MXene Adaptations for Complex Nanocomposite Structures

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Research Objectives

MXenes, a class of two-dimensional transition metal carbides and nitrides, have emerged as a promising material for various applications since their discovery in 2011. These materials are derived from MAX phases through selective etching of the A-layer, resulting in a unique layered structure with exceptional properties. MXenes have garnered significant attention in the scientific community due to their remarkable electrical conductivity, mechanical strength, and surface chemistry.

The evolution of MXene research has been rapid, with initial studies focusing on their synthesis and basic characterization. As understanding of these materials grew, researchers began exploring their potential in energy storage, electromagnetic interference shielding, and water purification. The versatility of MXenes stems from their tunable composition and surface terminations, allowing for tailored properties to suit specific applications.

Recent years have seen a shift towards more complex applications, particularly in the realm of nanocomposite structures. The integration of MXenes into composite materials has opened new avenues for enhancing mechanical, electrical, and thermal properties of existing materials. This trend has led to the current focus on adapting MXenes for complex nanocomposite structures, which presents both exciting opportunities and significant challenges.

The primary objective of this research is to explore and develop novel methods for incorporating MXenes into complex nanocomposite structures. This involves investigating the fundamental interactions between MXenes and various matrix materials, as well as developing techniques to control the dispersion and orientation of MXene sheets within these structures. The goal is to harness the unique properties of MXenes to create nanocomposites with superior performance characteristics.

Key research objectives include optimizing the interfacial interactions between MXenes and matrix materials, developing scalable production methods for MXene-based nanocomposites, and exploring new applications in areas such as aerospace, automotive, and biomedical industries. Additionally, there is a focus on understanding the long-term stability and environmental impact of these advanced materials.

The research also aims to address current limitations in MXene technology, such as oxidation stability and large-scale production challenges. By overcoming these hurdles, the potential for widespread adoption of MXene-based nanocomposites in various industrial applications can be realized. This research is expected to contribute significantly to the field of advanced materials and pave the way for next-generation composite technologies.

The evolution of MXene research has been rapid, with initial studies focusing on their synthesis and basic characterization. As understanding of these materials grew, researchers began exploring their potential in energy storage, electromagnetic interference shielding, and water purification. The versatility of MXenes stems from their tunable composition and surface terminations, allowing for tailored properties to suit specific applications.

Recent years have seen a shift towards more complex applications, particularly in the realm of nanocomposite structures. The integration of MXenes into composite materials has opened new avenues for enhancing mechanical, electrical, and thermal properties of existing materials. This trend has led to the current focus on adapting MXenes for complex nanocomposite structures, which presents both exciting opportunities and significant challenges.

The primary objective of this research is to explore and develop novel methods for incorporating MXenes into complex nanocomposite structures. This involves investigating the fundamental interactions between MXenes and various matrix materials, as well as developing techniques to control the dispersion and orientation of MXene sheets within these structures. The goal is to harness the unique properties of MXenes to create nanocomposites with superior performance characteristics.

Key research objectives include optimizing the interfacial interactions between MXenes and matrix materials, developing scalable production methods for MXene-based nanocomposites, and exploring new applications in areas such as aerospace, automotive, and biomedical industries. Additionally, there is a focus on understanding the long-term stability and environmental impact of these advanced materials.

The research also aims to address current limitations in MXene technology, such as oxidation stability and large-scale production challenges. By overcoming these hurdles, the potential for widespread adoption of MXene-based nanocomposites in various industrial applications can be realized. This research is expected to contribute significantly to the field of advanced materials and pave the way for next-generation composite technologies.

Market Analysis for MXene-based Nanocomposites

The market for MXene-based nanocomposites is experiencing rapid growth and diversification, driven by the unique properties and versatility of MXene materials. As two-dimensional transition metal carbides and nitrides, MXenes offer exceptional electrical conductivity, mechanical strength, and surface functionality, making them highly attractive for a wide range of applications in complex nanocomposite structures.

The global nanocomposite market, which includes MXene-based materials, is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) outpacing many other advanced materials sectors. This growth is fueled by increasing demand across various industries, including electronics, energy storage, aerospace, and automotive.

In the electronics sector, MXene nanocomposites are gaining traction for their potential in flexible and wearable devices, electromagnetic interference shielding, and high-performance sensors. The miniaturization trend in consumer electronics and the push for more efficient energy storage solutions are key drivers for MXene adoption in this market segment.

