Isopentane as a Blowing Agent in Food Product Stabilization

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Blowing Agent Background and Objectives

Isopentane, a volatile organic compound with the chemical formula C5H12, has emerged as a promising blowing agent in the food industry, particularly for product stabilization. The evolution of this technology can be traced back to the early 2000s when environmental concerns led to the phasing out of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) in various applications, including food packaging.

The primary objective of researching isopentane as a blowing agent in food product stabilization is to develop more sustainable and efficient methods for preserving food quality and extending shelf life. This aligns with the growing consumer demand for fresher, longer-lasting products with minimal use of artificial preservatives. Additionally, the food industry seeks to reduce its environmental footprint by adopting more eco-friendly packaging and preservation techniques.

Isopentane's potential as a blowing agent stems from its low boiling point (27.8°C) and its ability to create a uniform cellular structure in various materials. In food product stabilization, it can be used to create protective foams or expand packaging materials, effectively insulating the food from external temperature fluctuations and physical damage.

The technology's development has been driven by several factors, including stricter regulations on food safety and packaging materials, advancements in polymer science, and the need for more cost-effective preservation methods. As research progressed, scientists discovered that isopentane could offer advantages over traditional blowing agents, such as improved thermal insulation properties and reduced material usage.

One of the key milestones in this field was the successful application of isopentane-based foams in the packaging of temperature-sensitive foods, such as fresh produce and dairy products. This breakthrough demonstrated the potential for extending product shelf life while maintaining quality and reducing food waste.

The current research landscape focuses on optimizing isopentane formulations for different food types, enhancing its compatibility with various packaging materials, and ensuring compliance with food safety regulations. Scientists are also exploring ways to further reduce the environmental impact of isopentane production and improve its recyclability in food packaging applications.

Looking ahead, the objectives of ongoing research include developing smart packaging solutions that incorporate isopentane-based technologies, such as active packaging that can respond to environmental changes to maintain optimal food preservation conditions. Additionally, researchers aim to integrate this technology with other emerging preservation methods, like modified atmosphere packaging and nanotechnology, to create synergistic effects in food product stabilization.

The primary objective of researching isopentane as a blowing agent in food product stabilization is to develop more sustainable and efficient methods for preserving food quality and extending shelf life. This aligns with the growing consumer demand for fresher, longer-lasting products with minimal use of artificial preservatives. Additionally, the food industry seeks to reduce its environmental footprint by adopting more eco-friendly packaging and preservation techniques.

Isopentane's potential as a blowing agent stems from its low boiling point (27.8°C) and its ability to create a uniform cellular structure in various materials. In food product stabilization, it can be used to create protective foams or expand packaging materials, effectively insulating the food from external temperature fluctuations and physical damage.

The technology's development has been driven by several factors, including stricter regulations on food safety and packaging materials, advancements in polymer science, and the need for more cost-effective preservation methods. As research progressed, scientists discovered that isopentane could offer advantages over traditional blowing agents, such as improved thermal insulation properties and reduced material usage.

One of the key milestones in this field was the successful application of isopentane-based foams in the packaging of temperature-sensitive foods, such as fresh produce and dairy products. This breakthrough demonstrated the potential for extending product shelf life while maintaining quality and reducing food waste.

The current research landscape focuses on optimizing isopentane formulations for different food types, enhancing its compatibility with various packaging materials, and ensuring compliance with food safety regulations. Scientists are also exploring ways to further reduce the environmental impact of isopentane production and improve its recyclability in food packaging applications.

Looking ahead, the objectives of ongoing research include developing smart packaging solutions that incorporate isopentane-based technologies, such as active packaging that can respond to environmental changes to maintain optimal food preservation conditions. Additionally, researchers aim to integrate this technology with other emerging preservation methods, like modified atmosphere packaging and nanotechnology, to create synergistic effects in food product stabilization.

