Techniques for Extending Cycle Life through Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Lifecycle Extension Background and Objectives

Battery Management Systems (BMS) have become an integral component in the quest for extending the cycle life of batteries, particularly in the context of electric vehicles and renewable energy storage systems. The evolution of BMS technology has been driven by the increasing demand for more efficient, reliable, and long-lasting energy storage solutions. As the global shift towards electrification accelerates, the importance of maximizing battery lifespan through advanced management techniques has gained paramount significance.

The primary objective of BMS lifecycle extension techniques is to optimize the performance and longevity of battery systems while maintaining safety and reliability. This involves a multifaceted approach that encompasses real-time monitoring, predictive analytics, and adaptive control strategies. By leveraging these advanced techniques, BMS aims to mitigate the various factors that contribute to battery degradation, such as overcharging, deep discharging, and thermal stress.

The development of BMS lifecycle extension techniques has been marked by several key milestones. Early systems focused primarily on basic protection functions, such as overcharge and over-discharge prevention. As technology progressed, more sophisticated algorithms were introduced to balance cell voltages and manage thermal conditions. Recent advancements have seen the integration of machine learning and artificial intelligence to predict battery behavior and optimize charging strategies dynamically.

Current trends in BMS lifecycle extension are centered around the implementation of more granular cell-level monitoring and control. This approach allows for precise management of individual cells within a battery pack, addressing the inherent variations in cell characteristics and aging rates. Additionally, there is a growing emphasis on the development of adaptive BMS algorithms that can adjust their strategies based on real-time data and historical performance patterns.

The future trajectory of BMS lifecycle extension techniques points towards even more advanced integration with other vehicle systems and smart grid infrastructure. This holistic approach aims to optimize battery performance not just at the individual pack level, but also within the broader context of energy management systems. Emerging technologies, such as solid-state batteries and advanced materials, are expected to present new challenges and opportunities for BMS development, driving further innovation in lifecycle extension techniques.

As the field continues to evolve, the goals of BMS lifecycle extension techniques are expanding beyond mere lifespan improvement. There is an increasing focus on enhancing the overall value proposition of battery systems by improving their reliability, reducing maintenance costs, and enabling secondary applications such as vehicle-to-grid integration. These objectives align with broader sustainability goals, aiming to maximize the utility of battery resources throughout their entire lifecycle.

The primary objective of BMS lifecycle extension techniques is to optimize the performance and longevity of battery systems while maintaining safety and reliability. This involves a multifaceted approach that encompasses real-time monitoring, predictive analytics, and adaptive control strategies. By leveraging these advanced techniques, BMS aims to mitigate the various factors that contribute to battery degradation, such as overcharging, deep discharging, and thermal stress.

The development of BMS lifecycle extension techniques has been marked by several key milestones. Early systems focused primarily on basic protection functions, such as overcharge and over-discharge prevention. As technology progressed, more sophisticated algorithms were introduced to balance cell voltages and manage thermal conditions. Recent advancements have seen the integration of machine learning and artificial intelligence to predict battery behavior and optimize charging strategies dynamically.

Current trends in BMS lifecycle extension are centered around the implementation of more granular cell-level monitoring and control. This approach allows for precise management of individual cells within a battery pack, addressing the inherent variations in cell characteristics and aging rates. Additionally, there is a growing emphasis on the development of adaptive BMS algorithms that can adjust their strategies based on real-time data and historical performance patterns.

The future trajectory of BMS lifecycle extension techniques points towards even more advanced integration with other vehicle systems and smart grid infrastructure. This holistic approach aims to optimize battery performance not just at the individual pack level, but also within the broader context of energy management systems. Emerging technologies, such as solid-state batteries and advanced materials, are expected to present new challenges and opportunities for BMS development, driving further innovation in lifecycle extension techniques.

As the field continues to evolve, the goals of BMS lifecycle extension techniques are expanding beyond mere lifespan improvement. There is an increasing focus on enhancing the overall value proposition of battery systems by improving their reliability, reducing maintenance costs, and enabling secondary applications such as vehicle-to-grid integration. These objectives align with broader sustainability goals, aiming to maximize the utility of battery resources throughout their entire lifecycle.