The energy storage industry represents another substantial market for MXene-based nanocomposites. Their high electrical conductivity and large surface area make them promising candidates for next-generation batteries and supercapacitors. As the global focus on renewable energy and electric vehicles intensifies, the demand for advanced energy storage materials is expected to surge, creating significant opportunities for MXene nanocomposites.

In the aerospace and automotive sectors, the lightweight and high-strength characteristics of MXene nanocomposites are attracting attention for structural applications. These materials offer the potential to reduce vehicle weight, improve fuel efficiency, and enhance overall performance. The growing emphasis on sustainable transportation solutions is likely to drive further adoption in these industries.

The biomedical field is emerging as a promising market for MXene nanocomposites, with applications in drug delivery, biosensors, and tissue engineering. The biocompatibility and functionalization capabilities of MXenes make them suitable for various medical applications, opening up new avenues for market growth.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs associated with MXene synthesis and nanocomposite fabrication. Overcoming these hurdles will be crucial for widespread commercial adoption and market penetration.

As research and development efforts continue to advance, new applications and market opportunities for MXene-based nanocomposites are likely to emerge. The ability to tailor MXene properties through composition and surface modification presents vast potential for customized solutions across diverse industries, further expanding the market landscape for these innovative materials.

The global nanocomposite market, which includes MXene-based materials, is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) outpacing many other advanced materials sectors. This growth is fueled by increasing demand across various industries, including electronics, energy storage, aerospace, and automotive.

In the electronics sector, MXene nanocomposites are gaining traction for their potential in flexible and wearable devices, electromagnetic interference shielding, and high-performance sensors. The miniaturization trend in consumer electronics and the push for more efficient energy storage solutions are key drivers for MXene adoption in this market segment.

The energy storage industry represents another substantial market for MXene-based nanocomposites. Their high electrical conductivity and large surface area make them promising candidates for next-generation batteries and supercapacitors. As the global focus on renewable energy and electric vehicles intensifies, the demand for advanced energy storage materials is expected to surge, creating significant opportunities for MXene nanocomposites.

In the aerospace and automotive sectors, the lightweight and high-strength characteristics of MXene nanocomposites are attracting attention for structural applications. These materials offer the potential to reduce vehicle weight, improve fuel efficiency, and enhance overall performance. The growing emphasis on sustainable transportation solutions is likely to drive further adoption in these industries.

The biomedical field is emerging as a promising market for MXene nanocomposites, with applications in drug delivery, biosensors, and tissue engineering. The biocompatibility and functionalization capabilities of MXenes make them suitable for various medical applications, opening up new avenues for market growth.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs associated with MXene synthesis and nanocomposite fabrication. Overcoming these hurdles will be crucial for widespread commercial adoption and market penetration.

As research and development efforts continue to advance, new applications and market opportunities for MXene-based nanocomposites are likely to emerge. The ability to tailor MXene properties through composition and surface modification presents vast potential for customized solutions across diverse industries, further expanding the market landscape for these innovative materials.

Current MXene Synthesis and Adaptation Challenges

The synthesis and adaptation of MXenes for complex nanocomposite structures present several significant challenges that researchers are currently grappling with. One of the primary obstacles is achieving consistent and scalable production of high-quality MXene sheets. The traditional synthesis method, involving selective etching of MAX phases, often results in variations in flake size, thickness, and surface chemistry, which can impact the performance of the final nanocomposite.

Another critical challenge lies in the prevention of restacking and agglomeration of MXene sheets during the fabrication of nanocomposites. The strong van der Waals interactions between MXene layers tend to cause restacking, reducing the available surface area and limiting the full potential of MXene's properties in the composite structure. Researchers are exploring various strategies to overcome this issue, including the use of spacers, surface functionalization, and innovative assembly techniques.

The control of surface terminations on MXene sheets poses yet another hurdle in their adaptation for nanocomposites. The etching process typically results in a mixture of surface terminations (-O, -OH, -F), which can affect the interfacial interactions between MXenes and the matrix material. Tailoring these surface groups to enhance compatibility and bonding with specific matrix materials remains a complex task.

Stability is a crucial concern in MXene-based nanocomposites. MXenes are prone to oxidation, especially in aqueous environments, which can lead to degradation of their properties over time. Developing effective strategies to protect MXenes from oxidation while maintaining their desirable characteristics is an ongoing challenge in the field.

