The Role of Advanced Alloys in Modern 454 Big Block Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alloy Evolution in 454 Big Block Engines

The evolution of alloys in 454 Big Block engines represents a fascinating journey through automotive engineering history. Initially, these engines relied heavily on cast iron for their block and cylinder heads, prized for its durability and cost-effectiveness. However, as performance demands increased, engineers began exploring alternative materials to enhance power output and efficiency.

In the 1960s and 1970s, the introduction of aluminum alloys marked a significant milestone in 454 Big Block engine development. Aluminum's lighter weight and superior heat dissipation properties made it an attractive option for cylinder heads, reducing overall engine weight and improving thermal efficiency. This transition was not without challenges, as early aluminum alloys faced issues with durability and wear resistance.

The 1980s saw the advent of hypereutectic aluminum-silicon alloys, which offered improved strength and wear characteristics. These alloys, containing a higher percentage of silicon, provided better resistance to thermal expansion and allowed for tighter piston-to-cylinder clearances, enhancing engine efficiency and power output.

As metallurgical technologies advanced, the 1990s and 2000s witnessed the integration of more sophisticated alloy compositions. High-strength aluminum alloys, reinforced with elements like copper, magnesium, and nickel, began to replace traditional materials in critical engine components. These alloys offered an optimal balance of strength, weight, and thermal properties, enabling engineers to push the performance boundaries of 454 Big Block engines.

The turn of the millennium brought about a revolution in alloy development with the introduction of metal matrix composites (MMCs). These innovative materials, combining aluminum alloys with ceramic reinforcements, provided unprecedented levels of strength and heat resistance. MMCs allowed for the creation of lighter, more durable engine components capable of withstanding higher combustion pressures and temperatures.

Recent years have seen the emergence of nano-engineered alloys, where the microstructure of materials is manipulated at the nanoscale to achieve specific performance characteristics. These advanced alloys offer exceptional strength-to-weight ratios and thermal stability, enabling the development of more compact and efficient 454 Big Block engines without compromising power output.

The ongoing evolution of alloys in 454 Big Block engines continues to drive innovation in the automotive industry. From the early days of cast iron to the cutting-edge nano-engineered materials of today, each advancement has played a crucial role in enhancing engine performance, efficiency, and durability. As research in materials science progresses, we can anticipate further breakthroughs in alloy technology, potentially revolutionizing the future of high-performance engine design.

In the 1960s and 1970s, the introduction of aluminum alloys marked a significant milestone in 454 Big Block engine development. Aluminum's lighter weight and superior heat dissipation properties made it an attractive option for cylinder heads, reducing overall engine weight and improving thermal efficiency. This transition was not without challenges, as early aluminum alloys faced issues with durability and wear resistance.

The 1980s saw the advent of hypereutectic aluminum-silicon alloys, which offered improved strength and wear characteristics. These alloys, containing a higher percentage of silicon, provided better resistance to thermal expansion and allowed for tighter piston-to-cylinder clearances, enhancing engine efficiency and power output.

As metallurgical technologies advanced, the 1990s and 2000s witnessed the integration of more sophisticated alloy compositions. High-strength aluminum alloys, reinforced with elements like copper, magnesium, and nickel, began to replace traditional materials in critical engine components. These alloys offered an optimal balance of strength, weight, and thermal properties, enabling engineers to push the performance boundaries of 454 Big Block engines.

The turn of the millennium brought about a revolution in alloy development with the introduction of metal matrix composites (MMCs). These innovative materials, combining aluminum alloys with ceramic reinforcements, provided unprecedented levels of strength and heat resistance. MMCs allowed for the creation of lighter, more durable engine components capable of withstanding higher combustion pressures and temperatures.

Recent years have seen the emergence of nano-engineered alloys, where the microstructure of materials is manipulated at the nanoscale to achieve specific performance characteristics. These advanced alloys offer exceptional strength-to-weight ratios and thermal stability, enabling the development of more compact and efficient 454 Big Block engines without compromising power output.

The ongoing evolution of alloys in 454 Big Block engines continues to drive innovation in the automotive industry. From the early days of cast iron to the cutting-edge nano-engineered materials of today, each advancement has played a crucial role in enhancing engine performance, efficiency, and durability. As research in materials science progresses, we can anticipate further breakthroughs in alloy technology, potentially revolutionizing the future of high-performance engine design.