Market Analysis for Food Stabilization Technologies

The food stabilization technology market has been experiencing significant growth due to increasing consumer demand for processed and convenience foods with extended shelf life. This market segment is driven by the need for innovative solutions to maintain food quality, texture, and safety during storage and transportation. The global food stabilizer market was valued at approximately $7.8 billion in 2020 and is projected to reach $10.5 billion by 2025, growing at a CAGR of 6.1% during the forecast period.

Key factors contributing to market growth include the rising demand for processed foods, changing consumer lifestyles, and the need for food preservation in developing countries. The increasing awareness of food safety and quality among consumers has also led to a higher adoption of food stabilization technologies across various food and beverage sectors.

In the context of isopentane as a blowing agent for food product stabilization, the market shows promising potential. Blowing agents play a crucial role in creating stable foam structures in various food products, such as whipped toppings, mousses, and aerated desserts. The global blowing agents market, which includes applications in food and beverages, is expected to grow at a CAGR of 5.2% from 2021 to 2026.

The food stabilization technology market is segmented based on function, application, and region. Functions include texturizing, stabilizing, moisture retention, and others. Applications cover dairy products, bakery items, confectionery, beverages, convenience foods, and meat products. Geographically, North America and Europe lead the market due to their well-established food processing industries and stringent food safety regulations.

Emerging trends in the food stabilization market include the growing demand for clean label and natural stabilizers, increased focus on plant-based alternatives, and the development of multifunctional stabilizers. The use of novel technologies, such as microencapsulation and nanotechnology, is also gaining traction in food stabilization applications.

Challenges in the market include stringent regulations regarding food additives, fluctuating raw material prices, and the need for continuous innovation to meet evolving consumer preferences. However, opportunities lie in the development of eco-friendly and sustainable stabilization solutions, as well as in catering to the growing demand for organic and clean label products.

The competitive landscape of the food stabilization technology market is characterized by the presence of both large multinational corporations and smaller specialized companies. Key players are investing heavily in research and development to introduce innovative products and gain a competitive edge. Strategic partnerships, mergers, and acquisitions are common strategies employed by companies to expand their market presence and technological capabilities.

Key factors contributing to market growth include the rising demand for processed foods, changing consumer lifestyles, and the need for food preservation in developing countries. The increasing awareness of food safety and quality among consumers has also led to a higher adoption of food stabilization technologies across various food and beverage sectors.

In the context of isopentane as a blowing agent for food product stabilization, the market shows promising potential. Blowing agents play a crucial role in creating stable foam structures in various food products, such as whipped toppings, mousses, and aerated desserts. The global blowing agents market, which includes applications in food and beverages, is expected to grow at a CAGR of 5.2% from 2021 to 2026.

The food stabilization technology market is segmented based on function, application, and region. Functions include texturizing, stabilizing, moisture retention, and others. Applications cover dairy products, bakery items, confectionery, beverages, convenience foods, and meat products. Geographically, North America and Europe lead the market due to their well-established food processing industries and stringent food safety regulations.

Emerging trends in the food stabilization market include the growing demand for clean label and natural stabilizers, increased focus on plant-based alternatives, and the development of multifunctional stabilizers. The use of novel technologies, such as microencapsulation and nanotechnology, is also gaining traction in food stabilization applications.

Challenges in the market include stringent regulations regarding food additives, fluctuating raw material prices, and the need for continuous innovation to meet evolving consumer preferences. However, opportunities lie in the development of eco-friendly and sustainable stabilization solutions, as well as in catering to the growing demand for organic and clean label products.

The competitive landscape of the food stabilization technology market is characterized by the presence of both large multinational corporations and smaller specialized companies. Key players are investing heavily in research and development to introduce innovative products and gain a competitive edge. Strategic partnerships, mergers, and acquisitions are common strategies employed by companies to expand their market presence and technological capabilities.

Current Challenges in Isopentane Application

The application of isopentane as a blowing agent in food product stabilization faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the volatile nature of isopentane, which makes it difficult to control during the production process. This volatility can lead to inconsistent foam formation and stability, potentially compromising the quality and texture of the final food product.

