Water-Based Cooling Techniques for Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Cooling Evolution

Battery cooling technology has undergone significant evolution since the advent of electric vehicles (EVs) and large-scale energy storage systems. The early stages of battery cooling primarily relied on air-based systems, which were simple but often inadequate for high-performance applications. As battery technologies advanced and energy densities increased, the need for more efficient cooling methods became apparent.

The transition to liquid cooling marked a major milestone in battery thermal management. Initially, indirect liquid cooling systems were developed, where coolant circulated through plates or channels adjacent to battery cells. This approach offered improved heat transfer compared to air cooling but still had limitations in terms of thermal uniformity and efficiency.

The next significant step was the introduction of direct liquid cooling, where the coolant came into direct contact with battery cells. This method dramatically improved heat transfer rates and allowed for more compact battery pack designs. However, it also introduced new challenges related to electrical insulation and coolant compatibility with battery components.

Water-based cooling techniques emerged as a promising solution due to water's excellent thermal properties and environmental friendliness. Early water-based systems faced issues with corrosion and electrical conductivity, leading to the development of specialized coolants and advanced sealing technologies. The integration of additives and the use of deionized water helped overcome many of these initial challenges.

Recent advancements in water-based cooling for battery management systems have focused on optimizing flow patterns and thermal distribution. Computational fluid dynamics (CFD) simulations have played a crucial role in designing more efficient cooling channels and predicting thermal behavior under various operating conditions. This has led to the development of sophisticated cooling plate designs that ensure uniform temperature distribution across battery packs.

The latest trends in water-based battery cooling include the integration of phase change materials (PCMs) to enhance thermal capacity and stability. These hybrid systems combine the benefits of active water cooling with the passive thermal management capabilities of PCMs, offering improved performance during peak load conditions and better overall temperature control.

As battery technologies continue to evolve, with higher energy densities and faster charging capabilities, cooling systems are adapting to meet these new demands. Current research is exploring advanced nanofluid coolants, which promise enhanced heat transfer properties compared to traditional water-based solutions. Additionally, there is growing interest in intelligent thermal management systems that can dynamically adjust cooling strategies based on real-time battery conditions and environmental factors.

The transition to liquid cooling marked a major milestone in battery thermal management. Initially, indirect liquid cooling systems were developed, where coolant circulated through plates or channels adjacent to battery cells. This approach offered improved heat transfer compared to air cooling but still had limitations in terms of thermal uniformity and efficiency.

The next significant step was the introduction of direct liquid cooling, where the coolant came into direct contact with battery cells. This method dramatically improved heat transfer rates and allowed for more compact battery pack designs. However, it also introduced new challenges related to electrical insulation and coolant compatibility with battery components.

Water-based cooling techniques emerged as a promising solution due to water's excellent thermal properties and environmental friendliness. Early water-based systems faced issues with corrosion and electrical conductivity, leading to the development of specialized coolants and advanced sealing technologies. The integration of additives and the use of deionized water helped overcome many of these initial challenges.

Recent advancements in water-based cooling for battery management systems have focused on optimizing flow patterns and thermal distribution. Computational fluid dynamics (CFD) simulations have played a crucial role in designing more efficient cooling channels and predicting thermal behavior under various operating conditions. This has led to the development of sophisticated cooling plate designs that ensure uniform temperature distribution across battery packs.

The latest trends in water-based battery cooling include the integration of phase change materials (PCMs) to enhance thermal capacity and stability. These hybrid systems combine the benefits of active water cooling with the passive thermal management capabilities of PCMs, offering improved performance during peak load conditions and better overall temperature control.

As battery technologies continue to evolve, with higher energy densities and faster charging capabilities, cooling systems are adapting to meet these new demands. Current research is exploring advanced nanofluid coolants, which promise enhanced heat transfer properties compared to traditional water-based solutions. Additionally, there is growing interest in intelligent thermal management systems that can dynamically adjust cooling strategies based on real-time battery conditions and environmental factors.

Market Demand Analysis

The market demand for water-based cooling techniques in Battery Management Systems (BMS) has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing need for efficient thermal management in energy storage systems. As the global EV market continues to surge, with annual sales projected to reach 26.8 million units by 2030, the demand for advanced cooling solutions for battery packs has become paramount.

Water-based cooling systems offer several advantages over traditional air-cooling methods, including higher heat transfer efficiency, more uniform temperature distribution, and improved overall battery performance. These benefits have led to a growing interest from automotive manufacturers and battery suppliers in implementing water-based cooling techniques in their BMS designs.

