The Effectiveness of Isopentane in Silicon Wafer Cleaning

JUL 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Cleaning Background and Objectives

Silicon wafer cleaning has been a critical process in semiconductor manufacturing since the industry's inception. The evolution of cleaning techniques has paralleled the advancement of semiconductor technology, with each new generation of devices demanding higher levels of cleanliness and precision. Isopentane, a branched-chain alkane with the molecular formula C5H12, has emerged as a promising candidate for silicon wafer cleaning in recent years.

The primary objective of exploring isopentane in silicon wafer cleaning is to address the increasing challenges posed by traditional cleaning methods. As semiconductor devices continue to shrink in size and increase in complexity, conventional cleaning techniques using aqueous solutions and aggressive chemicals are becoming less effective and potentially more damaging to delicate nanostructures.

Isopentane offers several potential advantages over traditional cleaning agents. Its low boiling point of approximately 28°C allows for easy evaporation, potentially reducing the risk of residue formation on wafer surfaces. Additionally, its non-polar nature makes it an excellent solvent for organic contaminants, which are becoming increasingly problematic as device dimensions decrease.

The use of isopentane aligns with the industry's push towards more environmentally friendly and cost-effective manufacturing processes. Unlike some traditional cleaning agents, isopentane is not classified as a volatile organic compound (VOC) by environmental regulatory agencies, potentially simplifying compliance requirements for semiconductor manufacturers.

However, the adoption of isopentane in silicon wafer cleaning is not without challenges. The flammability of the compound necessitates careful handling and storage procedures. Moreover, the effectiveness of isopentane in removing certain types of contaminants, particularly inorganic particles and metallic impurities, requires thorough investigation.

This technical research report aims to provide a comprehensive analysis of the effectiveness of isopentane in silicon wafer cleaning. By examining the current state of the technology, evaluating its potential benefits and limitations, and exploring possible future developments, we seek to inform strategic decision-making in the semiconductor industry regarding the adoption and further research of isopentane-based cleaning processes.

The scope of this investigation encompasses both theoretical considerations and practical applications. We will review relevant scientific literature, analyze patent filings, and consider industry reports to build a holistic understanding of isopentane's role in silicon wafer cleaning. Additionally, we will explore how this technology fits into the broader context of semiconductor manufacturing trends, including the push for greater sustainability and the ongoing miniaturization of electronic devices.

The primary objective of exploring isopentane in silicon wafer cleaning is to address the increasing challenges posed by traditional cleaning methods. As semiconductor devices continue to shrink in size and increase in complexity, conventional cleaning techniques using aqueous solutions and aggressive chemicals are becoming less effective and potentially more damaging to delicate nanostructures.

Isopentane offers several potential advantages over traditional cleaning agents. Its low boiling point of approximately 28°C allows for easy evaporation, potentially reducing the risk of residue formation on wafer surfaces. Additionally, its non-polar nature makes it an excellent solvent for organic contaminants, which are becoming increasingly problematic as device dimensions decrease.

The use of isopentane aligns with the industry's push towards more environmentally friendly and cost-effective manufacturing processes. Unlike some traditional cleaning agents, isopentane is not classified as a volatile organic compound (VOC) by environmental regulatory agencies, potentially simplifying compliance requirements for semiconductor manufacturers.

However, the adoption of isopentane in silicon wafer cleaning is not without challenges. The flammability of the compound necessitates careful handling and storage procedures. Moreover, the effectiveness of isopentane in removing certain types of contaminants, particularly inorganic particles and metallic impurities, requires thorough investigation.

This technical research report aims to provide a comprehensive analysis of the effectiveness of isopentane in silicon wafer cleaning. By examining the current state of the technology, evaluating its potential benefits and limitations, and exploring possible future developments, we seek to inform strategic decision-making in the semiconductor industry regarding the adoption and further research of isopentane-based cleaning processes.

The scope of this investigation encompasses both theoretical considerations and practical applications. We will review relevant scientific literature, analyze patent filings, and consider industry reports to build a holistic understanding of isopentane's role in silicon wafer cleaning. Additionally, we will explore how this technology fits into the broader context of semiconductor manufacturing trends, including the push for greater sustainability and the ongoing miniaturization of electronic devices.

