High Density Polyethylene in Military Equipment Innovation

HDPE in Military Tech: Background and Objectives

High Density Polyethylene (HDPE) has emerged as a revolutionary material in military equipment innovation, offering a unique combination of properties that address the evolving needs of modern warfare. The background of HDPE in military technology traces back to its development in the 1950s, initially for civilian applications. However, its exceptional strength-to-weight ratio, chemical resistance, and durability quickly caught the attention of military researchers.

The evolution of HDPE in military applications has been driven by the increasing demand for lighter, more durable, and cost-effective equipment. As military operations have become more complex and geographically diverse, the need for materials that can withstand extreme conditions while maintaining performance has grown exponentially. HDPE's versatility has allowed it to be integrated into various military equipment, from personal gear to vehicle components and even structural elements in temporary military installations.

The primary objective of researching HDPE in military equipment innovation is to exploit its full potential in enhancing the effectiveness, safety, and efficiency of military operations. This includes developing new manufacturing techniques to improve HDPE's already impressive properties, such as impact resistance and thermal stability. Additionally, researchers aim to explore novel applications of HDPE in areas where traditional materials fall short, particularly in reducing the overall weight of military equipment without compromising strength or functionality.

Another critical objective is to investigate the integration of HDPE with other advanced materials and technologies. This includes exploring composite materials that combine HDPE with fibers or nanoparticles to create even more robust and versatile materials. The research also extends to developing smart HDPE-based materials that can respond to environmental stimuli or incorporate sensing capabilities, potentially revolutionizing military equipment design.

Environmental considerations form an essential part of the research objectives. As military organizations worldwide face increasing pressure to reduce their environmental footprint, the recyclability and potential biodegradability of HDPE-based military equipment have become significant areas of interest. Researchers are exploring ways to enhance the material's end-of-life management while maintaining its performance characteristics during its operational lifespan.

The technological trajectory of HDPE in military applications is closely aligned with broader trends in materials science and engineering. Advances in polymer science, nanotechnology, and additive manufacturing are expected to open new avenues for HDPE innovation in military contexts. As such, a key objective of ongoing research is to stay at the forefront of these technological developments, ensuring that military applications of HDPE continue to benefit from the latest scientific breakthroughs.

Market Analysis for HDPE Military Applications

The market for High Density Polyethylene (HDPE) in military applications has shown significant growth and potential in recent years. This robust polymer's unique properties, including high strength-to-density ratio, excellent chemical resistance, and durability, make it an attractive material for various military equipment innovations.

The global military equipment market, valued at $1.3 trillion in 2022, is expected to grow at a CAGR of 3.5% through 2030. Within this market, the demand for lightweight, durable, and cost-effective materials like HDPE is increasing rapidly. The HDPE market specifically for military applications was estimated at $450 million in 2022 and is projected to reach $650 million by 2027, growing at a CAGR of 7.6%.

Key drivers for the adoption of HDPE in military equipment include the need for weight reduction in vehicles and personal gear, improved fuel efficiency, and enhanced mobility for troops. The material's resistance to corrosion and chemicals also makes it ideal for storage containers, fuel tanks, and protective equipment.

The largest market segment for HDPE in military applications is currently in vehicle components, accounting for approximately 40% of the market share. This includes parts such as fuel tanks, body panels, and interior components. Personal protective equipment (PPE) follows closely, representing about 30% of the market, with applications in helmets, body armor inserts, and protective cases.

Geographically, North America dominates the market with a 45% share, driven by high defense spending and ongoing military modernization programs. Europe and Asia-Pacific follow with 25% and 20% market shares respectively, with both regions showing strong growth potential due to increasing defense budgets and technological advancements.

The market landscape is characterized by a mix of large defense contractors and specialized polymer manufacturers. Key players include Honeywell International, DuPont, SABIC, and Celanese Corporation, who are investing heavily in R&D to develop advanced HDPE formulations tailored for military applications.

Emerging trends in the market include the development of nano-enhanced HDPE for improved ballistic protection, the integration of HDPE in 3D-printed military components, and the use of recycled HDPE in non-critical applications to address sustainability concerns.

Challenges in the market include stringent military specifications, long procurement cycles, and competition from alternative materials such as advanced composites. However, the overall outlook remains positive, driven by ongoing military modernization efforts globally and the continuous search for materials that can enhance operational efficiency and soldier safety.

HDPE Challenges in Military Equipment

High Density Polyethylene (HDPE) has emerged as a promising material in military equipment innovation, offering unique properties that address several challenges faced by traditional materials. However, its implementation in military applications presents a set of complex challenges that require careful consideration and innovative solutions.

One of the primary challenges is the need for enhanced durability and impact resistance in military equipment. While HDPE exhibits excellent toughness and impact strength, further improvements are necessary to meet the rigorous demands of combat environments. Researchers are exploring methods to reinforce HDPE with nanoparticles or fibers to create composite materials with superior mechanical properties without significantly increasing weight.