Market Demand for Extended Battery Life

The market demand for extended battery life has been growing exponentially across various sectors, driven by the increasing reliance on portable electronic devices, electric vehicles, and renewable energy storage systems. As consumers and industries alike seek longer-lasting and more reliable power sources, the focus on techniques for extending cycle life through battery management systems has intensified.

In the consumer electronics sector, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect their devices to last longer between charges and maintain performance over extended periods. This expectation has led to a surge in research and development efforts aimed at improving battery management systems to optimize charge-discharge cycles and prolong overall battery lifespan.

The automotive industry, particularly the electric vehicle (EV) segment, represents a significant driver of demand for extended battery life. As EVs become more mainstream, consumers are increasingly concerned about range anxiety and long-term battery performance. Manufacturers are under pressure to develop battery management systems that not only extend the driving range but also ensure the longevity of the battery pack over the vehicle's lifetime.

In the renewable energy sector, the need for efficient and long-lasting energy storage solutions has become critical. Grid-scale battery systems and residential energy storage units require advanced battery management techniques to maximize cycle life and ensure reliable performance over many years. This demand is fueled by the growing adoption of solar and wind power, which rely on energy storage to balance supply and demand.

The industrial and commercial sectors also contribute significantly to the market demand for extended battery life. Uninterruptible power supplies (UPS), telecommunications infrastructure, and data centers all require reliable, long-lasting battery systems. In these applications, the cost of battery replacement and system downtime can be substantial, making the extension of battery cycle life through advanced management systems a top priority.

Healthcare is another sector where the demand for extended battery life is crucial. Medical devices, from portable diagnostic equipment to implantable devices, require batteries that can maintain performance over long periods without frequent replacement. This demand drives innovation in battery management systems to ensure patient safety and reduce the need for invasive procedures to replace batteries.

The market's response to this demand has been evident in the increasing investment in research and development of advanced battery management systems. Companies are focusing on developing sophisticated algorithms, sensors, and control systems that can monitor battery health, optimize charging patterns, and predict potential failures. This has led to the emergence of new players in the battery management system market and collaborations between battery manufacturers and technology companies.

In the consumer electronics sector, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect their devices to last longer between charges and maintain performance over extended periods. This expectation has led to a surge in research and development efforts aimed at improving battery management systems to optimize charge-discharge cycles and prolong overall battery lifespan.

The automotive industry, particularly the electric vehicle (EV) segment, represents a significant driver of demand for extended battery life. As EVs become more mainstream, consumers are increasingly concerned about range anxiety and long-term battery performance. Manufacturers are under pressure to develop battery management systems that not only extend the driving range but also ensure the longevity of the battery pack over the vehicle's lifetime.

In the renewable energy sector, the need for efficient and long-lasting energy storage solutions has become critical. Grid-scale battery systems and residential energy storage units require advanced battery management techniques to maximize cycle life and ensure reliable performance over many years. This demand is fueled by the growing adoption of solar and wind power, which rely on energy storage to balance supply and demand.

The industrial and commercial sectors also contribute significantly to the market demand for extended battery life. Uninterruptible power supplies (UPS), telecommunications infrastructure, and data centers all require reliable, long-lasting battery systems. In these applications, the cost of battery replacement and system downtime can be substantial, making the extension of battery cycle life through advanced management systems a top priority.

Healthcare is another sector where the demand for extended battery life is crucial. Medical devices, from portable diagnostic equipment to implantable devices, require batteries that can maintain performance over long periods without frequent replacement. This demand drives innovation in battery management systems to ensure patient safety and reduce the need for invasive procedures to replace batteries.

The market's response to this demand has been evident in the increasing investment in research and development of advanced battery management systems. Companies are focusing on developing sophisticated algorithms, sensors, and control systems that can monitor battery health, optimize charging patterns, and predict potential failures. This has led to the emergence of new players in the battery management system market and collaborations between battery manufacturers and technology companies.

Current BMS Challenges and Limitations

Battery Management Systems (BMS) play a crucial role in extending the cycle life of batteries, yet they face several challenges and limitations in achieving optimal performance. One of the primary challenges is the accurate estimation of the battery's state of charge (SOC) and state of health (SOH). Current BMS technologies often struggle to provide precise measurements, especially in dynamic operating conditions or as the battery ages. This inaccuracy can lead to suboptimal charging and discharging strategies, potentially reducing the battery's lifespan.