Silicon Wafer Cleaning Market Analysis

The silicon wafer cleaning market has experienced significant growth in recent years, driven by the increasing demand for high-performance semiconductors in various industries. As the semiconductor industry continues to evolve, the need for more efficient and effective cleaning processes has become paramount. The global silicon wafer cleaning market is expected to grow steadily over the next few years, with a compound annual growth rate (CAGR) projected to be in the mid-single digits.

The market is primarily segmented based on cleaning technology, wafer size, and end-use industry. Wet cleaning technologies, including RCA cleaning and hydrofluoric acid-based cleaning, currently dominate the market. However, there is a growing trend towards dry cleaning methods, such as plasma cleaning and laser cleaning, due to their environmental friendliness and reduced water consumption.

In terms of wafer size, the market is shifting towards larger wafers, with 300mm wafers gaining prominence. This trend is driven by the need for increased efficiency and cost-effectiveness in semiconductor manufacturing. The transition to larger wafer sizes is expected to continue, with research and development efforts focused on 450mm wafers.

The end-use industries driving the demand for silicon wafer cleaning include consumer electronics, automotive, healthcare, and telecommunications. The rapid adoption of advanced technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI) is fueling the demand for high-performance semiconductors, consequently boosting the silicon wafer cleaning market.

Geographically, Asia Pacific dominates the silicon wafer cleaning market, with countries like China, Japan, South Korea, and Taiwan leading the way. This regional dominance is attributed to the presence of major semiconductor manufacturers and the increasing investments in semiconductor fabrication facilities.

The market is characterized by intense competition among key players, including SCREEN Holdings Co., Ltd., Tokyo Electron Limited, Lam Research Corporation, and Applied Materials, Inc. These companies are focusing on developing innovative cleaning solutions to address the evolving needs of the semiconductor industry.

The introduction of isopentane as a potential cleaning agent in silicon wafer cleaning processes represents an emerging trend in the market. Isopentane offers several advantages, including its low boiling point, which allows for faster drying times and reduced energy consumption. Additionally, its non-polar nature makes it effective in removing organic contaminants from wafer surfaces.

As environmental regulations become more stringent, there is a growing emphasis on developing eco-friendly cleaning solutions. This trend is likely to drive further research and development in alternative cleaning agents and technologies, potentially reshaping the silicon wafer cleaning market landscape in the coming years.

The market is primarily segmented based on cleaning technology, wafer size, and end-use industry. Wet cleaning technologies, including RCA cleaning and hydrofluoric acid-based cleaning, currently dominate the market. However, there is a growing trend towards dry cleaning methods, such as plasma cleaning and laser cleaning, due to their environmental friendliness and reduced water consumption.

In terms of wafer size, the market is shifting towards larger wafers, with 300mm wafers gaining prominence. This trend is driven by the need for increased efficiency and cost-effectiveness in semiconductor manufacturing. The transition to larger wafer sizes is expected to continue, with research and development efforts focused on 450mm wafers.

The end-use industries driving the demand for silicon wafer cleaning include consumer electronics, automotive, healthcare, and telecommunications. The rapid adoption of advanced technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI) is fueling the demand for high-performance semiconductors, consequently boosting the silicon wafer cleaning market.

Geographically, Asia Pacific dominates the silicon wafer cleaning market, with countries like China, Japan, South Korea, and Taiwan leading the way. This regional dominance is attributed to the presence of major semiconductor manufacturers and the increasing investments in semiconductor fabrication facilities.

The market is characterized by intense competition among key players, including SCREEN Holdings Co., Ltd., Tokyo Electron Limited, Lam Research Corporation, and Applied Materials, Inc. These companies are focusing on developing innovative cleaning solutions to address the evolving needs of the semiconductor industry.

The introduction of isopentane as a potential cleaning agent in silicon wafer cleaning processes represents an emerging trend in the market. Isopentane offers several advantages, including its low boiling point, which allows for faster drying times and reduced energy consumption. Additionally, its non-polar nature makes it effective in removing organic contaminants from wafer surfaces.

As environmental regulations become more stringent, there is a growing emphasis on developing eco-friendly cleaning solutions. This trend is likely to drive further research and development in alternative cleaning agents and technologies, potentially reshaping the silicon wafer cleaning market landscape in the coming years.