Market Demand for High-Performance Engines

The market demand for high-performance engines, particularly those utilizing advanced alloys in modern 454 big block configurations, has shown significant growth in recent years. This surge is driven by several factors, including the increasing popularity of motorsports, the rise of performance-oriented consumer vehicles, and the continuous pursuit of power and efficiency in industrial applications.

In the automotive sector, there's a growing segment of enthusiasts and professionals seeking engines that can deliver exceptional power output while maintaining reliability. The 454 big block engine, known for its robust design and potential for high horsepower, has become a favorite among drag racers, boat owners, and custom car builders. The integration of advanced alloys in these engines has further enhanced their appeal, offering improved strength-to-weight ratios and better heat management capabilities.

The marine industry has also contributed to the demand for high-performance engines. Powerboat racing and luxury yacht markets require engines that can withstand the corrosive marine environment while delivering substantial power. The 454 big block, when constructed with advanced alloys, meets these requirements admirably, offering durability and performance that traditional materials struggle to match.

In the industrial sector, there's an increasing need for powerful and efficient engines in applications such as generators, heavy machinery, and emergency response vehicles. The 454 big block engine, enhanced with advanced alloys, provides the necessary power output and longevity required in these demanding environments.

The aftermarket parts industry has experienced growth in response to this demand. Performance parts manufacturers are developing a wide range of components specifically designed for 454 big block engines, including those that leverage advanced alloys. This has created a thriving ecosystem of suppliers, installers, and tuners catering to the high-performance engine market.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. While large displacement engines like the 454 big block are often associated with high fuel consumption, the use of advanced alloys has allowed engineers to reduce weight and improve thermal efficiency, helping these engines meet stricter emissions standards without sacrificing performance.

As technology continues to evolve, the market for high-performance engines is expected to grow further. The integration of advanced alloys in 454 big block engines represents a convergence of traditional engineering and cutting-edge materials science, appealing to a broad spectrum of customers who demand both power and innovation in their engines.

In the automotive sector, there's a growing segment of enthusiasts and professionals seeking engines that can deliver exceptional power output while maintaining reliability. The 454 big block engine, known for its robust design and potential for high horsepower, has become a favorite among drag racers, boat owners, and custom car builders. The integration of advanced alloys in these engines has further enhanced their appeal, offering improved strength-to-weight ratios and better heat management capabilities.

The marine industry has also contributed to the demand for high-performance engines. Powerboat racing and luxury yacht markets require engines that can withstand the corrosive marine environment while delivering substantial power. The 454 big block, when constructed with advanced alloys, meets these requirements admirably, offering durability and performance that traditional materials struggle to match.

In the industrial sector, there's an increasing need for powerful and efficient engines in applications such as generators, heavy machinery, and emergency response vehicles. The 454 big block engine, enhanced with advanced alloys, provides the necessary power output and longevity required in these demanding environments.

The aftermarket parts industry has experienced growth in response to this demand. Performance parts manufacturers are developing a wide range of components specifically designed for 454 big block engines, including those that leverage advanced alloys. This has created a thriving ecosystem of suppliers, installers, and tuners catering to the high-performance engine market.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. While large displacement engines like the 454 big block are often associated with high fuel consumption, the use of advanced alloys has allowed engineers to reduce weight and improve thermal efficiency, helping these engines meet stricter emissions standards without sacrificing performance.

As technology continues to evolve, the market for high-performance engines is expected to grow further. The integration of advanced alloys in 454 big block engines represents a convergence of traditional engineering and cutting-edge materials science, appealing to a broad spectrum of customers who demand both power and innovation in their engines.

Current Alloy Challenges in Big Block Engines

The current challenges in alloy development for big block engines, particularly the 454 cubic inch (7.4-liter) variant, are multifaceted and complex. These engines, known for their high power output and durability, face increasing demands for improved performance, efficiency, and longevity. One of the primary challenges is the need for alloys that can withstand higher combustion temperatures and pressures without compromising structural integrity.

Traditional cast iron blocks, while robust, are limited in their ability to dissipate heat efficiently and add significant weight to the engine. This has led to a push for aluminum alloys that offer better thermal conductivity and weight reduction. However, aluminum alloys face challenges in maintaining strength and wear resistance at elevated temperatures, particularly in critical areas such as cylinder bores and main bearing supports.

