Isopentane Waste Management and Sustainable Practices

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Waste Overview

Isopentane, a volatile organic compound (VOC) and hydrocarbon, is widely used in various industries, including refrigeration, foam blowing, and as a fuel additive. However, its improper handling and disposal can lead to significant environmental and health concerns. Isopentane waste primarily originates from industrial processes, particularly in the petrochemical and manufacturing sectors.

The environmental impact of isopentane waste is multifaceted. As a VOC, it contributes to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to respiratory issues and other health problems in humans and animals. Additionally, isopentane is highly flammable and poses a fire hazard if not properly managed. Its low boiling point makes it prone to evaporation, potentially leading to air pollution and increased greenhouse gas emissions.

In aquatic environments, isopentane can form a layer on the water surface, disrupting oxygen transfer and harming aquatic life. It can also contaminate soil and groundwater, potentially affecting ecosystems and human water supplies. The persistence of isopentane in the environment varies depending on conditions, but its volatility generally leads to rapid dispersion in air and slower degradation in soil and water.

Current waste management practices for isopentane vary across industries and regions. Common approaches include incineration, which can effectively destroy the compound but may produce harmful byproducts if not properly controlled. Recycling and recovery methods are increasingly being employed, particularly in industries where large volumes of isopentane are used. These methods aim to capture and purify the compound for reuse, reducing both waste and the need for new production.

Regulatory frameworks governing isopentane waste management differ globally. In many developed countries, strict regulations classify it as hazardous waste, requiring specialized handling and disposal. However, in some regions, regulations may be less stringent or poorly enforced, leading to potential environmental risks.

The economic implications of isopentane waste management are significant. Proper disposal and treatment can be costly for industries, but the potential environmental and health costs of mismanagement are far greater. This has led to increased interest in developing more cost-effective and sustainable waste management solutions.

As awareness of environmental issues grows, there is a rising trend towards developing sustainable practices for isopentane use and disposal. This includes research into alternative compounds with lower environmental impact, improved containment and recovery systems, and more efficient recycling technologies. The challenge lies in balancing the industrial utility of isopentane with the imperative of environmental protection and sustainable resource management.

The environmental impact of isopentane waste is multifaceted. As a VOC, it contributes to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to respiratory issues and other health problems in humans and animals. Additionally, isopentane is highly flammable and poses a fire hazard if not properly managed. Its low boiling point makes it prone to evaporation, potentially leading to air pollution and increased greenhouse gas emissions.

In aquatic environments, isopentane can form a layer on the water surface, disrupting oxygen transfer and harming aquatic life. It can also contaminate soil and groundwater, potentially affecting ecosystems and human water supplies. The persistence of isopentane in the environment varies depending on conditions, but its volatility generally leads to rapid dispersion in air and slower degradation in soil and water.

Current waste management practices for isopentane vary across industries and regions. Common approaches include incineration, which can effectively destroy the compound but may produce harmful byproducts if not properly controlled. Recycling and recovery methods are increasingly being employed, particularly in industries where large volumes of isopentane are used. These methods aim to capture and purify the compound for reuse, reducing both waste and the need for new production.

Regulatory frameworks governing isopentane waste management differ globally. In many developed countries, strict regulations classify it as hazardous waste, requiring specialized handling and disposal. However, in some regions, regulations may be less stringent or poorly enforced, leading to potential environmental risks.

The economic implications of isopentane waste management are significant. Proper disposal and treatment can be costly for industries, but the potential environmental and health costs of mismanagement are far greater. This has led to increased interest in developing more cost-effective and sustainable waste management solutions.

As awareness of environmental issues grows, there is a rising trend towards developing sustainable practices for isopentane use and disposal. This includes research into alternative compounds with lower environmental impact, improved containment and recovery systems, and more efficient recycling technologies. The challenge lies in balancing the industrial utility of isopentane with the imperative of environmental protection and sustainable resource management.

Market Demand Analysis

The market demand for isopentane waste management and sustainable practices has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations. Industries such as petrochemicals, refrigeration, and foam manufacturing are the primary generators of isopentane waste, creating a significant need for effective management solutions.

Environmental regulations, particularly those targeting volatile organic compounds (VOCs) and greenhouse gas emissions, have become more stringent globally. This regulatory pressure has compelled companies to seek innovative waste management techniques for isopentane, a highly volatile hydrocarbon. The market for such solutions is expected to expand as more countries implement stricter environmental policies.

