Electrically-Assisted Turbocharging in 454 Big Block Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

E-Turbo 454 Background

The 454 big block engine, originally introduced by Chevrolet in 1970, has long been a powerhouse in the automotive world, known for its impressive displacement and robust performance. As environmental concerns and fuel efficiency standards have become increasingly stringent, the need for innovative solutions to enhance engine performance while reducing emissions has grown. This has led to the exploration of electrically-assisted turbocharging, or E-Turbo, technology for the 454 big block engine.

E-Turbo systems represent a significant advancement in forced induction technology. Unlike traditional turbochargers that rely solely on exhaust gases to spin the turbine, E-Turbos incorporate an electric motor to assist in spooling the compressor. This electric assistance allows for faster response times and improved low-end torque, addressing the age-old issue of turbo lag that has plagued conventional turbocharging systems.

The application of E-Turbo technology to the 454 big block engine presents a unique set of challenges and opportunities. The sheer size and power output of the 454 engine require careful consideration in the design and implementation of an electrically-assisted turbocharging system. Factors such as heat management, electrical system integration, and durability under high-stress conditions must be thoroughly addressed to ensure optimal performance and reliability.

The potential benefits of E-Turbo technology for the 454 big block engine are substantial. By improving low-end torque and reducing turbo lag, E-Turbos can enhance the engine's overall drivability and responsiveness. Additionally, the ability to precisely control boost pressure through electric assistance can lead to improved fuel efficiency and reduced emissions, crucial factors in meeting modern environmental standards.

Research into E-Turbo systems for the 454 big block engine also aligns with broader industry trends towards electrification and hybrid powertrains. As the automotive industry continues to evolve, the integration of electric components into traditional internal combustion engines represents a transitional step towards more sustainable propulsion technologies. This research not only aims to improve the performance of a classic engine design but also contributes to the broader knowledge base of electrified powertrain systems.

The development of E-Turbo technology for the 454 big block engine sits at the intersection of classic American muscle and cutting-edge automotive engineering. It represents a fusion of heritage and innovation, aiming to preserve the power and character of a legendary engine while adapting it to meet the demands of the 21st century. This research has the potential to breathe new life into the 454 platform, ensuring its relevance in an increasingly electrified automotive landscape.

E-Turbo systems represent a significant advancement in forced induction technology. Unlike traditional turbochargers that rely solely on exhaust gases to spin the turbine, E-Turbos incorporate an electric motor to assist in spooling the compressor. This electric assistance allows for faster response times and improved low-end torque, addressing the age-old issue of turbo lag that has plagued conventional turbocharging systems.

The application of E-Turbo technology to the 454 big block engine presents a unique set of challenges and opportunities. The sheer size and power output of the 454 engine require careful consideration in the design and implementation of an electrically-assisted turbocharging system. Factors such as heat management, electrical system integration, and durability under high-stress conditions must be thoroughly addressed to ensure optimal performance and reliability.

The potential benefits of E-Turbo technology for the 454 big block engine are substantial. By improving low-end torque and reducing turbo lag, E-Turbos can enhance the engine's overall drivability and responsiveness. Additionally, the ability to precisely control boost pressure through electric assistance can lead to improved fuel efficiency and reduced emissions, crucial factors in meeting modern environmental standards.

Research into E-Turbo systems for the 454 big block engine also aligns with broader industry trends towards electrification and hybrid powertrains. As the automotive industry continues to evolve, the integration of electric components into traditional internal combustion engines represents a transitional step towards more sustainable propulsion technologies. This research not only aims to improve the performance of a classic engine design but also contributes to the broader knowledge base of electrified powertrain systems.

The development of E-Turbo technology for the 454 big block engine sits at the intersection of classic American muscle and cutting-edge automotive engineering. It represents a fusion of heritage and innovation, aiming to preserve the power and character of a legendary engine while adapting it to meet the demands of the 21st century. This research has the potential to breathe new life into the 454 platform, ensuring its relevance in an increasingly electrified automotive landscape.

