How Energy Storing Flywheels Revolutionize 454 Big Block Usage

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flywheel Energy Storage Evolution and Objectives

Flywheel energy storage technology has evolved significantly over the past century, with its roots tracing back to the early industrial era. Initially used in steam engines and potter's wheels, flywheels have transformed into sophisticated energy storage devices capable of revolutionizing various applications, including the 454 Big Block engine.

The evolution of flywheel energy storage can be divided into several key phases. In the early 20th century, flywheels were primarily mechanical devices used to smooth out power delivery in engines. The mid-20th century saw the introduction of advanced materials and designs, improving energy density and efficiency. By the late 20th century, the integration of magnetic bearings and vacuum enclosures dramatically reduced friction losses, enhancing overall performance.

The 21st century has witnessed a surge in flywheel technology development, driven by the need for efficient energy storage solutions in renewable energy systems and transportation. Modern flywheels utilize composite materials, such as carbon fiber, to achieve higher rotational speeds and energy densities. The incorporation of advanced control systems and power electronics has further improved their responsiveness and integration capabilities.

In the context of the 454 Big Block engine, the objectives of flywheel energy storage are multifaceted. Primarily, the technology aims to enhance the engine's power delivery characteristics by smoothing out torque fluctuations and improving acceleration response. This is particularly beneficial in high-performance applications where consistent power output is crucial.

Another key objective is to improve fuel efficiency by capturing and storing kinetic energy during deceleration, which can then be released during acceleration. This regenerative braking concept, when applied to the 454 Big Block, has the potential to significantly reduce fuel consumption, especially in stop-and-start driving conditions.

Furthermore, flywheel energy storage systems seek to reduce emissions by optimizing engine operation and minimizing idle time. By providing instantaneous power on demand, flywheels can allow for engine downsizing or more efficient operating strategies without compromising performance.

The integration of flywheel technology with the 454 Big Block also aims to enhance durability and longevity. By absorbing sudden load changes and reducing stress on engine components, flywheels can potentially extend the lifespan of critical parts and improve overall reliability.

Looking ahead, the objectives for flywheel energy storage in 454 Big Block applications include further miniaturization, cost reduction, and seamless integration with hybrid powertrains. Researchers are exploring advanced materials and manufacturing techniques to increase energy density while reducing weight and production costs. The ultimate goal is to create a highly efficient, compact, and cost-effective energy storage solution that can revolutionize the performance and efficiency of high-displacement engines like the 454 Big Block.

The evolution of flywheel energy storage can be divided into several key phases. In the early 20th century, flywheels were primarily mechanical devices used to smooth out power delivery in engines. The mid-20th century saw the introduction of advanced materials and designs, improving energy density and efficiency. By the late 20th century, the integration of magnetic bearings and vacuum enclosures dramatically reduced friction losses, enhancing overall performance.

The 21st century has witnessed a surge in flywheel technology development, driven by the need for efficient energy storage solutions in renewable energy systems and transportation. Modern flywheels utilize composite materials, such as carbon fiber, to achieve higher rotational speeds and energy densities. The incorporation of advanced control systems and power electronics has further improved their responsiveness and integration capabilities.

In the context of the 454 Big Block engine, the objectives of flywheel energy storage are multifaceted. Primarily, the technology aims to enhance the engine's power delivery characteristics by smoothing out torque fluctuations and improving acceleration response. This is particularly beneficial in high-performance applications where consistent power output is crucial.

Another key objective is to improve fuel efficiency by capturing and storing kinetic energy during deceleration, which can then be released during acceleration. This regenerative braking concept, when applied to the 454 Big Block, has the potential to significantly reduce fuel consumption, especially in stop-and-start driving conditions.

Furthermore, flywheel energy storage systems seek to reduce emissions by optimizing engine operation and minimizing idle time. By providing instantaneous power on demand, flywheels can allow for engine downsizing or more efficient operating strategies without compromising performance.

The integration of flywheel technology with the 454 Big Block also aims to enhance durability and longevity. By absorbing sudden load changes and reducing stress on engine components, flywheels can potentially extend the lifespan of critical parts and improve overall reliability.