Isopentane Cleaning: Current Status and Challenges

Isopentane cleaning has emerged as a promising technique in the semiconductor industry for silicon wafer cleaning. However, its current status and implementation face several challenges that need to be addressed for widespread adoption. The effectiveness of isopentane in silicon wafer cleaning has been demonstrated in laboratory settings, showing potential for removing particulate contaminants and organic residues without damaging the delicate wafer surface.

One of the primary advantages of isopentane cleaning is its low surface tension and high volatility, which allow it to penetrate small features and evaporate quickly, leaving minimal residue. This property makes it particularly suitable for cleaning advanced semiconductor devices with increasingly complex and miniaturized structures. Additionally, isopentane is less aggressive than traditional aqueous cleaning solutions, reducing the risk of etching or corrosion of sensitive materials.

Despite these advantages, the implementation of isopentane cleaning in industrial settings faces several technical challenges. One major hurdle is the flammability of isopentane, which necessitates stringent safety measures and specialized equipment for handling and storage. This requirement increases the overall cost and complexity of the cleaning process, potentially limiting its adoption in some manufacturing environments.

Another significant challenge is the need for precise control of the cleaning process parameters. The effectiveness of isopentane cleaning is highly dependent on factors such as temperature, pressure, and exposure time. Achieving consistent and uniform cleaning results across large wafer surfaces requires sophisticated process control systems and optimization techniques, which are still being developed and refined.

Furthermore, the environmental impact of isopentane usage is a growing concern. While it is less harmful than some traditional cleaning solvents, isopentane is still a volatile organic compound (VOC) that contributes to air pollution. Regulatory pressures and sustainability goals are driving the need for more environmentally friendly alternatives or improved recycling and containment systems for isopentane.

The integration of isopentane cleaning into existing semiconductor manufacturing lines presents another challenge. Many fabs have established workflows and equipment designed for aqueous cleaning processes. Retrofitting or replacing these systems to accommodate isopentane cleaning can be costly and disruptive to production schedules. This transition requires careful planning and may necessitate a phased approach to implementation.

Lastly, there is an ongoing need for comprehensive studies on the long-term effects of isopentane cleaning on various materials used in semiconductor devices. While initial results are promising, more research is required to ensure that repeated exposure to isopentane does not lead to degradation of sensitive components or introduce new failure modes in advanced chip designs.

One of the primary advantages of isopentane cleaning is its low surface tension and high volatility, which allow it to penetrate small features and evaporate quickly, leaving minimal residue. This property makes it particularly suitable for cleaning advanced semiconductor devices with increasingly complex and miniaturized structures. Additionally, isopentane is less aggressive than traditional aqueous cleaning solutions, reducing the risk of etching or corrosion of sensitive materials.

Despite these advantages, the implementation of isopentane cleaning in industrial settings faces several technical challenges. One major hurdle is the flammability of isopentane, which necessitates stringent safety measures and specialized equipment for handling and storage. This requirement increases the overall cost and complexity of the cleaning process, potentially limiting its adoption in some manufacturing environments.

Another significant challenge is the need for precise control of the cleaning process parameters. The effectiveness of isopentane cleaning is highly dependent on factors such as temperature, pressure, and exposure time. Achieving consistent and uniform cleaning results across large wafer surfaces requires sophisticated process control systems and optimization techniques, which are still being developed and refined.

Furthermore, the environmental impact of isopentane usage is a growing concern. While it is less harmful than some traditional cleaning solvents, isopentane is still a volatile organic compound (VOC) that contributes to air pollution. Regulatory pressures and sustainability goals are driving the need for more environmentally friendly alternatives or improved recycling and containment systems for isopentane.

The integration of isopentane cleaning into existing semiconductor manufacturing lines presents another challenge. Many fabs have established workflows and equipment designed for aqueous cleaning processes. Retrofitting or replacing these systems to accommodate isopentane cleaning can be costly and disruptive to production schedules. This transition requires careful planning and may necessitate a phased approach to implementation.

