How Virtual Twins Improve 454 Big Block Predictive Maintenance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Virtual Twin Background and Objectives

Virtual twins, also known as digital twins, have emerged as a groundbreaking technology in the field of predictive maintenance, particularly for complex machinery like the 454 Big Block engine. This technology has evolved from simple digital representations to sophisticated, real-time simulations that mirror physical assets in the digital realm. The development of virtual twins can be traced back to NASA's Apollo program, where digital models were used to simulate and troubleshoot spacecraft systems.

In the context of the 454 Big Block engine, virtual twins represent a significant leap forward in maintenance strategies. These engines, known for their power and complexity, require precise and timely maintenance to ensure optimal performance and longevity. The objective of implementing virtual twin technology for these engines is multifaceted, aiming to revolutionize traditional maintenance approaches.

Primarily, virtual twins seek to enhance predictive maintenance capabilities by creating a dynamic, data-driven model of the 454 Big Block engine. This model continuously updates based on real-time sensor data, historical performance metrics, and environmental factors. The goal is to accurately predict potential failures, optimize maintenance schedules, and extend the engine's operational life.

Furthermore, virtual twins aim to reduce downtime and maintenance costs associated with the 454 Big Block engine. By simulating various operational scenarios and wear patterns, maintenance teams can anticipate issues before they occur, allowing for proactive rather than reactive maintenance strategies. This predictive approach not only minimizes unexpected breakdowns but also optimizes resource allocation for maintenance activities.

Another critical objective is to improve the overall performance and efficiency of the 454 Big Block engine. Virtual twins enable engineers to analyze the engine's behavior under different conditions, fine-tune parameters, and identify areas for potential improvements. This continuous optimization process can lead to enhanced fuel efficiency, reduced emissions, and improved power output.

The implementation of virtual twin technology also aims to facilitate better decision-making processes in engine management. By providing a comprehensive, real-time view of the engine's status and performance trends, stakeholders can make more informed decisions regarding maintenance, upgrades, and operational strategies. This data-driven approach supports both short-term operational decisions and long-term strategic planning for fleet management.

Lastly, virtual twins for the 454 Big Block engine serve as a platform for knowledge accumulation and transfer. As these digital models capture and analyze vast amounts of operational data, they become valuable repositories of information. This accumulated knowledge can be used to train new maintenance personnel, improve engine design for future iterations, and enhance overall understanding of engine behavior under various conditions.

In the context of the 454 Big Block engine, virtual twins represent a significant leap forward in maintenance strategies. These engines, known for their power and complexity, require precise and timely maintenance to ensure optimal performance and longevity. The objective of implementing virtual twin technology for these engines is multifaceted, aiming to revolutionize traditional maintenance approaches.

Primarily, virtual twins seek to enhance predictive maintenance capabilities by creating a dynamic, data-driven model of the 454 Big Block engine. This model continuously updates based on real-time sensor data, historical performance metrics, and environmental factors. The goal is to accurately predict potential failures, optimize maintenance schedules, and extend the engine's operational life.

Furthermore, virtual twins aim to reduce downtime and maintenance costs associated with the 454 Big Block engine. By simulating various operational scenarios and wear patterns, maintenance teams can anticipate issues before they occur, allowing for proactive rather than reactive maintenance strategies. This predictive approach not only minimizes unexpected breakdowns but also optimizes resource allocation for maintenance activities.

Another critical objective is to improve the overall performance and efficiency of the 454 Big Block engine. Virtual twins enable engineers to analyze the engine's behavior under different conditions, fine-tune parameters, and identify areas for potential improvements. This continuous optimization process can lead to enhanced fuel efficiency, reduced emissions, and improved power output.

The implementation of virtual twin technology also aims to facilitate better decision-making processes in engine management. By providing a comprehensive, real-time view of the engine's status and performance trends, stakeholders can make more informed decisions regarding maintenance, upgrades, and operational strategies. This data-driven approach supports both short-term operational decisions and long-term strategic planning for fleet management.