Looking ahead, the objectives for flywheel energy storage in 454 Big Block applications include further miniaturization, cost reduction, and seamless integration with hybrid powertrains. Researchers are exploring advanced materials and manufacturing techniques to increase energy density while reducing weight and production costs. The ultimate goal is to create a highly efficient, compact, and cost-effective energy storage solution that can revolutionize the performance and efficiency of high-displacement engines like the 454 Big Block.

Market Demand for Advanced 454 Big Block Systems

The market demand for advanced 454 Big Block systems has been steadily growing, driven by the increasing need for more efficient and powerful engines in various industries. The integration of energy-storing flywheels into these systems has sparked significant interest among manufacturers and end-users alike, as it promises to revolutionize the performance and efficiency of these iconic engines.

In the automotive sector, there is a resurgence of interest in high-performance vehicles, particularly in the muscle car and drag racing segments. Enthusiasts and professional racers are constantly seeking ways to extract more power and improve the overall performance of their engines. The incorporation of energy-storing flywheels into 454 Big Block systems offers a compelling solution to meet these demands, as it can provide instant power boosts and improve energy recovery during deceleration.

The marine industry has also shown considerable interest in advanced 454 Big Block systems with flywheel technology. Boat manufacturers and owners are looking for ways to enhance the power output of their vessels while simultaneously improving fuel efficiency. The ability of energy-storing flywheels to capture and release energy quickly makes them particularly attractive for marine applications, where sudden bursts of power are often required.

In the industrial sector, there is a growing demand for more efficient power generation systems. Large-scale generators and power plants that utilize 454 Big Block engines are exploring the integration of flywheel technology to improve overall system efficiency and reduce fuel consumption. This trend is driven by both economic factors and increasing environmental regulations that require more sustainable power generation solutions.

The agricultural sector has also shown interest in advanced 454 Big Block systems, particularly for use in heavy machinery and tractors. Farmers and agricultural equipment manufacturers are seeking ways to improve the power output and fuel efficiency of their machinery, and the integration of energy-storing flywheels offers a promising solution to meet these needs.

Market analysts predict that the demand for advanced 454 Big Block systems with flywheel technology will continue to grow in the coming years. This growth is expected to be driven by ongoing technological advancements, increasing awareness of the benefits of flywheel energy storage, and the push for more efficient and environmentally friendly power solutions across various industries.

In the automotive sector, there is a resurgence of interest in high-performance vehicles, particularly in the muscle car and drag racing segments. Enthusiasts and professional racers are constantly seeking ways to extract more power and improve the overall performance of their engines. The incorporation of energy-storing flywheels into 454 Big Block systems offers a compelling solution to meet these demands, as it can provide instant power boosts and improve energy recovery during deceleration.

The marine industry has also shown considerable interest in advanced 454 Big Block systems with flywheel technology. Boat manufacturers and owners are looking for ways to enhance the power output of their vessels while simultaneously improving fuel efficiency. The ability of energy-storing flywheels to capture and release energy quickly makes them particularly attractive for marine applications, where sudden bursts of power are often required.

In the industrial sector, there is a growing demand for more efficient power generation systems. Large-scale generators and power plants that utilize 454 Big Block engines are exploring the integration of flywheel technology to improve overall system efficiency and reduce fuel consumption. This trend is driven by both economic factors and increasing environmental regulations that require more sustainable power generation solutions.

The agricultural sector has also shown interest in advanced 454 Big Block systems, particularly for use in heavy machinery and tractors. Farmers and agricultural equipment manufacturers are seeking ways to improve the power output and fuel efficiency of their machinery, and the integration of energy-storing flywheels offers a promising solution to meet these needs.

Market analysts predict that the demand for advanced 454 Big Block systems with flywheel technology will continue to grow in the coming years. This growth is expected to be driven by ongoing technological advancements, increasing awareness of the benefits of flywheel energy storage, and the push for more efficient and environmentally friendly power solutions across various industries.