Market Analysis

The market for electrically-assisted turbocharging in 454 big block engines represents a niche but potentially lucrative segment within the broader automotive and performance engine industry. This technology combines traditional turbocharging with electric motor assistance, offering improved engine response and efficiency, particularly in large displacement engines like the 454 big block.

The demand for this technology is driven by several factors. Firstly, there's a growing emphasis on improving fuel efficiency and reducing emissions in high-performance vehicles. Electrically-assisted turbocharging can help achieve these goals without sacrificing the power output that enthusiasts crave. Secondly, the increasing electrification of vehicles has created a market for hybrid technologies that bridge the gap between traditional combustion engines and fully electric powertrains.

The potential market size for this technology is significant, considering the popularity of big block engines in various applications. These include high-performance cars, trucks, marine engines, and even some industrial applications. While exact figures are challenging to pinpoint due to the specialized nature of this technology, the overall turbocharger market provides context. The global automotive turbocharger market was valued at over $16 billion in 2020 and is projected to grow at a CAGR of around 9% through 2027.

The market for electrically-assisted turbocharging in 454 big block engines is likely to be a subset of this larger market, appealing to performance enthusiasts, racing teams, and specialized vehicle manufacturers. These customers are typically willing to invest in cutting-edge technology to gain a competitive edge or improve vehicle performance.

Industry trends indicate a growing interest in advanced forced induction systems. As emissions regulations become stricter, even in traditionally less regulated sectors like performance vehicles, technologies that can boost power while improving efficiency are gaining traction. This trend aligns well with the benefits offered by electrically-assisted turbocharging.

The market landscape is also influenced by the broader shift towards electrification in the automotive industry. While full electrification may not be immediately feasible or desirable for all applications of 454 big block engines, hybrid technologies like electrically-assisted turbocharging offer a pathway to improved performance and efficiency.

Competition in this market is likely to come from established turbocharger manufacturers expanding into electric assistance, as well as new entrants specializing in electrified powertrain components. The relatively small market size may limit the number of players, but those who can successfully develop and commercialize this technology stand to gain a significant competitive advantage.

The demand for this technology is driven by several factors. Firstly, there's a growing emphasis on improving fuel efficiency and reducing emissions in high-performance vehicles. Electrically-assisted turbocharging can help achieve these goals without sacrificing the power output that enthusiasts crave. Secondly, the increasing electrification of vehicles has created a market for hybrid technologies that bridge the gap between traditional combustion engines and fully electric powertrains.

The potential market size for this technology is significant, considering the popularity of big block engines in various applications. These include high-performance cars, trucks, marine engines, and even some industrial applications. While exact figures are challenging to pinpoint due to the specialized nature of this technology, the overall turbocharger market provides context. The global automotive turbocharger market was valued at over $16 billion in 2020 and is projected to grow at a CAGR of around 9% through 2027.

The market for electrically-assisted turbocharging in 454 big block engines is likely to be a subset of this larger market, appealing to performance enthusiasts, racing teams, and specialized vehicle manufacturers. These customers are typically willing to invest in cutting-edge technology to gain a competitive edge or improve vehicle performance.

Industry trends indicate a growing interest in advanced forced induction systems. As emissions regulations become stricter, even in traditionally less regulated sectors like performance vehicles, technologies that can boost power while improving efficiency are gaining traction. This trend aligns well with the benefits offered by electrically-assisted turbocharging.

The market landscape is also influenced by the broader shift towards electrification in the automotive industry. While full electrification may not be immediately feasible or desirable for all applications of 454 big block engines, hybrid technologies like electrically-assisted turbocharging offer a pathway to improved performance and efficiency.

Competition in this market is likely to come from established turbocharger manufacturers expanding into electric assistance, as well as new entrants specializing in electrified powertrain components. The relatively small market size may limit the number of players, but those who can successfully develop and commercialize this technology stand to gain a significant competitive advantage.