Another major challenge is the environmental impact of isopentane. As a hydrocarbon, it contributes to volatile organic compound (VOC) emissions, raising concerns about air quality and potential health effects. This has led to increased regulatory scrutiny and the need for advanced emission control systems in manufacturing facilities, adding complexity and cost to the production process.

Safety considerations also pose significant challenges in the use of isopentane. Its high flammability requires stringent safety protocols and specialized handling equipment, which can be a barrier to adoption for smaller food manufacturers. The risk of fire and explosion necessitates substantial investments in safety infrastructure and training, further increasing operational costs.

The interaction between isopentane and various food matrices presents another set of challenges. Different food compositions can affect the blowing agent's performance, leading to variations in foam structure and stability across different product types. This variability requires extensive research and formulation adjustments to achieve consistent results across a range of food applications.

Furthermore, the food industry faces challenges in optimizing the concentration of isopentane used in products. Too little may result in inadequate foam formation, while excessive amounts can lead to off-flavors, textural issues, or regulatory non-compliance. Achieving the right balance to meet both functional and sensory requirements demands precise control and advanced measurement techniques.

Lastly, there are ongoing concerns about the potential migration of isopentane into food products over time. This raises questions about long-term stability and shelf life, as well as potential health implications for consumers. Addressing these concerns requires extensive stability testing and the development of effective barrier technologies to minimize migration.

Another major challenge is the environmental impact of isopentane. As a hydrocarbon, it contributes to volatile organic compound (VOC) emissions, raising concerns about air quality and potential health effects. This has led to increased regulatory scrutiny and the need for advanced emission control systems in manufacturing facilities, adding complexity and cost to the production process.

Safety considerations also pose significant challenges in the use of isopentane. Its high flammability requires stringent safety protocols and specialized handling equipment, which can be a barrier to adoption for smaller food manufacturers. The risk of fire and explosion necessitates substantial investments in safety infrastructure and training, further increasing operational costs.

The interaction between isopentane and various food matrices presents another set of challenges. Different food compositions can affect the blowing agent's performance, leading to variations in foam structure and stability across different product types. This variability requires extensive research and formulation adjustments to achieve consistent results across a range of food applications.

Furthermore, the food industry faces challenges in optimizing the concentration of isopentane used in products. Too little may result in inadequate foam formation, while excessive amounts can lead to off-flavors, textural issues, or regulatory non-compliance. Achieving the right balance to meet both functional and sensory requirements demands precise control and advanced measurement techniques.

Lastly, there are ongoing concerns about the potential migration of isopentane into food products over time. This raises questions about long-term stability and shelf life, as well as potential health implications for consumers. Addressing these concerns requires extensive stability testing and the development of effective barrier technologies to minimize migration.

Existing Isopentane-based Stabilization Solutions

01 Chemical stabilization methods

Various chemical methods are employed to stabilize isopentane. These include the use of antioxidants, inhibitors, and other additives that prevent degradation and maintain the chemical properties of isopentane over time. Such stabilization techniques are crucial for preserving the quality and performance of isopentane in different applications.- Chemical stabilization methods: Various chemical methods are employed to stabilize isopentane. These include the use of antioxidants, inhibitors, and other additives that prevent degradation and maintain the chemical properties of isopentane over time. Such stabilization techniques are crucial for preserving the quality and performance of isopentane in different applications.

- Physical stabilization techniques: Physical methods are utilized to stabilize isopentane, including temperature control, pressure regulation, and specialized storage conditions. These techniques help maintain the stability of isopentane by preventing phase changes, minimizing evaporation, and reducing the risk of contamination. Proper physical stabilization is essential for safe handling and storage of isopentane.

- Stabilization for specific applications: Isopentane stabilization methods are tailored for specific industrial applications, such as in the production of polymers, refrigerants, or fuel additives. These specialized stabilization techniques ensure that isopentane maintains its desired properties and performance characteristics in the intended application, often involving a combination of chemical and physical stabilization methods.

- Purification and separation processes: Purification and separation processes play a crucial role in isopentane stabilization. These methods involve removing impurities, contaminants, and unwanted byproducts that can affect the stability of isopentane. Advanced separation techniques, such as distillation and adsorption, are employed to achieve high-purity isopentane with improved stability characteristics.