Another significant limitation is the difficulty in managing thermal issues effectively. Batteries are sensitive to temperature fluctuations, and excessive heat can accelerate degradation. While BMS can monitor temperature, the ability to actively control and uniformly distribute heat across large battery packs remains a challenge. This is particularly problematic in electric vehicles and large-scale energy storage systems where thermal management is critical for safety and longevity.

The complexity of battery chemistry and the variability between individual cells within a battery pack pose additional challenges. Current BMS often lack the sophistication to address the unique characteristics of each cell, leading to imbalances that can reduce overall pack performance and lifespan. The development of more advanced cell-level monitoring and balancing techniques is necessary but faces obstacles in terms of cost and computational requirements.

Data management and processing present another set of limitations. As BMS collect vast amounts of data, the ability to efficiently process, analyze, and act upon this information in real-time becomes increasingly challenging. This is particularly true for applications requiring rapid decision-making, such as in electric vehicles or grid-scale energy storage.

Furthermore, the adaptability of BMS to different battery chemistries and configurations is limited. As new battery technologies emerge, BMS must evolve to accommodate varying voltage ranges, charging profiles, and safety parameters. This lack of flexibility can hinder the adoption of innovative battery technologies and limit the overall advancement of energy storage solutions.

Lastly, the integration of BMS with other vehicle or grid systems remains a challenge. Improved communication protocols and standardization are needed to ensure seamless interaction between BMS and other components, such as power electronics, thermal management systems, and higher-level control systems. This integration is essential for optimizing overall system performance and extending battery life in complex applications.

Another significant limitation is the difficulty in managing thermal issues effectively. Batteries are sensitive to temperature fluctuations, and excessive heat can accelerate degradation. While BMS can monitor temperature, the ability to actively control and uniformly distribute heat across large battery packs remains a challenge. This is particularly problematic in electric vehicles and large-scale energy storage systems where thermal management is critical for safety and longevity.

The complexity of battery chemistry and the variability between individual cells within a battery pack pose additional challenges. Current BMS often lack the sophistication to address the unique characteristics of each cell, leading to imbalances that can reduce overall pack performance and lifespan. The development of more advanced cell-level monitoring and balancing techniques is necessary but faces obstacles in terms of cost and computational requirements.

Data management and processing present another set of limitations. As BMS collect vast amounts of data, the ability to efficiently process, analyze, and act upon this information in real-time becomes increasingly challenging. This is particularly true for applications requiring rapid decision-making, such as in electric vehicles or grid-scale energy storage.

Furthermore, the adaptability of BMS to different battery chemistries and configurations is limited. As new battery technologies emerge, BMS must evolve to accommodate varying voltage ranges, charging profiles, and safety parameters. This lack of flexibility can hinder the adoption of innovative battery technologies and limit the overall advancement of energy storage solutions.

Lastly, the integration of BMS with other vehicle or grid systems remains a challenge. Improved communication protocols and standardization are needed to ensure seamless interaction between BMS and other components, such as power electronics, thermal management systems, and higher-level control systems. This integration is essential for optimizing overall system performance and extending battery life in complex applications.

Existing BMS Lifecycle Extension Techniques

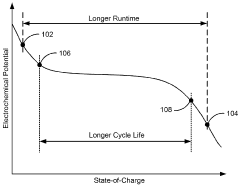

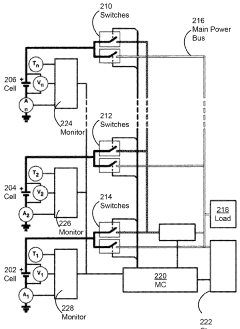

01 Battery cycle life optimization through advanced management systems

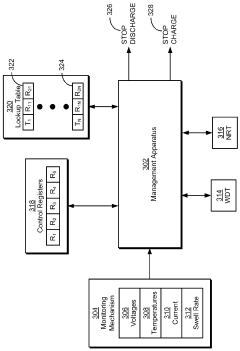

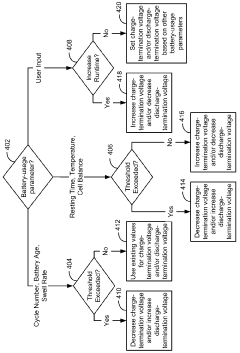

Advanced battery management systems employ sophisticated algorithms and monitoring techniques to optimize charging and discharging cycles, effectively extending the overall lifespan of batteries. These systems can adapt to various usage patterns and environmental conditions, ensuring optimal performance and longevity.- Battery cycle life optimization through advanced management systems: Battery Management Systems (BMS) employ sophisticated algorithms and monitoring techniques to optimize charging and discharging cycles, effectively extending the overall lifespan of batteries. These systems continuously analyze battery performance, adjust charging parameters, and implement protective measures to prevent overcharging or deep discharging, which are detrimental to battery health.

