Graphene Oxide in Battery Technology: Next Steps

Graphene Oxide Battery Tech Evolution and Objectives

Graphene oxide (GO) has emerged as a promising material in battery technology, revolutionizing energy storage systems. The evolution of GO in battery applications can be traced back to the early 2000s when researchers first explored its potential as an electrode material. Since then, significant advancements have been made in understanding and harnessing the unique properties of GO for battery enhancement.

The primary objective of GO research in battery technology is to improve overall battery performance, including energy density, power density, cycling stability, and charging speed. GO's high surface area, excellent electrical conductivity, and mechanical strength make it an ideal candidate for addressing current limitations in battery technology. Researchers aim to leverage these properties to develop next-generation batteries that can meet the growing demands of various applications, from portable electronics to electric vehicles and grid-scale energy storage.

One of the key goals in GO battery research is to optimize the synthesis and functionalization of GO to tailor its properties for specific battery components. This includes developing methods to control the oxygen content, defect density, and interlayer spacing of GO sheets, which directly impact its electrochemical performance. Additionally, researchers are exploring ways to integrate GO with other materials, such as metal oxides and conductive polymers, to create hybrid structures with enhanced properties.

Another important objective is to understand and mitigate the challenges associated with GO in battery applications. These include addressing the issue of restacking of GO sheets, which can reduce the accessible surface area and hinder ion transport. Researchers are also focusing on improving the long-term stability of GO-based electrodes and electrolytes, as well as developing scalable and cost-effective production methods for GO materials.

The evolution of GO in battery technology has seen several significant milestones. Early research focused on using GO as a conductive additive in electrode materials. This was followed by the development of GO-based composite electrodes, which demonstrated improved capacity and cycling stability. More recently, researchers have explored the use of GO in solid-state electrolytes and as a protective coating for battery components.

Looking ahead, the objectives for GO research in battery technology include developing high-performance, environmentally friendly, and commercially viable battery systems. This involves optimizing GO-based materials for specific battery chemistries, such as lithium-ion, sodium-ion, and metal-air batteries. Additionally, researchers aim to leverage GO's unique properties to enable novel battery designs, such as flexible and printable batteries for wearable devices and Internet of Things applications.

Market Demand for Advanced Battery Solutions

The demand for advanced battery solutions has been steadily increasing across various sectors, driven by the growing need for efficient energy storage systems. The automotive industry, in particular, has been a significant driver of this demand, with the rise of electric vehicles (EVs) necessitating high-performance, long-lasting batteries. The global EV battery market is projected to reach substantial growth in the coming years, reflecting the increasing adoption of electric vehicles worldwide.

In addition to the automotive sector, the renewable energy industry has also been a major contributor to the demand for advanced battery technologies. As solar and wind power generation becomes more prevalent, the need for reliable energy storage solutions to manage intermittent power supply has become crucial. This has led to a surge in demand for grid-scale battery systems, with lithium-ion batteries currently dominating the market.

Consumer electronics continue to be another significant market for advanced battery solutions. The ever-increasing functionality and power requirements of smartphones, laptops, and wearable devices have created a constant demand for batteries with higher energy density and faster charging capabilities. This sector has been particularly interested in developments that can extend battery life and reduce charging times.

The industrial and aerospace sectors are also showing growing interest in advanced battery technologies. Industrial applications, such as in robotics and automated systems, require batteries that can provide high power output and long operational times. In aerospace, the push towards more electric aircraft and the development of electric vertical takeoff and landing (eVTOL) vehicles are creating new demands for lightweight, high-energy-density batteries.

The integration of graphene oxide in battery technology has garnered significant attention due to its potential to address many of the current limitations in battery performance. Graphene oxide's unique properties, including high surface area, excellent conductivity, and mechanical strength, make it a promising material for enhancing battery electrodes and electrolytes. The market has shown particular interest in graphene oxide's potential to improve energy density, charging speeds, and overall battery lifespan.

As environmental concerns continue to grow, there is an increasing demand for more sustainable battery solutions. This has led to a focus on developing batteries with reduced environmental impact, both in terms of raw material sourcing and end-of-life recycling. The potential of graphene oxide to enhance battery efficiency and longevity aligns well with these sustainability goals, further driving market interest in this technology.

Current Graphene Oxide Battery Challenges

Despite the promising potential of graphene oxide in battery technology, several significant challenges currently hinder its widespread adoption and commercialization. One of the primary obstacles is the high production cost of graphene oxide, which limits its scalability for mass production. The complex synthesis process and the need for high-quality precursor materials contribute to this cost barrier, making it difficult for graphene oxide-based batteries to compete with existing technologies on a price-performance basis.