The petrochemical industry, a major consumer of isopentane, has shown a strong interest in sustainable practices. With the global petrochemical market projected to grow, the demand for efficient isopentane waste management solutions is likely to increase proportionally. Refineries and chemical plants are actively seeking technologies that can reduce isopentane emissions and improve resource recovery.

In the refrigeration sector, the phaseout of hydrochlorofluorocarbons (HCFCs) has led to increased use of hydrocarbons like isopentane as alternative refrigerants. This shift has created a new market segment for isopentane waste management, particularly in developing countries where the transition to new refrigerants is ongoing.

The foam manufacturing industry, another significant user of isopentane, has been experiencing growth due to rising demand in construction and automotive sectors. As this industry expands, the need for sustainable isopentane handling practices becomes more critical, driving market demand for waste management solutions.

Circular economy initiatives and the push for sustainability in industrial processes have further boosted the market for isopentane recycling and reuse technologies. Companies are increasingly looking for ways to close the loop on isopentane use, creating opportunities for innovative waste management approaches.

The market also shows a growing interest in technologies that can convert isopentane waste into value-added products. This trend aligns with the broader movement towards resource efficiency and waste valorization in industrial operations.

Geographically, developed regions like North America and Europe are currently leading in adopting advanced isopentane waste management practices. However, rapid industrialization in emerging economies of Asia-Pacific and Latin America is expected to create significant market opportunities in these regions in the coming years.

Overall, the market demand for isopentane waste management and sustainable practices is poised for substantial growth. This trend is supported by a combination of regulatory pressures, industry initiatives for sustainability, and the economic benefits of efficient resource management.

Environmental regulations, particularly those targeting volatile organic compounds (VOCs) and greenhouse gas emissions, have become more stringent globally. This regulatory pressure has compelled companies to seek innovative waste management techniques for isopentane, a highly volatile hydrocarbon. The market for such solutions is expected to expand as more countries implement stricter environmental policies.

The petrochemical industry, a major consumer of isopentane, has shown a strong interest in sustainable practices. With the global petrochemical market projected to grow, the demand for efficient isopentane waste management solutions is likely to increase proportionally. Refineries and chemical plants are actively seeking technologies that can reduce isopentane emissions and improve resource recovery.

In the refrigeration sector, the phaseout of hydrochlorofluorocarbons (HCFCs) has led to increased use of hydrocarbons like isopentane as alternative refrigerants. This shift has created a new market segment for isopentane waste management, particularly in developing countries where the transition to new refrigerants is ongoing.

The foam manufacturing industry, another significant user of isopentane, has been experiencing growth due to rising demand in construction and automotive sectors. As this industry expands, the need for sustainable isopentane handling practices becomes more critical, driving market demand for waste management solutions.

Circular economy initiatives and the push for sustainability in industrial processes have further boosted the market for isopentane recycling and reuse technologies. Companies are increasingly looking for ways to close the loop on isopentane use, creating opportunities for innovative waste management approaches.

The market also shows a growing interest in technologies that can convert isopentane waste into value-added products. This trend aligns with the broader movement towards resource efficiency and waste valorization in industrial operations.

Geographically, developed regions like North America and Europe are currently leading in adopting advanced isopentane waste management practices. However, rapid industrialization in emerging economies of Asia-Pacific and Latin America is expected to create significant market opportunities in these regions in the coming years.

Overall, the market demand for isopentane waste management and sustainable practices is poised for substantial growth. This trend is supported by a combination of regulatory pressures, industry initiatives for sustainability, and the economic benefits of efficient resource management.

Current Challenges

The management of isopentane waste presents several significant challenges in the current industrial landscape. One of the primary issues is the volatile nature of isopentane, which makes it difficult to handle and store safely. This volatility also contributes to high evaporation rates, leading to potential air pollution and increased greenhouse gas emissions if not properly contained.

Another major challenge is the lack of widespread, cost-effective recycling technologies specifically designed for isopentane. While some methods exist for recovering and purifying used isopentane, these processes are often energy-intensive and may not be economically viable for smaller-scale operations. This results in a significant amount of isopentane waste being disposed of through less sustainable methods.