- Monitoring and quality control: Effective monitoring and quality control systems are implemented to ensure the ongoing stability of isopentane. These systems involve regular testing, analysis, and documentation of isopentane properties throughout its lifecycle. Advanced analytical techniques and specialized equipment are used to detect any signs of instability or degradation, allowing for timely corrective actions to maintain isopentane quality.

02 Physical stabilization techniques

Physical methods are utilized to stabilize isopentane, including temperature control, pressure regulation, and specialized storage conditions. These techniques help prevent evaporation, maintain purity, and ensure the stability of isopentane during storage and transportation. Proper physical stabilization is essential for maintaining the integrity of isopentane in various industrial processes.Expand Specific Solutions03 Isopentane purification processes

Purification processes play a crucial role in isopentane stabilization. These methods involve removing impurities, contaminants, and unwanted byproducts that may affect the stability of isopentane. Advanced separation techniques, distillation processes, and filtration systems are employed to achieve high-purity isopentane, which contributes to its overall stability and performance in various applications.Expand Specific Solutions04 Stabilization through blending and formulation

Isopentane can be stabilized by blending it with other compatible substances or incorporating it into specific formulations. This approach involves creating mixtures or compositions that enhance the stability of isopentane while maintaining its desired properties. Careful selection of complementary components and optimized ratios are key factors in achieving effective stabilization through blending and formulation techniques.Expand Specific Solutions05 Monitoring and control systems for isopentane stability

Advanced monitoring and control systems are implemented to ensure the ongoing stability of isopentane. These systems involve real-time monitoring of various parameters, such as temperature, pressure, and chemical composition. Automated control mechanisms and feedback loops are utilized to maintain optimal conditions for isopentane stability. Such systems play a crucial role in preventing degradation and ensuring consistent quality in industrial applications.Expand Specific Solutions

Key Players in Food Stabilization Sector

The research on isopentane as a blowing agent in food product stabilization is in an emerging phase, with the market showing potential for growth. The technology is still developing, as evidenced by the involvement of major chemical and petrochemical companies like BASF, Honeywell, and Sinopec. These industry leaders are likely investing in R&D to improve the application of isopentane in food stabilization. The market size is expected to expand as food manufacturers seek innovative solutions for product preservation. Companies such as Nestlé and Bayer are also showing interest, indicating a growing demand across the food and agricultural sectors. The technology's maturity is progressing, with specialized firms like JSP Corp. and Arkema contributing to advancements in foaming technologies.

BASF Corp.

Technical Solution: BASF has developed a proprietary technology for using isopentane as a blowing agent in food product stabilization. Their approach involves encapsulating isopentane within a polymer matrix, creating microcapsules that can be incorporated into food products. This technology allows for controlled release of the blowing agent, resulting in improved texture and stability of various food items. BASF's method also includes the use of food-grade surfactants to enhance the dispersion of isopentane microcapsules throughout the product[1][3]. The company has conducted extensive safety studies to ensure the compatibility of their isopentane-based system with food applications, meeting regulatory requirements in multiple regions[2].

Strengths: Controlled release technology, improved product stability, and extensive safety testing. Weaknesses: Potential higher production costs and limited application range compared to traditional methods.

Honeywell International Technologies Ltd.

