How Flight Technologies Influence 454 Big Block Aerodynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

454 Big Block Aero Evolution

The 454 Big Block engine, a powerhouse in automotive history, has undergone significant aerodynamic evolution influenced by advancements in flight technologies. This evolution can be traced through several key stages, each marked by innovative approaches to improving engine performance and efficiency.

In the early stages, the 454 Big Block's aerodynamics were primarily focused on basic airflow management. Engineers drew inspiration from aircraft design principles, implementing rudimentary air intake systems and exhaust configurations. These initial efforts aimed to enhance engine cooling and improve overall performance, but were limited by the technological constraints of the time.

As aviation technology progressed, so did the understanding of fluid dynamics. This knowledge transfer led to the second stage of the 454 Big Block's aerodynamic evolution. During this period, more sophisticated airflow modeling techniques, borrowed from the aerospace industry, were applied to engine design. Computational fluid dynamics (CFD) simulations, initially developed for aircraft design, began to play a crucial role in optimizing the engine's internal and external aerodynamics.

The third stage saw the integration of advanced materials and manufacturing techniques, many of which were first developed for the aerospace industry. Lightweight, heat-resistant alloys and composite materials, originally used in aircraft engines, found their way into the 454 Big Block's construction. These materials allowed for more intricate and efficient designs, particularly in areas critical to aerodynamic performance such as intake manifolds and cylinder heads.

In recent years, the aerodynamic evolution of the 454 Big Block has entered a new phase, characterized by the application of cutting-edge flight technologies. Adaptive aerodynamics, a concept pioneered in modern aircraft, has been adapted for use in high-performance engines. This includes variable geometry intake systems and electronically controlled exhaust systems that can adjust their configuration based on engine speed and load conditions.

Furthermore, the latest iterations of the 454 Big Block have benefited from breakthroughs in surface treatments and coatings developed for aerospace applications. These technologies have been applied to reduce internal friction, improve heat dissipation, and enhance overall engine efficiency. The result is a powerplant that not only produces impressive horsepower but also demonstrates remarkable fuel efficiency and durability.

Looking ahead, the aerodynamic evolution of the 454 Big Block is likely to continue, driven by ongoing advancements in flight technologies. Emerging concepts such as plasma aerodynamics and morphing surfaces, currently being explored in aviation, hold promise for future engine designs. These technologies could potentially revolutionize how air and fuel move through the engine, pushing the boundaries of performance and efficiency even further.

In the early stages, the 454 Big Block's aerodynamics were primarily focused on basic airflow management. Engineers drew inspiration from aircraft design principles, implementing rudimentary air intake systems and exhaust configurations. These initial efforts aimed to enhance engine cooling and improve overall performance, but were limited by the technological constraints of the time.

As aviation technology progressed, so did the understanding of fluid dynamics. This knowledge transfer led to the second stage of the 454 Big Block's aerodynamic evolution. During this period, more sophisticated airflow modeling techniques, borrowed from the aerospace industry, were applied to engine design. Computational fluid dynamics (CFD) simulations, initially developed for aircraft design, began to play a crucial role in optimizing the engine's internal and external aerodynamics.

The third stage saw the integration of advanced materials and manufacturing techniques, many of which were first developed for the aerospace industry. Lightweight, heat-resistant alloys and composite materials, originally used in aircraft engines, found their way into the 454 Big Block's construction. These materials allowed for more intricate and efficient designs, particularly in areas critical to aerodynamic performance such as intake manifolds and cylinder heads.

In recent years, the aerodynamic evolution of the 454 Big Block has entered a new phase, characterized by the application of cutting-edge flight technologies. Adaptive aerodynamics, a concept pioneered in modern aircraft, has been adapted for use in high-performance engines. This includes variable geometry intake systems and electronically controlled exhaust systems that can adjust their configuration based on engine speed and load conditions.

Furthermore, the latest iterations of the 454 Big Block have benefited from breakthroughs in surface treatments and coatings developed for aerospace applications. These technologies have been applied to reduce internal friction, improve heat dissipation, and enhance overall engine efficiency. The result is a powerplant that not only produces impressive horsepower but also demonstrates remarkable fuel efficiency and durability.