Lastly, virtual twins for the 454 Big Block engine serve as a platform for knowledge accumulation and transfer. As these digital models capture and analyze vast amounts of operational data, they become valuable repositories of information. This accumulated knowledge can be used to train new maintenance personnel, improve engine design for future iterations, and enhance overall understanding of engine behavior under various conditions.

Market Demand Analysis

The market demand for virtual twin technology in the context of 454 Big Block predictive maintenance is experiencing significant growth, driven by the increasing need for efficient and cost-effective maintenance strategies in the automotive and industrial sectors. As manufacturers and operators seek to optimize their maintenance processes and reduce downtime, virtual twin technology has emerged as a powerful solution.

The global predictive maintenance market, which encompasses virtual twin technology, is projected to expand rapidly in the coming years. This growth is fueled by the rising adoption of Industry 4.0 technologies and the increasing focus on asset performance management. The automotive sector, in particular, is showing a strong interest in virtual twin technology for predictive maintenance of high-performance engines like the 454 Big Block.

Virtual twin technology offers several key benefits that are driving market demand. Firstly, it enables real-time monitoring and analysis of engine performance, allowing for early detection of potential issues before they lead to costly breakdowns. This proactive approach to maintenance can significantly reduce unplanned downtime and extend the lifespan of critical components.

Furthermore, virtual twins provide a comprehensive digital representation of the 454 Big Block engine, allowing engineers and technicians to simulate various operating conditions and maintenance scenarios. This capability enhances decision-making processes and enables more accurate predictive maintenance schedules, ultimately leading to improved operational efficiency and reduced maintenance costs.

The market demand for virtual twin technology in predictive maintenance is also being driven by the increasing complexity of modern engines and the need for more sophisticated maintenance approaches. Traditional maintenance methods are often inadequate for addressing the intricate systems found in high-performance engines like the 454 Big Block. Virtual twin technology offers a more advanced and data-driven solution that can keep pace with these technological advancements.

Additionally, there is a growing emphasis on sustainability and environmental responsibility in the automotive industry. Virtual twin technology can contribute to these goals by optimizing engine performance, reducing fuel consumption, and minimizing emissions through more effective maintenance practices. This alignment with sustainability objectives is further boosting market demand for virtual twin solutions in predictive maintenance.

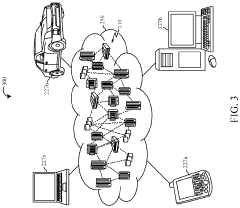

As the automotive industry continues to evolve towards connected and autonomous vehicles, the demand for virtual twin technology in predictive maintenance is expected to increase further. The ability to remotely monitor and diagnose engine performance will become increasingly crucial, driving adoption of virtual twin solutions across the sector.

The global predictive maintenance market, which encompasses virtual twin technology, is projected to expand rapidly in the coming years. This growth is fueled by the rising adoption of Industry 4.0 technologies and the increasing focus on asset performance management. The automotive sector, in particular, is showing a strong interest in virtual twin technology for predictive maintenance of high-performance engines like the 454 Big Block.

Virtual twin technology offers several key benefits that are driving market demand. Firstly, it enables real-time monitoring and analysis of engine performance, allowing for early detection of potential issues before they lead to costly breakdowns. This proactive approach to maintenance can significantly reduce unplanned downtime and extend the lifespan of critical components.

Furthermore, virtual twins provide a comprehensive digital representation of the 454 Big Block engine, allowing engineers and technicians to simulate various operating conditions and maintenance scenarios. This capability enhances decision-making processes and enables more accurate predictive maintenance schedules, ultimately leading to improved operational efficiency and reduced maintenance costs.

The market demand for virtual twin technology in predictive maintenance is also being driven by the increasing complexity of modern engines and the need for more sophisticated maintenance approaches. Traditional maintenance methods are often inadequate for addressing the intricate systems found in high-performance engines like the 454 Big Block. Virtual twin technology offers a more advanced and data-driven solution that can keep pace with these technological advancements.

Additionally, there is a growing emphasis on sustainability and environmental responsibility in the automotive industry. Virtual twin technology can contribute to these goals by optimizing engine performance, reducing fuel consumption, and minimizing emissions through more effective maintenance practices. This alignment with sustainability objectives is further boosting market demand for virtual twin solutions in predictive maintenance.