Temperature resistance poses another significant challenge. Military equipment often operates in extreme conditions, from arctic cold to desert heat. HDPE's relatively low melting point and tendency to soften at elevated temperatures limit its use in certain applications. Developing heat-stabilized HDPE formulations or creating hybrid materials that maintain structural integrity across a wider temperature range is crucial for expanding its military applications.

Chemical resistance is a critical factor in military environments where exposure to fuels, solvents, and other aggressive substances is common. While HDPE generally exhibits good chemical resistance, certain military-specific chemicals may degrade its properties over time. Enhancing HDPE's chemical resistance through surface treatments or the incorporation of specialized additives is an ongoing area of research.

The challenge of achieving optimal balance between strength and weight reduction is paramount in military equipment design. HDPE offers a favorable strength-to-weight ratio, but further optimization is required to compete with or surpass traditional materials like metals and advanced composites in specific applications. This involves developing new processing techniques and exploring novel HDPE-based composite structures.

Long-term performance and aging characteristics of HDPE in military applications remain areas of concern. The material must maintain its properties over extended periods, often in harsh environmental conditions. Accelerated aging tests and the development of more stable HDPE formulations are essential to address this challenge and ensure the longevity of military equipment.

Joining and bonding HDPE components in complex military equipment assemblies present technical difficulties. Traditional welding and adhesive bonding techniques may not always be suitable or provide sufficient strength. Innovative joining methods, such as friction stir welding or advanced adhesive systems, are being investigated to overcome these limitations.

Finally, the challenge of integrating HDPE with other materials and technologies in military equipment is significant. This includes incorporating electronic components, sensors, and smart materials into HDPE structures without compromising their integrity or functionality. Developing compatible manufacturing processes and design methodologies that allow for seamless integration is crucial for realizing the full potential of HDPE in next-generation military equipment.

Current HDPE Solutions for Military Gear

01 Manufacturing processes for HDPE

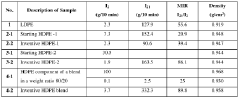

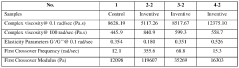

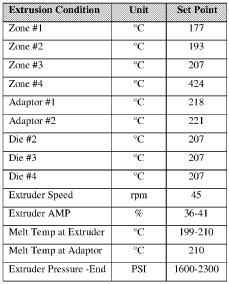

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including different polymerization techniques and reactor designs. These processes aim to control the molecular weight, density, and other properties of the resulting HDPE material.- Manufacturing processes for HDPE: Various methods are employed to produce high-density polyethylene, including polymerization techniques and the use of specific catalysts. These processes aim to control the molecular structure and properties of the resulting HDPE, such as density and melt flow rate.

- HDPE blends and composites: High-density polyethylene can be blended with other materials or reinforced to create composites with enhanced properties. These blends and composites often exhibit improved mechanical strength, thermal stability, or specific functional characteristics tailored for particular applications.

- HDPE applications in packaging and containers: High-density polyethylene is widely used in packaging and container applications due to its excellent chemical resistance, durability, and barrier properties. It is commonly employed in the production of bottles, drums, and various types of packaging materials.

- Modification and functionalization of HDPE: Techniques for modifying and functionalizing high-density polyethylene are developed to enhance its properties or introduce new functionalities. These modifications can include grafting, crosslinking, or the incorporation of additives to improve specific characteristics such as adhesion, printability, or UV resistance.

- Recycling and sustainability of HDPE: Methods for recycling high-density polyethylene and improving its sustainability are being developed. These include techniques for processing post-consumer HDPE, incorporating recycled content into new products, and developing more environmentally friendly production processes.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to enhance its properties or create specialized materials. These blends and composites can improve characteristics such as strength, durability, or specific functional properties for various applications.Expand Specific Solutions03 HDPE applications in packaging and containers

High-density polyethylene is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. It is commonly used in bottles, food packaging, and industrial containers.Expand Specific Solutions04 Modification and functionalization of HDPE

Various techniques are employed to modify or functionalize HDPE, enhancing its properties or adding new functionalities. These modifications can include crosslinking, grafting, or the addition of specific additives to improve performance in targeted applications.Expand Specific Solutions05 Recycling and sustainability of HDPE

As environmental concerns grow, there is increasing focus on the recycling and sustainability of HDPE. This includes developing improved recycling processes, creating products from recycled HDPE, and exploring bio-based alternatives to traditional petroleum-derived HDPE.Expand Specific Solutions

Key Players in Military HDPE Innovation

The research on High Density Polyethylene (HDPE) in military equipment innovation is in a mature yet evolving stage, with a growing market driven by increasing defense budgets and demand for lightweight, durable materials. The global market for HDPE in military applications is substantial, with steady growth projected. Technologically, HDPE applications are well-established, but ongoing research focuses on enhancing properties for specific military needs. Key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV are at the forefront, investing in R&D to improve HDPE's performance in extreme conditions. Emerging companies from China, such as Shenhua (Beijing) New Material Technology Co., Ltd., are also making significant contributions, indicating a competitive and innovative landscape.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Breakthrough HDPE Technologies for Defense

- A modified HDPE is produced by treating high density polyethylene with oxygen or peroxide to enhance its melt strength and processability, allowing for the creation of a foamable composition that can be foamed to achieve a wide range of densities with increased stiffness, including closed cell foams with densities similar or lower than LDPE.

