Efficient Design Topologies for Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Design Evolution

The evolution of Battery Management System (BMS) design has been a critical factor in the advancement of energy storage technologies, particularly in the realm of electric vehicles and renewable energy systems. Over the past decades, BMS topologies have undergone significant transformations, driven by the need for improved efficiency, reliability, and scalability.

In the early stages of BMS development, centralized architectures were predominant. These systems featured a single control unit responsible for monitoring and managing all cells within a battery pack. While simple and cost-effective, centralized designs often struggled with scalability and were prone to single points of failure.

As battery technologies advanced and the demand for larger, more complex energy storage systems grew, distributed BMS architectures emerged. This topology distributed monitoring and control functions across multiple nodes, each responsible for a subset of cells. Distributed designs offered improved scalability and redundancy, but introduced challenges in terms of communication complexity and system integration.

The next significant evolution came with the introduction of modular BMS designs. These systems combined aspects of both centralized and distributed architectures, offering a balance between scalability and simplicity. Modular BMS topologies allowed for easier expansion and maintenance of battery systems, making them particularly attractive for large-scale applications.

Recent years have seen the rise of intelligent BMS designs, incorporating advanced algorithms and machine learning capabilities. These systems can adapt to changing battery conditions, predict potential issues, and optimize performance in real-time. Intelligent BMS topologies have significantly improved the accuracy of state-of-charge and state-of-health estimations, leading to more efficient and reliable battery operations.

The latest trend in BMS design evolution is the move towards wireless and cloud-connected systems. These topologies leverage IoT technologies to enable remote monitoring, over-the-air updates, and integration with broader energy management ecosystems. Wireless BMS designs offer reduced wiring complexity and improved flexibility, although they must address challenges related to data security and reliability.

Throughout this evolution, a consistent focus has been on improving the efficiency of BMS designs. This has involved optimizing power consumption, enhancing thermal management strategies, and developing more accurate cell balancing techniques. The pursuit of efficient design topologies has led to significant improvements in overall battery system performance and longevity.

Looking ahead, the evolution of BMS design is likely to continue, driven by advancements in battery chemistries, power electronics, and data analytics. Future topologies may incorporate more decentralized architectures, leveraging blockchain-like technologies for enhanced security and transparency in battery management operations.

In the early stages of BMS development, centralized architectures were predominant. These systems featured a single control unit responsible for monitoring and managing all cells within a battery pack. While simple and cost-effective, centralized designs often struggled with scalability and were prone to single points of failure.

As battery technologies advanced and the demand for larger, more complex energy storage systems grew, distributed BMS architectures emerged. This topology distributed monitoring and control functions across multiple nodes, each responsible for a subset of cells. Distributed designs offered improved scalability and redundancy, but introduced challenges in terms of communication complexity and system integration.

The next significant evolution came with the introduction of modular BMS designs. These systems combined aspects of both centralized and distributed architectures, offering a balance between scalability and simplicity. Modular BMS topologies allowed for easier expansion and maintenance of battery systems, making them particularly attractive for large-scale applications.

Recent years have seen the rise of intelligent BMS designs, incorporating advanced algorithms and machine learning capabilities. These systems can adapt to changing battery conditions, predict potential issues, and optimize performance in real-time. Intelligent BMS topologies have significantly improved the accuracy of state-of-charge and state-of-health estimations, leading to more efficient and reliable battery operations.

The latest trend in BMS design evolution is the move towards wireless and cloud-connected systems. These topologies leverage IoT technologies to enable remote monitoring, over-the-air updates, and integration with broader energy management ecosystems. Wireless BMS designs offer reduced wiring complexity and improved flexibility, although they must address challenges related to data security and reliability.

Throughout this evolution, a consistent focus has been on improving the efficiency of BMS designs. This has involved optimizing power consumption, enhancing thermal management strategies, and developing more accurate cell balancing techniques. The pursuit of efficient design topologies has led to significant improvements in overall battery system performance and longevity.

Looking ahead, the evolution of BMS design is likely to continue, driven by advancements in battery chemistries, power electronics, and data analytics. Future topologies may incorporate more decentralized architectures, leveraging blockchain-like technologies for enhanced security and transparency in battery management operations.

Market Demand Analysis

The market demand for efficient Battery Management Systems (BMS) has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing adoption of renewable energy storage solutions. As the global push for electrification and sustainable energy solutions intensifies, the need for advanced BMS technologies has become paramount.