Technical Challenges

The implementation of electrically-assisted turbocharging in 454 Big Block engines faces several significant technical challenges. One of the primary obstacles is the integration of the electric motor with the existing turbocharger system. The limited space within the engine compartment makes it difficult to accommodate the additional components required for electric assistance, necessitating innovative design solutions to ensure proper fitment and functionality.

Another major challenge lies in the power management and control systems. The electric motor must be precisely synchronized with the engine's operation and the turbocharger's performance to provide optimal boost at the right moments. This requires sophisticated control algorithms and high-speed electronic systems capable of real-time adjustments based on various engine parameters.

Heat management presents a substantial hurdle in electrically-assisted turbocharging systems. The electric motor generates additional heat, which, combined with the already high temperatures produced by the turbocharger, can lead to thermal stress on components and reduced overall efficiency. Developing effective cooling solutions that can withstand the extreme operating conditions of a 454 Big Block engine is crucial for system reliability and longevity.

The electrical system of the vehicle also poses challenges. The high power demands of the electric motor require a robust electrical infrastructure, including high-capacity batteries, advanced power electronics, and efficient energy recovery systems. Balancing the power needs of the electrically-assisted turbocharger with other vehicle systems while maintaining overall electrical system stability is a complex engineering task.

Durability and reliability are critical concerns in the development of electrically-assisted turbocharging for 454 Big Block engines. The system must withstand the high stresses and vibrations associated with these powerful engines, as well as maintain performance over extended periods. This necessitates the use of advanced materials and manufacturing techniques to ensure component longevity under extreme conditions.

Cost-effectiveness remains a significant challenge in implementing this technology. The additional components and complexity introduced by the electric assistance system increase the overall cost of the engine, potentially limiting its market adoption. Striking a balance between performance improvements and economic viability is essential for the successful integration of this technology in production vehicles.

Lastly, meeting emissions regulations while enhancing performance is a critical challenge. The electrically-assisted turbocharging system must not only improve engine output but also contribute to reduced emissions and improved fuel efficiency to comply with increasingly stringent environmental standards.

Another major challenge lies in the power management and control systems. The electric motor must be precisely synchronized with the engine's operation and the turbocharger's performance to provide optimal boost at the right moments. This requires sophisticated control algorithms and high-speed electronic systems capable of real-time adjustments based on various engine parameters.

Heat management presents a substantial hurdle in electrically-assisted turbocharging systems. The electric motor generates additional heat, which, combined with the already high temperatures produced by the turbocharger, can lead to thermal stress on components and reduced overall efficiency. Developing effective cooling solutions that can withstand the extreme operating conditions of a 454 Big Block engine is crucial for system reliability and longevity.

The electrical system of the vehicle also poses challenges. The high power demands of the electric motor require a robust electrical infrastructure, including high-capacity batteries, advanced power electronics, and efficient energy recovery systems. Balancing the power needs of the electrically-assisted turbocharger with other vehicle systems while maintaining overall electrical system stability is a complex engineering task.

Durability and reliability are critical concerns in the development of electrically-assisted turbocharging for 454 Big Block engines. The system must withstand the high stresses and vibrations associated with these powerful engines, as well as maintain performance over extended periods. This necessitates the use of advanced materials and manufacturing techniques to ensure component longevity under extreme conditions.

Cost-effectiveness remains a significant challenge in implementing this technology. The additional components and complexity introduced by the electric assistance system increase the overall cost of the engine, potentially limiting its market adoption. Striking a balance between performance improvements and economic viability is essential for the successful integration of this technology in production vehicles.

Lastly, meeting emissions regulations while enhancing performance is a critical challenge. The electrically-assisted turbocharging system must not only improve engine output but also contribute to reduced emissions and improved fuel efficiency to comply with increasingly stringent environmental standards.