Current Challenges in Flywheel Energy Storage

Flywheel energy storage systems have made significant strides in recent years, yet they still face several challenges that hinder their widespread adoption and integration with 454 Big Block engines. One of the primary obstacles is the high initial cost associated with manufacturing and installing these systems. The precision engineering required for high-speed rotating components and the advanced materials used in their construction contribute to elevated expenses, making it difficult for many potential users to justify the investment.

Another significant challenge lies in the safety concerns surrounding flywheel energy storage. The high rotational speeds involved create potential risks of mechanical failure, which could lead to catastrophic consequences if not properly managed. This necessitates robust containment systems and fail-safe mechanisms, adding further complexity and cost to the overall design.

Energy density and storage capacity remain limiting factors for flywheel systems when compared to other energy storage technologies. While flywheels excel in power density and rapid charge/discharge cycles, their ability to store large amounts of energy for extended periods is relatively limited. This constraint poses challenges for applications requiring long-duration energy storage, such as in automotive or grid-scale implementations.

The integration of flywheel systems with existing 454 Big Block engines presents its own set of challenges. Adapting these powerful engines to work efficiently with flywheel energy storage requires careful engineering to manage power flow, synchronization, and overall system dynamics. The complexity of this integration can lead to increased development time and costs.

Efficiency losses due to friction and air resistance are ongoing concerns in flywheel technology. While advances in magnetic bearings and vacuum enclosures have mitigated some of these issues, further improvements are needed to maximize energy retention and overall system efficiency. These losses become particularly significant during longer storage periods, affecting the viability of flywheels for certain applications.

Scalability is another challenge facing flywheel energy storage systems. As energy requirements increase, scaling up flywheel systems can become problematic due to the physical limitations of materials and the exponential increase in centrifugal forces. This scalability issue can restrict the application of flywheels in larger-scale energy storage scenarios.

Lastly, the environmental impact and lifecycle considerations of flywheel systems present challenges. While generally considered environmentally friendly due to their lack of chemical components, the production and eventual disposal of advanced composite materials used in high-performance flywheels raise sustainability concerns that need to be addressed.

Another significant challenge lies in the safety concerns surrounding flywheel energy storage. The high rotational speeds involved create potential risks of mechanical failure, which could lead to catastrophic consequences if not properly managed. This necessitates robust containment systems and fail-safe mechanisms, adding further complexity and cost to the overall design.

Energy density and storage capacity remain limiting factors for flywheel systems when compared to other energy storage technologies. While flywheels excel in power density and rapid charge/discharge cycles, their ability to store large amounts of energy for extended periods is relatively limited. This constraint poses challenges for applications requiring long-duration energy storage, such as in automotive or grid-scale implementations.

The integration of flywheel systems with existing 454 Big Block engines presents its own set of challenges. Adapting these powerful engines to work efficiently with flywheel energy storage requires careful engineering to manage power flow, synchronization, and overall system dynamics. The complexity of this integration can lead to increased development time and costs.

Efficiency losses due to friction and air resistance are ongoing concerns in flywheel technology. While advances in magnetic bearings and vacuum enclosures have mitigated some of these issues, further improvements are needed to maximize energy retention and overall system efficiency. These losses become particularly significant during longer storage periods, affecting the viability of flywheels for certain applications.

Scalability is another challenge facing flywheel energy storage systems. As energy requirements increase, scaling up flywheel systems can become problematic due to the physical limitations of materials and the exponential increase in centrifugal forces. This scalability issue can restrict the application of flywheels in larger-scale energy storage scenarios.

Lastly, the environmental impact and lifecycle considerations of flywheel systems present challenges. While generally considered environmentally friendly due to their lack of chemical components, the production and eventual disposal of advanced composite materials used in high-performance flywheels raise sustainability concerns that need to be addressed.