The integration of MXenes into polymer matrices presents its own set of difficulties. Achieving uniform dispersion and strong interfacial bonding between MXenes and polymers is essential for enhancing the mechanical, electrical, and thermal properties of the resulting nanocomposites. However, the hydrophilic nature of MXenes often conflicts with the hydrophobic character of many polymers, necessitating the development of novel compatibilization techniques.

Furthermore, the scalability of MXene production and nanocomposite fabrication processes remains a significant barrier to their widespread industrial application. Current synthesis methods are often limited to laboratory scales, and translating these processes to large-scale production while maintaining quality and cost-effectiveness is a major challenge facing the field.

Another critical challenge lies in the prevention of restacking and agglomeration of MXene sheets during the fabrication of nanocomposites. The strong van der Waals interactions between MXene layers tend to cause restacking, reducing the available surface area and limiting the full potential of MXene's properties in the composite structure. Researchers are exploring various strategies to overcome this issue, including the use of spacers, surface functionalization, and innovative assembly techniques.

The control of surface terminations on MXene sheets poses yet another hurdle in their adaptation for nanocomposites. The etching process typically results in a mixture of surface terminations (-O, -OH, -F), which can affect the interfacial interactions between MXenes and the matrix material. Tailoring these surface groups to enhance compatibility and bonding with specific matrix materials remains a complex task.

Stability is a crucial concern in MXene-based nanocomposites. MXenes are prone to oxidation, especially in aqueous environments, which can lead to degradation of their properties over time. Developing effective strategies to protect MXenes from oxidation while maintaining their desirable characteristics is an ongoing challenge in the field.

The integration of MXenes into polymer matrices presents its own set of difficulties. Achieving uniform dispersion and strong interfacial bonding between MXenes and polymers is essential for enhancing the mechanical, electrical, and thermal properties of the resulting nanocomposites. However, the hydrophilic nature of MXenes often conflicts with the hydrophobic character of many polymers, necessitating the development of novel compatibilization techniques.

Furthermore, the scalability of MXene production and nanocomposite fabrication processes remains a significant barrier to their widespread industrial application. Current synthesis methods are often limited to laboratory scales, and translating these processes to large-scale production while maintaining quality and cost-effectiveness is a major challenge facing the field.

Existing MXene Adaptation Techniques

01 MXene-based energy storage devices

MXenes are being adapted for use in energy storage applications, particularly in the development of high-performance batteries and supercapacitors. Their unique 2D structure and excellent electrical conductivity make them promising materials for improving energy density and charge/discharge rates in these devices.- MXene-based energy storage devices: MXenes are being adapted for use in energy storage applications, particularly in the development of high-performance batteries and supercapacitors. Their unique 2D structure and excellent electrical conductivity make them promising materials for improving energy density and charge/discharge rates in these devices.

- MXene composites for electromagnetic shielding: Researchers are developing MXene-based composites that exhibit exceptional electromagnetic interference (EMI) shielding properties. These adaptations involve combining MXenes with polymers or other materials to create lightweight, flexible, and highly effective EMI shielding materials for various applications in electronics and telecommunications.

- MXene-enhanced sensors and biosensors: MXenes are being adapted for use in various sensing applications, including chemical sensors and biosensors. Their large surface area and unique surface chemistry allow for high sensitivity and selectivity in detecting various analytes, making them promising materials for next-generation sensing devices.

- MXene-based water purification membranes: Adaptations of MXenes for water treatment and purification are being explored. MXene-based membranes show potential for efficient removal of contaminants, including heavy metals and organic pollutants, due to their unique surface properties and controllable pore sizes.

- MXene adaptations for thermal management: MXenes are being adapted for thermal management applications, particularly in electronic devices and aerospace materials. Their high thermal conductivity and ability to form thin, flexible films make them suitable for heat dissipation and thermal interface materials in various high-performance systems.