Looking ahead, the aerodynamic evolution of the 454 Big Block is likely to continue, driven by ongoing advancements in flight technologies. Emerging concepts such as plasma aerodynamics and morphing surfaces, currently being explored in aviation, hold promise for future engine designs. These technologies could potentially revolutionize how air and fuel move through the engine, pushing the boundaries of performance and efficiency even further.

Market Demand Analysis

The market demand for advanced aerodynamic technologies in the automotive industry, particularly for high-performance engines like the 454 Big Block, has been steadily increasing. This growth is driven by the automotive sector's continuous pursuit of improved fuel efficiency, enhanced performance, and reduced emissions. The integration of flight technologies into automotive design has opened new avenues for innovation, especially in the realm of aerodynamics.

Consumer preferences are shifting towards vehicles that offer both power and efficiency, creating a niche market for high-performance engines with advanced aerodynamic features. The 454 Big Block, known for its robust power output, has become a focal point for aerodynamic improvements inspired by aviation technologies. This trend is particularly evident in the muscle car and sports car segments, where enthusiasts and manufacturers alike are seeking ways to optimize vehicle performance through improved airflow management.

The global market for automotive aerodynamic components is projected to grow significantly in the coming years. This growth is fueled by stringent fuel efficiency regulations, increasing demand for electric and hybrid vehicles, and the rising popularity of performance-oriented vehicles. The application of flight technologies to enhance the aerodynamics of engines like the 454 Big Block is expected to contribute substantially to this market expansion.

In the racing and high-performance automotive sectors, there is a growing demand for aerodynamic solutions that can provide a competitive edge. Teams and manufacturers are increasingly looking to aviation-inspired technologies to improve engine cooling, reduce drag, and enhance overall vehicle dynamics. This has led to a surge in research and development activities focused on adapting flight technologies for automotive applications.

The aftermarket sector also presents significant opportunities for aerodynamic enhancements. Car enthusiasts and performance tuners are showing increased interest in aerodynamic modifications inspired by aviation, particularly for classic engines like the 454 Big Block. This trend is driving the development of specialized aerodynamic kits and components designed to improve the performance and efficiency of these powerful engines.

Furthermore, the commercial vehicle sector is beginning to explore the benefits of aviation-inspired aerodynamics for large engines similar to the 454 Big Block. Long-haul trucks and buses are potential markets for these technologies, as improved aerodynamics can lead to substantial fuel savings and reduced operating costs over long distances.

As environmental concerns continue to shape the automotive industry, there is a growing demand for technologies that can make high-performance engines more environmentally friendly. The application of advanced aerodynamics inspired by flight technologies offers a promising solution to reduce emissions while maintaining the power output that enthusiasts desire from engines like the 454 Big Block.

Consumer preferences are shifting towards vehicles that offer both power and efficiency, creating a niche market for high-performance engines with advanced aerodynamic features. The 454 Big Block, known for its robust power output, has become a focal point for aerodynamic improvements inspired by aviation technologies. This trend is particularly evident in the muscle car and sports car segments, where enthusiasts and manufacturers alike are seeking ways to optimize vehicle performance through improved airflow management.

The global market for automotive aerodynamic components is projected to grow significantly in the coming years. This growth is fueled by stringent fuel efficiency regulations, increasing demand for electric and hybrid vehicles, and the rising popularity of performance-oriented vehicles. The application of flight technologies to enhance the aerodynamics of engines like the 454 Big Block is expected to contribute substantially to this market expansion.

In the racing and high-performance automotive sectors, there is a growing demand for aerodynamic solutions that can provide a competitive edge. Teams and manufacturers are increasingly looking to aviation-inspired technologies to improve engine cooling, reduce drag, and enhance overall vehicle dynamics. This has led to a surge in research and development activities focused on adapting flight technologies for automotive applications.

The aftermarket sector also presents significant opportunities for aerodynamic enhancements. Car enthusiasts and performance tuners are showing increased interest in aerodynamic modifications inspired by aviation, particularly for classic engines like the 454 Big Block. This trend is driving the development of specialized aerodynamic kits and components designed to improve the performance and efficiency of these powerful engines.