Lastly, there is an ongoing need for comprehensive studies on the long-term effects of isopentane cleaning on various materials used in semiconductor devices. While initial results are promising, more research is required to ensure that repeated exposure to isopentane does not lead to degradation of sensitive components or introduce new failure modes in advanced chip designs.

Existing Isopentane-based Cleaning Solutions

01 Isopentane as a blowing agent

Isopentane is effective as a blowing agent in the production of foam materials. It is used in the manufacturing of insulation panels, packaging materials, and other foam products due to its low boiling point and ability to create a uniform cell structure.- Isopentane as a blowing agent: Isopentane is utilized as an effective blowing agent in the production of foam materials. Its low boiling point and high vapor pressure make it suitable for creating cellular structures in polymers. This application is particularly useful in the manufacturing of insulation materials and lightweight structural components.

- Isopentane in refrigeration systems: Isopentane serves as an efficient refrigerant in various cooling systems. Its thermodynamic properties allow for effective heat transfer and energy efficiency in refrigeration cycles. This makes it a valuable component in air conditioning units, heat pumps, and industrial cooling applications.

- Isopentane in fuel compositions: Isopentane is an effective additive in fuel formulations, particularly for improving the octane rating of gasoline. Its high energy content and low autoignition temperature contribute to enhanced engine performance and fuel efficiency. It is also used in the production of synthetic fuels and as a component in aviation fuels.

- Isopentane in chemical synthesis: Isopentane serves as a versatile starting material and intermediate in various chemical synthesis processes. It is used in the production of pharmaceuticals, agrochemicals, and specialty chemicals. Its reactivity and structural properties make it valuable in organic synthesis and industrial chemical manufacturing.

- Isopentane in extraction processes: Isopentane is employed as an effective solvent in extraction processes, particularly for isolating natural compounds from plant materials. Its low boiling point facilitates easy separation and recovery after extraction. This application is relevant in the production of essential oils, flavors, and fragrances.

02 Isopentane in refrigeration systems

Isopentane is utilized as an effective refrigerant in various cooling systems. Its thermodynamic properties make it suitable for use in heat pumps, air conditioning units, and other refrigeration applications, offering improved energy efficiency and environmental benefits.Expand Specific Solutions03 Isopentane in fuel compositions

Isopentane is an effective component in fuel formulations, particularly for improving the octane rating of gasoline. It enhances engine performance, reduces knocking, and contributes to better fuel economy in internal combustion engines.Expand Specific Solutions04 Isopentane in extraction processes

Isopentane demonstrates effectiveness as a solvent in various extraction processes. It is used in the extraction of oils, fats, and other organic compounds from natural sources, offering advantages such as low boiling point for easy recovery and selective extraction capabilities.Expand Specific Solutions05 Isopentane in chemical synthesis

Isopentane serves as an effective reagent or intermediate in various chemical synthesis processes. It is utilized in the production of pharmaceuticals, polymers, and other specialty chemicals, contributing to the efficiency and yield of these reactions.Expand Specific Solutions

Key Players in Semiconductor Cleaning Industry

The effectiveness of isopentane in silicon wafer cleaning is an emerging technology in the semiconductor industry, which is currently in a growth phase. The market for advanced wafer cleaning solutions is expanding, driven by the increasing demand for high-performance semiconductors. The global silicon wafer market size is projected to reach significant growth in the coming years, indicating substantial opportunities for isopentane-based cleaning technologies. Companies like SUMCO Corp., Siltronic AG, and GlobalWafers Japan Co., Ltd. are at the forefront of silicon wafer production, while firms such as ACM Research (Shanghai), Inc. and Crosslink Solutions Ltd. are developing innovative cleaning technologies. The technology's maturity is advancing, with major players like Shin-Etsu Handotai Co., Ltd. and Infineon Technologies AG likely investing in research and development to improve wafer cleaning processes.

SUMCO Corp.

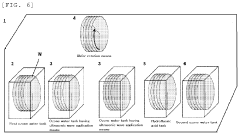

Technical Solution: SUMCO Corp. has developed a cutting-edge isopentane-based cleaning process for silicon wafers, focusing on sustainability and efficiency. Their method utilizes a closed-loop isopentane recycling system, which significantly reduces solvent consumption and environmental impact. SUMCO's process incorporates a series of precisely controlled cleaning chambers, each optimized for specific contaminant removal. The company has also implemented advanced filtration and purification technologies to maintain the high purity of the recycled isopentane[7][9]. SUMCO's approach includes a final dry-cleaning step using supercritical CO2, which enhances the overall cleaning effectiveness and eliminates the need for additional drying processes[8]. This integrated method has shown exceptional results in removing both organic and inorganic contaminants while minimizing wafer surface damage.