In the automotive sector, the surge in EV production and sales has created a substantial market for high-performance BMS. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups in the coming decades. This transition is fueling the demand for BMS that can optimize battery performance, extend range, and ensure safety. The automotive BMS market is expected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years.

Beyond automotive applications, the renewable energy sector is also driving demand for efficient BMS designs. As grid-scale energy storage systems become more prevalent, the need for sophisticated BMS to manage large-scale battery installations is increasing. These systems require BMS that can handle high power levels, ensure long-term reliability, and provide advanced monitoring and control capabilities.

The consumer electronics industry represents another significant market for BMS, with smartphones, laptops, and wearable devices requiring increasingly sophisticated power management solutions. As consumers demand longer battery life and faster charging times, manufacturers are turning to advanced BMS topologies to meet these expectations.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading in BMS demand due to its dominant position in EV manufacturing and battery production. However, North America and Europe are also showing strong growth, driven by stringent emissions regulations and government incentives for electric vehicles and renewable energy adoption.

The industrial sector is emerging as a key market for BMS, with applications in robotics, automated guided vehicles, and industrial energy storage systems. These applications require BMS that can operate reliably in harsh environments and provide precise control over battery performance.

As the market expands, there is a growing emphasis on BMS designs that offer improved efficiency, reduced cost, and enhanced functionality. Manufacturers are seeking BMS solutions that can provide accurate state-of-charge and state-of-health estimations, support fast charging capabilities, and integrate seamlessly with other vehicle or energy system components.

The increasing complexity of battery systems, with higher voltages and larger capacities, is driving demand for more sophisticated BMS architectures. There is a particular interest in distributed and modular BMS designs that can scale effectively for different battery configurations and sizes.

In the automotive sector, the surge in EV production and sales has created a substantial market for high-performance BMS. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups in the coming decades. This transition is fueling the demand for BMS that can optimize battery performance, extend range, and ensure safety. The automotive BMS market is expected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years.

Beyond automotive applications, the renewable energy sector is also driving demand for efficient BMS designs. As grid-scale energy storage systems become more prevalent, the need for sophisticated BMS to manage large-scale battery installations is increasing. These systems require BMS that can handle high power levels, ensure long-term reliability, and provide advanced monitoring and control capabilities.

The consumer electronics industry represents another significant market for BMS, with smartphones, laptops, and wearable devices requiring increasingly sophisticated power management solutions. As consumers demand longer battery life and faster charging times, manufacturers are turning to advanced BMS topologies to meet these expectations.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading in BMS demand due to its dominant position in EV manufacturing and battery production. However, North America and Europe are also showing strong growth, driven by stringent emissions regulations and government incentives for electric vehicles and renewable energy adoption.

The industrial sector is emerging as a key market for BMS, with applications in robotics, automated guided vehicles, and industrial energy storage systems. These applications require BMS that can operate reliably in harsh environments and provide precise control over battery performance.

As the market expands, there is a growing emphasis on BMS designs that offer improved efficiency, reduced cost, and enhanced functionality. Manufacturers are seeking BMS solutions that can provide accurate state-of-charge and state-of-health estimations, support fast charging capabilities, and integrate seamlessly with other vehicle or energy system components.

The increasing complexity of battery systems, with higher voltages and larger capacities, is driving demand for more sophisticated BMS architectures. There is a particular interest in distributed and modular BMS designs that can scale effectively for different battery configurations and sizes.

BMS Topology Challenges

Battery Management Systems (BMS) play a crucial role in ensuring the safe and efficient operation of lithium-ion batteries. However, as battery technologies advance and applications diversify, BMS designers face numerous challenges in creating efficient topologies. One of the primary challenges is balancing performance with cost-effectiveness, as more complex topologies often come with higher implementation costs.

The increasing energy density and capacity of modern battery packs necessitate more sophisticated monitoring and control mechanisms. This requirement puts pressure on BMS designers to develop topologies that can accurately measure and manage a large number of cells simultaneously without compromising response time or data accuracy. The challenge lies in optimizing the communication architecture to handle high-volume data transfer while minimizing latency and power consumption.