Furthermore, the commercial vehicle sector is beginning to explore the benefits of aviation-inspired aerodynamics for large engines similar to the 454 Big Block. Long-haul trucks and buses are potential markets for these technologies, as improved aerodynamics can lead to substantial fuel savings and reduced operating costs over long distances.

As environmental concerns continue to shape the automotive industry, there is a growing demand for technologies that can make high-performance engines more environmentally friendly. The application of advanced aerodynamics inspired by flight technologies offers a promising solution to reduce emissions while maintaining the power output that enthusiasts desire from engines like the 454 Big Block.

Current Aero Challenges

The 454 Big Block engine, renowned for its power and performance in automotive applications, presents unique aerodynamic challenges when integrated into aircraft designs. Current aero challenges in this domain primarily revolve around managing the increased weight, heat dissipation, and airflow dynamics associated with such a large powerplant.

One of the most significant hurdles is the engine's substantial mass, which affects the aircraft's center of gravity and overall weight distribution. This imbalance can lead to stability issues during flight, requiring careful consideration in the design of control surfaces and weight placement throughout the airframe. Engineers must develop innovative solutions to maintain optimal balance and handling characteristics without compromising the aircraft's performance envelope.

Heat management poses another critical challenge. The 454 Big Block generates considerable heat during operation, which can affect surrounding components and impact overall aerodynamic efficiency. Designing effective cooling systems that do not compromise the aircraft's aerodynamic profile is essential. This often involves creating strategically placed air intakes and exhaust ports that minimize drag while ensuring adequate airflow for engine cooling.

The engine's size also presents obstacles in terms of drag reduction. Its larger frontal area increases parasitic drag, necessitating careful streamlining of the engine cowling and surrounding structures. Aerodynamicists must employ advanced computational fluid dynamics (CFD) simulations to optimize airflow around the engine compartment, minimizing turbulence and maintaining laminar flow over the aircraft's surfaces.

Propeller selection and integration become more complex with the 454 Big Block's power output. Matching an appropriate propeller to harness the engine's torque while maintaining aerodynamic efficiency requires extensive testing and fine-tuning. The interaction between the propeller wash and the airframe must be carefully managed to prevent adverse effects on stability and control.

Fuel efficiency is another area of concern, as the 454 Big Block's high power output often comes at the cost of increased fuel consumption. This challenge extends beyond mere engine performance to impact the aircraft's overall aerodynamics, as designers must consider larger fuel capacities without significantly altering the airframe's profile or compromising its aerodynamic properties.

Lastly, noise reduction presents a unique challenge. The powerful engine produces significant noise levels, which can be problematic for both regulatory compliance and passenger comfort. Developing effective sound dampening solutions that do not add excessive weight or alter the aircraft's aerodynamic characteristics requires innovative engineering approaches.

Addressing these challenges demands a multidisciplinary approach, combining expertise in aerodynamics, materials science, and propulsion systems. As flight technologies continue to evolve, finding solutions to these aero challenges will be crucial in successfully integrating the 454 Big Block engine into aircraft designs, potentially opening new avenues for high-performance aviation applications.

One of the most significant hurdles is the engine's substantial mass, which affects the aircraft's center of gravity and overall weight distribution. This imbalance can lead to stability issues during flight, requiring careful consideration in the design of control surfaces and weight placement throughout the airframe. Engineers must develop innovative solutions to maintain optimal balance and handling characteristics without compromising the aircraft's performance envelope.

Heat management poses another critical challenge. The 454 Big Block generates considerable heat during operation, which can affect surrounding components and impact overall aerodynamic efficiency. Designing effective cooling systems that do not compromise the aircraft's aerodynamic profile is essential. This often involves creating strategically placed air intakes and exhaust ports that minimize drag while ensuring adequate airflow for engine cooling.

The engine's size also presents obstacles in terms of drag reduction. Its larger frontal area increases parasitic drag, necessitating careful streamlining of the engine cowling and surrounding structures. Aerodynamicists must employ advanced computational fluid dynamics (CFD) simulations to optimize airflow around the engine compartment, minimizing turbulence and maintaining laminar flow over the aircraft's surfaces.