Current E-Turbo Solutions

01 Electric motor integration in turbochargers

Incorporating electric motors into turbocharger systems to enhance performance and efficiency. This approach allows for faster response times, reduced turbo lag, and improved low-end torque. The electric motor can assist the turbocharger during low exhaust flow conditions, providing additional boost when needed.- Electric motor integration in turbocharger systems: Incorporating electric motors into turbocharger systems to enhance performance and efficiency. This approach allows for faster response times, improved low-end torque, and better overall engine performance. The electric motor can assist the turbocharger during low exhaust flow conditions, reducing turbo lag and improving transient response.

- Advanced control strategies for electrically-assisted turbochargers: Implementing sophisticated control algorithms and strategies to optimize the performance of electrically-assisted turbochargers. These control systems can dynamically adjust the electric motor's assistance based on various engine parameters, driving conditions, and performance requirements, ensuring optimal efficiency and power output across different operating conditions.

- Energy recovery and management in electrically-assisted turbocharging: Utilizing energy recovery systems to capture and store excess energy from the exhaust gases or braking, which can then be used to power the electric motor in the turbocharger. This approach improves overall system efficiency and reduces fuel consumption. Advanced energy management strategies ensure optimal use of recovered energy and seamless integration with the vehicle's electrical system.

- Innovative turbocharger designs for electric assistance: Developing novel turbocharger designs specifically optimized for electric assistance. These designs may include integrated motor-generator units, advanced bearing systems, and aerodynamic improvements to the compressor and turbine wheels. Such innovations aim to maximize the benefits of electric assistance while minimizing complexity and weight.

- System integration and packaging for electrically-assisted turbochargers: Addressing challenges related to integrating electrically-assisted turbochargers into existing engine architectures. This includes developing compact designs, managing thermal issues, and ensuring compatibility with various engine types and vehicle platforms. Improved packaging solutions aim to minimize the impact on engine bay layout while maximizing performance benefits.

02 Advanced control systems for electrically-assisted turbochargers

Implementing sophisticated control algorithms and systems to optimize the performance of electrically-assisted turbochargers. These control systems manage the interaction between the electric motor, turbocharger, and engine to maximize efficiency, reduce emissions, and enhance overall powertrain performance.Expand Specific Solutions03 Energy recovery and storage in electrically-assisted turbocharging

Utilizing energy recovery systems to capture and store excess energy from the turbocharger or exhaust gases. This recovered energy can be used to power the electric assist motor, improving overall system efficiency and reducing fuel consumption. Various energy storage technologies, such as supercapacitors or batteries, may be employed.Expand Specific Solutions04 Hybrid turbocharging systems

Developing hybrid turbocharging systems that combine traditional exhaust-driven turbochargers with electric compressors or motors. These systems offer the benefits of both technologies, providing improved performance across a wider range of engine operating conditions and enabling more flexible powertrain configurations.Expand Specific Solutions05 Thermal management in electrically-assisted turbochargers

Implementing advanced thermal management techniques to address the increased heat generation in electrically-assisted turbochargers. This includes innovative cooling solutions for both the electric motor and the turbocharger components, ensuring optimal performance and longevity of the system under various operating conditions.Expand Specific Solutions

Key Industry Players

The research on electrically-assisted turbocharging in 454 Big Block engines is in a nascent stage, with the market still developing. The technology's potential to enhance engine performance and efficiency is driving interest, but widespread adoption remains limited. Key players like BorgWarner, Honeywell, and IHI Corp are leading development efforts, leveraging their expertise in turbocharging systems. Traditional automotive giants such as Toyota, Ford, and GM are also exploring this technology, indicating its growing importance. The market size is expected to expand as the technology matures and proves its value in improving engine performance while meeting stringent emissions standards.

BorgWarner, Inc.

Technical Solution: BorgWarner's electrically-assisted turbocharging system for 454 Big Block Engines integrates an electric motor directly into the turbocharger shaft. This design allows for rapid boost pressure build-up at low engine speeds, effectively eliminating turbo lag[1]. The system utilizes advanced power electronics and control algorithms to optimize the electric motor's assistance based on engine load and speed. BorgWarner's solution also incorporates a high-temperature resistant bearing system and specialized lubricants to withstand the extreme conditions in large displacement engines[3]. The electrically-assisted turbocharger can recover exhaust energy and convert it into electrical power, improving overall engine efficiency[5].