- Thermal management for improved battery longevity: Effective thermal management is crucial for maintaining optimal battery performance and extending cycle life. BMS incorporate temperature monitoring and control mechanisms to prevent overheating and ensure uniform temperature distribution across battery cells. This helps to minimize degradation caused by thermal stress and maintains consistent performance over time.

- State of health estimation and predictive maintenance: Advanced BMS utilize machine learning and data analytics to accurately estimate the state of health of batteries and predict potential failures. By continuously monitoring various parameters such as voltage, current, and internal resistance, these systems can identify early signs of degradation and recommend preventive maintenance, thereby extending the overall cycle life of the battery.

- Adaptive charging strategies for cycle life extension: BMS implement adaptive charging strategies that adjust charging profiles based on the battery's current condition and usage patterns. These strategies may include pulse charging, variable current charging, or multi-stage charging protocols, all aimed at minimizing stress on the battery and optimizing the charging process to extend cycle life.

- Cell balancing techniques for uniform degradation: To ensure uniform degradation across all cells in a battery pack, BMS employ various cell balancing techniques. These methods redistribute charge between cells, preventing overcharging of individual cells and ensuring that all cells in the pack age at a similar rate. This approach significantly contributes to extending the overall cycle life of the battery system.

02 Thermal management for improved battery cycle life

Effective thermal management is crucial for maintaining optimal battery performance and extending cycle life. Battery management systems incorporate temperature monitoring and control mechanisms to prevent overheating and ensure uniform temperature distribution across battery cells, thereby reducing degradation and improving longevity.Expand Specific Solutions03 State of health monitoring and predictive maintenance

Battery management systems utilize advanced sensors and data analytics to continuously monitor the state of health of battery cells. This enables predictive maintenance strategies, allowing for timely interventions to prevent premature degradation and extend the overall cycle life of the battery system.Expand Specific Solutions04 Adaptive charging strategies for cycle life extension

Intelligent battery management systems implement adaptive charging strategies that adjust charging parameters based on the battery's current condition and usage history. These strategies can include variable charging rates, pulse charging, and rest periods to minimize stress on the battery and maximize its cycle life.Expand Specific Solutions05 Cell balancing techniques for uniform degradation

Battery management systems employ cell balancing techniques to ensure uniform charge distribution and degradation across all cells in a battery pack. This approach prevents individual cells from experiencing accelerated wear, thereby extending the overall cycle life of the entire battery system.Expand Specific Solutions

Key Players in BMS Industry

The battery management system (BMS) market for extending cycle life is in a growth phase, driven by increasing demand for electric vehicles and energy storage solutions. The market size is expanding rapidly, with projections indicating significant growth over the next decade. Technologically, BMS solutions are advancing, but there is still room for innovation. Key players like LG Energy Solution, Contemporary Amperex Technology, and Bosch are investing heavily in R&D to improve BMS efficiency and reliability. Established automotive companies such as Honda and Stellantis are also entering this space, recognizing its importance for their electric vehicle strategies. The competition is intensifying as both specialized BMS providers and large tech companies like Apple and IBM seek to capture market share in this critical component of the energy transition.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced Battery Management Systems (BMS) that utilize machine learning algorithms to predict and optimize battery performance[1]. Their system continuously monitors cell voltage, temperature, and current to adjust charging and discharging patterns in real-time. This adaptive approach helps to prevent overcharging and deep discharging, which are major factors in battery degradation. Additionally, they have implemented a novel thermal management system that maintains optimal operating temperatures across the entire battery pack, significantly reducing thermal stress and extending cycle life[2].