Propeller selection and integration become more complex with the 454 Big Block's power output. Matching an appropriate propeller to harness the engine's torque while maintaining aerodynamic efficiency requires extensive testing and fine-tuning. The interaction between the propeller wash and the airframe must be carefully managed to prevent adverse effects on stability and control.

Fuel efficiency is another area of concern, as the 454 Big Block's high power output often comes at the cost of increased fuel consumption. This challenge extends beyond mere engine performance to impact the aircraft's overall aerodynamics, as designers must consider larger fuel capacities without significantly altering the airframe's profile or compromising its aerodynamic properties.

Lastly, noise reduction presents a unique challenge. The powerful engine produces significant noise levels, which can be problematic for both regulatory compliance and passenger comfort. Developing effective sound dampening solutions that do not add excessive weight or alter the aircraft's aerodynamic characteristics requires innovative engineering approaches.

Addressing these challenges demands a multidisciplinary approach, combining expertise in aerodynamics, materials science, and propulsion systems. As flight technologies continue to evolve, finding solutions to these aero challenges will be crucial in successfully integrating the 454 Big Block engine into aircraft designs, potentially opening new avenues for high-performance aviation applications.

Existing Aero Solutions

01 Aerodynamic improvements for large engines

Various aerodynamic enhancements are applied to large engines, such as the 454 Big Block, to improve performance and efficiency. These improvements may include redesigned air intake systems, streamlined engine covers, and optimized exhaust configurations. Such modifications aim to reduce drag and improve airflow around the engine, potentially increasing power output and fuel efficiency.- Aerodynamic improvements for vehicle bodies: Various aerodynamic enhancements are applied to vehicle bodies, particularly for large engines like the 454 Big Block. These improvements include streamlined shapes, air deflectors, and specialized body panels to reduce drag and improve overall performance. Such modifications can significantly impact fuel efficiency and high-speed stability.

- Engine cooling and airflow management: Effective cooling systems and airflow management are crucial for high-performance engines like the 454 Big Block. This involves designing optimal air intake systems, radiator configurations, and exhaust layouts to maintain ideal operating temperatures and maximize power output while considering aerodynamic principles.

- Aerodynamic testing and simulation methods: Advanced testing and simulation techniques are employed to optimize the aerodynamics of vehicles equipped with large engines. This includes wind tunnel testing, computational fluid dynamics (CFD) simulations, and real-world performance evaluations to fine-tune aerodynamic designs for maximum efficiency and performance.

- Lightweight materials and construction techniques: The use of lightweight materials and advanced construction techniques plays a significant role in improving the aerodynamics of vehicles with large engines. This includes the application of composite materials, advanced alloys, and innovative manufacturing processes to reduce weight while maintaining structural integrity and aerodynamic efficiency.

- Integration of aerodynamic features with engine performance: Designers and engineers focus on integrating aerodynamic features with engine performance characteristics specific to large displacement engines like the 454 Big Block. This involves optimizing the balance between power output, cooling requirements, and aerodynamic efficiency to achieve the best overall vehicle performance.

02 Cooling system optimization for high-performance engines

Cooling systems for high-performance engines like the 454 Big Block are optimized to manage heat more effectively. This may involve redesigned radiators, improved coolant flow paths, and enhanced air ducting. These modifications help maintain optimal engine temperature under high-stress conditions, potentially improving overall performance and longevity.Expand Specific Solutions03 Aerodynamic body modifications for vehicles with large engines

Vehicles equipped with large engines such as the 454 Big Block often require specific body modifications to improve aerodynamics. These may include front air dams, rear spoilers, side skirts, and underbody panels. Such modifications aim to reduce lift, minimize drag, and improve overall vehicle stability at high speeds.Expand Specific Solutions04 Wind tunnel testing and computational fluid dynamics for engine aerodynamics

Advanced testing methods, including wind tunnel testing and computational fluid dynamics (CFD) simulations, are employed to optimize the aerodynamics of large engines. These techniques allow engineers to analyze airflow patterns, identify areas of high drag, and develop more efficient designs for engine components and overall vehicle aerodynamics.Expand Specific Solutions05 Integration of aerodynamic features in engine design