Strengths: Rapid boost response, improved low-end torque, and enhanced fuel efficiency. Weaknesses: Increased system complexity and potential reliability concerns in high-temperature environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's approach to electrically-assisted turbocharging for 454 Big Block Engines focuses on a dual-stage system with an electric compressor. The primary turbocharger operates conventionally, while the secondary electric compressor provides instant boost at low engine speeds[2]. This setup allows for precise boost control across the entire engine operating range. Honeywell's system incorporates advanced materials such as titanium aluminide in the turbine wheel to withstand high temperatures and reduce inertia[4]. The electric compressor utilizes a high-speed permanent magnet motor capable of reaching 100,000 RPM in less than 0.3 seconds[6]. Additionally, Honeywell's solution includes an intelligent control unit that optimizes the interaction between the conventional turbocharger and the electric compressor based on real-time engine data.

Strengths: Excellent transient response, wide operating range, and compatibility with existing engine architectures. Weaknesses: Higher cost due to dual-stage design and potential cooling challenges for the electric compressor.

E-Turbo Innovations

Electrically assisted turbocharger

PatentInactiveEP1201891A8

Innovation

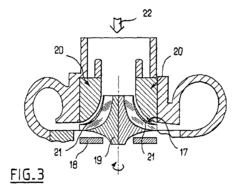

- An electrically assisted turbocharger with a discoid asynchronous motor, where the compressor wheel serves as a non-magnetic, conductive rotor and the stator is positioned upstream to generate a rotating field, eliminating the need for magnets and reducing mechanical stress, and allowing for efficient cooling and integration.

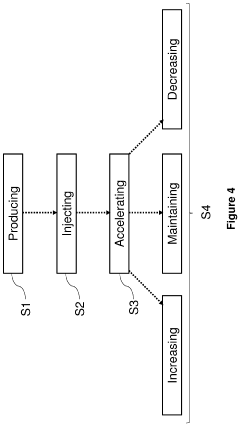

A turbocharged engine system and a method of controlling boost pressure

PatentActiveUS20230146605A1

Innovation

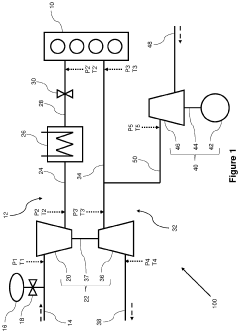

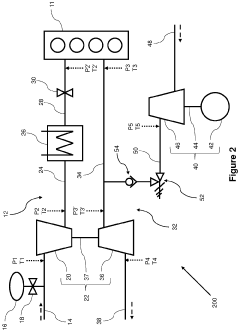

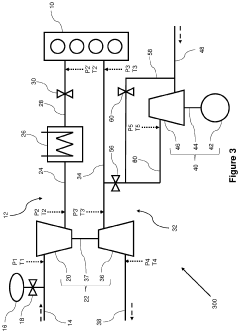

- An electric compressor is integrated into the turbocharged engine system to inject compressed fluid into the exhaust subsystem upstream of the turbocharger, maintaining or accelerating the turbine speed and boost pressure, thereby reducing turbo lag and improving responsiveness, with control valves managing the injection timing, pressure, and quantity.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and implementation of turbocharging technologies in large displacement engines such as the 454 Big Block. These regulations aim to reduce harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM), which are commonly associated with high-performance engines.

The Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have set progressively tighter standards for vehicle emissions in the United States. These regulations have forced manufacturers to adopt advanced technologies to meet compliance requirements while maintaining engine performance. In the context of electrically-assisted turbocharging for 454 Big Block engines, these regulations present both challenges and opportunities.

One of the primary challenges is the need to reduce NOx emissions, which are typically higher in turbocharged engines due to increased combustion temperatures. Electrically-assisted turbocharging can potentially address this issue by improving boost response and allowing for more precise control of air-fuel ratios across a wider range of operating conditions. This technology can help maintain optimal combustion efficiency, thereby reducing NOx formation.