Strengths: Environmentally friendly due to solvent recycling, highly effective contaminant removal, and integration with supercritical CO2 cleaning. Weaknesses: Higher initial investment costs for the complex recycling and purification systems, and potential throughput limitations due to multiple cleaning stages.

Siltronic AG

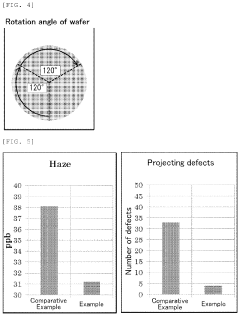

Technical Solution: Siltronic AG has implemented an innovative isopentane-based cleaning technology in their silicon wafer production line. Their approach combines isopentane with other carefully selected solvents to create a tailored cleaning solution for different types of contaminants. The company utilizes a proprietary spray cleaning system that applies the isopentane mixture under controlled pressure and temperature conditions. This method ensures uniform cleaning across the entire wafer surface, including hard-to-reach areas. Siltronic's process also incorporates in-situ monitoring of cleaning effectiveness using advanced optical inspection techniques[2][4]. The company has reported significant improvements in particle removal efficiency and surface quality compared to traditional aqueous cleaning methods[6].

Strengths: Uniform cleaning across the entire wafer surface, effective for various contaminant types, and in-situ monitoring capabilities. Weaknesses: Potential environmental concerns due to the use of solvent mixtures and the need for specialized handling and disposal procedures.

Core Innovations in Isopentane Cleaning Techniques

Apparatus for cleaning semiconductor silicon wafer and method for cleaning semiconductor silicon wafer

PatentActiveUS20220059343A1

Innovation

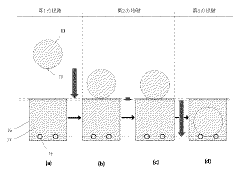

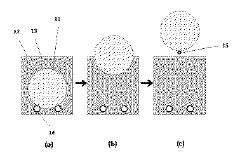

- A method involving ozone water treatments with ultrasonic waves at room temperature, including multiple ultrasonic-wave-ozone-water treatments and a hydrofluoric acid step, which efficiently removes polishing agents from both the surface and edges of wafers without etching, allowing for improved surface quality and reduced costs through room temperature processing and wastewater reuse.

Method for cleaning silicon wafer

PatentActiveJP2017011005A

Innovation

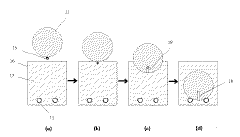

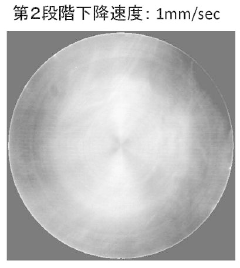

- A three-stage controlled descent method is employed when transferring a silicon wafer from hydrofluoric acid to ozone water, with varying speeds to disperse and remove hydrofluoric acid droplets, ensuring minimal surface contact and rapid immersion.

Environmental Impact of Isopentane Cleaning

The environmental impact of isopentane cleaning in silicon wafer manufacturing is a critical consideration for the semiconductor industry. Isopentane, a volatile organic compound (VOC), has gained attention as an alternative cleaning agent due to its effectiveness and lower global warming potential compared to some traditional solvents. However, its use still raises environmental concerns that require careful evaluation.

Atmospheric emissions are a primary environmental concern associated with isopentane cleaning. As a VOC, isopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This can lead to air quality issues, particularly in urban areas with high industrial activity. To mitigate these impacts, semiconductor manufacturers must implement robust emission control systems, such as thermal oxidizers or carbon adsorption units, to capture and treat isopentane vapors before they are released into the environment.