02 MXene composites for electromagnetic shielding

Researchers are developing MXene-based composites that exhibit exceptional electromagnetic interference (EMI) shielding properties. These adaptations involve combining MXenes with polymers or other materials to create lightweight, flexible, and highly effective EMI shielding materials for various applications in electronics and telecommunications.Expand Specific Solutions03 MXene-enhanced sensors and biosensors

MXenes are being adapted for use in various sensing applications, including chemical sensors and biosensors. Their large surface area and tunable surface chemistry allow for high sensitivity and selectivity in detecting various analytes, making them promising materials for next-generation sensing devices.Expand Specific Solutions04 MXene-based water purification membranes

Adaptations of MXenes for water purification applications are being explored. MXene-based membranes show potential for efficient removal of contaminants, including heavy metals and organic pollutants, due to their unique surface properties and controllable pore sizes.Expand Specific Solutions05 MXene adaptations for thermal management

MXenes are being adapted for thermal management applications, particularly in electronic devices and aerospace materials. Their high thermal conductivity and ability to form thin, flexible films make them attractive for heat dissipation and thermal interface materials.Expand Specific Solutions

Key Players in MXene Research and Development

The research on MXene adaptations for complex nanocomposite structures is in an emerging stage, with significant potential for growth. The market size is expanding rapidly, driven by increasing applications in energy storage, electronics, and environmental remediation. The technology's maturity is progressing, with key players like Drexel University, Harbin Institute of Technology, and Dalian University of Technology leading in fundamental research. Companies such as Suzhou Beike Nano Technology Co., Ltd. are beginning to commercialize MXene-based products, indicating a transition from lab-scale to industrial applications. However, the field is still characterized by intense academic research, suggesting that full commercial maturity is yet to be achieved.

Drexel University

Technical Solution: Drexel University has pioneered research on MXene adaptations for complex nanocomposite structures. Their approach involves synthesizing MXene nanosheets with controlled thickness and lateral size, typically ranging from 1-3 nm in thickness and 0.1-5 μm in lateral dimensions [1]. They have developed a method to create MXene-polymer nanocomposites through solution processing, which allows for uniform dispersion of MXenes in various polymer matrices [2]. This technique has enabled the creation of nanocomposites with enhanced mechanical properties, electrical conductivity, and electromagnetic interference shielding capabilities. Drexel's researchers have also explored the use of MXene in hierarchical structures, combining them with other nanomaterials like carbon nanotubes or graphene to create multi-functional composites [3].

Strengths: Pioneering research in MXene synthesis and nanocomposite fabrication; Expertise in solution processing techniques for uniform MXene dispersion. Weaknesses: Potential scalability challenges for industrial-scale production; Limited long-term stability data for MXene-based nanocomposites.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has made significant contributions to MXene adaptations for complex nanocomposite structures, focusing on enhancing the interfacial interactions between MXenes and polymer matrices. Their approach involves surface functionalization of MXene nanosheets using various chemical treatments, such as silane coupling agents or polymer grafting [4]. This modification improves the dispersion and compatibility of MXenes in different polymer systems, leading to nanocomposites with superior mechanical and functional properties. HIT researchers have also developed a novel in-situ polymerization technique that allows for the creation of highly aligned MXene-polymer nanocomposites with anisotropic properties [5]. Additionally, they have explored the use of MXenes in multi-phase polymer blends to create nanocomposites with synergistic properties and unique microstructures.

Strengths: Expertise in surface functionalization of MXenes for improved compatibility; Innovative in-situ polymerization techniques for aligned nanocomposites. Weaknesses: Potential increase in production costs due to additional functionalization steps; Possible alteration of intrinsic MXene properties during modification processes.

Innovative MXene Nanocomposite Structures

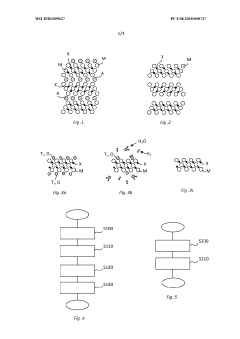

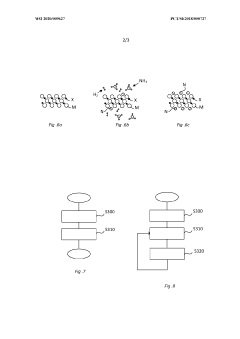

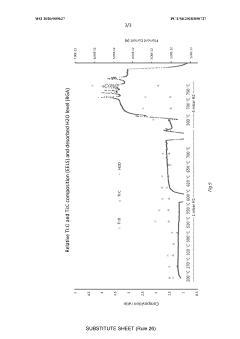

Process for production of a substantially two-dimensional sheet of transition metal carbide, nitride or carbonitride

PatentWO2020009627A1

Innovation

- A process involving chemical etching to remove A atoms from a three-dimensional MAX phase, followed by placing the sheets in a vacuum chamber with hydrogen gas to desorb oxygen-containing surface terminations, resulting in sheets with significantly reduced oxygen content.