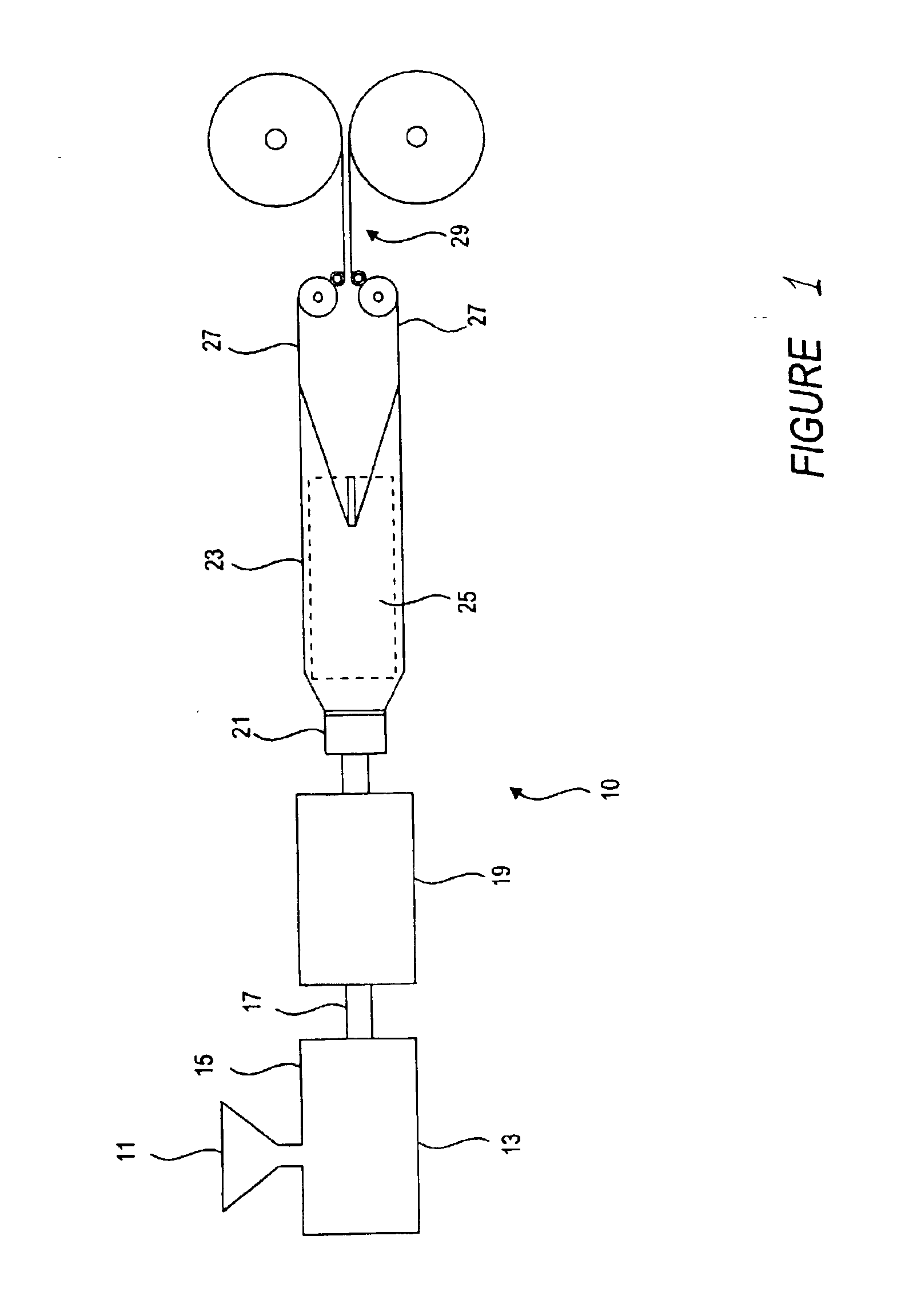

Technical Solution: Honeywell has innovated in the field of isopentane as a blowing agent for food product stabilization by developing a low-global warming potential (GWP) isopentane blend. Their technology focuses on optimizing the thermodynamic properties of isopentane to achieve better expansion and insulation characteristics in food packaging. Honeywell's approach includes a patented process for purifying isopentane to food-grade standards, ensuring minimal impurities and consistent performance[4]. The company has also created specialized equipment for precise dosing and mixing of their isopentane blend in food production lines, allowing for seamless integration into existing manufacturing processes[5].

Strengths: Low environmental impact, high purity standards, and specialized equipment for easy integration. Weaknesses: Potentially higher initial costs and the need for specialized training for implementation.