The market for water-based cooling systems in BMS is closely tied to the broader EV battery market, which is expected to grow at a compound annual growth rate (CAGR) of 25.3% from 2021 to 2028. This growth is fueled by increasing government initiatives to promote electric mobility, rising environmental concerns, and advancements in battery technology.

In addition to the automotive sector, the demand for water-based cooling techniques in BMS extends to stationary energy storage applications, such as grid-scale battery systems and renewable energy integration. The global energy storage market is projected to deploy 411 GWh of capacity by 2030, further driving the need for efficient cooling solutions.

The market demand is also influenced by stringent regulations on vehicle emissions and fuel efficiency standards worldwide. As automakers strive to meet these requirements, the adoption of advanced thermal management systems becomes crucial for optimizing battery performance and longevity.

Furthermore, the increasing focus on fast charging capabilities in EVs has created a new dimension of demand for water-based cooling techniques. Rapid charging generates significant heat, necessitating more effective cooling solutions to maintain battery health and safety during the charging process.

The Asia-Pacific region, particularly China, leads the market demand for water-based cooling techniques in BMS, followed by Europe and North America. This regional distribution aligns with the global EV market trends and the presence of major battery manufacturers and automotive OEMs in these areas.

As the industry continues to evolve, there is a growing emphasis on developing more compact, lightweight, and cost-effective water-based cooling systems. This trend is driven by the need to improve overall vehicle efficiency and reduce manufacturing costs, further stimulating market demand for innovative cooling solutions in BMS.

Water-based cooling systems offer several advantages over traditional air-cooling methods, including higher heat transfer efficiency, more uniform temperature distribution, and improved overall battery performance. These benefits have led to a growing interest from automotive manufacturers and battery suppliers in implementing water-based cooling techniques in their BMS designs.

The market for water-based cooling systems in BMS is closely tied to the broader EV battery market, which is expected to grow at a compound annual growth rate (CAGR) of 25.3% from 2021 to 2028. This growth is fueled by increasing government initiatives to promote electric mobility, rising environmental concerns, and advancements in battery technology.

In addition to the automotive sector, the demand for water-based cooling techniques in BMS extends to stationary energy storage applications, such as grid-scale battery systems and renewable energy integration. The global energy storage market is projected to deploy 411 GWh of capacity by 2030, further driving the need for efficient cooling solutions.

The market demand is also influenced by stringent regulations on vehicle emissions and fuel efficiency standards worldwide. As automakers strive to meet these requirements, the adoption of advanced thermal management systems becomes crucial for optimizing battery performance and longevity.

Furthermore, the increasing focus on fast charging capabilities in EVs has created a new dimension of demand for water-based cooling techniques. Rapid charging generates significant heat, necessitating more effective cooling solutions to maintain battery health and safety during the charging process.

The Asia-Pacific region, particularly China, leads the market demand for water-based cooling techniques in BMS, followed by Europe and North America. This regional distribution aligns with the global EV market trends and the presence of major battery manufacturers and automotive OEMs in these areas.

As the industry continues to evolve, there is a growing emphasis on developing more compact, lightweight, and cost-effective water-based cooling systems. This trend is driven by the need to improve overall vehicle efficiency and reduce manufacturing costs, further stimulating market demand for innovative cooling solutions in BMS.

Current Challenges

Water-based cooling techniques for Battery Management Systems (BMS) face several significant challenges in their current state of development and implementation. One of the primary obstacles is the inherent risk of liquid coolant leakage within the battery pack. Such leaks can lead to short circuits, electrical failures, and potentially hazardous situations, compromising the safety and reliability of the entire system.

Another major challenge lies in the complexity of integrating water-based cooling systems into existing battery pack designs. The addition of coolant channels, pumps, and heat exchangers increases the overall weight and volume of the battery pack, which can negatively impact the energy density and performance of electric vehicles. This trade-off between cooling efficiency and energy density presents a significant hurdle for engineers and designers.

The uniformity of cooling across all cells within a battery pack remains a persistent challenge. Achieving consistent temperature distribution is crucial for maintaining optimal performance and longevity of the battery. However, the current water-based cooling techniques often struggle to provide uniform cooling, especially in large-scale battery packs with numerous cells.

Corrosion and degradation of cooling system components pose another significant concern. The prolonged exposure of metal parts to water-based coolants can lead to corrosion, potentially compromising the integrity of the cooling system over time. This necessitates the use of corrosion-resistant materials, which can increase manufacturing costs and complexity.