As the automotive industry continues to evolve towards connected and autonomous vehicles, the demand for virtual twin technology in predictive maintenance is expected to increase further. The ability to remotely monitor and diagnose engine performance will become increasingly crucial, driving adoption of virtual twin solutions across the sector.

Current State and Challenges

The current state of virtual twin technology for improving 454 Big Block predictive maintenance is characterized by significant advancements, yet it still faces several challenges. Virtual twins, also known as digital twins, have gained traction in the automotive industry, particularly in the realm of engine maintenance. These digital replicas of physical assets provide real-time insights into the performance and condition of 454 Big Block engines, enabling more accurate and timely maintenance predictions.

One of the primary challenges in implementing virtual twins for 454 Big Block engines is the complexity of data integration. These engines generate vast amounts of data from various sensors and systems, which must be seamlessly integrated into the virtual twin model. Ensuring data accuracy, consistency, and real-time synchronization between the physical engine and its digital counterpart remains a significant hurdle.

Another challenge lies in the development of sophisticated algorithms capable of accurately predicting maintenance needs. While machine learning and artificial intelligence have made substantial progress in this area, fine-tuning these algorithms to account for the unique characteristics and operating conditions of 454 Big Block engines requires ongoing research and development.

The scalability of virtual twin solutions presents another obstacle. As the number of engines monitored increases, the computational resources required to process and analyze the data grow exponentially. This scalability issue can limit the widespread adoption of virtual twin technology in large-scale fleet management scenarios.

Interoperability between different virtual twin platforms and existing maintenance management systems is also a significant challenge. The lack of standardized protocols and data formats can hinder the seamless integration of virtual twin solutions into existing maintenance workflows, potentially limiting their effectiveness and adoption.

Security and data privacy concerns pose additional challenges. The sensitive nature of engine performance data and the potential for cyber attacks on connected systems necessitate robust security measures, which can be complex to implement and maintain.

Despite these challenges, the current state of virtual twin technology for 454 Big Block predictive maintenance shows promising developments. Advanced sensor technologies, coupled with improvements in data analytics and machine learning algorithms, have enhanced the accuracy of predictive maintenance models. These advancements have led to reduced downtime, optimized maintenance schedules, and improved overall engine performance.

The geographical distribution of virtual twin technology development is primarily concentrated in regions with strong automotive and technology sectors. North America, particularly the United States, leads in research and implementation, followed closely by European countries such as Germany and the United Kingdom. Asian countries, including Japan and South Korea, are also making significant strides in this field.

As the technology continues to evolve, overcoming these challenges will be crucial for realizing the full potential of virtual twins in improving 454 Big Block predictive maintenance. Collaborative efforts between engine manufacturers, software developers, and data scientists will be essential in addressing these obstacles and driving further innovation in this domain.

One of the primary challenges in implementing virtual twins for 454 Big Block engines is the complexity of data integration. These engines generate vast amounts of data from various sensors and systems, which must be seamlessly integrated into the virtual twin model. Ensuring data accuracy, consistency, and real-time synchronization between the physical engine and its digital counterpart remains a significant hurdle.

Another challenge lies in the development of sophisticated algorithms capable of accurately predicting maintenance needs. While machine learning and artificial intelligence have made substantial progress in this area, fine-tuning these algorithms to account for the unique characteristics and operating conditions of 454 Big Block engines requires ongoing research and development.

The scalability of virtual twin solutions presents another obstacle. As the number of engines monitored increases, the computational resources required to process and analyze the data grow exponentially. This scalability issue can limit the widespread adoption of virtual twin technology in large-scale fleet management scenarios.

Interoperability between different virtual twin platforms and existing maintenance management systems is also a significant challenge. The lack of standardized protocols and data formats can hinder the seamless integration of virtual twin solutions into existing maintenance workflows, potentially limiting their effectiveness and adoption.

Security and data privacy concerns pose additional challenges. The sensitive nature of engine performance data and the potential for cyber attacks on connected systems necessitate robust security measures, which can be complex to implement and maintain.