Existing Flywheel Solutions for 454 Big Block

01 Energy storage and power management

Flywheels are used for energy storage and power management in various applications. They can store excess energy during low demand periods and release it during peak demand, helping to stabilize power grids and improve energy efficiency. This technology is particularly useful in renewable energy systems, where energy production can be intermittent.- Energy storage and power management: Flywheels are used for energy storage and power management in various applications. They can store excess energy during low demand periods and release it during peak demand, helping to stabilize power grids and improve energy efficiency. This technology is particularly useful in renewable energy systems, where power output can be intermittent.

- Aerospace and satellite applications: Energy storing flywheels are utilized in aerospace and satellite systems for attitude control, energy storage, and power distribution. They provide a reliable and efficient means of energy management in space, where traditional energy storage methods may be less effective or impractical.

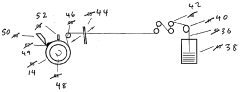

- Transportation and automotive systems: Flywheels are employed in transportation systems, particularly in hybrid and electric vehicles, to capture and store energy from regenerative braking. This stored energy can then be used to assist acceleration, improving overall vehicle efficiency and reducing fuel consumption.

- Grid stabilization and frequency regulation: Energy storing flywheels play a crucial role in grid stabilization and frequency regulation. They can quickly respond to changes in power demand, helping to maintain grid frequency and stability. This application is particularly important in microgrids and areas with high renewable energy penetration.

- Industrial and manufacturing applications: Flywheels are used in various industrial and manufacturing processes for energy recovery and power quality improvement. They can help manage peak loads, reduce energy costs, and provide backup power in critical industrial applications. This technology is particularly beneficial in industries with high-power, short-duration energy demands.

02 Aerospace and satellite applications

Energy storing flywheels are utilized in aerospace and satellite systems for attitude control, energy storage, and power distribution. They provide a reliable and efficient means of energy management in space, where traditional battery systems may be less effective due to weight constraints and environmental factors.Expand Specific Solutions03 Transportation and automotive systems

Flywheels are employed in transportation systems, particularly in hybrid and electric vehicles, to capture and store energy from regenerative braking. This stored energy can then be used to assist acceleration, improving overall vehicle efficiency and reducing fuel consumption.Expand Specific Solutions04 Industrial and manufacturing applications

Energy storing flywheels find applications in industrial settings for load leveling, power quality improvement, and uninterruptible power supply systems. They can help manage peak power demands in manufacturing processes, reducing strain on the electrical grid and potentially lowering energy costs.Expand Specific Solutions05 Smart grid and renewable energy integration

Flywheels play a crucial role in smart grid systems and renewable energy integration. They help balance supply and demand, provide frequency regulation, and enhance grid stability. This technology enables more efficient use of renewable energy sources by storing excess energy and releasing it when needed.Expand Specific Solutions

Key Players in Flywheel and Engine Industries

The energy storing flywheel technology for 454 Big Block engines is in an early development stage, with a growing market potential as the automotive industry shifts towards more efficient and sustainable solutions. The market size is expected to expand significantly in the coming years, driven by increasing demand for energy-efficient vehicles and stricter emissions regulations. Companies like Torus, Inc. and KineticCore Solutions are pioneering this technology, focusing on integrating flywheels with renewable energy sources and improving energy storage capabilities. Established players such as Bosch Ltd. and Mitsubishi Electric Corp. are also investing in research and development to adapt flywheel technology for automotive applications, indicating a competitive landscape with both startups and industry giants vying for market share.

Kineticcore Solutions LLC

Technical Solution: Kineticcore Solutions LLC has developed advanced flywheel energy storage systems that could potentially revolutionize 454 Big Block usage. Their technology focuses on high-efficiency, compact flywheel designs suitable for automotive applications[9]. For 454 Big Block engines, Kineticcore's flywheels could be integrated to capture and store kinetic energy during deceleration and engine braking, then rapidly release this energy to boost acceleration or power auxiliary systems. The company's flywheels typically operate at speeds between 20,000 to 50,000 RPM, offering a balance between energy density and safety[10]. This system could allow 454 Big Block engines to maintain their high-performance characteristics while improving fuel efficiency and reducing emissions by optimizing energy use across various driving conditions.