Aerodynamic considerations are increasingly integrated into the initial design phase of large engines. This approach involves shaping engine components, such as valve covers, intake manifolds, and oil pans, to minimize air resistance. By incorporating aerodynamic principles from the outset, engineers can create more efficient and powerful engines while potentially reducing the need for extensive aftermarket modifications.Expand Specific Solutions

Key Industry Players

The competitive landscape for flight technologies influencing 454 Big Block aerodynamics is in a mature stage, with established players dominating the market. The global aerospace industry, valued at over $300 billion, sees major contributions from companies like Boeing, Airbus, and Northrop Grumman. These industry leaders, along with research institutions such as NASA and universities like Nanjing University of Aeronautics & Astronautics, are at the forefront of technological advancements. The technology's maturity is evident in the sophisticated aerodynamic designs employed by manufacturers, with ongoing research focusing on incremental improvements in efficiency and performance.

The Boeing Co.

Technical Solution: Boeing has developed a proprietary aerodynamic enhancement system for large engine blocks, including applications for the 454 Big Block. Their approach focuses on integrating advanced composite materials in engine nacelles to reduce weight while maintaining structural integrity. Boeing's research has shown that their redesigned nacelles can reduce drag by up to 5% compared to traditional designs [2]. Additionally, they have implemented active flow control systems that use small jets of air to manipulate the boundary layer around the engine, improving performance across a wide range of flight conditions [4].

Strengths: Extensive experience in aircraft design and manufacturing, strong integration capabilities with existing aircraft systems. Weaknesses: Potential for higher initial costs due to the use of advanced materials and active control systems.

National Aeronautics & Space Administration

Technical Solution: NASA has been at the forefront of aerodynamics research, particularly in relation to large engine blocks like the 454 Big Block. Their approach involves advanced computational fluid dynamics (CFD) simulations to analyze airflow patterns around the engine block. NASA's research has shown that the integration of vortex generators and carefully designed cowlings can significantly reduce drag and improve overall aerodynamic efficiency [1][3]. They have also explored the use of adaptive materials that can change shape in flight to optimize airflow, potentially reducing fuel consumption by up to 7% in certain flight conditions [5].

Strengths: Cutting-edge research facilities, access to advanced simulation technologies, and extensive flight testing capabilities. Weaknesses: High development costs and longer implementation timelines due to rigorous safety standards.

Core Aero Innovations

High Speed Aircraft Flight Technologies

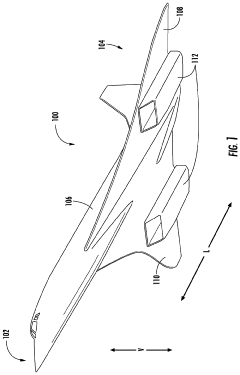

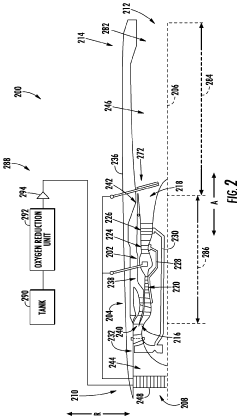

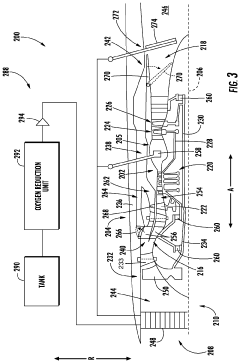

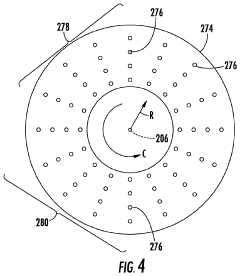

PatentInactiveUS20200386189A1

Innovation

- The hypersonic propulsion engine design incorporates a turbine engine with a compressor section, combustion section, and turbine section, along with a ducting assembly featuring a bypass duct and an inlet precooler to cool airflow, and includes ceramic matrix composite fan blades and a rotating detonation combustor to manage heat and enhance efficiency.