Despite these challenges, the current state of virtual twin technology for 454 Big Block predictive maintenance shows promising developments. Advanced sensor technologies, coupled with improvements in data analytics and machine learning algorithms, have enhanced the accuracy of predictive maintenance models. These advancements have led to reduced downtime, optimized maintenance schedules, and improved overall engine performance.

The geographical distribution of virtual twin technology development is primarily concentrated in regions with strong automotive and technology sectors. North America, particularly the United States, leads in research and implementation, followed closely by European countries such as Germany and the United Kingdom. Asian countries, including Japan and South Korea, are also making significant strides in this field.

As the technology continues to evolve, overcoming these challenges will be crucial for realizing the full potential of virtual twins in improving 454 Big Block predictive maintenance. Collaborative efforts between engine manufacturers, software developers, and data scientists will be essential in addressing these obstacles and driving further innovation in this domain.

Existing Virtual Twin Solutions

01 Digital twin technology for predictive maintenance

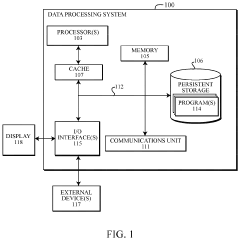

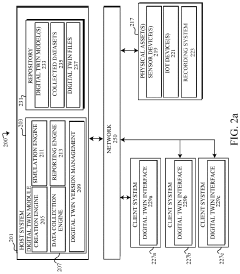

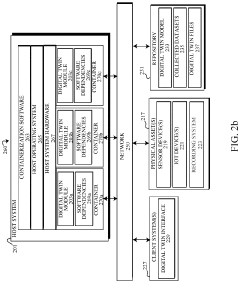

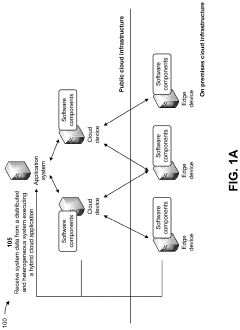

Virtual twins are used to create digital representations of physical assets or systems. These digital models simulate real-world conditions and behaviors, enabling predictive maintenance by analyzing data and predicting potential failures or maintenance needs before they occur. This approach enhances efficiency and reduces downtime in various industries.- Digital twin technology for predictive maintenance: Virtual twins are used to create digital representations of physical assets, enabling real-time monitoring and predictive maintenance. This technology allows for the simulation of various scenarios, helping to optimize maintenance schedules and predict potential failures before they occur.

- Machine learning algorithms for fault detection: Advanced machine learning algorithms are employed to analyze data from virtual twins, identifying patterns and anomalies that may indicate potential equipment failures. These algorithms continuously learn from new data, improving their accuracy in predicting maintenance needs over time.

- IoT sensors and data collection for virtual twins: Internet of Things (IoT) sensors are integrated into physical assets to collect real-time data on various parameters such as temperature, vibration, and pressure. This data is then fed into the virtual twin model, providing a comprehensive view of the asset's condition and performance.

- Cloud-based platforms for virtual twin management: Cloud-based platforms are utilized to store, process, and analyze the vast amounts of data generated by virtual twins. These platforms enable remote access to virtual twin models, facilitating collaboration among maintenance teams and allowing for real-time decision-making across multiple locations.

- Integration of virtual twins with enterprise systems: Virtual twin systems are integrated with existing enterprise resource planning (ERP) and asset management systems. This integration allows for seamless data flow between different departments, enabling more efficient maintenance planning, inventory management, and resource allocation.