Strengths: Compact design suitable for automotive integration, good balance of energy density and safety, potential for significant efficiency improvements. Weaknesses: May require significant modifications to existing engine designs, potential for increased complexity and maintenance requirements.

Levistor Ltd.

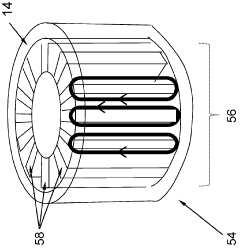

Technical Solution: Levistor Ltd. has developed advanced flywheel energy storage systems that could potentially revolutionize 454 Big Block usage. Their technology utilizes high-speed carbon fiber flywheels suspended in vacuum chambers with magnetic bearings, capable of storing and releasing large amounts of energy quickly[1]. This system can be integrated with 454 Big Block engines to capture and reuse kinetic energy, significantly improving fuel efficiency and power output. The flywheels can spin up to 60,000 RPM, storing energy during deceleration and releasing it during acceleration, effectively acting as a mechanical battery[2]. This technology could allow 454 Big Block engines to meet stricter emissions standards while maintaining their high-performance characteristics.

Strengths: High power density, rapid charge/discharge cycles, long operational life. Weaknesses: Initial cost, complexity of integration with existing engine systems, safety concerns with high-speed rotating masses.

Core Innovations in Flywheel Energy Storage

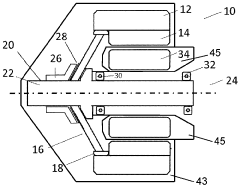

Flywheel assembly

PatentActiveGB2517808A

Innovation

- An annular rotor design with a matrix of fibres wound in layers and magnetic particles, where the winding angle and magnetic particle size are carefully controlled to optimize mechanical strength and magnetic properties, allowing for efficient energy storage and recovery while minimizing heat buildup and enhancing safety.

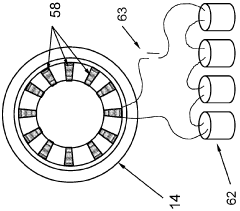

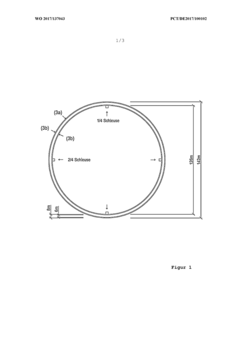

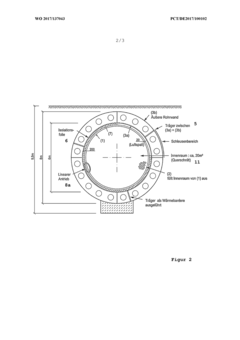

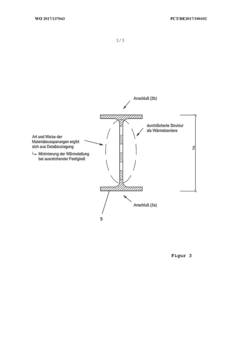

Kinetic large power accumulator

PatentWO2017137043A1

Innovation

- A large kinetic storage system employing a circular ring design with a significant increase in centrifugal mass, rotational speed up to 1,300 m/s, and the use of superconducting magnets and linear motors to enhance energy storage capacity to 14 MWh to 1,600 MWh, suitable for stationary applications and grid stabilization.

Environmental Impact of Flywheel Technology

The integration of flywheel technology in 454 Big Block engines represents a significant step towards more sustainable and environmentally friendly automotive solutions. Flywheels, as energy storage devices, offer several environmental benefits that can revolutionize the use of these powerful engines.

One of the primary environmental advantages of flywheel technology is its potential to reduce fuel consumption and, consequently, greenhouse gas emissions. By capturing and storing kinetic energy that would otherwise be lost during braking or deceleration, flywheels enable a more efficient use of energy in 454 Big Block engines. This regenerative braking system can lead to substantial fuel savings, particularly in urban driving conditions with frequent stops and starts.

Moreover, flywheels provide a clean and sustainable alternative to traditional battery-based energy storage systems. Unlike batteries, which rely on environmentally harmful materials and complex recycling processes, flywheels are made from relatively simple and recyclable materials. This characteristic significantly reduces the environmental impact associated with the production, use, and disposal of energy storage components in vehicles.

