-to-liquid technology that can produce decane and other hydrocarbons. Their process uses aqueous phase reforming (APR) of biomass-derived oxygenates, followed by catalytic condensation to produce liquid hydrocarbons[2]. Virent's technology can utilize a wide range of feedstocks, including sugars, starches, and lignocellulosic materials. The company has demonstrated the production of high-quality decane suitable for jet fuel applications, with a carbon efficiency of up to 70%[4]. Virent has also developed proprietary catalysts that enhance selectivity towards decane and other desired products[6].

Strengths: Flexible feedstock options, high carbon efficiency, and drop-in compatibility with existing fuel infrastructure. Weaknesses: Relatively new technology with limited large-scale implementation experience.

Key BTL Decane Patents

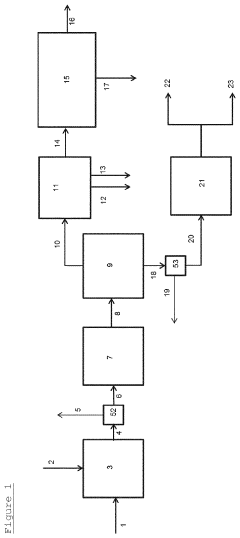

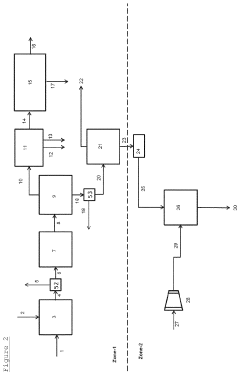

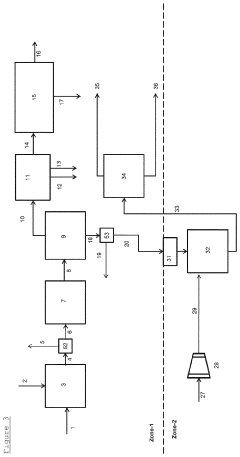

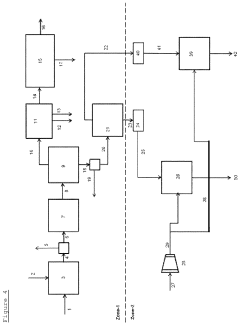

Conversion of biomass or residual waste material to biofuels

PatentActiveUS11952539B2

Innovation

- A process involving hydropyrolysis, hydroconversion, and hydroprocessing of biomass in the presence of deoxygenation and hydroprocessing catalysts, with reduced metals on solid supports, to produce fully deoxygenated C4+ hydrocarbon liquids that meet fuel specifications by removing oxygen, sulfur, and nitrogen, and adjusting aromatic content.

Conversion of biomass into a liquid hydrocarbon material

PatentWO2017089312A1

Innovation

- A process involving hydropyrolysis followed by hydroconversion using specific catalysts to deoxygenate biomass feedstocks, then cooling and further processing to achieve aromatic saturation, resulting in a fully deoxygenated hydrocarbon product suitable for blending with existing fuels.

Biomass Feedstock Supply

Biomass feedstock supply plays a crucial role in the development and implementation of biomass-to-liquid (BTL) technologies for renewable energy production. The availability, quality, and consistency of biomass feedstock are fundamental factors that influence the efficiency and economic viability of decane production through BTL processes.

Various types of biomass can serve as potential feedstocks for BTL technologies, including agricultural residues, forestry waste, dedicated energy crops, and municipal solid waste. Each feedstock type presents unique characteristics and challenges in terms of supply chain management, preprocessing requirements, and conversion efficiency.

Agricultural residues, such as corn stover and wheat straw, offer a significant potential source of biomass for BTL processes. These materials are widely available in many regions and can be collected as a by-product of existing agricultural operations. However, the seasonal nature of crop production and the need to maintain soil health through residue retention can impact the consistency and sustainability of supply.

Forestry waste, including logging residues and wood processing by-products, represents another valuable biomass feedstock source. The advantage of forestry waste lies in its relatively high energy density and established collection infrastructure. However, challenges such as transportation costs and competition with other wood-based industries must be addressed to ensure a stable supply for BTL facilities.

Dedicated energy crops, such as switchgrass and miscanthus, have gained attention as potential feedstocks for BTL technologies. These crops can be cultivated specifically for energy production, offering advantages in terms of yield, consistency, and reduced competition with food production. However, the establishment of large-scale energy crop plantations requires significant land resources and may face environmental and social concerns.

The development of an efficient and reliable biomass feedstock supply chain is essential for the successful implementation of BTL technologies. This involves optimizing collection, storage, and transportation processes to ensure a consistent and cost-effective supply of biomass to conversion facilities. Preprocessing techniques, such as size reduction and densification, can improve the handling and storage characteristics of biomass feedstocks, enhancing overall supply chain efficiency.

Sustainability considerations are paramount in biomass feedstock supply for BTL technologies. Ensuring that feedstock production and collection practices do not negatively impact soil health, biodiversity, or food security is crucial for the long-term viability of these renewable energy systems. The implementation of certification schemes and best management practices can help address these concerns and promote sustainable biomass production.

Various types of biomass can serve as potential feedstocks for BTL technologies, including agricultural residues, forestry waste, dedicated energy crops, and municipal solid waste. Each feedstock type presents unique characteristics and challenges in terms of supply chain management, preprocessing requirements, and conversion efficiency.

Agricultural residues, such as corn stover and wheat straw, offer a significant potential source of biomass for BTL processes. These materials are widely available in many regions and can be collected as a by-product of existing agricultural operations. However, the seasonal nature of crop production and the need to maintain soil health through residue retention can impact the consistency and sustainability of supply.