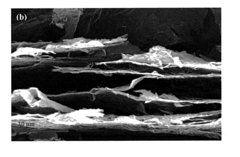

Another major challenge lies in the stability and durability of graphene oxide in battery applications. When used as an electrode material, graphene oxide tends to undergo structural changes during charge-discharge cycles, leading to capacity fading and reduced battery lifespan. This instability is particularly pronounced in lithium-ion batteries, where the repeated intercalation and de-intercalation of lithium ions can cause exfoliation and degradation of the graphene oxide layers.

The conductivity of graphene oxide presents a dual challenge. While graphene is known for its excellent electrical conductivity, graphene oxide is an insulator due to the presence of oxygen-containing functional groups. Although these groups are beneficial for certain battery applications, they also impede electron transport. Striking the right balance between conductivity and functionality remains a significant hurdle in optimizing graphene oxide for battery performance.

Furthermore, the integration of graphene oxide into existing battery manufacturing processes poses technical difficulties. The unique properties of graphene oxide often require modifications to standard production techniques, which can be costly and time-consuming to implement at an industrial scale. This integration challenge extends to ensuring uniform dispersion of graphene oxide in composite materials and maintaining its structural integrity during battery assembly.

Environmental and safety concerns also present challenges in the development of graphene oxide-based batteries. The potential release of nanomaterials during production, use, or disposal raises questions about long-term environmental impacts and human health effects. Addressing these concerns requires extensive research and the development of robust safety protocols, which can slow down the commercialization process.

Lastly, there is a knowledge gap in understanding the long-term performance and aging mechanisms of graphene oxide in battery systems. Limited data on extended cycling and real-world usage scenarios create uncertainty about the technology's viability for long-term energy storage applications. Overcoming this challenge requires extensive testing and validation, which is both time-consuming and resource-intensive.

Existing Graphene Oxide Battery Implementations

01 Synthesis and production methods of graphene oxide

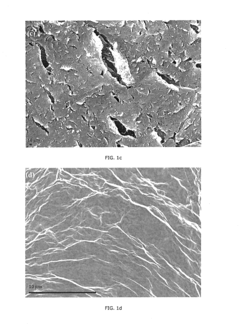

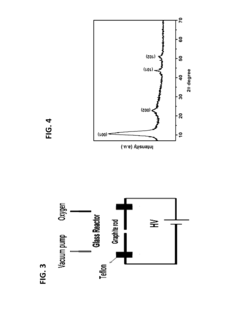

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in energy storage devices: Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.

- Functionalization and modification of graphene oxide: Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and surface modifications to improve its performance in different fields.

- Graphene oxide-based composites and nanocomposites: The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with other materials to create hybrid structures with enhanced properties. These composites find applications in various fields, including electronics, sensors, and structural materials.

- Characterization and analysis techniques for graphene oxide: Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand the material's composition, morphology, and behavior.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.Expand Specific Solutions04 Graphene oxide in environmental applications

Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and large surface area make it an effective material for these purposes.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand and optimize the material's characteristics.Expand Specific Solutions

Key Players in Graphene Oxide Battery Research

The research on graphene oxide in battery technology is in a dynamic phase, with significant market potential and ongoing technological advancements. The industry is transitioning from early-stage research to practical applications, driven by the growing demand for high-performance energy storage solutions. Market size is expanding rapidly, fueled by investments in electric vehicles and renewable energy sectors. Technologically, while progress is evident, full commercialization remains a challenge. Companies like Semiconductor Energy Laboratory, Northwestern University, and Samsung Electronics are at the forefront, pushing boundaries in graphene oxide battery applications. Other key players, including Global Graphene Group and NEC Corp., are contributing to the technology's maturation, indicating a competitive and collaborative landscape in this promising field.

Resonac Holdings Corp.

Samsung Electronics Co., Ltd.

Breakthrough Graphene Oxide Battery Patents

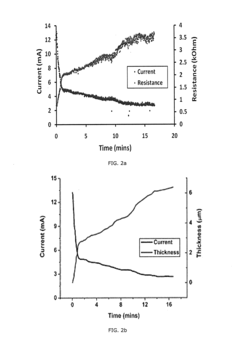

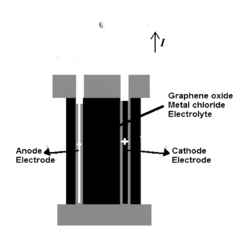

- A method involving the combination of graphite oxide with water to form a colloidal suspension, applying a potentiostatic field, and drying to create a graphene oxide paper, followed by photo-thermal or thermal exfoliation to produce reduced graphene oxide (RGO) paper with high thickness and surface area, enabling scalable and efficient production.