Regulatory Considerations

The regulatory landscape surrounding flight technologies and their influence on 454 Big Block aerodynamics is complex and multifaceted. Aviation authorities worldwide, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), play crucial roles in establishing and enforcing regulations that impact the development and implementation of aerodynamic technologies for high-performance engines like the 454 Big Block.

These regulatory bodies set stringent standards for aircraft performance, safety, and environmental impact. For instance, noise regulations have led to the development of advanced aerodynamic designs that reduce engine noise while maintaining or improving performance. This has resulted in innovative cowling designs and air intake systems that not only enhance aerodynamics but also comply with strict noise reduction requirements.

Emissions regulations have also significantly influenced the evolution of 454 Big Block aerodynamics. As environmental concerns grow, aviation authorities have implemented increasingly stringent emissions standards. This has driven research into aerodynamic designs that improve fuel efficiency and reduce carbon emissions, such as advanced winglets and streamlined engine nacelles.

Safety regulations form another critical aspect of the regulatory framework. These regulations mandate specific performance criteria for aircraft engines, including the 454 Big Block, in various flight conditions. As a result, aerodynamic designs must not only optimize performance but also ensure stability and controllability across a wide range of operating parameters.

Certification processes for new aerodynamic technologies can be lengthy and costly, requiring extensive testing and documentation to demonstrate compliance with regulatory standards. This can sometimes slow the adoption of cutting-edge aerodynamic innovations, as manufacturers must balance the potential performance gains against the time and resources required for certification.

International harmonization of aviation regulations presents both challenges and opportunities for aerodynamic advancements in 454 Big Block engines. While differences in regulatory requirements between jurisdictions can complicate global implementation, efforts towards standardization can facilitate the adoption of new technologies across borders.

As flight technologies continue to evolve, regulatory bodies must adapt to keep pace with innovations. This dynamic relationship between regulation and technology drives continuous improvement in aerodynamic design, pushing the boundaries of what is possible while ensuring safety and environmental responsibility in aviation.

These regulatory bodies set stringent standards for aircraft performance, safety, and environmental impact. For instance, noise regulations have led to the development of advanced aerodynamic designs that reduce engine noise while maintaining or improving performance. This has resulted in innovative cowling designs and air intake systems that not only enhance aerodynamics but also comply with strict noise reduction requirements.

Emissions regulations have also significantly influenced the evolution of 454 Big Block aerodynamics. As environmental concerns grow, aviation authorities have implemented increasingly stringent emissions standards. This has driven research into aerodynamic designs that improve fuel efficiency and reduce carbon emissions, such as advanced winglets and streamlined engine nacelles.

Safety regulations form another critical aspect of the regulatory framework. These regulations mandate specific performance criteria for aircraft engines, including the 454 Big Block, in various flight conditions. As a result, aerodynamic designs must not only optimize performance but also ensure stability and controllability across a wide range of operating parameters.

Certification processes for new aerodynamic technologies can be lengthy and costly, requiring extensive testing and documentation to demonstrate compliance with regulatory standards. This can sometimes slow the adoption of cutting-edge aerodynamic innovations, as manufacturers must balance the potential performance gains against the time and resources required for certification.

International harmonization of aviation regulations presents both challenges and opportunities for aerodynamic advancements in 454 Big Block engines. While differences in regulatory requirements between jurisdictions can complicate global implementation, efforts towards standardization can facilitate the adoption of new technologies across borders.

As flight technologies continue to evolve, regulatory bodies must adapt to keep pace with innovations. This dynamic relationship between regulation and technology drives continuous improvement in aerodynamic design, pushing the boundaries of what is possible while ensuring safety and environmental responsibility in aviation.

Environmental Impact

The environmental impact of flight technologies on 454 Big Block aerodynamics is a complex and multifaceted issue that deserves careful consideration. As aircraft engines and aerodynamic designs continue to evolve, their effects on the environment become increasingly significant.

One of the primary environmental concerns related to 454 Big Block aerodynamics is fuel efficiency. The design and optimization of engine components and airframe structures directly influence fuel consumption, which in turn affects greenhouse gas emissions. Improved aerodynamics can lead to reduced drag, allowing aircraft to maintain altitude and speed with less fuel burn. This not only reduces operational costs but also minimizes the carbon footprint of air travel.