- A bimodal polyethylene composition comprising a higher molecular weight ethylene copolymer and a lower molecular weight ethylene homopolymer or copolymer, with specific density, melt index, and molecular weight distribution ranges, enhancing processability and environmental stress crack resistance.

Environmental Impact of HDPE in Defense

The environmental impact of High Density Polyethylene (HDPE) in defense applications is a critical consideration as military organizations strive to balance operational effectiveness with sustainability. HDPE, widely used in military equipment due to its durability and versatility, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of HDPE in defense applications is its potential for recycling. Unlike many other materials used in military equipment, HDPE can be recycled multiple times without significant degradation of its properties. This characteristic allows for the development of closed-loop systems within military supply chains, reducing waste and conserving resources. Additionally, the long lifespan of HDPE products in military applications contributes to reduced frequency of replacement, thereby minimizing the overall environmental footprint.

However, the production of HDPE for defense purposes does raise environmental concerns. The manufacturing process relies heavily on fossil fuels, contributing to greenhouse gas emissions and energy consumption. While advancements in production technologies have improved efficiency, the carbon footprint of HDPE production remains a significant consideration for military organizations aiming to reduce their environmental impact.

The disposal of HDPE products at the end of their lifecycle presents another environmental challenge. While recyclable, not all HDPE waste from military applications is properly collected and processed. Improper disposal can lead to pollution, particularly in marine environments where HDPE debris can persist for centuries. This issue is especially pertinent for naval and coastal defense operations, where the risk of HDPE waste entering aquatic ecosystems is heightened.

In response to these challenges, military organizations are increasingly exploring eco-friendly alternatives and sustainable practices. Bio-based HDPE, derived from renewable resources such as sugarcane, is emerging as a promising option for reducing the reliance on fossil fuels. Additionally, advanced recycling technologies, such as chemical recycling, are being investigated to improve the efficiency and scope of HDPE recycling in military contexts.

The defense sector is also implementing lifecycle assessment methodologies to evaluate the environmental impact of HDPE products from production to disposal. This approach enables more informed decision-making regarding material selection and end-of-life management. Furthermore, military research and development efforts are focusing on designing HDPE-based equipment with enhanced recyclability and biodegradability, without compromising performance or durability.

As environmental regulations become more stringent globally, the defense industry is under increasing pressure to adopt sustainable practices. The use of HDPE in military equipment innovation must therefore be balanced with environmental considerations, driving the need for continuous improvement in material science and waste management strategies within the defense sector.

Standardization of HDPE in Military Equipment

The standardization of High Density Polyethylene (HDPE) in military equipment represents a critical step towards enhancing the efficiency, reliability, and interoperability of defense systems. This process involves establishing uniform specifications, testing procedures, and quality control measures for HDPE materials used across various military applications. By implementing standardized practices, armed forces can ensure consistent performance, streamline procurement processes, and reduce lifecycle costs associated with HDPE-based equipment.

One of the primary objectives of HDPE standardization in military equipment is to create a common language and set of requirements for manufacturers, suppliers, and end-users. This includes developing detailed material specifications that outline the physical, chemical, and mechanical properties required for different military applications. These specifications typically cover aspects such as density, molecular weight distribution, tensile strength, impact resistance, and environmental stability.

Standardization efforts also focus on establishing uniform testing methodologies to evaluate HDPE materials and components. This ensures that all products meet the same performance criteria, regardless of their source or manufacturer. Standardized tests may include accelerated weathering, chemical resistance, ballistic performance, and long-term durability assessments. By adopting these common testing protocols, military organizations can more effectively compare and select HDPE products that meet their specific operational needs.

Another crucial aspect of HDPE standardization in military equipment is the development of quality control and assurance procedures. This involves implementing rigorous inspection and verification processes throughout the supply chain, from raw material production to final product assembly. Standardized quality control measures help identify and eliminate potential defects or inconsistencies that could compromise the performance or reliability of military equipment in the field.

Furthermore, standardization efforts extend to the design and manufacturing processes used in HDPE-based military equipment. This includes establishing guidelines for mold design, processing parameters, and post-production treatments. By standardizing these aspects, military organizations can ensure greater consistency in product quality and performance across different suppliers and production batches.

The implementation of HDPE standardization in military equipment also facilitates improved interoperability between different systems and components. This is particularly important in multinational operations or when integrating equipment from various manufacturers. Standardized HDPE materials and components can be more easily interchanged or replaced, reducing logistical complexities and improving operational flexibility.