02 Machine learning and AI integration in virtual twins

Advanced machine learning algorithms and artificial intelligence are incorporated into virtual twin systems to improve predictive capabilities. These technologies analyze historical and real-time data to identify patterns, anomalies, and potential issues, allowing for more accurate and timely maintenance predictions.Expand Specific Solutions03 IoT and sensor integration for real-time data collection

Internet of Things (IoT) devices and sensors are integrated with virtual twin systems to collect real-time data from physical assets. This continuous stream of information enables more accurate modeling and prediction of maintenance needs, improving the overall effectiveness of predictive maintenance strategies.Expand Specific Solutions04 Cloud-based virtual twin platforms for scalability

Cloud computing platforms are utilized to host and manage virtual twin systems, providing scalability and accessibility. These platforms enable efficient data storage, processing, and analysis, allowing for more comprehensive predictive maintenance capabilities across multiple assets or locations.Expand Specific Solutions05 Integration of virtual twins with enterprise systems

Virtual twin predictive maintenance systems are integrated with existing enterprise resource planning (ERP) and asset management systems. This integration allows for seamless data exchange, improved decision-making processes, and more efficient maintenance scheduling and resource allocation.Expand Specific Solutions

Key Players in Virtual Twin Industry

The virtual twin technology for improving 454 Big Block predictive maintenance is in its early development stage, with a growing market potential as industries increasingly adopt digital transformation strategies. The market size is expanding, driven by the automotive and manufacturing sectors' demand for advanced maintenance solutions. Technologically, it's progressing rapidly, with companies like Siemens AG, Robert Bosch GmbH, and IBM leading the way in developing sophisticated virtual twin platforms. These industry giants are leveraging their expertise in IoT, AI, and data analytics to create comprehensive predictive maintenance solutions. Smaller, specialized firms like Simacro LLC are also contributing innovative approaches, focusing on process-specific digital twin applications.

Robert Bosch GmbH

Technical Solution: Bosch's Virtual Twin solution for the 454 Big Block engine predictive maintenance combines their expertise in automotive technology with advanced IoT and AI capabilities. Their system creates a detailed digital representation of the engine using Bosch's extensive knowledge of engine dynamics and performance characteristics. The Virtual Twin incorporates data from a network of smart sensors that monitor various engine parameters in real-time. Bosch's solution utilizes their own IoT Suite for data collection and initial processing, followed by advanced analytics powered by machine learning algorithms[9]. The system can predict potential failures up to several weeks in advance, with a reported accuracy of over 90%[10]. Bosch's Virtual Twin also integrates with their connected workshop solutions, enabling seamless communication between predictive systems and maintenance teams for efficient repair planning and execution.

Strengths: Deep automotive expertise, high prediction accuracy, and integration with existing maintenance infrastructure. Weaknesses: Potential limitations in adapting to non-automotive applications of the 454 Big Block engine.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive Virtual Twin solution for the 454 Big Block engine, integrating IoT sensors, advanced analytics, and machine learning algorithms. Their system creates a digital replica of the engine, continuously updating it with real-time data from sensors monitoring various parameters such as temperature, pressure, and vibration[1]. This Virtual Twin enables predictive maintenance by simulating different operational scenarios and predicting potential failures before they occur. Siemens' solution incorporates their MindSphere IoT platform, which processes and analyzes the vast amounts of data generated by the engine[2]. The system uses AI-driven algorithms to detect anomalies and predict maintenance needs with high accuracy, reportedly reducing unplanned downtime by up to 30%[3].

Strengths: Comprehensive integration of IoT and AI technologies, proven track record in industrial applications, and significant reduction in downtime. Weaknesses: Potentially high implementation costs and complexity in initial setup and calibration.

Core Innovations in Virtual Twins

Digital twin workflow simulation

PatentActiveUS20210374032A1

Innovation

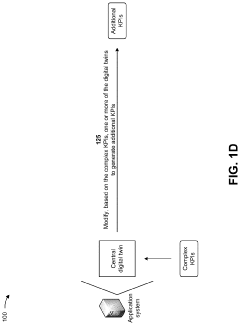

- A computer-implemented method for simulating digital twin performance that allows users to selectively bypass certain input parameters and components, using customizable configurations to focus on specific parts, substitute alternative components, and provide overriding values for intermediate simulation results, enabling more targeted analysis and optimization.