Innovative Isopentane Applications in Food Preservation

Formable styrenic resin particle, and pre-formed particle and foamed molding using the same

PatentInactiveUS20050261455A1

Innovation

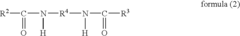

- Expandable styrene resin particles coated with 0.2 to 0.5 parts by weight of zinc stearate containing not more than 0.1 wt % fatty acid sodium salt, and optionally fatty acid amides or bisamides, with a highly volatile blowing agent composition of 15 to 60 wt % isopentane, are used to prevent permeation and staining, ensuring effective fusion and strength.

Polyolefin foams made with isopentane-based blowing agents

PatentInactiveUS7045556B2

Innovation

- A blowing agent blend comprising isopentane and a co-blowing agent, either physical or chemical, with a boiling point less than 28°C, is used to create a stable polyolefin foam structure with minimized or no corrugation, where the blend consists of less than 99 mol% isopentane and includes nucleating agents and gas permeation modifiers to control cell formation and expansion.

Environmental Impact of Isopentane Use

The use of isopentane as a blowing agent in food product stabilization raises important environmental considerations. Isopentane, a volatile organic compound (VOC), has potential impacts on air quality and climate change that must be carefully evaluated.

In terms of air quality, isopentane emissions can contribute to the formation of ground-level ozone, a key component of smog. When released into the atmosphere, isopentane reacts with nitrogen oxides in the presence of sunlight, leading to the production of photochemical smog. This can have adverse effects on human health, particularly respiratory issues, and can damage vegetation.

From a climate change perspective, isopentane has a global warming potential (GWP) that, while lower than some other blowing agents, is still significant. Its atmospheric lifetime is relatively short, estimated at a few months, but during this period, it can contribute to the greenhouse effect. The Intergovernmental Panel on Climate Change (IPCC) has included isopentane in its list of compounds that contribute to radiative forcing.

However, when compared to some traditional blowing agents like chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), isopentane presents a more environmentally friendly alternative. It has zero ozone depletion potential (ODP), which is a significant advantage in the context of stratospheric ozone protection.

The environmental impact of isopentane use in food product stabilization also depends on the efficiency of containment and recovery systems in production facilities. Proper handling, storage, and disposal practices can significantly reduce emissions and minimize environmental risks. Advanced production technologies that incorporate closed-loop systems and efficient recovery methods can help mitigate the release of isopentane into the environment.

It's important to consider the entire lifecycle of isopentane use, from production to disposal. This includes the energy consumption and associated emissions during the manufacturing process, as well as the potential for release during the use phase of food products and at the end of their life cycle.

Regulatory frameworks play a crucial role in managing the environmental impact of isopentane. Many countries have implemented VOC emission limits and require best available techniques for emission reduction in industrial processes. Compliance with these regulations is essential for minimizing the environmental footprint of isopentane use in food product stabilization.

In terms of air quality, isopentane emissions can contribute to the formation of ground-level ozone, a key component of smog. When released into the atmosphere, isopentane reacts with nitrogen oxides in the presence of sunlight, leading to the production of photochemical smog. This can have adverse effects on human health, particularly respiratory issues, and can damage vegetation.

From a climate change perspective, isopentane has a global warming potential (GWP) that, while lower than some other blowing agents, is still significant. Its atmospheric lifetime is relatively short, estimated at a few months, but during this period, it can contribute to the greenhouse effect. The Intergovernmental Panel on Climate Change (IPCC) has included isopentane in its list of compounds that contribute to radiative forcing.

However, when compared to some traditional blowing agents like chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), isopentane presents a more environmentally friendly alternative. It has zero ozone depletion potential (ODP), which is a significant advantage in the context of stratospheric ozone protection.

The environmental impact of isopentane use in food product stabilization also depends on the efficiency of containment and recovery systems in production facilities. Proper handling, storage, and disposal practices can significantly reduce emissions and minimize environmental risks. Advanced production technologies that incorporate closed-loop systems and efficient recovery methods can help mitigate the release of isopentane into the environment.