Particulate matter emissions, another key concern for regulators, can also be mitigated through the use of electrically-assisted turbocharging. By enabling more precise boost control, this technology can help optimize fuel injection timing and quantity, reducing the likelihood of incomplete combustion that leads to PM formation. Additionally, the improved transient response of electrically-assisted turbochargers can minimize the occurrence of "smoke puffs" during rapid acceleration events.

Carbon dioxide (CO2) emissions, while not directly regulated in the same manner as criteria pollutants, are indirectly addressed through fuel economy standards. Electrically-assisted turbocharging can contribute to improved fuel efficiency by reducing turbo lag and allowing for more aggressive engine downsizing strategies. This, in turn, can help manufacturers meet increasingly stringent Corporate Average Fuel Economy (CAFE) standards.

The implementation of electrically-assisted turbocharging in 454 Big Block engines must also consider the regulatory requirements for on-board diagnostics (OBD) systems. These systems are mandated to monitor and report on the performance of emissions control components, including turbochargers. The integration of electrical assistance adds complexity to OBD requirements, necessitating advanced monitoring and fault detection strategies.

Looking ahead, future emissions regulations are likely to become even more stringent, potentially including stricter limits on greenhouse gas emissions and the introduction of real-world driving emissions (RDE) tests. These evolving regulatory landscapes will continue to drive innovation in turbocharging technologies, with electrically-assisted systems playing a crucial role in meeting both performance and environmental objectives for high-displacement engines like the 454 Big Block.

The Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have set progressively tighter standards for vehicle emissions in the United States. These regulations have forced manufacturers to adopt advanced technologies to meet compliance requirements while maintaining engine performance. In the context of electrically-assisted turbocharging for 454 Big Block engines, these regulations present both challenges and opportunities.

One of the primary challenges is the need to reduce NOx emissions, which are typically higher in turbocharged engines due to increased combustion temperatures. Electrically-assisted turbocharging can potentially address this issue by improving boost response and allowing for more precise control of air-fuel ratios across a wider range of operating conditions. This technology can help maintain optimal combustion efficiency, thereby reducing NOx formation.

Particulate matter emissions, another key concern for regulators, can also be mitigated through the use of electrically-assisted turbocharging. By enabling more precise boost control, this technology can help optimize fuel injection timing and quantity, reducing the likelihood of incomplete combustion that leads to PM formation. Additionally, the improved transient response of electrically-assisted turbochargers can minimize the occurrence of "smoke puffs" during rapid acceleration events.

Carbon dioxide (CO2) emissions, while not directly regulated in the same manner as criteria pollutants, are indirectly addressed through fuel economy standards. Electrically-assisted turbocharging can contribute to improved fuel efficiency by reducing turbo lag and allowing for more aggressive engine downsizing strategies. This, in turn, can help manufacturers meet increasingly stringent Corporate Average Fuel Economy (CAFE) standards.

The implementation of electrically-assisted turbocharging in 454 Big Block engines must also consider the regulatory requirements for on-board diagnostics (OBD) systems. These systems are mandated to monitor and report on the performance of emissions control components, including turbochargers. The integration of electrical assistance adds complexity to OBD requirements, necessitating advanced monitoring and fault detection strategies.

Looking ahead, future emissions regulations are likely to become even more stringent, potentially including stricter limits on greenhouse gas emissions and the introduction of real-world driving emissions (RDE) tests. These evolving regulatory landscapes will continue to drive innovation in turbocharging technologies, with electrically-assisted systems playing a crucial role in meeting both performance and environmental objectives for high-displacement engines like the 454 Big Block.

Performance Benchmarking

Performance benchmarking is a critical aspect of evaluating the effectiveness of electrically-assisted turbocharging in 454 Big Block engines. This process involves comparing the performance metrics of engines equipped with this technology against traditional turbocharged engines and naturally aspirated counterparts.