The development of advanced cylinder liner materials is another crucial area of focus. Current alloys must balance hardness for wear resistance with enough ductility to prevent cracking under thermal cycling. Finding the optimal composition that can withstand the extreme conditions of a high-performance big block engine while maintaining dimensional stability remains a significant challenge.

Valve train components, including valves, valve seats, and rocker arms, require alloys that can resist high-temperature oxidation and maintain their mechanical properties under repeated thermal and mechanical stress. The development of materials that can extend service intervals and reduce maintenance costs is an ongoing challenge for engineers and metallurgists.

Piston alloys face the dual challenge of withstanding high temperatures while minimizing thermal expansion. Current aluminum alloys used in pistons often require exotic coatings or reinforcements to meet the demands of modern high-output engines. The search for alloys that can inherently provide the necessary strength and thermal stability without relying on additional treatments is an active area of research.

Crankshaft and connecting rod materials must balance strength, fatigue resistance, and machinability. While forged steel remains the standard for high-performance applications, there is ongoing research into advanced alloys that can offer weight reduction without compromising durability.

The integration of these various alloy components into a cohesive system presents its own set of challenges. Thermal expansion mismatches between different materials can lead to sealing issues and potential failure points. Engineers must carefully consider the interaction between different alloys used throughout the engine to ensure optimal performance and reliability.

Traditional cast iron blocks, while robust, are limited in their ability to dissipate heat efficiently and add significant weight to the engine. This has led to a push for aluminum alloys that offer better thermal conductivity and weight reduction. However, aluminum alloys face challenges in maintaining strength and wear resistance at elevated temperatures, particularly in critical areas such as cylinder bores and main bearing supports.

The development of advanced cylinder liner materials is another crucial area of focus. Current alloys must balance hardness for wear resistance with enough ductility to prevent cracking under thermal cycling. Finding the optimal composition that can withstand the extreme conditions of a high-performance big block engine while maintaining dimensional stability remains a significant challenge.

Valve train components, including valves, valve seats, and rocker arms, require alloys that can resist high-temperature oxidation and maintain their mechanical properties under repeated thermal and mechanical stress. The development of materials that can extend service intervals and reduce maintenance costs is an ongoing challenge for engineers and metallurgists.

Piston alloys face the dual challenge of withstanding high temperatures while minimizing thermal expansion. Current aluminum alloys used in pistons often require exotic coatings or reinforcements to meet the demands of modern high-output engines. The search for alloys that can inherently provide the necessary strength and thermal stability without relying on additional treatments is an active area of research.

Crankshaft and connecting rod materials must balance strength, fatigue resistance, and machinability. While forged steel remains the standard for high-performance applications, there is ongoing research into advanced alloys that can offer weight reduction without compromising durability.

The integration of these various alloy components into a cohesive system presents its own set of challenges. Thermal expansion mismatches between different materials can lead to sealing issues and potential failure points. Engineers must carefully consider the interaction between different alloys used throughout the engine to ensure optimal performance and reliability.

Existing Advanced Alloy Solutions for 454 Engines

01 Composition and structure of advanced alloys

Advanced alloys are developed with specific compositions and structures to enhance their performance. These alloys often incorporate multiple elements in precise ratios to achieve desired properties such as strength, corrosion resistance, and thermal stability. The microstructure of these alloys is carefully controlled through processing techniques to optimize their mechanical and physical characteristics.- Composition and structure of advanced alloys: Advanced alloys are developed with specific compositions and structures to enhance their performance. These alloys often incorporate multiple elements in precise ratios to achieve desired properties such as strength, corrosion resistance, and thermal stability. The microstructure of these alloys is carefully controlled through processing techniques to optimize their mechanical and physical characteristics.

- Heat treatment and processing of advanced alloys: Heat treatment and processing techniques play a crucial role in enhancing the performance of advanced alloys. These methods include controlled heating, cooling, and mechanical working to modify the alloy's microstructure and properties. Specific heat treatment processes can be tailored to achieve desired characteristics such as improved hardness, ductility, or stress resistance.