The regulatory landscape surrounding isopentane waste management is complex and varies significantly across different regions and countries. This inconsistency creates difficulties for multinational corporations in implementing standardized waste management practices. Additionally, the classification of isopentane as a hazardous material in many jurisdictions imposes strict handling and disposal requirements, which can be burdensome for businesses to comply with.

Environmental concerns pose another set of challenges. Isopentane, if released into the environment, can contribute to the formation of ground-level ozone and smog. It also has the potential to contaminate soil and water sources, posing risks to ecosystems and human health. The long-term environmental impacts of isopentane waste are not yet fully understood, which complicates the development of comprehensive management strategies.

From a technical standpoint, the separation of isopentane from other waste streams can be challenging due to its similar properties to other hydrocarbons. This makes it difficult to achieve high purity levels in recycling processes, potentially limiting the reusability of recovered isopentane in certain high-precision applications.

The economic aspects of isopentane waste management also present challenges. The fluctuating prices of raw isopentane can impact the cost-effectiveness of recycling efforts. When virgin isopentane prices are low, there is less economic incentive to invest in recycling infrastructure and technologies. This creates a cyclical problem where the lack of investment in recycling technologies perpetuates the reliance on virgin materials.

Lastly, there is a significant knowledge gap in many industries regarding best practices for isopentane waste management. This lack of awareness and expertise can lead to improper handling and disposal, exacerbating environmental and safety risks. Addressing this challenge requires concerted efforts in education, training, and knowledge sharing across industries that utilize isopentane.

Another major challenge is the lack of widespread, cost-effective recycling technologies specifically designed for isopentane. While some methods exist for recovering and purifying used isopentane, these processes are often energy-intensive and may not be economically viable for smaller-scale operations. This results in a significant amount of isopentane waste being disposed of through less sustainable methods.

The regulatory landscape surrounding isopentane waste management is complex and varies significantly across different regions and countries. This inconsistency creates difficulties for multinational corporations in implementing standardized waste management practices. Additionally, the classification of isopentane as a hazardous material in many jurisdictions imposes strict handling and disposal requirements, which can be burdensome for businesses to comply with.

Environmental concerns pose another set of challenges. Isopentane, if released into the environment, can contribute to the formation of ground-level ozone and smog. It also has the potential to contaminate soil and water sources, posing risks to ecosystems and human health. The long-term environmental impacts of isopentane waste are not yet fully understood, which complicates the development of comprehensive management strategies.

From a technical standpoint, the separation of isopentane from other waste streams can be challenging due to its similar properties to other hydrocarbons. This makes it difficult to achieve high purity levels in recycling processes, potentially limiting the reusability of recovered isopentane in certain high-precision applications.

The economic aspects of isopentane waste management also present challenges. The fluctuating prices of raw isopentane can impact the cost-effectiveness of recycling efforts. When virgin isopentane prices are low, there is less economic incentive to invest in recycling infrastructure and technologies. This creates a cyclical problem where the lack of investment in recycling technologies perpetuates the reliance on virgin materials.

Lastly, there is a significant knowledge gap in many industries regarding best practices for isopentane waste management. This lack of awareness and expertise can lead to improper handling and disposal, exacerbating environmental and safety risks. Addressing this challenge requires concerted efforts in education, training, and knowledge sharing across industries that utilize isopentane.

Existing Solutions

01 Recycling and recovery of isopentane

Methods for recycling and recovering isopentane from waste streams, including separation techniques and purification processes to reclaim the compound for reuse in industrial applications. This approach helps reduce environmental impact and conserve resources.- Recycling and recovery of isopentane: Methods for recycling and recovering isopentane from waste streams in industrial processes. This includes techniques for separating isopentane from other components, purification processes, and reuse strategies to minimize environmental impact and maximize resource efficiency.

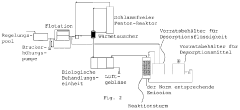

- Treatment of isopentane-containing wastewater: Processes for treating wastewater containing isopentane, including advanced oxidation, biological treatment, and membrane filtration techniques. These methods aim to remove or reduce isopentane concentrations in wastewater before discharge, ensuring compliance with environmental regulations.

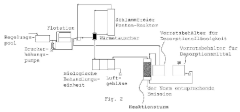

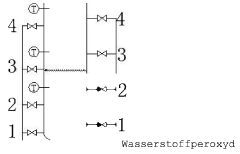

- Emission control and vapor recovery: Technologies and systems designed to control isopentane emissions and recover vapors during storage, handling, and transportation. This includes vapor recovery units, closed-loop systems, and adsorption techniques to minimize atmospheric release of isopentane.