The implementation of flywheel technology also contributes to noise reduction in urban environments. As flywheels operate silently, they can help mitigate the noise pollution typically associated with powerful engines like the 454 Big Block. This aspect is particularly beneficial in densely populated areas where noise regulations are becoming increasingly stringent.

Furthermore, the use of flywheels can extend the lifespan of engine components by reducing the strain on the powertrain during acceleration and deceleration. This longevity translates to fewer replacements and repairs, ultimately reducing the environmental impact associated with manufacturing and disposing of automotive parts.

The environmental benefits of flywheel technology extend beyond the operational phase of the vehicle. The manufacturing process of flywheels is generally less energy-intensive and produces fewer harmful byproducts compared to the production of traditional energy storage systems. This factor contributes to a lower overall carbon footprint for vehicles equipped with flywheel technology.

Additionally, the integration of flywheels in 454 Big Block engines can pave the way for more efficient hybrid powertrains. By combining the power of the internal combustion engine with the energy-saving capabilities of flywheels, manufacturers can create vehicles that offer both high performance and improved fuel efficiency. This hybrid approach can significantly reduce the environmental impact of high-performance vehicles without compromising their appeal to enthusiasts.

In conclusion, the environmental impact of flywheel technology in 454 Big Block engines is overwhelmingly positive. From reduced emissions and improved energy efficiency to decreased noise pollution and enhanced sustainability in manufacturing, flywheels offer a promising solution for mitigating the environmental concerns associated with powerful automotive engines. As this technology continues to evolve and gain wider adoption, it has the potential to play a crucial role in the automotive industry's transition towards more sustainable practices.

One of the primary environmental advantages of flywheel technology is its potential to reduce fuel consumption and, consequently, greenhouse gas emissions. By capturing and storing kinetic energy that would otherwise be lost during braking or deceleration, flywheels enable a more efficient use of energy in 454 Big Block engines. This regenerative braking system can lead to substantial fuel savings, particularly in urban driving conditions with frequent stops and starts.

Moreover, flywheels provide a clean and sustainable alternative to traditional battery-based energy storage systems. Unlike batteries, which rely on environmentally harmful materials and complex recycling processes, flywheels are made from relatively simple and recyclable materials. This characteristic significantly reduces the environmental impact associated with the production, use, and disposal of energy storage components in vehicles.

The implementation of flywheel technology also contributes to noise reduction in urban environments. As flywheels operate silently, they can help mitigate the noise pollution typically associated with powerful engines like the 454 Big Block. This aspect is particularly beneficial in densely populated areas where noise regulations are becoming increasingly stringent.

Furthermore, the use of flywheels can extend the lifespan of engine components by reducing the strain on the powertrain during acceleration and deceleration. This longevity translates to fewer replacements and repairs, ultimately reducing the environmental impact associated with manufacturing and disposing of automotive parts.

The environmental benefits of flywheel technology extend beyond the operational phase of the vehicle. The manufacturing process of flywheels is generally less energy-intensive and produces fewer harmful byproducts compared to the production of traditional energy storage systems. This factor contributes to a lower overall carbon footprint for vehicles equipped with flywheel technology.

Additionally, the integration of flywheels in 454 Big Block engines can pave the way for more efficient hybrid powertrains. By combining the power of the internal combustion engine with the energy-saving capabilities of flywheels, manufacturers can create vehicles that offer both high performance and improved fuel efficiency. This hybrid approach can significantly reduce the environmental impact of high-performance vehicles without compromising their appeal to enthusiasts.

In conclusion, the environmental impact of flywheel technology in 454 Big Block engines is overwhelmingly positive. From reduced emissions and improved energy efficiency to decreased noise pollution and enhanced sustainability in manufacturing, flywheels offer a promising solution for mitigating the environmental concerns associated with powerful automotive engines. As this technology continues to evolve and gain wider adoption, it has the potential to play a crucial role in the automotive industry's transition towards more sustainable practices.