Thermal management presents another significant challenge in BMS topology design. As batteries become more powerful and compact, heat dissipation becomes a critical concern. BMS topologies must incorporate efficient thermal monitoring and management strategies to prevent overheating and ensure uniform temperature distribution across the battery pack. This often requires integrating temperature sensors and cooling systems into the BMS architecture, adding complexity to the overall design.

Scalability and flexibility are also key challenges in BMS topology design. With the diverse range of battery applications, from small consumer electronics to large-scale energy storage systems, BMS topologies need to be adaptable to different battery configurations and sizes. Designing a modular and scalable architecture that can be easily customized for various applications without significant redesign is a complex task.

The increasing demand for fast charging capabilities introduces additional challenges for BMS topologies. Rapid charging requires precise control of charging currents and voltages to prevent damage to the battery cells. BMS designers must develop topologies that can handle high-power charging scenarios while maintaining cell balancing and preventing thermal runaway.

Safety and reliability remain paramount in BMS design. Topologies must incorporate robust fault detection and protection mechanisms to safeguard against various failure modes, such as short circuits, over-voltage, and over-current conditions. Implementing redundancy and fail-safe features without overly complicating the system or increasing costs is a delicate balance that designers must strike.

As the automotive industry shifts towards electrification, BMS topologies face unique challenges in meeting stringent automotive safety standards and reliability requirements. Designers must consider factors such as electromagnetic compatibility, vibration resistance, and long-term durability in harsh operating environments. These considerations often necessitate more robust and sophisticated topologies, further complicating the design process.

The increasing energy density and capacity of modern battery packs necessitate more sophisticated monitoring and control mechanisms. This requirement puts pressure on BMS designers to develop topologies that can accurately measure and manage a large number of cells simultaneously without compromising response time or data accuracy. The challenge lies in optimizing the communication architecture to handle high-volume data transfer while minimizing latency and power consumption.

Thermal management presents another significant challenge in BMS topology design. As batteries become more powerful and compact, heat dissipation becomes a critical concern. BMS topologies must incorporate efficient thermal monitoring and management strategies to prevent overheating and ensure uniform temperature distribution across the battery pack. This often requires integrating temperature sensors and cooling systems into the BMS architecture, adding complexity to the overall design.

Scalability and flexibility are also key challenges in BMS topology design. With the diverse range of battery applications, from small consumer electronics to large-scale energy storage systems, BMS topologies need to be adaptable to different battery configurations and sizes. Designing a modular and scalable architecture that can be easily customized for various applications without significant redesign is a complex task.

The increasing demand for fast charging capabilities introduces additional challenges for BMS topologies. Rapid charging requires precise control of charging currents and voltages to prevent damage to the battery cells. BMS designers must develop topologies that can handle high-power charging scenarios while maintaining cell balancing and preventing thermal runaway.

Safety and reliability remain paramount in BMS design. Topologies must incorporate robust fault detection and protection mechanisms to safeguard against various failure modes, such as short circuits, over-voltage, and over-current conditions. Implementing redundancy and fail-safe features without overly complicating the system or increasing costs is a delicate balance that designers must strike.

As the automotive industry shifts towards electrification, BMS topologies face unique challenges in meeting stringent automotive safety standards and reliability requirements. Designers must consider factors such as electromagnetic compatibility, vibration resistance, and long-term durability in harsh operating environments. These considerations often necessitate more robust and sophisticated topologies, further complicating the design process.

Current BMS Topologies

01 Adaptive power management techniques

Battery Management Systems (BMS) can employ adaptive power management techniques to optimize energy usage and extend battery life. These techniques involve dynamically adjusting power consumption based on real-time usage patterns, environmental conditions, and battery state. By intelligently allocating power resources, the system can significantly improve overall efficiency and performance.- Advanced Battery Management System Architectures: Modern battery management systems employ sophisticated architectures to enhance efficiency. These systems integrate advanced monitoring, control, and optimization techniques to improve battery performance, longevity, and safety. Key features include real-time data analysis, predictive maintenance algorithms, and adaptive power management strategies.

- Thermal Management in Battery Systems: Efficient thermal management is crucial for battery system performance. Advanced cooling and heating mechanisms are implemented to maintain optimal operating temperatures, preventing overheating and extending battery life. These systems may include active cooling, phase change materials, or intelligent temperature control algorithms.