Strengths: Advanced AI integration, real-time adaptive management, and superior thermal control. Weaknesses: Potentially higher initial cost and complexity in implementation.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered a cell-to-pack (CTP) technology that integrates advanced BMS directly into the battery structure[3]. This approach allows for more precise control over individual cells, enabling the system to balance charge levels more effectively and extend overall pack life. Their BMS incorporates predictive analytics to forecast battery health and adjust usage patterns accordingly. CATL has also developed a novel electrolyte formula that works in tandem with their BMS to reduce capacity fade and improve cycle life by up to 30% compared to conventional lithium-ion batteries[4].

Strengths: Innovative cell-to-pack integration, advanced predictive analytics, and improved electrolyte chemistry. Weaknesses: Potential challenges in retrofitting existing battery systems with this technology.

Core BMS Innovations for Longevity

Managing cycle life and runtime in batteries for portable electronic devices

PatentWO2013151821A2

Innovation

- A system that monitors battery usage parameters such as cycle number, age, swell rate, temperature, and user input to adjust charge-termination and discharge-termination voltages, using a lookup table to dynamically manage cycle life and runtime by altering the voltage range based on thresholds and user input.

Mechanism for extending cycle life of a battery

PatentActiveKR1020230098707A

Innovation

- Implementing a mechanism to monitor degradation rates and adjust charging parameters, such as current and voltage, to mitigate degradation by slowing down the charging process when accelerated degradation is detected.

BMS Standards and Regulations

Battery Management System (BMS) standards and regulations play a crucial role in ensuring the safety, reliability, and performance of battery systems across various industries. These standards provide guidelines for the design, implementation, and operation of BMS, contributing to the overall improvement of battery cycle life and efficiency.

One of the primary standards governing BMS is the ISO 26262, which focuses on functional safety for road vehicles. This standard outlines requirements for electronic and electrical systems in automobiles, including BMS. It emphasizes the importance of risk assessment, system design, and validation processes to ensure the safe operation of battery systems in electric and hybrid vehicles.

The UL 1642 standard, developed by Underwriters Laboratories, specifically addresses the safety of lithium batteries. It provides guidelines for battery cell construction, testing procedures, and safety mechanisms. BMS designers must adhere to these standards to ensure that their systems effectively protect against overcharging, over-discharging, and thermal runaway.

In the aerospace industry, the DO-311A standard, issued by RTCA, sets requirements for rechargeable lithium batteries and battery systems in aircraft. This standard emphasizes the importance of BMS in monitoring and controlling battery parameters to maintain safety during flight operations.

The IEC 62133 standard, developed by the International Electrotechnical Commission, focuses on the safety requirements for portable sealed secondary cells and batteries. It outlines specific tests and criteria for BMS to prevent hazardous conditions in portable electronic devices.

For grid energy storage applications, the IEEE 1547 standard provides guidelines for interconnecting distributed energy resources with electric power systems. This standard includes requirements for BMS in large-scale battery storage systems, ensuring their safe and efficient integration into the power grid.

The SAE J2464 standard, developed by the Society of Automotive Engineers, addresses electric and hybrid vehicle rechargeable energy storage systems. It provides safety and abuse testing procedures for battery systems, including requirements for BMS to mitigate potential hazards.

Compliance with these standards and regulations is essential for BMS manufacturers and integrators. It not only ensures the safety and reliability of battery systems but also contributes to extending battery cycle life through standardized management practices. As the battery technology landscape evolves, these standards are regularly updated to address new challenges and incorporate emerging best practices in battery management.

One of the primary standards governing BMS is the ISO 26262, which focuses on functional safety for road vehicles. This standard outlines requirements for electronic and electrical systems in automobiles, including BMS. It emphasizes the importance of risk assessment, system design, and validation processes to ensure the safe operation of battery systems in electric and hybrid vehicles.

The UL 1642 standard, developed by Underwriters Laboratories, specifically addresses the safety of lithium batteries. It provides guidelines for battery cell construction, testing procedures, and safety mechanisms. BMS designers must adhere to these standards to ensure that their systems effectively protect against overcharging, over-discharging, and thermal runaway.

In the aerospace industry, the DO-311A standard, issued by RTCA, sets requirements for rechargeable lithium batteries and battery systems in aircraft. This standard emphasizes the importance of BMS in monitoring and controlling battery parameters to maintain safety during flight operations.

The IEC 62133 standard, developed by the International Electrotechnical Commission, focuses on the safety requirements for portable sealed secondary cells and batteries. It outlines specific tests and criteria for BMS to prevent hazardous conditions in portable electronic devices.