- Sustainable disposal and destruction methods: Environmentally friendly methods for disposing of isopentane waste that cannot be recycled or recovered. This may include thermal oxidation, catalytic conversion, or other chemical processes that transform isopentane into less harmful substances.

- Monitoring and management systems: Advanced monitoring and management systems for tracking isopentane waste throughout its lifecycle. This includes software solutions, IoT-enabled sensors, and data analytics tools to optimize waste management processes, ensure regulatory compliance, and improve overall efficiency in handling isopentane waste.

02 Treatment of isopentane-containing waste

Techniques for treating waste streams containing isopentane, including chemical and physical processes to neutralize or safely dispose of the compound. These methods aim to minimize environmental hazards associated with isopentane waste.Expand Specific Solutions03 Conversion of isopentane to valuable products

Processes for converting isopentane waste into useful products or less harmful substances through chemical reactions or biotransformation. This approach aims to reduce waste while creating value from the byproducts.Expand Specific Solutions04 Containment and storage solutions for isopentane waste

Specialized containment and storage systems designed for safely handling and storing isopentane waste. These solutions aim to prevent leaks, reduce emissions, and ensure proper isolation of the waste material.Expand Specific Solutions05 Monitoring and management systems for isopentane waste

Advanced monitoring and management systems for tracking, analyzing, and controlling isopentane waste throughout its lifecycle. These systems may include sensors, data analytics, and automated control mechanisms to optimize waste management processes.Expand Specific Solutions

Key Industry Players

The research on Isopentane Waste Management and Sustainable Practices is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of established petrochemical companies and emerging sustainable technology firms. Major players like ExxonMobil, BASF, and Sinopec are investing in research and development, while smaller companies like Amyris are focusing on sustainable alternatives. The market size is expected to grow as environmental regulations tighten globally. Technologically, the field is evolving rapidly, with companies like Goodyear and Phillips 66 exploring innovative waste management solutions. However, the technology is not yet fully mature, indicating significant potential for further advancements and market expansion in the coming years.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to isopentane waste management through their advanced catalytic cracking process. This technology efficiently converts isopentane waste into valuable petrochemical products, reducing environmental impact. The process utilizes a specialized zeolite catalyst that selectively cracks isopentane molecules at optimal temperatures and pressures[1]. Additionally, Sinopec has implemented a closed-loop recycling system that captures and reuses isopentane vapors, significantly reducing emissions. Their sustainable practices also include the integration of renewable energy sources to power the waste management facilities, further decreasing the carbon footprint of the operation[3].

Strengths: Efficient conversion of waste to valuable products, reduced emissions through vapor recovery. Weaknesses: High initial investment costs, potential catalyst deactivation over time.

BASF Corp.

Technical Solution: BASF Corp. has pioneered a comprehensive isopentane waste management solution focusing on circular economy principles. Their approach involves a multi-step process that begins with advanced separation techniques to isolate isopentane from waste streams. The purified isopentane is then subjected to chemical transformation using BASF's proprietary catalysts, converting it into higher-value chemicals such as isoprene[2]. This process not only manages waste but also creates new revenue streams. BASF has also developed a novel adsorption technology that captures trace amounts of isopentane from air emissions, ensuring minimal environmental impact. Furthermore, they have implemented AI-driven predictive maintenance systems to optimize the efficiency of their waste management facilities, reducing downtime and improving overall sustainability[4].

Strengths: Circular economy approach, value-added product creation, advanced emission control. Weaknesses: Complex process requiring specialized expertise, potential market fluctuations for converted products.