Environmental Impact of MXene Production

The production of MXene materials, while promising for various applications, raises significant environmental concerns that warrant careful consideration. The synthesis process of MXenes typically involves the use of strong acids and hazardous chemicals, which can have detrimental effects on the environment if not properly managed. The etching of MAX phases, a crucial step in MXene production, often utilizes hydrofluoric acid (HF) or other fluoride-containing compounds, posing risks of air and water pollution if released into the environment.

Water contamination is a primary concern in MXene production. The etching and washing processes generate large volumes of acidic wastewater containing metal ions and fluoride compounds. Without proper treatment, this effluent can lead to soil and groundwater contamination, potentially harming aquatic ecosystems and human health. Additionally, the disposal of solid waste byproducts from MXene synthesis, such as metal fluorides and unreacted MAX phases, requires careful handling to prevent leaching of toxic substances into the environment.

Air pollution is another environmental impact associated with MXene production. The use of volatile organic compounds (VOCs) and the potential release of acid vapors during synthesis can contribute to air quality degradation. Furthermore, the energy-intensive nature of MXene production processes, particularly in large-scale manufacturing, may indirectly contribute to greenhouse gas emissions if reliant on non-renewable energy sources.

The environmental footprint of MXene production extends to resource consumption as well. The extraction and processing of raw materials for MAX phase synthesis, such as titanium, aluminum, and various transition metals, can have significant environmental impacts, including habitat destruction, water usage, and energy consumption. Moreover, the use of rare or strategically important elements in some MXene compositions may raise concerns about resource depletion and geopolitical tensions.

To address these environmental challenges, researchers and manufacturers are exploring more sustainable production methods for MXenes. This includes the development of less hazardous etching agents, such as Lewis acidic molten salts or electrochemical etching techniques, which aim to reduce or eliminate the use of HF. Closed-loop systems for chemical recycling and water treatment are being implemented to minimize waste and resource consumption. Additionally, efforts are being made to optimize synthesis processes for energy efficiency and to explore the use of renewable energy sources in MXene production facilities.

As the field of MXene research advances, there is a growing emphasis on life cycle assessment (LCA) studies to comprehensively evaluate the environmental impacts of MXene production and application. These assessments consider factors such as raw material extraction, synthesis, use phase, and end-of-life disposal, providing valuable insights for developing more environmentally friendly MXene-based technologies. The integration of green chemistry principles and sustainable engineering practices in MXene research is crucial for ensuring that the potential benefits of these materials are not outweighed by their environmental costs.

Water contamination is a primary concern in MXene production. The etching and washing processes generate large volumes of acidic wastewater containing metal ions and fluoride compounds. Without proper treatment, this effluent can lead to soil and groundwater contamination, potentially harming aquatic ecosystems and human health. Additionally, the disposal of solid waste byproducts from MXene synthesis, such as metal fluorides and unreacted MAX phases, requires careful handling to prevent leaching of toxic substances into the environment.

Air pollution is another environmental impact associated with MXene production. The use of volatile organic compounds (VOCs) and the potential release of acid vapors during synthesis can contribute to air quality degradation. Furthermore, the energy-intensive nature of MXene production processes, particularly in large-scale manufacturing, may indirectly contribute to greenhouse gas emissions if reliant on non-renewable energy sources.

The environmental footprint of MXene production extends to resource consumption as well. The extraction and processing of raw materials for MAX phase synthesis, such as titanium, aluminum, and various transition metals, can have significant environmental impacts, including habitat destruction, water usage, and energy consumption. Moreover, the use of rare or strategically important elements in some MXene compositions may raise concerns about resource depletion and geopolitical tensions.

To address these environmental challenges, researchers and manufacturers are exploring more sustainable production methods for MXenes. This includes the development of less hazardous etching agents, such as Lewis acidic molten salts or electrochemical etching techniques, which aim to reduce or eliminate the use of HF. Closed-loop systems for chemical recycling and water treatment are being implemented to minimize waste and resource consumption. Additionally, efforts are being made to optimize synthesis processes for energy efficiency and to explore the use of renewable energy sources in MXene production facilities.

As the field of MXene research advances, there is a growing emphasis on life cycle assessment (LCA) studies to comprehensively evaluate the environmental impacts of MXene production and application. These assessments consider factors such as raw material extraction, synthesis, use phase, and end-of-life disposal, providing valuable insights for developing more environmentally friendly MXene-based technologies. The integration of green chemistry principles and sustainable engineering practices in MXene research is crucial for ensuring that the potential benefits of these materials are not outweighed by their environmental costs.