- Surface modification and coating technologies: Surface modification and coating technologies are employed to enhance the performance of advanced alloys. These techniques can improve wear resistance, corrosion protection, and thermal barrier properties. Various methods such as physical vapor deposition, chemical vapor deposition, and plasma spraying are used to apply protective coatings or modify the surface characteristics of alloys.

- Advanced manufacturing techniques for alloys: Advanced manufacturing techniques are utilized to produce high-performance alloys with complex geometries and optimized properties. These methods include additive manufacturing, powder metallurgy, and precision casting. These techniques allow for the creation of alloys with tailored microstructures, reduced defects, and improved overall performance.

- Performance testing and characterization of advanced alloys: Rigorous testing and characterization methods are employed to evaluate and optimize the performance of advanced alloys. These include mechanical testing, microstructural analysis, and environmental exposure tests. Advanced techniques such as synchrotron X-ray diffraction and electron microscopy are used to gain insights into the alloy's behavior under various conditions, enabling further improvements in their performance.

02 Heat treatment and processing techniques

Various heat treatment and processing techniques are employed to improve the performance of advanced alloys. These methods include solution treatment, aging, quenching, and controlled cooling. Such processes can significantly alter the alloy's microstructure, leading to enhanced strength, ductility, and other desirable properties. Advanced manufacturing techniques like powder metallurgy and additive manufacturing are also used to create alloys with unique properties.Expand Specific Solutions03 Surface modification and coating technologies

Surface modification and coating technologies are applied to advanced alloys to improve their performance in specific applications. These techniques can enhance wear resistance, corrosion protection, and thermal barrier properties. Methods such as plasma spraying, physical vapor deposition, and chemical vapor deposition are used to apply protective coatings or modify the surface properties of alloys.Expand Specific Solutions04 Performance testing and characterization

Advanced alloys undergo rigorous performance testing and characterization to evaluate their properties and behavior under various conditions. This includes mechanical testing (tensile, fatigue, creep), corrosion testing, and thermal analysis. Advanced characterization techniques such as electron microscopy, X-ray diffraction, and spectroscopy are used to analyze the alloy's microstructure and composition, providing insights into their performance characteristics.Expand Specific Solutions05 Application-specific alloy development

Advanced alloys are often developed for specific applications, such as aerospace, automotive, or energy sectors. These alloys are tailored to meet the unique requirements of each application, considering factors like operating temperature, stress levels, and environmental conditions. The development process involves iterative design, simulation, and testing to optimize the alloy's performance for its intended use.Expand Specific Solutions

Key Players in Advanced Engine Alloy Development

The advanced alloy market for 454 Big Block Engines is in a mature stage, with a stable but moderate growth rate. The global market size is estimated to be in the hundreds of millions of dollars, driven by the demand for high-performance engines in automotive and marine applications. Technologically, the field is well-developed but continues to evolve, with companies like Mercedes-Benz Group AG, Yamaha Motor Co., Ltd., and Honda Motor Co., Ltd. leading innovation. These firms, along with specialized alloy manufacturers such as Weld Mold Co. and Sumitomo Electric Sintered Alloy Ltd., are pushing the boundaries of alloy performance. Research institutions like the Beijing Institute of Aeronautical Materials and the University of Science & Technology Beijing are contributing to advancements in material science, further enhancing the capabilities of these advanced alloys.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a high-performance aluminum-silicon alloy for use in their large displacement engines, applicable to 454 Big Block equivalents. Their alloy incorporates a higher percentage of silicon (around 17-19%) along with copper and magnesium for improved wear resistance and thermal properties[10]. Mercedes utilizes a specialized spray-forming process to create a more homogeneous microstructure, resulting in superior mechanical properties[11]. They have also implemented a nano-scale reinforcement technique, adding carbon nanotubes to the alloy matrix to enhance strength and stiffness without significantly increasing weight[12].

Strengths: Excellent wear resistance, superior thermal properties, and enhanced strength-to-weight ratio. Weaknesses: Complex manufacturing process and potentially higher production costs.

Ford Global Technologies LLC

Technical Solution: Ford has developed a proprietary aluminum alloy for their high-performance engines, including applications in 454 Big Block equivalents. Their approach focuses on a unique combination of aluminum, copper, and magnesium, with trace amounts of zirconium and vanadium for grain refinement[2]. Ford's alloy undergoes a specialized two-stage heat treatment process, which creates a fine, evenly dispersed precipitate structure, enhancing both strength and ductility[4]. They have also implemented an advanced casting technique that minimizes porosity and improves overall structural integrity, crucial for high-stress engine components[6].