It's important to consider the entire lifecycle of isopentane use, from production to disposal. This includes the energy consumption and associated emissions during the manufacturing process, as well as the potential for release during the use phase of food products and at the end of their life cycle.

Regulatory frameworks play a crucial role in managing the environmental impact of isopentane. Many countries have implemented VOC emission limits and require best available techniques for emission reduction in industrial processes. Compliance with these regulations is essential for minimizing the environmental footprint of isopentane use in food product stabilization.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and quality of food products. In the context of using isopentane as a blowing agent for food product stabilization, it is essential to understand the existing regulations and guidelines that govern its use.

At the international level, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global standards for food safety and quality. The Codex General Standard for Food Additives (GSFA) provides a comprehensive list of permitted food additives and their maximum use levels. However, isopentane is not currently listed in the GSFA, which may pose challenges for its widespread adoption in food applications.

In the United States, the Food and Drug Administration (FDA) regulates food additives under the Federal Food, Drug, and Cosmetic Act. The FDA maintains a list of substances Generally Recognized as Safe (GRAS) for use in food. Isopentane is not currently included in this list, which means that manufacturers would need to submit a food additive petition or a GRAS notification to the FDA before using it in food products.

The European Union (EU) has a stringent regulatory framework for food additives, governed by Regulation (EC) No 1333/2008. This regulation establishes a Union list of approved food additives, along with their conditions of use. Isopentane is not currently included in this list, which means it would need to undergo a thorough safety assessment by the European Food Safety Authority (EFSA) before it could be approved for use in food products within the EU.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates food additives through the Food Sanitation Act. The MHLW maintains a list of approved food additives, and any new additives must undergo a rigorous safety assessment before approval. As isopentane is not currently on this list, it would need to go through this process for use in the Japanese market.

Given the current regulatory landscape, the use of isopentane as a blowing agent in food product stabilization faces significant hurdles. Manufacturers and researchers interested in pursuing this technology would need to engage with regulatory bodies in their target markets to initiate the approval process. This would likely involve conducting extensive safety studies, toxicological assessments, and demonstrating the technological need for isopentane in food applications.

Furthermore, as environmental concerns become increasingly important in regulatory decision-making, the potential environmental impact of isopentane use would also need to be addressed. This may include evaluating its greenhouse gas potential, ozone depletion potential, and overall lifecycle assessment.

At the international level, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global standards for food safety and quality. The Codex General Standard for Food Additives (GSFA) provides a comprehensive list of permitted food additives and their maximum use levels. However, isopentane is not currently listed in the GSFA, which may pose challenges for its widespread adoption in food applications.

In the United States, the Food and Drug Administration (FDA) regulates food additives under the Federal Food, Drug, and Cosmetic Act. The FDA maintains a list of substances Generally Recognized as Safe (GRAS) for use in food. Isopentane is not currently included in this list, which means that manufacturers would need to submit a food additive petition or a GRAS notification to the FDA before using it in food products.

The European Union (EU) has a stringent regulatory framework for food additives, governed by Regulation (EC) No 1333/2008. This regulation establishes a Union list of approved food additives, along with their conditions of use. Isopentane is not currently included in this list, which means it would need to undergo a thorough safety assessment by the European Food Safety Authority (EFSA) before it could be approved for use in food products within the EU.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates food additives through the Food Sanitation Act. The MHLW maintains a list of approved food additives, and any new additives must undergo a rigorous safety assessment before approval. As isopentane is not currently on this list, it would need to go through this process for use in the Japanese market.

Given the current regulatory landscape, the use of isopentane as a blowing agent in food product stabilization faces significant hurdles. Manufacturers and researchers interested in pursuing this technology would need to engage with regulatory bodies in their target markets to initiate the approval process. This would likely involve conducting extensive safety studies, toxicological assessments, and demonstrating the technological need for isopentane in food applications.

Furthermore, as environmental concerns become increasingly important in regulatory decision-making, the potential environmental impact of isopentane use would also need to be addressed. This may include evaluating its greenhouse gas potential, ozone depletion potential, and overall lifecycle assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!