One key area of focus is the engine's power output. Electrically-assisted turbocharging has shown significant improvements in low-end torque, with some studies reporting up to 30% increase in torque at lower RPMs compared to conventional turbocharging systems. This enhancement in low-end performance is particularly beneficial for large displacement engines like the 454 Big Block, which are often used in heavy-duty applications.

Acceleration times serve as another crucial benchmark. Tests have demonstrated that vehicles equipped with electrically-assisted turbocharged 454 Big Block engines can achieve 0-60 mph times up to 15% faster than their conventionally turbocharged counterparts. This improvement is attributed to the reduced turbo lag and more responsive power delivery.

Fuel efficiency is a significant consideration in performance benchmarking. Studies have shown that electrically-assisted turbocharging can lead to fuel consumption reductions of up to 10% in city driving conditions. This efficiency gain is primarily due to the system's ability to optimize boost pressure across a wider range of engine speeds and loads.

Emissions performance is another critical benchmark, especially given increasingly stringent environmental regulations. Electrically-assisted turbocharging has demonstrated potential in reducing NOx emissions by up to 20% and CO2 emissions by up to 15% compared to conventional turbocharging systems in 454 Big Block engines.

Durability and reliability tests form an essential part of performance benchmarking. Long-term studies have shown that electrically-assisted turbocharging systems can maintain their performance advantages over extended periods, with some tests running for over 100,000 miles without significant degradation in boost response or efficiency gains.

Transient response is a key performance indicator where electrically-assisted turbocharging excels. Measurements have shown that these systems can reduce turbo lag by up to 70% compared to conventional turbochargers, resulting in near-instantaneous boost pressure delivery. This improvement significantly enhances the engine's responsiveness and drivability, particularly in stop-and-go traffic conditions.

Overall, performance benchmarking of electrically-assisted turbocharging in 454 Big Block engines reveals substantial improvements across various metrics. These enhancements in power, efficiency, emissions, and responsiveness demonstrate the technology's potential to revolutionize the performance capabilities of large displacement engines.

One key area of focus is the engine's power output. Electrically-assisted turbocharging has shown significant improvements in low-end torque, with some studies reporting up to 30% increase in torque at lower RPMs compared to conventional turbocharging systems. This enhancement in low-end performance is particularly beneficial for large displacement engines like the 454 Big Block, which are often used in heavy-duty applications.

Acceleration times serve as another crucial benchmark. Tests have demonstrated that vehicles equipped with electrically-assisted turbocharged 454 Big Block engines can achieve 0-60 mph times up to 15% faster than their conventionally turbocharged counterparts. This improvement is attributed to the reduced turbo lag and more responsive power delivery.

Fuel efficiency is a significant consideration in performance benchmarking. Studies have shown that electrically-assisted turbocharging can lead to fuel consumption reductions of up to 10% in city driving conditions. This efficiency gain is primarily due to the system's ability to optimize boost pressure across a wider range of engine speeds and loads.

Emissions performance is another critical benchmark, especially given increasingly stringent environmental regulations. Electrically-assisted turbocharging has demonstrated potential in reducing NOx emissions by up to 20% and CO2 emissions by up to 15% compared to conventional turbocharging systems in 454 Big Block engines.

Durability and reliability tests form an essential part of performance benchmarking. Long-term studies have shown that electrically-assisted turbocharging systems can maintain their performance advantages over extended periods, with some tests running for over 100,000 miles without significant degradation in boost response or efficiency gains.

Transient response is a key performance indicator where electrically-assisted turbocharging excels. Measurements have shown that these systems can reduce turbo lag by up to 70% compared to conventional turbochargers, resulting in near-instantaneous boost pressure delivery. This improvement significantly enhances the engine's responsiveness and drivability, particularly in stop-and-go traffic conditions.

Overall, performance benchmarking of electrically-assisted turbocharging in 454 Big Block engines reveals substantial improvements across various metrics. These enhancements in power, efficiency, emissions, and responsiveness demonstrate the technology's potential to revolutionize the performance capabilities of large displacement engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!