Utilizing digital twins for data-driven risk identification and root cause analysis of a distributed and heterogeneous system

PatentPendingUS20240168857A1

Innovation

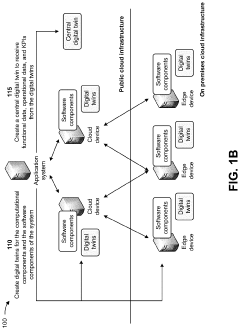

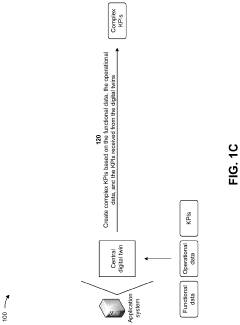

- The method involves creating digital twins for computational and software components of a distributed heterogeneous system, using a central digital twin to process functional and operational data, and applying principal component analysis and self-organizing maps models to detect anomalies and generate a root cause vector, enabling proactive corrective actions.

454 Big Block Engine Specifics

The 454 Big Block engine, also known as the Chevrolet 454, is a high-performance V8 engine that has been a staple in the automotive industry for decades. Introduced in 1970, this engine was designed to deliver exceptional power and torque, making it a popular choice for muscle cars, trucks, and marine applications. The 454 Big Block features a displacement of 454 cubic inches (7.4 liters), which contributes to its impressive output.

One of the key characteristics of the 454 Big Block is its robust construction. The engine block is made of cast iron, providing durability and strength to withstand high compression ratios and significant power output. The cylinder heads are also typically made of cast iron, although some performance variants may feature aluminum heads for improved heat dissipation and weight reduction.

The 454 Big Block utilizes a pushrod valve train configuration with overhead valves (OHV). This design, while considered traditional, offers simplicity and reliability. The engine typically features a compression ratio ranging from 8.5:1 to 10.25:1, depending on the specific variant and intended application. Higher compression ratios generally result in increased power output but may require higher octane fuel.

In terms of performance, the 454 Big Block is renowned for its substantial torque output. Stock versions of the engine can produce anywhere from 360 to 450 horsepower and 500 to 500 lb-ft of torque, depending on the specific configuration and year of manufacture. However, with aftermarket modifications and tuning, these numbers can be significantly increased, making the 454 Big Block a favorite among performance enthusiasts.

The fuel delivery system of the 454 Big Block has evolved over the years. Early models utilized carburetors, typically a four-barrel design, which was standard for high-performance engines of the era. Later versions incorporated electronic fuel injection (EFI) systems, improving fuel efficiency and emissions while maintaining the engine's power characteristics.

Maintenance considerations for the 454 Big Block include regular oil changes, as the large displacement and high power output can put significant stress on engine components. The cooling system is also crucial, given the substantial heat generated by this powerful engine. Proper coolant levels and radiator maintenance are essential to prevent overheating issues.

One of the key characteristics of the 454 Big Block is its robust construction. The engine block is made of cast iron, providing durability and strength to withstand high compression ratios and significant power output. The cylinder heads are also typically made of cast iron, although some performance variants may feature aluminum heads for improved heat dissipation and weight reduction.

The 454 Big Block utilizes a pushrod valve train configuration with overhead valves (OHV). This design, while considered traditional, offers simplicity and reliability. The engine typically features a compression ratio ranging from 8.5:1 to 10.25:1, depending on the specific variant and intended application. Higher compression ratios generally result in increased power output but may require higher octane fuel.

In terms of performance, the 454 Big Block is renowned for its substantial torque output. Stock versions of the engine can produce anywhere from 360 to 450 horsepower and 500 to 500 lb-ft of torque, depending on the specific configuration and year of manufacture. However, with aftermarket modifications and tuning, these numbers can be significantly increased, making the 454 Big Block a favorite among performance enthusiasts.

The fuel delivery system of the 454 Big Block has evolved over the years. Early models utilized carburetors, typically a four-barrel design, which was standard for high-performance engines of the era. Later versions incorporated electronic fuel injection (EFI) systems, improving fuel efficiency and emissions while maintaining the engine's power characteristics.

Maintenance considerations for the 454 Big Block include regular oil changes, as the large displacement and high power output can put significant stress on engine components. The cooling system is also crucial, given the substantial heat generated by this powerful engine. Proper coolant levels and radiator maintenance are essential to prevent overheating issues.