Innovative Technologies

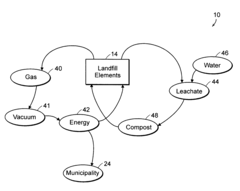

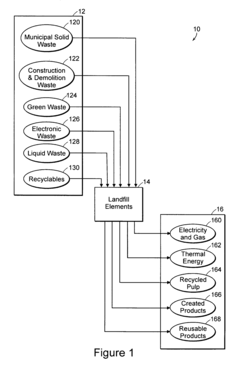

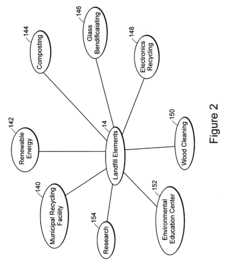

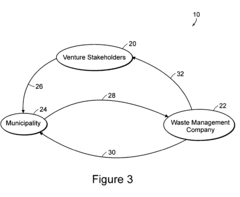

Methods and facilities for a municipal solid waste management system

PatentActiveUS8560459B2

Innovation

- A synergistic system integrating municipal recycling facilities, electronic recycling, landfill gas energy production, biomass production, and composting, along with a community-company venture model that values environmental and economic objectives, to create a zero-emissions waste management system that increases landfill capacity and promotes renewable energy and resource recovery.

process for the treatment of poorly degradable industrial effluents

PatentInactiveBE1027967A1

Innovation

- A process involving the use of a biocatalyst system comprising a microbial consortium and a bioreactor to degrade and transform recalcitrant organic pollutants into less harmful substances.

Regulatory Framework

The regulatory framework surrounding isopentane waste management and sustainable practices is complex and multifaceted, involving various levels of governance and international agreements. At the global level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a foundation for managing hazardous waste, including isopentane-containing materials. This convention establishes guidelines for the responsible handling, transport, and disposal of such wastes across international borders.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating isopentane waste through the Resource Conservation and Recovery Act (RCRA). This legislation classifies isopentane as a hazardous waste due to its flammability and potential environmental impact. The RCRA mandates specific handling, storage, and disposal procedures for isopentane waste, including requirements for proper labeling, containment, and documentation.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which establishes a legal framework for waste treatment within EU member states. This directive emphasizes waste prevention, reuse, and recycling, principles that are particularly relevant to isopentane waste management. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use and disposal of isopentane in industrial processes.

At the national level, many countries have enacted specific regulations governing the management of volatile organic compounds (VOCs), including isopentane. These regulations often set emission limits, require the use of best available technologies for waste reduction, and mandate regular monitoring and reporting of waste generation and disposal practices.

Industry-specific regulations also play a significant role in isopentane waste management. For instance, in the automotive industry, regulations such as the EU End-of-Life Vehicles Directive (2000/53/EC) influence the design and disposal of vehicles, including components that may contain isopentane. Similarly, the electronics industry is subject to regulations like the Waste Electrical and Electronic Equipment (WEEE) Directive, which impacts the disposal of products potentially containing isopentane.

The regulatory landscape is continually evolving, with increasing emphasis on circular economy principles and sustainable waste management practices. This shift is driving the development of new regulations and standards that promote the reduction, reuse, and recycling of isopentane and other potentially hazardous materials. As environmental concerns grow, it is likely that future regulations will impose stricter controls on isopentane waste, potentially encouraging the development of alternative materials or more efficient recycling technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating isopentane waste through the Resource Conservation and Recovery Act (RCRA). This legislation classifies isopentane as a hazardous waste due to its flammability and potential environmental impact. The RCRA mandates specific handling, storage, and disposal procedures for isopentane waste, including requirements for proper labeling, containment, and documentation.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which establishes a legal framework for waste treatment within EU member states. This directive emphasizes waste prevention, reuse, and recycling, principles that are particularly relevant to isopentane waste management. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use and disposal of isopentane in industrial processes.

At the national level, many countries have enacted specific regulations governing the management of volatile organic compounds (VOCs), including isopentane. These regulations often set emission limits, require the use of best available technologies for waste reduction, and mandate regular monitoring and reporting of waste generation and disposal practices.

Industry-specific regulations also play a significant role in isopentane waste management. For instance, in the automotive industry, regulations such as the EU End-of-Life Vehicles Directive (2000/53/EC) influence the design and disposal of vehicles, including components that may contain isopentane. Similarly, the electronics industry is subject to regulations like the Waste Electrical and Electronic Equipment (WEEE) Directive, which impacts the disposal of products potentially containing isopentane.

The regulatory landscape is continually evolving, with increasing emphasis on circular economy principles and sustainable waste management practices. This shift is driving the development of new regulations and standards that promote the reduction, reuse, and recycling of isopentane and other potentially hazardous materials. As environmental concerns grow, it is likely that future regulations will impose stricter controls on isopentane waste, potentially encouraging the development of alternative materials or more efficient recycling technologies.