Energy efficiency is another critical challenge in water-based cooling systems for BMS. The power required to operate pumps and other cooling components can reduce the overall efficiency of the battery system, particularly in electric vehicle applications where energy conservation is paramount. Balancing cooling performance with energy consumption remains a key area of focus for researchers and engineers.

The thermal management of batteries during extreme conditions, such as rapid charging or high-power discharge scenarios, presents additional challenges for water-based cooling systems. These systems must be capable of quickly dissipating large amounts of heat to prevent thermal runaway and maintain safe operating temperatures, which can be particularly demanding for current cooling technologies.

Lastly, the cost-effectiveness of water-based cooling systems in mass production scenarios is a significant hurdle. While these systems can offer effective thermal management, the additional components and complexity they introduce can substantially increase manufacturing and maintenance costs. This economic factor plays a crucial role in the widespread adoption of water-based cooling techniques in commercial battery management systems.

Another major challenge lies in the complexity of integrating water-based cooling systems into existing battery pack designs. The addition of coolant channels, pumps, and heat exchangers increases the overall weight and volume of the battery pack, which can negatively impact the energy density and performance of electric vehicles. This trade-off between cooling efficiency and energy density presents a significant hurdle for engineers and designers.

The uniformity of cooling across all cells within a battery pack remains a persistent challenge. Achieving consistent temperature distribution is crucial for maintaining optimal performance and longevity of the battery. However, the current water-based cooling techniques often struggle to provide uniform cooling, especially in large-scale battery packs with numerous cells.

Corrosion and degradation of cooling system components pose another significant concern. The prolonged exposure of metal parts to water-based coolants can lead to corrosion, potentially compromising the integrity of the cooling system over time. This necessitates the use of corrosion-resistant materials, which can increase manufacturing costs and complexity.

Energy efficiency is another critical challenge in water-based cooling systems for BMS. The power required to operate pumps and other cooling components can reduce the overall efficiency of the battery system, particularly in electric vehicle applications where energy conservation is paramount. Balancing cooling performance with energy consumption remains a key area of focus for researchers and engineers.

The thermal management of batteries during extreme conditions, such as rapid charging or high-power discharge scenarios, presents additional challenges for water-based cooling systems. These systems must be capable of quickly dissipating large amounts of heat to prevent thermal runaway and maintain safe operating temperatures, which can be particularly demanding for current cooling technologies.

Lastly, the cost-effectiveness of water-based cooling systems in mass production scenarios is a significant hurdle. While these systems can offer effective thermal management, the additional components and complexity they introduce can substantially increase manufacturing and maintenance costs. This economic factor plays a crucial role in the widespread adoption of water-based cooling techniques in commercial battery management systems.

Water-Based Solutions

01 Evaporative cooling systems

Evaporative cooling techniques utilize the principle of water evaporation to reduce air temperature. These systems are energy-efficient and particularly effective in dry climates. They work by passing air through water-saturated pads or mists, causing the water to evaporate and cool the air in the process.- Evaporative cooling systems: Evaporative cooling techniques utilize the principle of water evaporation to reduce temperatures. These systems are energy-efficient and particularly effective in dry climates. They work by passing air through water-saturated media, causing the water to evaporate and cool the air in the process.

- Water-based heat exchangers: Heat exchangers using water as a cooling medium are widely used in various applications. These systems transfer heat from one fluid to another through a solid medium, with water often serving as the coolant. They are efficient in removing heat from industrial processes, HVAC systems, and electronic equipment.

- Spray cooling techniques: Spray cooling involves the use of fine water droplets to cool surfaces or air. This method is effective for rapid heat removal and can be applied in various settings, from industrial processes to outdoor cooling systems. The evaporation of water droplets absorbs heat, providing a cooling effect.

- Circulating water cooling systems: These systems use a continuous flow of water to remove heat from equipment or processes. The heated water is then cooled and recirculated, creating an efficient closed-loop cooling system. This method is commonly used in industrial applications, power plants, and large-scale air conditioning systems.

- Mist-based cooling technologies: Mist cooling systems create a fine water mist that quickly evaporates, absorbing heat from the surrounding air. This technique is often used in outdoor spaces, greenhouses, and industrial settings to provide localized cooling. The small size of mist droplets allows for rapid evaporation and efficient cooling.