Forestry waste, including logging residues and wood processing by-products, represents another valuable biomass feedstock source. The advantage of forestry waste lies in its relatively high energy density and established collection infrastructure. However, challenges such as transportation costs and competition with other wood-based industries must be addressed to ensure a stable supply for BTL facilities.

Dedicated energy crops, such as switchgrass and miscanthus, have gained attention as potential feedstocks for BTL technologies. These crops can be cultivated specifically for energy production, offering advantages in terms of yield, consistency, and reduced competition with food production. However, the establishment of large-scale energy crop plantations requires significant land resources and may face environmental and social concerns.

The development of an efficient and reliable biomass feedstock supply chain is essential for the successful implementation of BTL technologies. This involves optimizing collection, storage, and transportation processes to ensure a consistent and cost-effective supply of biomass to conversion facilities. Preprocessing techniques, such as size reduction and densification, can improve the handling and storage characteristics of biomass feedstocks, enhancing overall supply chain efficiency.

Sustainability considerations are paramount in biomass feedstock supply for BTL technologies. Ensuring that feedstock production and collection practices do not negatively impact soil health, biodiversity, or food security is crucial for the long-term viability of these renewable energy systems. The implementation of certification schemes and best management practices can help address these concerns and promote sustainable biomass production.

Environmental Impact

The environmental impact of decane production through biomass-to-liquid (BTL) technologies for renewable energy is a critical aspect to consider in the broader context of sustainable energy solutions. BTL processes offer a promising pathway for converting biomass into liquid fuels, with decane being a key component in the production of renewable diesel and jet fuel.

One of the primary environmental benefits of decane production via BTL technologies is the potential reduction in greenhouse gas emissions compared to conventional fossil fuel production. The carbon dioxide released during the combustion of BTL-derived decane is offset by the carbon absorbed by the biomass feedstock during its growth, resulting in a more favorable carbon balance. This closed carbon cycle contributes to mitigating climate change impacts associated with transportation and energy sectors.

However, the environmental impact of BTL processes extends beyond carbon emissions. Land use change is a significant concern, as large-scale biomass cultivation for fuel production may compete with food crops or lead to deforestation. Careful management of land resources and selection of appropriate feedstocks are essential to minimize negative impacts on biodiversity and ecosystem services.

Water consumption and quality are also important environmental considerations in BTL decane production. The process requires substantial amounts of water for biomass cultivation, processing, and cooling. Implementing water-efficient technologies and proper wastewater treatment systems can help mitigate these impacts and ensure responsible water management.

Air quality is another aspect affected by BTL decane production. While the end-use of BTL-derived fuels generally results in lower emissions of particulate matter and sulfur compounds compared to conventional fossil fuels, the production process itself may generate air pollutants. Advanced emission control technologies and optimized process designs are crucial for minimizing air quality impacts.

The life cycle assessment (LCA) of decane production through BTL technologies reveals both positive and negative environmental impacts. While the overall carbon footprint is generally lower than that of fossil fuel-derived decane, the energy intensity of the conversion process and the potential for indirect land use change must be carefully evaluated. Continuous improvement in process efficiency and the integration of renewable energy sources in BTL facilities can further enhance the environmental performance of decane production.

In conclusion, the environmental impact of decane production through BTL technologies is multifaceted, encompassing aspects of climate change mitigation, land use, water resources, air quality, and overall ecosystem health. As research and development in this field progress, it is crucial to address these environmental considerations holistically to ensure that BTL-derived decane contributes positively to renewable energy goals while minimizing adverse ecological effects.

One of the primary environmental benefits of decane production via BTL technologies is the potential reduction in greenhouse gas emissions compared to conventional fossil fuel production. The carbon dioxide released during the combustion of BTL-derived decane is offset by the carbon absorbed by the biomass feedstock during its growth, resulting in a more favorable carbon balance. This closed carbon cycle contributes to mitigating climate change impacts associated with transportation and energy sectors.

However, the environmental impact of BTL processes extends beyond carbon emissions. Land use change is a significant concern, as large-scale biomass cultivation for fuel production may compete with food crops or lead to deforestation. Careful management of land resources and selection of appropriate feedstocks are essential to minimize negative impacts on biodiversity and ecosystem services.

Water consumption and quality are also important environmental considerations in BTL decane production. The process requires substantial amounts of water for biomass cultivation, processing, and cooling. Implementing water-efficient technologies and proper wastewater treatment systems can help mitigate these impacts and ensure responsible water management.

Air quality is another aspect affected by BTL decane production. While the end-use of BTL-derived fuels generally results in lower emissions of particulate matter and sulfur compounds compared to conventional fossil fuels, the production process itself may generate air pollutants. Advanced emission control technologies and optimized process designs are crucial for minimizing air quality impacts.

The life cycle assessment (LCA) of decane production through BTL technologies reveals both positive and negative environmental impacts. While the overall carbon footprint is generally lower than that of fossil fuel-derived decane, the energy intensity of the conversion process and the potential for indirect land use change must be carefully evaluated. Continuous improvement in process efficiency and the integration of renewable energy sources in BTL facilities can further enhance the environmental performance of decane production.

In conclusion, the environmental impact of decane production through BTL technologies is multifaceted, encompassing aspects of climate change mitigation, land use, water resources, air quality, and overall ecosystem health. As research and development in this field progress, it is crucial to address these environmental considerations holistically to ensure that BTL-derived decane contributes positively to renewable energy goals while minimizing adverse ecological effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!