For grid energy storage applications, the IEEE 1547 standard provides guidelines for interconnecting distributed energy resources with electric power systems. This standard includes requirements for BMS in large-scale battery storage systems, ensuring their safe and efficient integration into the power grid.

The SAE J2464 standard, developed by the Society of Automotive Engineers, addresses electric and hybrid vehicle rechargeable energy storage systems. It provides safety and abuse testing procedures for battery systems, including requirements for BMS to mitigate potential hazards.

Compliance with these standards and regulations is essential for BMS manufacturers and integrators. It not only ensures the safety and reliability of battery systems but also contributes to extending battery cycle life through standardized management practices. As the battery technology landscape evolves, these standards are regularly updated to address new challenges and incorporate emerging best practices in battery management.

Environmental Impact of Extended Battery Life

The extension of battery life through advanced Battery Management Systems (BMS) has significant environmental implications. By prolonging the operational lifespan of batteries, these techniques contribute to a reduction in electronic waste, a growing concern in our increasingly digital world. The decreased need for battery replacements leads to a lower demand for raw materials used in battery production, such as lithium, cobalt, and nickel. This reduction in resource extraction helps preserve natural habitats and reduces the environmental impact associated with mining activities.

Furthermore, extended battery life translates to improved energy efficiency over the lifecycle of electronic devices. This efficiency gain results in lower overall energy consumption, indirectly reducing greenhouse gas emissions associated with power generation. The environmental benefits are particularly pronounced in applications such as electric vehicles, where longer-lasting batteries can significantly decrease the carbon footprint of transportation.

However, the environmental impact of extended battery life is not entirely positive. The sophisticated electronics and algorithms used in advanced BMS may require more complex manufacturing processes and potentially introduce new materials into the battery ecosystem. This complexity could pose challenges for recycling and proper disposal at the end of the battery's life. It is crucial to consider the entire lifecycle of these advanced battery systems, including their eventual decommissioning and recycling.

The shift towards longer-lasting batteries also has implications for the circular economy. While it reduces the frequency of battery replacements, it may slow down the adoption of newer, more environmentally friendly battery technologies. This potential delay in upgrading to more sustainable options needs to be balanced against the immediate benefits of extended battery life.

In the context of grid energy storage, extended battery life through BMS can enhance the integration of renewable energy sources. By providing more reliable and long-lasting energy storage solutions, these systems can help mitigate the intermittency issues associated with solar and wind power, thereby supporting the transition to cleaner energy sources.

Lastly, the environmental impact extends to consumer behavior and product design. Longer-lasting batteries may encourage the development of more durable and repairable electronic devices, potentially shifting consumer attitudes away from the current "throwaway" culture. This change could lead to a broader reduction in electronic waste and promote more sustainable consumption patterns.

Furthermore, extended battery life translates to improved energy efficiency over the lifecycle of electronic devices. This efficiency gain results in lower overall energy consumption, indirectly reducing greenhouse gas emissions associated with power generation. The environmental benefits are particularly pronounced in applications such as electric vehicles, where longer-lasting batteries can significantly decrease the carbon footprint of transportation.

However, the environmental impact of extended battery life is not entirely positive. The sophisticated electronics and algorithms used in advanced BMS may require more complex manufacturing processes and potentially introduce new materials into the battery ecosystem. This complexity could pose challenges for recycling and proper disposal at the end of the battery's life. It is crucial to consider the entire lifecycle of these advanced battery systems, including their eventual decommissioning and recycling.

The shift towards longer-lasting batteries also has implications for the circular economy. While it reduces the frequency of battery replacements, it may slow down the adoption of newer, more environmentally friendly battery technologies. This potential delay in upgrading to more sustainable options needs to be balanced against the immediate benefits of extended battery life.

In the context of grid energy storage, extended battery life through BMS can enhance the integration of renewable energy sources. By providing more reliable and long-lasting energy storage solutions, these systems can help mitigate the intermittency issues associated with solar and wind power, thereby supporting the transition to cleaner energy sources.

Lastly, the environmental impact extends to consumer behavior and product design. Longer-lasting batteries may encourage the development of more durable and repairable electronic devices, potentially shifting consumer attitudes away from the current "throwaway" culture. This change could lead to a broader reduction in electronic waste and promote more sustainable consumption patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!