02 Water-cooled heat exchangers

Water-cooled heat exchangers use circulating water to absorb and dissipate heat from various systems or processes. These systems are commonly used in industrial applications, HVAC systems, and power plants. They offer efficient heat transfer and can handle high heat loads, making them suitable for large-scale cooling applications.Expand Specific Solutions03 Spray cooling systems

Spray cooling techniques involve the use of fine water droplets or mists to cool air or surfaces. These systems can be used for both indoor and outdoor applications, such as cooling industrial processes, data centers, or creating comfortable microclimates in outdoor spaces. The small water droplets quickly evaporate, absorbing heat and reducing temperatures.Expand Specific Solutions04 Chilled water cooling systems

Chilled water cooling systems use a refrigeration cycle to produce cold water, which is then circulated through a building or industrial process for cooling purposes. These systems are commonly used in large commercial buildings, hospitals, and industrial facilities. They offer precise temperature control and can be more energy-efficient than air-based cooling systems for large spaces.Expand Specific Solutions05 Water-based phase change materials

Water-based phase change materials (PCMs) utilize the latent heat of water during phase transitions for cooling applications. These materials can absorb large amounts of heat while maintaining a constant temperature, making them useful for thermal energy storage and temperature regulation in buildings or electronic devices. PCMs can enhance the efficiency of cooling systems and help reduce energy consumption.Expand Specific Solutions

Key Industry Players

The water-based cooling techniques for Battery Management Systems (BMS) market is in a growth phase, driven by the increasing demand for electric vehicles and energy storage solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, but there's still room for innovation and improvement. Key players like Hyundai Motor, Kia, CATL, and LG Energy Solution are investing heavily in R&D to enhance cooling efficiency and battery performance. Companies such as Samsung SDI and Hanon Systems are also making strides in this area, leveraging their expertise in electronics and thermal management. The competition is intensifying as automotive giants and specialized battery manufacturers vie for market share, pushing the boundaries of water-based cooling technology for BMS.

Hyundai Motor Co., Ltd.

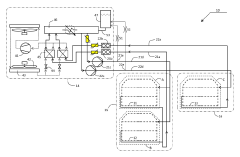

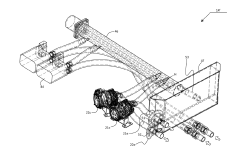

Technical Solution: Hyundai Motor Co. has developed a water-based cooling technique for battery management systems that utilizes a dual-circuit cooling architecture. This system employs two separate cooling circuits: one for the battery cells and another for the power electronics. The company's approach involves a water-glycol mixture as the primary coolant, which circulates through specially designed cooling plates integrated into the battery pack[9]. Hyundai's system also features a heat pump technology that can repurpose waste heat from the cooling system to improve overall vehicle efficiency. The company has implemented advanced thermal modeling and predictive control algorithms to optimize cooling performance under various driving conditions. Hyundai reports that this water-based cooling technique can maintain battery temperature within an optimal range of 20-40°C, even in extreme weather conditions, resulting in improved battery performance and longevity[10].

Strengths: Efficient heat management, improved overall vehicle efficiency through heat recovery, and adaptability to various climate conditions. Weaknesses: Increased system complexity, potential for higher manufacturing costs, and the need for regular maintenance of the dual-circuit system.

Contemporary Amperex Technology Co., Ltd.

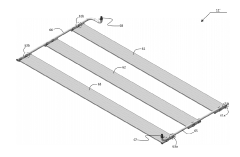

Technical Solution: CATL has developed an innovative water-based cooling technique for battery management systems, utilizing a direct liquid cooling system. This system employs a coolant that circulates directly through channels integrated into the battery pack, ensuring efficient heat dissipation. The company's approach involves a dual-layer cooling structure, where coolant flows through both the top and bottom of the battery cells, maximizing thermal management efficiency[1]. CATL's system also incorporates advanced temperature sensors and control algorithms to maintain optimal operating temperatures across various driving conditions. The company has reported that this water-based cooling technique can reduce battery temperature by up to 20°C compared to traditional air cooling methods, significantly enhancing battery life and performance[2].

Strengths: Highly efficient heat dissipation, improved battery life and performance, adaptable to various electric vehicle designs. Weaknesses: Potentially higher manufacturing costs, increased complexity in battery pack design, and the need for regular maintenance of the cooling system.