- Energy-Efficient Power Electronics: Innovations in power electronics contribute significantly to battery management system efficiency. High-efficiency converters, advanced switching technologies, and intelligent power routing systems minimize energy losses during charging and discharging processes. These improvements lead to better overall system performance and energy utilization.

- Machine Learning and AI in Battery Management: Artificial intelligence and machine learning algorithms are increasingly integrated into battery management systems. These technologies enable predictive analytics for battery health, adaptive charging strategies, and optimized energy distribution. AI-driven systems can learn from usage patterns to maximize efficiency and prolong battery lifespan.

- Communication and Integration Protocols: Efficient communication protocols and seamless integration with other vehicle or grid systems are essential for modern battery management. Advanced systems utilize high-speed data transfer, secure wireless communication, and standardized interfaces to enhance overall system efficiency and enable smart grid interactions or vehicle-to-grid technologies.

02 Advanced cell balancing algorithms

Implementing sophisticated cell balancing algorithms in BMS can enhance the overall efficiency of battery packs. These algorithms ensure uniform charge distribution across individual cells, preventing overcharging or undercharging. By maintaining optimal charge levels in each cell, the system can maximize the battery's capacity, lifespan, and overall performance.Expand Specific Solutions03 Thermal management optimization

Efficient thermal management is crucial for maintaining optimal battery performance and longevity. Advanced BMS incorporate intelligent thermal management systems that monitor and regulate battery temperature. By preventing overheating and maintaining ideal operating temperatures, these systems can significantly improve energy efficiency and extend battery life.Expand Specific Solutions04 Predictive maintenance and diagnostics

Incorporating predictive maintenance and diagnostic capabilities into BMS can enhance overall system efficiency. By utilizing machine learning algorithms and real-time data analysis, these systems can predict potential issues before they occur, schedule maintenance proactively, and optimize battery performance. This approach minimizes downtime and extends the operational life of the battery.Expand Specific Solutions05 Integration with renewable energy sources

BMS efficiency can be improved by integrating with renewable energy sources and smart grid systems. This integration allows for optimized charging schedules, utilizing excess renewable energy during off-peak hours, and implementing vehicle-to-grid (V2G) technologies. By leveraging these synergies, the overall energy efficiency of the battery system can be significantly enhanced.Expand Specific Solutions

Key BMS Manufacturers

The research on efficient design topologies for Battery Management Systems (BMS) is in a rapidly evolving phase, driven by the growing electric vehicle market and renewable energy storage demands. The global BMS market is expanding significantly, with projections indicating substantial growth in the coming years. Technologically, the field is advancing quickly, with companies like Robert Bosch GmbH, Samsung SDI Co., Ltd., and Texas Instruments Incorporated leading innovation. These firms are developing sophisticated BMS solutions, integrating advanced features such as real-time monitoring, predictive maintenance, and enhanced safety protocols. Emerging players like BattGenie, Inc. are also contributing to the competitive landscape by offering specialized software solutions for battery simulation and management.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Battery Management System (BMS) topology that utilizes a distributed architecture. This design incorporates multiple local control units connected to a central master controller, enabling efficient monitoring and control of individual battery cells[1]. The system employs high-precision voltage and current sensors, coupled with sophisticated algorithms for state estimation and thermal management. Bosch's BMS integrates machine learning techniques to optimize battery performance and longevity, adapting to various operating conditions and usage patterns[2]. The topology also includes a robust communication network, utilizing CAN-FD or Ethernet protocols for high-speed data transfer between components[3].

Strengths: Scalable architecture suitable for various battery sizes, improved accuracy in cell monitoring, and adaptive performance optimization. Weaknesses: Potentially higher initial cost due to distributed components and complexity in system integration.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei's efficient BMS design topology focuses on a modular and intelligent approach. Their system utilizes a hierarchical structure with a central management unit overseeing multiple battery cell supervision circuits (CSCs)[4]. Each CSC monitors a group of cells, reducing wiring complexity and improving fault tolerance. Huawei's BMS incorporates AI algorithms for predictive maintenance and state-of-health estimation, enhancing overall battery life and performance[5]. The topology also features a dual-redundant communication bus for increased reliability and real-time data processing capabilities. Huawei's design emphasizes energy efficiency, with low-power components and intelligent power management strategies to minimize the BMS's own energy consumption[6].

Strengths: High reliability due to modular design, advanced AI integration for predictive maintenance, and energy-efficient operation. Weaknesses: Potential for higher complexity in software management and initial setup costs.