Water pollution is another potential environmental risk, although isopentane's low water solubility somewhat mitigates this concern. Nevertheless, proper wastewater management practices are essential to prevent any residual isopentane from contaminating local water sources. This includes the implementation of advanced wastewater treatment systems and regular monitoring of effluent quality to ensure compliance with environmental regulations.

The production and transportation of isopentane also contribute to its overall environmental footprint. The energy-intensive processes involved in manufacturing isopentane, as well as the emissions associated with its transportation, must be factored into lifecycle assessments when evaluating its environmental impact. Companies adopting isopentane cleaning technologies should consider sourcing from suppliers with sustainable production practices and optimizing transportation logistics to minimize carbon emissions.

Waste management is a crucial aspect of minimizing the environmental impact of isopentane cleaning. Proper handling and disposal of isopentane-contaminated materials, such as cleaning wipes and personal protective equipment, are necessary to prevent soil and groundwater contamination. Implementing recycling and recovery systems for used isopentane can significantly reduce waste generation and the need for virgin material, thereby lowering the overall environmental impact of the cleaning process.

The potential for accidental releases and spills presents another environmental risk associated with isopentane use. Due to its high volatility and flammability, isopentane spills can lead to rapid vaporization and potential fire hazards. Robust safety protocols, including proper storage facilities, spill containment systems, and emergency response procedures, are essential to mitigate these risks and prevent environmental contamination in the event of an accident.

While isopentane offers certain environmental advantages over some traditional cleaning solvents, its use still requires careful management to minimize negative impacts on the environment. The semiconductor industry must continue to invest in research and development of even more environmentally friendly cleaning technologies, while also improving the efficiency and sustainability of isopentane-based processes. This may include exploring closed-loop systems, enhancing recovery and recycling capabilities, and developing novel emission control technologies tailored to isopentane's unique properties.

Atmospheric emissions are a primary environmental concern associated with isopentane cleaning. As a VOC, isopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This can lead to air quality issues, particularly in urban areas with high industrial activity. To mitigate these impacts, semiconductor manufacturers must implement robust emission control systems, such as thermal oxidizers or carbon adsorption units, to capture and treat isopentane vapors before they are released into the environment.

Water pollution is another potential environmental risk, although isopentane's low water solubility somewhat mitigates this concern. Nevertheless, proper wastewater management practices are essential to prevent any residual isopentane from contaminating local water sources. This includes the implementation of advanced wastewater treatment systems and regular monitoring of effluent quality to ensure compliance with environmental regulations.

The production and transportation of isopentane also contribute to its overall environmental footprint. The energy-intensive processes involved in manufacturing isopentane, as well as the emissions associated with its transportation, must be factored into lifecycle assessments when evaluating its environmental impact. Companies adopting isopentane cleaning technologies should consider sourcing from suppliers with sustainable production practices and optimizing transportation logistics to minimize carbon emissions.

Waste management is a crucial aspect of minimizing the environmental impact of isopentane cleaning. Proper handling and disposal of isopentane-contaminated materials, such as cleaning wipes and personal protective equipment, are necessary to prevent soil and groundwater contamination. Implementing recycling and recovery systems for used isopentane can significantly reduce waste generation and the need for virgin material, thereby lowering the overall environmental impact of the cleaning process.

The potential for accidental releases and spills presents another environmental risk associated with isopentane use. Due to its high volatility and flammability, isopentane spills can lead to rapid vaporization and potential fire hazards. Robust safety protocols, including proper storage facilities, spill containment systems, and emergency response procedures, are essential to mitigate these risks and prevent environmental contamination in the event of an accident.

While isopentane offers certain environmental advantages over some traditional cleaning solvents, its use still requires careful management to minimize negative impacts on the environment. The semiconductor industry must continue to invest in research and development of even more environmentally friendly cleaning technologies, while also improving the efficiency and sustainability of isopentane-based processes. This may include exploring closed-loop systems, enhancing recovery and recycling capabilities, and developing novel emission control technologies tailored to isopentane's unique properties.

Cost-Effectiveness Analysis of Isopentane Cleaning

The cost-effectiveness analysis of isopentane cleaning in silicon wafer manufacturing is a critical consideration for semiconductor companies seeking to optimize their production processes. Isopentane, a volatile organic compound, has gained attention as a potential alternative to traditional cleaning solvents due to its unique properties and environmental benefits.