Innovative Cooling Tech

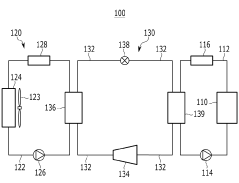

Battery Thermal Management System for Electric Vehicle

PatentInactiveKR1020230103670A

Innovation

- A thermal management system with a circulation path network that includes last-in-first-out cooling water input/output relationships and multi-channel tubes, along with a heating and cooling unit featuring a bypass flow path and air bleeding structure to manage temperature uniformly across multiple battery packs, reducing flow resistance and ensuring consistent heat transfer.

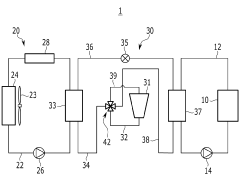

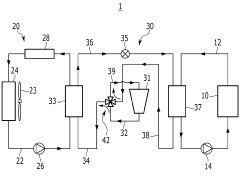

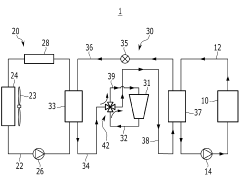

Thermal management system for battery

PatentActiveKR1020190064057A

Innovation

- A thermal management system that utilizes thermal energy from refrigerant phase change to efficiently heat or cool batteries through a CE module with a compressor, heat exchangers, and expansion valves, using R152-a, R744, or R290 refrigerants, and a modular structure to simplify the system.

Environmental Impact

Water-based cooling techniques for battery management systems have significant environmental implications that warrant careful consideration. These systems offer several environmental benefits compared to traditional air-cooling methods. Firstly, water-based cooling is more energy-efficient, reducing the overall power consumption of battery management systems. This increased efficiency translates to lower greenhouse gas emissions associated with energy production, contributing to climate change mitigation efforts.

Moreover, water-based cooling systems can operate at higher temperatures than air-cooled systems, potentially reducing the need for refrigerants with high global warming potential. This shift away from harmful refrigerants aligns with global efforts to phase out substances that deplete the ozone layer and contribute to climate change. The reduced reliance on these chemicals minimizes the risk of their release into the atmosphere during system maintenance or disposal.

Water-based cooling techniques also offer improved thermal management, which can extend the lifespan of batteries. Longer-lasting batteries mean fewer replacements over time, reducing the environmental impact associated with battery production and disposal. This aspect is particularly crucial given the growing concerns about the sustainability of battery manufacturing and the challenges of recycling lithium-ion batteries.

However, the environmental impact of water-based cooling systems is not entirely positive. The use of water as a coolant raises concerns about water consumption, especially in water-scarce regions. While these systems often use closed-loop designs that minimize water loss, there is still a need for periodic replenishment and the potential for leaks. Additionally, the treatment and disposal of coolant water, which may contain contaminants from the cooling process, require careful management to prevent water pollution.

The manufacturing of water-based cooling components, such as pumps, heat exchangers, and piping, also has environmental implications. The production of these components involves resource extraction and energy consumption, which must be balanced against the long-term environmental benefits of the system. Furthermore, the end-of-life disposal or recycling of these components presents additional environmental challenges that need to be addressed.

In conclusion, while water-based cooling techniques for battery management systems offer significant environmental advantages, particularly in terms of energy efficiency and reduced reliance on harmful refrigerants, they also present new environmental challenges. Balancing these factors is crucial for developing sustainable cooling solutions that minimize overall environmental impact throughout their lifecycle.

Moreover, water-based cooling systems can operate at higher temperatures than air-cooled systems, potentially reducing the need for refrigerants with high global warming potential. This shift away from harmful refrigerants aligns with global efforts to phase out substances that deplete the ozone layer and contribute to climate change. The reduced reliance on these chemicals minimizes the risk of their release into the atmosphere during system maintenance or disposal.

Water-based cooling techniques also offer improved thermal management, which can extend the lifespan of batteries. Longer-lasting batteries mean fewer replacements over time, reducing the environmental impact associated with battery production and disposal. This aspect is particularly crucial given the growing concerns about the sustainability of battery manufacturing and the challenges of recycling lithium-ion batteries.

However, the environmental impact of water-based cooling systems is not entirely positive. The use of water as a coolant raises concerns about water consumption, especially in water-scarce regions. While these systems often use closed-loop designs that minimize water loss, there is still a need for periodic replenishment and the potential for leaks. Additionally, the treatment and disposal of coolant water, which may contain contaminants from the cooling process, require careful management to prevent water pollution.

The manufacturing of water-based cooling components, such as pumps, heat exchangers, and piping, also has environmental implications. The production of these components involves resource extraction and energy consumption, which must be balanced against the long-term environmental benefits of the system. Furthermore, the end-of-life disposal or recycling of these components presents additional environmental challenges that need to be addressed.