Innovative BMS Designs

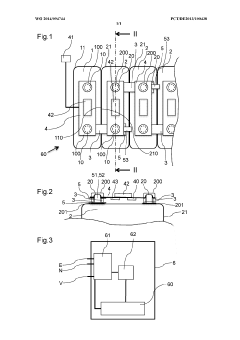

Battery system comprising a battery management system, store system for storing electrical energy comprising such a battery system, and method for bringing such a battery system into operation

PatentWO2014094744A1

Innovation

- The battery system employs optocouplers with light transmitters and receivers for potential-free data transmission between battery voltage regulator units, allowing for centralized monitoring and control without direct connections, along with plate-shaped battery pole connectors for mechanical coupling and robust construction, and optoelectronic data buses for efficient data transfer.

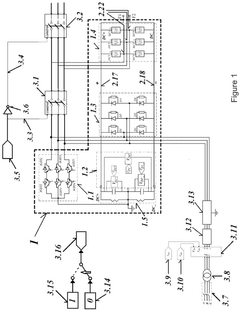

Active battery management system fed from a modified t-type two-way converter

PatentWO2025085039A1

Innovation

- An active battery management system utilizing a modified T-type bidirectional converter, which includes a power factor corrector circuit and a 3-level 6-switch bidirectional inverter, allows for individual control of each battery's charging and discharging, ensuring compliance with grid standards and extending battery life through desulfation.

BMS Safety Standards

Battery Management System (BMS) safety standards play a crucial role in ensuring the reliable and secure operation of battery systems, particularly in electric vehicles and energy storage applications. These standards are designed to address potential hazards associated with battery usage, such as thermal runaway, electrical shock, and fire risks. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed comprehensive safety standards for BMS, including IEC 62619 and SAE J2464.

IEC 62619 focuses on safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard outlines specifications for battery system design, testing procedures, and safety mechanisms. It emphasizes the importance of implementing protective measures against overcharging, over-discharging, and short circuits. The standard also mandates the inclusion of thermal management systems to prevent thermal runaway and ensure safe operation under various environmental conditions.

SAE J2464, on the other hand, specifically addresses electric and hybrid electric vehicle rechargeable energy storage systems. This standard provides guidelines for safety and abuse testing of battery systems, including mechanical shock, vibration, and thermal cycling tests. It also outlines requirements for battery management systems to monitor and control critical parameters such as cell voltage, temperature, and state of charge.

In addition to these standards, the United Nations (UN) has established regulations for the transportation of lithium batteries, known as UN 38.3. These regulations require rigorous testing of battery systems to ensure their safety during shipping and handling. BMS designs must comply with these regulations to enable the safe transportation of battery-powered devices and vehicles.

The implementation of BMS safety standards has led to the development of advanced safety features in battery systems. These include cell balancing techniques to prevent overcharging of individual cells, isolation detection systems to identify potential electrical faults, and sophisticated thermal management strategies to maintain optimal operating temperatures. Furthermore, BMS designs now incorporate redundant safety mechanisms and fail-safe modes to mitigate risks associated with component failures or system malfunctions.

As battery technologies continue to evolve, safety standards are regularly updated to address new challenges and emerging risks. For instance, recent updates to BMS safety standards have focused on cybersecurity measures to protect battery systems from potential hacking attempts and unauthorized access. This highlights the importance of continuous research and development in BMS design to stay ahead of potential safety threats and ensure the long-term reliability of battery-powered systems.

IEC 62619 focuses on safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard outlines specifications for battery system design, testing procedures, and safety mechanisms. It emphasizes the importance of implementing protective measures against overcharging, over-discharging, and short circuits. The standard also mandates the inclusion of thermal management systems to prevent thermal runaway and ensure safe operation under various environmental conditions.

SAE J2464, on the other hand, specifically addresses electric and hybrid electric vehicle rechargeable energy storage systems. This standard provides guidelines for safety and abuse testing of battery systems, including mechanical shock, vibration, and thermal cycling tests. It also outlines requirements for battery management systems to monitor and control critical parameters such as cell voltage, temperature, and state of charge.

In addition to these standards, the United Nations (UN) has established regulations for the transportation of lithium batteries, known as UN 38.3. These regulations require rigorous testing of battery systems to ensure their safety during shipping and handling. BMS designs must comply with these regulations to enable the safe transportation of battery-powered devices and vehicles.