Scalability of MXene Manufacturing Processes

The scalability of MXene manufacturing processes is a critical factor in the widespread adoption and commercialization of MXene-based nanocomposite structures. Current production methods, primarily based on selective etching of MAX phases, face significant challenges when scaling up to industrial levels.

One of the main obstacles in scaling MXene production is the time-consuming nature of the etching process. The traditional method involves using hydrofluoric acid (HF) or in-situ HF-generating etchants, which can take several days to complete. This lengthy process time significantly limits production capacity and increases costs. To address this issue, researchers are exploring alternative etching methods, such as electrochemical etching and molten salt etching, which show promise for faster and more efficient MXene synthesis.

Another challenge in scaling MXene manufacturing is the need for precise control over the etching process to maintain consistent quality and yield. As production volumes increase, maintaining uniform etching conditions across larger batches becomes increasingly difficult. This can lead to variations in MXene flake size, thickness, and surface chemistry, potentially affecting the performance of the final nanocomposite structures.

The post-etching delamination and purification steps also present scalability challenges. Current methods often involve manual processes or small-scale equipment, which are not suitable for large-scale production. Developing automated and continuous flow processes for delamination and purification is crucial for improving scalability.

Environmental and safety concerns associated with the use of hazardous etchants, particularly HF, pose additional challenges to scaling up MXene production. Implementing safer and more environmentally friendly etching methods is essential for large-scale manufacturing. Recent research has focused on developing "green" synthesis routes, such as using Lewis acidic molten salts or electrochemical methods, which show promise for safer and more sustainable large-scale production.

The availability and cost of raw materials, particularly MAX phase precursors, can also impact the scalability of MXene manufacturing. As demand for MXenes increases, ensuring a stable and cost-effective supply of high-quality MAX phases becomes crucial. This may require the development of new synthesis methods for MAX phases or the exploration of alternative precursor materials.

To address these scalability challenges, researchers and industry partners are exploring various approaches. These include the development of continuous flow reactors for etching and delamination, the use of advanced process control systems for maintaining consistent quality, and the implementation of in-line characterization techniques for real-time monitoring of MXene production. Additionally, efforts are being made to optimize post-processing steps, such as drying and storage, to ensure the stability and quality of MXenes produced at larger scales.

One of the main obstacles in scaling MXene production is the time-consuming nature of the etching process. The traditional method involves using hydrofluoric acid (HF) or in-situ HF-generating etchants, which can take several days to complete. This lengthy process time significantly limits production capacity and increases costs. To address this issue, researchers are exploring alternative etching methods, such as electrochemical etching and molten salt etching, which show promise for faster and more efficient MXene synthesis.

Another challenge in scaling MXene manufacturing is the need for precise control over the etching process to maintain consistent quality and yield. As production volumes increase, maintaining uniform etching conditions across larger batches becomes increasingly difficult. This can lead to variations in MXene flake size, thickness, and surface chemistry, potentially affecting the performance of the final nanocomposite structures.

The post-etching delamination and purification steps also present scalability challenges. Current methods often involve manual processes or small-scale equipment, which are not suitable for large-scale production. Developing automated and continuous flow processes for delamination and purification is crucial for improving scalability.

Environmental and safety concerns associated with the use of hazardous etchants, particularly HF, pose additional challenges to scaling up MXene production. Implementing safer and more environmentally friendly etching methods is essential for large-scale manufacturing. Recent research has focused on developing "green" synthesis routes, such as using Lewis acidic molten salts or electrochemical methods, which show promise for safer and more sustainable large-scale production.

The availability and cost of raw materials, particularly MAX phase precursors, can also impact the scalability of MXene manufacturing. As demand for MXenes increases, ensuring a stable and cost-effective supply of high-quality MAX phases becomes crucial. This may require the development of new synthesis methods for MAX phases or the exploration of alternative precursor materials.

To address these scalability challenges, researchers and industry partners are exploring various approaches. These include the development of continuous flow reactors for etching and delamination, the use of advanced process control systems for maintaining consistent quality, and the implementation of in-line characterization techniques for real-time monitoring of MXene production. Additionally, efforts are being made to optimize post-processing steps, such as drying and storage, to ensure the stability and quality of MXenes produced at larger scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!