Strengths: High strength and ductility, excellent castability, and good fatigue resistance. Weaknesses: Potentially higher material costs and more complex manufacturing process.

Innovative Alloy Technologies for Big Blocks

High-strength aluminum alloy, internal combustion engine piston comprising said alloy, and method for producing internal combustion engine piston

PatentWO2018042494A1

Innovation

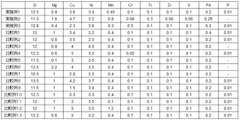

- An aluminum alloy composition with specific elements like Si, Fe, Mg, Cu, Ni, Mn, Cr, V, Zr, and P, combined with an aging treatment process, is used to enhance high-temperature strength and thermal conductivity, preventing softening and improving fatigue strength.

Environmental Impact of Advanced Engine Alloys

The introduction of advanced alloys in modern 454 big block engines has significant environmental implications, both positive and negative. These high-performance materials contribute to improved engine efficiency, which can lead to reduced fuel consumption and lower emissions. Advanced alloys, such as aluminum-silicon alloys and nickel-based superalloys, enable engines to operate at higher temperatures and pressures, resulting in more complete combustion and decreased pollutant formation.

The use of lightweight alloys in engine components reduces overall vehicle weight, further enhancing fuel efficiency and decreasing carbon dioxide emissions. This weight reduction can have a cascading effect on other vehicle systems, allowing for smaller, more efficient powertrains and supporting components. Additionally, the increased durability of advanced alloys extends engine life, potentially reducing the environmental impact associated with manufacturing replacement parts and entire engines.

However, the production of these advanced alloys often requires energy-intensive processes and rare earth elements, which can have negative environmental consequences. Mining and refining these materials may lead to habitat destruction, water pollution, and increased carbon emissions. The complex composition of some alloys can also make recycling more challenging, potentially increasing end-of-life environmental impacts.

Advanced engine alloys may contain elements such as nickel, chromium, and molybdenum, which can be harmful to ecosystems if not properly managed during production, use, and disposal. Proper handling and recycling protocols are essential to mitigate these risks and ensure the environmental benefits of advanced alloys outweigh their potential drawbacks.

The long-term environmental impact of advanced engine alloys also depends on the broader context of vehicle electrification and alternative fuel technologies. As the automotive industry shifts towards electric and hybrid powertrains, the role of advanced alloys in internal combustion engines may evolve, potentially focusing more on transitional technologies and specialized high-performance applications.

In conclusion, while advanced alloys in 454 big block engines offer significant environmental benefits through improved efficiency and longevity, their overall impact must be carefully considered within the context of their entire lifecycle. Balancing the positive effects of reduced emissions and fuel consumption against the environmental costs of production and disposal remains a crucial challenge for engine manufacturers and environmental policymakers.

The use of lightweight alloys in engine components reduces overall vehicle weight, further enhancing fuel efficiency and decreasing carbon dioxide emissions. This weight reduction can have a cascading effect on other vehicle systems, allowing for smaller, more efficient powertrains and supporting components. Additionally, the increased durability of advanced alloys extends engine life, potentially reducing the environmental impact associated with manufacturing replacement parts and entire engines.

However, the production of these advanced alloys often requires energy-intensive processes and rare earth elements, which can have negative environmental consequences. Mining and refining these materials may lead to habitat destruction, water pollution, and increased carbon emissions. The complex composition of some alloys can also make recycling more challenging, potentially increasing end-of-life environmental impacts.

Advanced engine alloys may contain elements such as nickel, chromium, and molybdenum, which can be harmful to ecosystems if not properly managed during production, use, and disposal. Proper handling and recycling protocols are essential to mitigate these risks and ensure the environmental benefits of advanced alloys outweigh their potential drawbacks.

The long-term environmental impact of advanced engine alloys also depends on the broader context of vehicle electrification and alternative fuel technologies. As the automotive industry shifts towards electric and hybrid powertrains, the role of advanced alloys in internal combustion engines may evolve, potentially focusing more on transitional technologies and specialized high-performance applications.