The implementation of BMS safety standards has led to the development of advanced safety features in battery systems. These include cell balancing techniques to prevent overcharging of individual cells, isolation detection systems to identify potential electrical faults, and sophisticated thermal management strategies to maintain optimal operating temperatures. Furthermore, BMS designs now incorporate redundant safety mechanisms and fail-safe modes to mitigate risks associated with component failures or system malfunctions.

As battery technologies continue to evolve, safety standards are regularly updated to address new challenges and emerging risks. For instance, recent updates to BMS safety standards have focused on cybersecurity measures to protect battery systems from potential hacking attempts and unauthorized access. This highlights the importance of continuous research and development in BMS design to stay ahead of potential safety threats and ensure the long-term reliability of battery-powered systems.

BMS Efficiency Metrics

Battery Management System (BMS) efficiency metrics are crucial indicators for evaluating the performance and effectiveness of BMS designs in electric vehicles and energy storage systems. These metrics provide quantitative measures to assess how well a BMS optimizes battery performance, prolongs battery life, and ensures safe operation.

One key efficiency metric is power consumption. An efficient BMS design minimizes its own power draw, typically aiming for less than 1% of the total battery capacity. This is particularly important in applications where energy conservation is critical, such as in electric vehicles where every watt-hour counts towards extending range.

Accuracy of state estimation is another vital metric. This includes the precision of State of Charge (SoC) and State of Health (SoH) calculations. High-performance BMS designs achieve SoC estimation errors below 2% and SoH estimation errors within 5%. These accurate estimations are essential for optimal battery utilization and predictive maintenance.

Response time is a critical efficiency metric, especially in high-power applications. An efficient BMS should be capable of detecting and responding to fault conditions within milliseconds. This rapid response is crucial for preventing thermal runaway and other potentially catastrophic failures.

Thermal management efficiency is measured by the BMS's ability to maintain optimal battery temperature across various operating conditions. Effective designs typically keep cell temperature variations within a 5°C range, maximizing battery performance and longevity.

Balancing efficiency is another key metric, quantifying how quickly and effectively the BMS can equalize charge levels across cells. Advanced systems can achieve full pack balancing within hours, ensuring optimal capacity utilization and preventing premature cell degradation.

Scalability and modularity are increasingly important efficiency metrics. A well-designed BMS should maintain high performance across various battery configurations with minimal redesign. This adaptability is measured by the system's ability to scale from small to large battery packs while maintaining consistent performance metrics.

Lastly, data processing and communication efficiency are crucial in modern BMS designs. This is measured by the system's ability to handle high data throughput with minimal latency, typically processing thousands of data points per second while maintaining real-time responsiveness.

One key efficiency metric is power consumption. An efficient BMS design minimizes its own power draw, typically aiming for less than 1% of the total battery capacity. This is particularly important in applications where energy conservation is critical, such as in electric vehicles where every watt-hour counts towards extending range.

Accuracy of state estimation is another vital metric. This includes the precision of State of Charge (SoC) and State of Health (SoH) calculations. High-performance BMS designs achieve SoC estimation errors below 2% and SoH estimation errors within 5%. These accurate estimations are essential for optimal battery utilization and predictive maintenance.

Response time is a critical efficiency metric, especially in high-power applications. An efficient BMS should be capable of detecting and responding to fault conditions within milliseconds. This rapid response is crucial for preventing thermal runaway and other potentially catastrophic failures.

Thermal management efficiency is measured by the BMS's ability to maintain optimal battery temperature across various operating conditions. Effective designs typically keep cell temperature variations within a 5°C range, maximizing battery performance and longevity.

Balancing efficiency is another key metric, quantifying how quickly and effectively the BMS can equalize charge levels across cells. Advanced systems can achieve full pack balancing within hours, ensuring optimal capacity utilization and preventing premature cell degradation.

Scalability and modularity are increasingly important efficiency metrics. A well-designed BMS should maintain high performance across various battery configurations with minimal redesign. This adaptability is measured by the system's ability to scale from small to large battery packs while maintaining consistent performance metrics.

Lastly, data processing and communication efficiency are crucial in modern BMS designs. This is measured by the system's ability to handle high data throughput with minimal latency, typically processing thousands of data points per second while maintaining real-time responsiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!