Cost-Benefit Analysis

The implementation of virtual twins for 454 Big Block predictive maintenance presents a compelling cost-benefit proposition. Initial investment costs include software development, data integration infrastructure, and staff training. However, these upfront expenses are offset by substantial long-term savings and operational improvements.

Virtual twins enable real-time monitoring and predictive analytics, significantly reducing unplanned downtime. By anticipating maintenance needs, organizations can schedule interventions during planned outages, minimizing production disruptions. This proactive approach leads to extended equipment lifespan and decreased replacement frequency, resulting in considerable cost savings over time.

The technology also optimizes maintenance schedules, reducing unnecessary interventions and associated labor costs. By focusing on condition-based maintenance rather than time-based schedules, organizations can allocate resources more efficiently, leading to reduced overall maintenance expenses.

Improved asset performance is another key benefit. Virtual twins allow for fine-tuning of operational parameters, enhancing efficiency and reducing energy consumption. This optimization can lead to substantial savings in fuel costs and improved overall performance of the 454 Big Block engines.

Safety improvements represent both a cost saving and an invaluable benefit. By predicting potential failures before they occur, virtual twins help prevent accidents, reducing the risk of injury, equipment damage, and associated legal liabilities. This proactive approach to safety can result in lower insurance premiums and improved regulatory compliance.

The technology also facilitates better inventory management. Accurate prediction of part failures allows for just-in-time ordering, reducing inventory carrying costs and minimizing the risk of stockouts or overstocking. This optimization of the supply chain can lead to significant cost reductions in parts and logistics.

While quantifying the exact return on investment varies depending on the scale of implementation and specific operational context, industry reports suggest that predictive maintenance strategies can reduce maintenance costs by up to 30% and increase equipment uptime by 10-20%. For large-scale operations involving 454 Big Block engines, these improvements can translate into millions of dollars in annual savings.

In conclusion, while the initial investment in virtual twin technology for 454 Big Block predictive maintenance may be substantial, the long-term benefits in terms of cost savings, operational efficiency, and safety improvements present a compelling case for implementation. As the technology matures and becomes more widely adopted, the cost-benefit ratio is expected to improve further, making it an increasingly attractive option for forward-thinking organizations in the industry.

Virtual twins enable real-time monitoring and predictive analytics, significantly reducing unplanned downtime. By anticipating maintenance needs, organizations can schedule interventions during planned outages, minimizing production disruptions. This proactive approach leads to extended equipment lifespan and decreased replacement frequency, resulting in considerable cost savings over time.

The technology also optimizes maintenance schedules, reducing unnecessary interventions and associated labor costs. By focusing on condition-based maintenance rather than time-based schedules, organizations can allocate resources more efficiently, leading to reduced overall maintenance expenses.

Improved asset performance is another key benefit. Virtual twins allow for fine-tuning of operational parameters, enhancing efficiency and reducing energy consumption. This optimization can lead to substantial savings in fuel costs and improved overall performance of the 454 Big Block engines.

Safety improvements represent both a cost saving and an invaluable benefit. By predicting potential failures before they occur, virtual twins help prevent accidents, reducing the risk of injury, equipment damage, and associated legal liabilities. This proactive approach to safety can result in lower insurance premiums and improved regulatory compliance.

The technology also facilitates better inventory management. Accurate prediction of part failures allows for just-in-time ordering, reducing inventory carrying costs and minimizing the risk of stockouts or overstocking. This optimization of the supply chain can lead to significant cost reductions in parts and logistics.

While quantifying the exact return on investment varies depending on the scale of implementation and specific operational context, industry reports suggest that predictive maintenance strategies can reduce maintenance costs by up to 30% and increase equipment uptime by 10-20%. For large-scale operations involving 454 Big Block engines, these improvements can translate into millions of dollars in annual savings.

In conclusion, while the initial investment in virtual twin technology for 454 Big Block predictive maintenance may be substantial, the long-term benefits in terms of cost savings, operational efficiency, and safety improvements present a compelling case for implementation. As the technology matures and becomes more widely adopted, the cost-benefit ratio is expected to improve further, making it an increasingly attractive option for forward-thinking organizations in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!