In conclusion, while water-based cooling techniques for battery management systems offer significant environmental advantages, particularly in terms of energy efficiency and reduced reliance on harmful refrigerants, they also present new environmental challenges. Balancing these factors is crucial for developing sustainable cooling solutions that minimize overall environmental impact throughout their lifecycle.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of water-based cooling techniques for battery management systems. These regulations are designed to ensure the safe operation of cooling systems and protect both users and the environment from potential hazards.

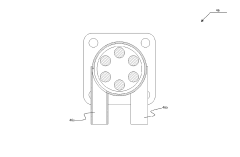

One of the primary safety concerns addressed by regulations is the prevention of electrical hazards. Water-based cooling systems must be designed and installed in a manner that prevents any contact between the coolant and electrical components. This includes proper insulation, sealing, and separation of cooling channels from electrical pathways. Regulations often specify minimum distances between cooling elements and live electrical parts, as well as requirements for materials used in the construction of cooling systems.

Thermal management is another key aspect covered by safety regulations. These regulations typically mandate the use of temperature sensors and control systems to monitor and regulate the temperature of both the coolant and the battery cells. Maximum temperature limits are often specified to prevent thermal runaway and ensure the longevity of the battery system. Additionally, regulations may require fail-safe mechanisms that can quickly shut down the cooling system in case of overheating or other abnormal conditions.

Pressure management is also a critical safety consideration in water-based cooling systems. Regulations often specify maximum operating pressures and require the installation of pressure relief valves to prevent system rupture or leakage. The design and testing of cooling system components must adhere to specific pressure ratings and safety factors to ensure their integrity under various operating conditions.

Environmental protection is another important aspect addressed by safety regulations. These regulations typically mandate the use of environmentally friendly coolants and prohibit the use of substances that may pose risks to human health or the environment. Requirements for proper disposal and recycling of coolants and cooling system components are often included to minimize environmental impact.

Maintenance and inspection requirements are frequently outlined in safety regulations to ensure the ongoing safe operation of water-based cooling systems. These may include regular inspections, leak detection procedures, and maintenance schedules for critical components. Documentation and record-keeping requirements are often specified to facilitate compliance monitoring and traceability.

Emergency response procedures are another crucial element of safety regulations. These may include requirements for automatic shutdown systems, emergency drainage capabilities, and protocols for handling coolant leaks or spills. Training requirements for personnel involved in the operation and maintenance of water-based cooling systems are often specified to ensure proper handling of emergency situations.

One of the primary safety concerns addressed by regulations is the prevention of electrical hazards. Water-based cooling systems must be designed and installed in a manner that prevents any contact between the coolant and electrical components. This includes proper insulation, sealing, and separation of cooling channels from electrical pathways. Regulations often specify minimum distances between cooling elements and live electrical parts, as well as requirements for materials used in the construction of cooling systems.

Thermal management is another key aspect covered by safety regulations. These regulations typically mandate the use of temperature sensors and control systems to monitor and regulate the temperature of both the coolant and the battery cells. Maximum temperature limits are often specified to prevent thermal runaway and ensure the longevity of the battery system. Additionally, regulations may require fail-safe mechanisms that can quickly shut down the cooling system in case of overheating or other abnormal conditions.

Pressure management is also a critical safety consideration in water-based cooling systems. Regulations often specify maximum operating pressures and require the installation of pressure relief valves to prevent system rupture or leakage. The design and testing of cooling system components must adhere to specific pressure ratings and safety factors to ensure their integrity under various operating conditions.

Environmental protection is another important aspect addressed by safety regulations. These regulations typically mandate the use of environmentally friendly coolants and prohibit the use of substances that may pose risks to human health or the environment. Requirements for proper disposal and recycling of coolants and cooling system components are often included to minimize environmental impact.

Maintenance and inspection requirements are frequently outlined in safety regulations to ensure the ongoing safe operation of water-based cooling systems. These may include regular inspections, leak detection procedures, and maintenance schedules for critical components. Documentation and record-keeping requirements are often specified to facilitate compliance monitoring and traceability.

Emergency response procedures are another crucial element of safety regulations. These may include requirements for automatic shutdown systems, emergency drainage capabilities, and protocols for handling coolant leaks or spills. Training requirements for personnel involved in the operation and maintenance of water-based cooling systems are often specified to ensure proper handling of emergency situations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!