Environmental Impact

Isopentane, a volatile organic compound (VOC) commonly used in various industrial processes, poses significant environmental challenges when not properly managed. The environmental impact of isopentane waste extends across multiple ecosystems and contributes to various forms of pollution.

Air pollution is a primary concern associated with isopentane waste. As a highly volatile substance, isopentane readily evaporates into the atmosphere, contributing to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health, causing respiratory issues and exacerbating existing conditions such as asthma. Moreover, isopentane emissions contribute to the overall increase in greenhouse gases, potentially accelerating climate change.

Water contamination is another critical environmental issue linked to improper isopentane waste management. When released into water bodies, isopentane can form a thin film on the surface, disrupting oxygen exchange and harming aquatic life. This contamination can lead to the degradation of water quality, affecting both freshwater and marine ecosystems. The persistence of isopentane in water systems can also result in bioaccumulation in aquatic organisms, potentially entering the food chain and impacting higher trophic levels.

Soil pollution is an additional concern, particularly in areas where isopentane waste is improperly disposed of or where spills occur. The compound can seep into the soil, altering its chemical composition and potentially affecting soil microorganisms. This contamination can lead to reduced soil fertility and impact plant growth, ultimately affecting local ecosystems and agricultural productivity.

The environmental impact of isopentane waste extends beyond immediate pollution concerns. Its production and disposal contribute to resource depletion, as isopentane is derived from non-renewable fossil fuels. The energy-intensive processes involved in its manufacture and the subsequent waste management practices further contribute to the overall carbon footprint associated with its use.

Biodiversity loss is another potential consequence of isopentane waste mismanagement. The compound's toxicity to various organisms, combined with its ability to disrupt ecosystems, can lead to reduced species diversity in affected areas. This loss of biodiversity can have far-reaching consequences for ecosystem stability and resilience.

Addressing the environmental impact of isopentane waste requires a comprehensive approach that encompasses prevention, mitigation, and sustainable management practices. Implementing stricter regulations on isopentane use and disposal, developing more efficient production processes, and investing in alternative, environmentally friendly substances are crucial steps towards minimizing its ecological footprint. Additionally, promoting circular economy principles and encouraging the development of recycling and recovery technologies for isopentane can significantly reduce its environmental impact while fostering sustainable industrial practices.

Air pollution is a primary concern associated with isopentane waste. As a highly volatile substance, isopentane readily evaporates into the atmosphere, contributing to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health, causing respiratory issues and exacerbating existing conditions such as asthma. Moreover, isopentane emissions contribute to the overall increase in greenhouse gases, potentially accelerating climate change.

Water contamination is another critical environmental issue linked to improper isopentane waste management. When released into water bodies, isopentane can form a thin film on the surface, disrupting oxygen exchange and harming aquatic life. This contamination can lead to the degradation of water quality, affecting both freshwater and marine ecosystems. The persistence of isopentane in water systems can also result in bioaccumulation in aquatic organisms, potentially entering the food chain and impacting higher trophic levels.

Soil pollution is an additional concern, particularly in areas where isopentane waste is improperly disposed of or where spills occur. The compound can seep into the soil, altering its chemical composition and potentially affecting soil microorganisms. This contamination can lead to reduced soil fertility and impact plant growth, ultimately affecting local ecosystems and agricultural productivity.

The environmental impact of isopentane waste extends beyond immediate pollution concerns. Its production and disposal contribute to resource depletion, as isopentane is derived from non-renewable fossil fuels. The energy-intensive processes involved in its manufacture and the subsequent waste management practices further contribute to the overall carbon footprint associated with its use.

Biodiversity loss is another potential consequence of isopentane waste mismanagement. The compound's toxicity to various organisms, combined with its ability to disrupt ecosystems, can lead to reduced species diversity in affected areas. This loss of biodiversity can have far-reaching consequences for ecosystem stability and resilience.

Addressing the environmental impact of isopentane waste requires a comprehensive approach that encompasses prevention, mitigation, and sustainable management practices. Implementing stricter regulations on isopentane use and disposal, developing more efficient production processes, and investing in alternative, environmentally friendly substances are crucial steps towards minimizing its ecological footprint. Additionally, promoting circular economy principles and encouraging the development of recycling and recovery technologies for isopentane can significantly reduce its environmental impact while fostering sustainable industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!