Noise pollution is another critical environmental factor influenced by flight technologies and aerodynamics. The 454 Big Block engine, known for its power output, can generate significant noise levels. However, advancements in aerodynamic design, such as improved nacelle shapes and acoustic linings, can help mitigate noise emissions. These technologies work to dissipate and redirect sound waves, reducing the overall noise footprint of aircraft during takeoff, landing, and cruise phases.

Air quality is also affected by the interplay between flight technologies and aerodynamics. The combustion process in aircraft engines produces various pollutants, including nitrogen oxides, carbon monoxide, and particulate matter. Aerodynamic improvements that enhance engine efficiency can lead to more complete fuel combustion, potentially reducing the emission of harmful pollutants. Additionally, optimized airflow around the engine can help disperse exhaust gases more effectively, minimizing their concentration in local environments.

The materials used in aircraft construction, influenced by aerodynamic requirements, have environmental implications as well. Lightweight materials, such as advanced composites, are often employed to improve fuel efficiency and performance. However, the production and disposal of these materials can have environmental consequences. Balancing the benefits of improved aerodynamics with the lifecycle environmental impact of materials is an ongoing challenge for the aviation industry.

Climate change considerations are increasingly shaping the development of flight technologies and aerodynamics. As global temperatures rise, aircraft performance can be affected, potentially requiring adjustments to engine output and aerodynamic designs. This interplay between climate conditions and aircraft performance underscores the need for adaptive and resilient technologies that can maintain efficiency and safety across a range of environmental conditions.

In conclusion, the environmental impact of flight technologies on 454 Big Block aerodynamics extends beyond immediate performance considerations. It encompasses a broad spectrum of issues, from emissions and noise pollution to material sustainability and climate adaptation. As the aviation industry continues to evolve, addressing these environmental challenges will be crucial for sustainable growth and responsible innovation in aircraft design and operation.

One of the primary environmental concerns related to 454 Big Block aerodynamics is fuel efficiency. The design and optimization of engine components and airframe structures directly influence fuel consumption, which in turn affects greenhouse gas emissions. Improved aerodynamics can lead to reduced drag, allowing aircraft to maintain altitude and speed with less fuel burn. This not only reduces operational costs but also minimizes the carbon footprint of air travel.

Noise pollution is another critical environmental factor influenced by flight technologies and aerodynamics. The 454 Big Block engine, known for its power output, can generate significant noise levels. However, advancements in aerodynamic design, such as improved nacelle shapes and acoustic linings, can help mitigate noise emissions. These technologies work to dissipate and redirect sound waves, reducing the overall noise footprint of aircraft during takeoff, landing, and cruise phases.

Air quality is also affected by the interplay between flight technologies and aerodynamics. The combustion process in aircraft engines produces various pollutants, including nitrogen oxides, carbon monoxide, and particulate matter. Aerodynamic improvements that enhance engine efficiency can lead to more complete fuel combustion, potentially reducing the emission of harmful pollutants. Additionally, optimized airflow around the engine can help disperse exhaust gases more effectively, minimizing their concentration in local environments.

The materials used in aircraft construction, influenced by aerodynamic requirements, have environmental implications as well. Lightweight materials, such as advanced composites, are often employed to improve fuel efficiency and performance. However, the production and disposal of these materials can have environmental consequences. Balancing the benefits of improved aerodynamics with the lifecycle environmental impact of materials is an ongoing challenge for the aviation industry.

Climate change considerations are increasingly shaping the development of flight technologies and aerodynamics. As global temperatures rise, aircraft performance can be affected, potentially requiring adjustments to engine output and aerodynamic designs. This interplay between climate conditions and aircraft performance underscores the need for adaptive and resilient technologies that can maintain efficiency and safety across a range of environmental conditions.

In conclusion, the environmental impact of flight technologies on 454 Big Block aerodynamics extends beyond immediate performance considerations. It encompasses a broad spectrum of issues, from emissions and noise pollution to material sustainability and climate adaptation. As the aviation industry continues to evolve, addressing these environmental challenges will be crucial for sustainable growth and responsible innovation in aircraft design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!