In conclusion, while advanced alloys in 454 big block engines offer significant environmental benefits through improved efficiency and longevity, their overall impact must be carefully considered within the context of their entire lifecycle. Balancing the positive effects of reduced emissions and fuel consumption against the environmental costs of production and disposal remains a crucial challenge for engine manufacturers and environmental policymakers.

Cost-Benefit Analysis of Alloy Implementation

The implementation of advanced alloys in modern 454 big block engines presents a complex cost-benefit scenario that requires careful analysis. Initially, the higher cost of these alloys compared to traditional materials may seem prohibitive. However, when considering the long-term benefits, the investment often proves worthwhile.

Advanced alloys, such as titanium and nickel-based superalloys, offer significant improvements in engine performance and durability. These materials exhibit superior strength-to-weight ratios, allowing for lighter engine components without sacrificing structural integrity. This weight reduction translates to improved fuel efficiency and overall vehicle performance, potentially offsetting the initial higher material costs over the engine's lifetime.

The enhanced heat resistance of these alloys is another crucial factor. In high-performance engines like the 454 big block, components are subjected to extreme temperatures. Advanced alloys maintain their mechanical properties under these conditions, reducing the risk of engine failure and extending the intervals between maintenance or replacement. This increased reliability can lead to substantial cost savings in the long run, particularly for commercial or racing applications where downtime is expensive.

Furthermore, the superior wear resistance of advanced alloys contributes to extended engine life. Components made from these materials experience less degradation over time, potentially doubling or tripling the service life compared to traditional alloys. This longevity not only reduces replacement costs but also enhances the engine's resale value, an important consideration for both manufacturers and end-users.

However, the implementation of advanced alloys is not without challenges. The manufacturing processes for these materials are often more complex and energy-intensive, contributing to higher production costs. Additionally, specialized tooling and expertise may be required for machining and assembly, further increasing the initial investment.

When evaluating the cost-benefit ratio, it's essential to consider the target market and application. For high-performance or luxury vehicles, where customers are willing to pay a premium for superior performance and durability, the use of advanced alloys can be a significant selling point. In contrast, for budget-oriented vehicles, the cost-benefit analysis may favor more traditional materials.

In conclusion, while the upfront costs of implementing advanced alloys in 454 big block engines are higher, the long-term benefits in performance, durability, and efficiency often justify the investment. As manufacturing techniques continue to evolve and economies of scale come into play, the cost-benefit ratio is likely to improve further, making advanced alloys an increasingly attractive option for engine manufacturers.

Advanced alloys, such as titanium and nickel-based superalloys, offer significant improvements in engine performance and durability. These materials exhibit superior strength-to-weight ratios, allowing for lighter engine components without sacrificing structural integrity. This weight reduction translates to improved fuel efficiency and overall vehicle performance, potentially offsetting the initial higher material costs over the engine's lifetime.

The enhanced heat resistance of these alloys is another crucial factor. In high-performance engines like the 454 big block, components are subjected to extreme temperatures. Advanced alloys maintain their mechanical properties under these conditions, reducing the risk of engine failure and extending the intervals between maintenance or replacement. This increased reliability can lead to substantial cost savings in the long run, particularly for commercial or racing applications where downtime is expensive.

Furthermore, the superior wear resistance of advanced alloys contributes to extended engine life. Components made from these materials experience less degradation over time, potentially doubling or tripling the service life compared to traditional alloys. This longevity not only reduces replacement costs but also enhances the engine's resale value, an important consideration for both manufacturers and end-users.

However, the implementation of advanced alloys is not without challenges. The manufacturing processes for these materials are often more complex and energy-intensive, contributing to higher production costs. Additionally, specialized tooling and expertise may be required for machining and assembly, further increasing the initial investment.

When evaluating the cost-benefit ratio, it's essential to consider the target market and application. For high-performance or luxury vehicles, where customers are willing to pay a premium for superior performance and durability, the use of advanced alloys can be a significant selling point. In contrast, for budget-oriented vehicles, the cost-benefit analysis may favor more traditional materials.

In conclusion, while the upfront costs of implementing advanced alloys in 454 big block engines are higher, the long-term benefits in performance, durability, and efficiency often justify the investment. As manufacturing techniques continue to evolve and economies of scale come into play, the cost-benefit ratio is likely to improve further, making advanced alloys an increasingly attractive option for engine manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!