Cost-Benefit Analysis of Flywheel Implementation

The implementation of energy-storing flywheels in 454 Big Block engines presents a compelling case for cost-benefit analysis. Initial investment costs for flywheel systems are substantial, encompassing the flywheel itself, associated control systems, and integration expenses. However, these upfront costs must be weighed against long-term operational savings and performance enhancements.

Energy efficiency improvements constitute a primary benefit of flywheel integration. By capturing and storing kinetic energy during deceleration, flywheels can significantly reduce fuel consumption in 454 Big Block engines. This translates to direct cost savings for vehicle operators, particularly in applications with frequent start-stop cycles or variable power demands.

Maintenance costs represent another crucial factor in the cost-benefit equation. While flywheels introduce additional components requiring periodic inspection and maintenance, they can potentially extend the lifespan of other engine components by smoothing power delivery and reducing stress on the drivetrain. This may lead to decreased overall maintenance expenses and improved vehicle uptime.

Performance benefits, though less directly quantifiable, contribute significantly to the value proposition of flywheel implementation. Enhanced acceleration, improved power delivery, and reduced emissions can increase vehicle productivity and potentially open new market opportunities for 454 Big Block-equipped vehicles.

Environmental considerations also play a role in the cost-benefit analysis. Reduced fuel consumption and emissions can lead to compliance with stricter environmental regulations, potentially avoiding fines or enabling access to markets with stringent emissions standards. This aspect may become increasingly important as environmental regulations continue to evolve.

The payback period for flywheel implementation varies depending on usage patterns and specific applications. Heavy-duty vehicles with high utilization rates and frequent power fluctuations are likely to see faster returns on investment compared to light-duty or intermittently used vehicles.

Scalability and future-proofing should also be factored into the analysis. As flywheel technology continues to advance, the potential for retrofitting or upgrading existing systems may provide additional long-term value and adaptability to changing market demands or regulatory requirements.

In conclusion, while the initial costs of flywheel implementation for 454 Big Block engines are significant, the potential for long-term operational savings, performance improvements, and environmental benefits presents a compelling case for adoption in many applications. A thorough analysis of specific use cases and operational profiles is essential to determine the precise cost-benefit ratio for individual implementations.

Energy efficiency improvements constitute a primary benefit of flywheel integration. By capturing and storing kinetic energy during deceleration, flywheels can significantly reduce fuel consumption in 454 Big Block engines. This translates to direct cost savings for vehicle operators, particularly in applications with frequent start-stop cycles or variable power demands.

Maintenance costs represent another crucial factor in the cost-benefit equation. While flywheels introduce additional components requiring periodic inspection and maintenance, they can potentially extend the lifespan of other engine components by smoothing power delivery and reducing stress on the drivetrain. This may lead to decreased overall maintenance expenses and improved vehicle uptime.

Performance benefits, though less directly quantifiable, contribute significantly to the value proposition of flywheel implementation. Enhanced acceleration, improved power delivery, and reduced emissions can increase vehicle productivity and potentially open new market opportunities for 454 Big Block-equipped vehicles.

Environmental considerations also play a role in the cost-benefit analysis. Reduced fuel consumption and emissions can lead to compliance with stricter environmental regulations, potentially avoiding fines or enabling access to markets with stringent emissions standards. This aspect may become increasingly important as environmental regulations continue to evolve.

The payback period for flywheel implementation varies depending on usage patterns and specific applications. Heavy-duty vehicles with high utilization rates and frequent power fluctuations are likely to see faster returns on investment compared to light-duty or intermittently used vehicles.

Scalability and future-proofing should also be factored into the analysis. As flywheel technology continues to advance, the potential for retrofitting or upgrading existing systems may provide additional long-term value and adaptability to changing market demands or regulatory requirements.

In conclusion, while the initial costs of flywheel implementation for 454 Big Block engines are significant, the potential for long-term operational savings, performance improvements, and environmental benefits presents a compelling case for adoption in many applications. A thorough analysis of specific use cases and operational profiles is essential to determine the precise cost-benefit ratio for individual implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!