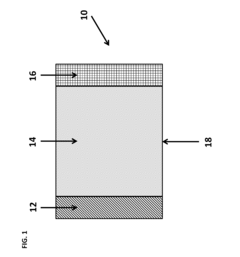

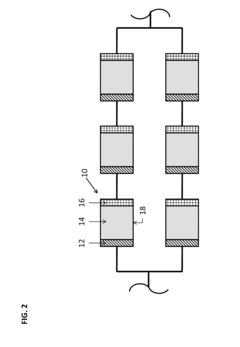

- A graphene oxide-based electrochemical cell with an aqueous electrolyte solution containing water, graphene oxide nanosheets, and a transition metal salt like CuCl2, paired with an aluminum anode and graphite cathode, which enhances energy density and stability, reducing the need for additional energy sources.

Environmental Impact of Graphene Oxide Batteries

The environmental impact of graphene oxide batteries is a critical consideration as this technology advances. While graphene oxide offers promising improvements in battery performance, its production and disposal processes require careful scrutiny to ensure sustainability.

The manufacturing of graphene oxide involves chemical processes that can generate hazardous waste. The use of strong oxidizing agents and acids in the production of graphene oxide from graphite may lead to the release of harmful byproducts if not properly managed. Additionally, the energy-intensive nature of graphene oxide production contributes to its carbon footprint, potentially offsetting some of the environmental benefits gained from improved battery efficiency.

However, the enhanced performance of graphene oxide batteries could lead to a net positive environmental impact. The increased energy density and faster charging capabilities may result in fewer batteries needed overall, reducing the total amount of materials required for energy storage. This could potentially decrease the environmental burden associated with battery production and disposal.

The longevity of graphene oxide batteries is another factor to consider. If these batteries indeed demonstrate a significantly longer lifespan compared to conventional lithium-ion batteries, it could substantially reduce electronic waste. This would alleviate the strain on recycling facilities and landfills, as well as conserve the resources needed for battery production.

End-of-life management for graphene oxide batteries presents both challenges and opportunities. The complex composition of these batteries may require specialized recycling processes to recover valuable materials effectively. Developing efficient recycling methods for graphene oxide batteries will be crucial to minimize their environmental impact and promote a circular economy approach.

Water usage and potential contamination are additional environmental concerns. The production and processing of graphene oxide often involve significant water consumption. Ensuring proper treatment and recycling of water used in manufacturing processes will be essential to mitigate potential negative impacts on local water resources.

As research progresses, it will be vital to conduct comprehensive life cycle assessments of graphene oxide batteries. These studies should compare the environmental footprint of graphene oxide batteries with conventional battery technologies across all stages, from raw material extraction to end-of-life disposal or recycling. Such assessments will provide valuable insights into the true environmental implications of adopting this technology on a large scale.

Scalability and Manufacturing Considerations

As graphene oxide (GO) continues to show promise in battery technology, scaling up production and optimizing manufacturing processes become critical considerations for its widespread adoption. The transition from laboratory-scale synthesis to industrial-scale production presents several challenges that need to be addressed.

One of the primary concerns is the development of cost-effective and environmentally friendly methods for large-scale GO production. Current synthesis techniques, such as the modified Hummers method, often involve hazardous chemicals and generate significant waste. Research into greener alternatives, like electrochemical exfoliation or mechanochemical approaches, is ongoing but requires further refinement for industrial viability.

Consistency in GO quality across large batches is another crucial factor. The performance of GO in battery applications is highly dependent on its structural and chemical properties, which can vary significantly based on production methods and conditions. Establishing standardized production protocols and implementing robust quality control measures are essential steps towards ensuring uniform GO characteristics at scale.

The integration of GO into existing battery manufacturing processes also presents challenges. Current battery production lines may require modifications to accommodate GO-based materials effectively. This includes developing new coating techniques, adjusting drying processes, and potentially redesigning electrode structures to maximize the benefits of GO incorporation.

Furthermore, the handling and storage of GO at industrial scales introduce additional complexities. GO's sensitivity to environmental conditions, such as humidity and temperature, necessitates the development of specialized storage and transportation solutions to maintain its properties throughout the supply chain.

Addressing these scalability and manufacturing considerations will likely require collaborative efforts between research institutions and industry partners. Pilot-scale production facilities can serve as crucial intermediaries, allowing for the optimization of processes before full-scale implementation. Additionally, the development of in-line characterization techniques and real-time monitoring systems will be vital for maintaining quality control during large-scale production.

As research progresses, focus should also be placed on reducing the overall cost of GO production and integration into battery systems. This may involve exploring alternative precursor materials, optimizing reaction conditions, and developing more efficient purification methods. The economic viability of GO-enhanced batteries will ultimately depend on striking a balance between performance improvements and manufacturing costs.