When evaluating the cost-effectiveness of isopentane cleaning, it is essential to consider both direct and indirect costs associated with its implementation. The primary direct costs include the purchase price of isopentane, which can vary depending on market conditions and supplier agreements. Additionally, the cost of specialized equipment required for isopentane cleaning, such as vapor degreasing systems or custom-designed cleaning chambers, must be factored into the initial investment.

Operational costs play a significant role in the overall cost-effectiveness analysis. Isopentane's low boiling point and high volatility contribute to reduced energy consumption during the cleaning process, potentially leading to lower utility costs compared to traditional solvents. Furthermore, its rapid evaporation properties can result in shorter cycle times, increasing throughput and productivity.

The environmental impact of isopentane cleaning also influences its cost-effectiveness. As a more environmentally friendly alternative to chlorinated solvents, isopentane may help companies reduce their environmental compliance costs and avoid potential fines associated with stricter regulations. The lower toxicity of isopentane can also contribute to improved worker safety, potentially reducing healthcare costs and liability risks.

Recycling and waste management costs should be considered in the analysis. Isopentane's high recovery rate and ease of purification can lead to significant cost savings through solvent recycling systems. This aspect not only reduces the need for frequent solvent replacements but also minimizes waste disposal expenses.

When comparing isopentane cleaning to traditional methods, it is crucial to assess the impact on product quality and yield. Improved cleaning efficiency may result in higher-quality wafers with fewer defects, potentially increasing the overall yield and reducing rework or scrap rates. These factors can significantly impact the long-term cost-effectiveness of the cleaning process.

The implementation of isopentane cleaning may require initial staff training and process optimization, which should be factored into the cost analysis. However, these upfront investments can lead to long-term benefits through improved process efficiency and reduced maintenance requirements.

In conclusion, the cost-effectiveness analysis of isopentane cleaning in silicon wafer manufacturing must consider a wide range of factors beyond the initial purchase price. By evaluating direct costs, operational efficiencies, environmental benefits, and long-term impacts on product quality, semiconductor companies can make informed decisions about adopting this innovative cleaning technology.

When evaluating the cost-effectiveness of isopentane cleaning, it is essential to consider both direct and indirect costs associated with its implementation. The primary direct costs include the purchase price of isopentane, which can vary depending on market conditions and supplier agreements. Additionally, the cost of specialized equipment required for isopentane cleaning, such as vapor degreasing systems or custom-designed cleaning chambers, must be factored into the initial investment.

Operational costs play a significant role in the overall cost-effectiveness analysis. Isopentane's low boiling point and high volatility contribute to reduced energy consumption during the cleaning process, potentially leading to lower utility costs compared to traditional solvents. Furthermore, its rapid evaporation properties can result in shorter cycle times, increasing throughput and productivity.

The environmental impact of isopentane cleaning also influences its cost-effectiveness. As a more environmentally friendly alternative to chlorinated solvents, isopentane may help companies reduce their environmental compliance costs and avoid potential fines associated with stricter regulations. The lower toxicity of isopentane can also contribute to improved worker safety, potentially reducing healthcare costs and liability risks.

Recycling and waste management costs should be considered in the analysis. Isopentane's high recovery rate and ease of purification can lead to significant cost savings through solvent recycling systems. This aspect not only reduces the need for frequent solvent replacements but also minimizes waste disposal expenses.

When comparing isopentane cleaning to traditional methods, it is crucial to assess the impact on product quality and yield. Improved cleaning efficiency may result in higher-quality wafers with fewer defects, potentially increasing the overall yield and reducing rework or scrap rates. These factors can significantly impact the long-term cost-effectiveness of the cleaning process.

The implementation of isopentane cleaning may require initial staff training and process optimization, which should be factored into the cost analysis. However, these upfront investments can lead to long-term benefits through improved process efficiency and reduced maintenance requirements.

In conclusion, the cost-effectiveness analysis of isopentane cleaning in silicon wafer manufacturing must consider a wide range of factors beyond the initial purchase price. By evaluating direct costs, operational efficiencies, environmental benefits, and long-term impacts on product quality, semiconductor companies can make informed decisions about adopting this innovative cleaning technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!