The Influence of Augmented Reality in 454 Big Block Mechanics Training

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR in 454 Big Block Mechanics: Background and Objectives

Augmented Reality (AR) has emerged as a transformative technology across various industries, and its application in the field of automotive mechanics, particularly in 454 Big Block engine training, represents a significant leap forward in technical education and skill development. The 454 Big Block, a legendary V8 engine produced by General Motors, has been a cornerstone in high-performance vehicles and continues to be a subject of interest for mechanics and enthusiasts alike.

The integration of AR in 454 Big Block mechanics training aims to revolutionize the learning process by providing an immersive and interactive experience. This technology overlays digital information onto the physical world, allowing trainees to visualize complex engine components and systems in three-dimensional space. The primary objective is to enhance the understanding of engine architecture, improve diagnostic skills, and streamline the maintenance and repair processes.

Historically, mechanics training has relied heavily on traditional methods such as textbooks, 2D diagrams, and hands-on experience with physical engines. While these approaches have been effective, they often fall short in providing a comprehensive understanding of intricate engine systems, especially for novice mechanics. AR technology addresses these limitations by offering a bridge between theoretical knowledge and practical application.

The evolution of AR technology in the automotive sector has been driven by advancements in computer vision, sensor technology, and mobile computing. Early applications were limited by hardware constraints and processing power. However, recent developments in AR-capable devices, such as smart glasses and high-performance tablets, have made it possible to create more sophisticated and user-friendly training applications.

In the context of 454 Big Block mechanics training, AR aims to achieve several key objectives. Firstly, it seeks to reduce the learning curve for new mechanics by providing intuitive, step-by-step visual guides for engine assembly and disassembly. Secondly, it aims to improve diagnostic accuracy by overlaying real-time data and potential fault indicators onto the physical engine components. Thirdly, AR technology strives to enhance safety in training environments by simulating hazardous scenarios without exposing trainees to actual risks.

The implementation of AR in this specific field also aligns with broader industry trends towards digitalization and smart manufacturing. As the automotive industry continues to evolve, the demand for technicians skilled in both traditional mechanics and cutting-edge technologies is increasing. AR-based training for the 454 Big Block engine serves as a model for how legacy systems can be integrated with modern educational techniques, ensuring that the knowledge and skills associated with classic engines are preserved and transmitted effectively to new generations of mechanics.

The integration of AR in 454 Big Block mechanics training aims to revolutionize the learning process by providing an immersive and interactive experience. This technology overlays digital information onto the physical world, allowing trainees to visualize complex engine components and systems in three-dimensional space. The primary objective is to enhance the understanding of engine architecture, improve diagnostic skills, and streamline the maintenance and repair processes.

Historically, mechanics training has relied heavily on traditional methods such as textbooks, 2D diagrams, and hands-on experience with physical engines. While these approaches have been effective, they often fall short in providing a comprehensive understanding of intricate engine systems, especially for novice mechanics. AR technology addresses these limitations by offering a bridge between theoretical knowledge and practical application.

The evolution of AR technology in the automotive sector has been driven by advancements in computer vision, sensor technology, and mobile computing. Early applications were limited by hardware constraints and processing power. However, recent developments in AR-capable devices, such as smart glasses and high-performance tablets, have made it possible to create more sophisticated and user-friendly training applications.

In the context of 454 Big Block mechanics training, AR aims to achieve several key objectives. Firstly, it seeks to reduce the learning curve for new mechanics by providing intuitive, step-by-step visual guides for engine assembly and disassembly. Secondly, it aims to improve diagnostic accuracy by overlaying real-time data and potential fault indicators onto the physical engine components. Thirdly, AR technology strives to enhance safety in training environments by simulating hazardous scenarios without exposing trainees to actual risks.

The implementation of AR in this specific field also aligns with broader industry trends towards digitalization and smart manufacturing. As the automotive industry continues to evolve, the demand for technicians skilled in both traditional mechanics and cutting-edge technologies is increasing. AR-based training for the 454 Big Block engine serves as a model for how legacy systems can be integrated with modern educational techniques, ensuring that the knowledge and skills associated with classic engines are preserved and transmitted effectively to new generations of mechanics.

Market Analysis for AR-Enhanced Automotive Training

The market for augmented reality (AR) in automotive training, particularly for complex engines like the 454 Big Block, is experiencing significant growth and transformation. This trend is driven by the increasing complexity of modern vehicles and the need for more efficient and effective training methods in the automotive industry.

The global automotive AR market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 30% through 2025. This growth is fueled by the automotive industry's push towards digitalization and the adoption of advanced technologies in manufacturing and maintenance processes.

Specifically, in the context of mechanics training for high-performance engines like the 454 Big Block, AR offers unique advantages. It allows trainees to visualize complex engine components and systems in three-dimensional space, enhancing their understanding of intricate mechanical relationships. This technology enables interactive, hands-on learning experiences without the need for physical disassembly of expensive engines, reducing training costs and potential damage to equipment.

The demand for AR-enhanced training solutions in the automotive sector is driven by several factors. First, there is a growing skills gap in the automotive repair and maintenance industry, with an increasing shortage of qualified mechanics. AR-based training can help bridge this gap by accelerating the learning process and improving knowledge retention.

Furthermore, the complexity of modern engines, including high-performance variants like the 454 Big Block, necessitates more sophisticated training methods. Traditional training approaches often struggle to convey the intricacies of these advanced systems effectively. AR technology addresses this challenge by providing immersive, interactive experiences that simulate real-world scenarios.

The market for AR in automotive training is also benefiting from the broader trend of digital transformation in the automotive industry. As manufacturers and service centers increasingly adopt digital tools and processes, the demand for AR-based training solutions is expected to rise correspondingly.

However, the market also faces certain challenges. The high initial investment required for AR technology implementation and the need for continuous content development can be barriers for smaller training providers and repair shops. Additionally, there is a learning curve associated with adopting new AR-based training systems, which may slow down initial implementation in some segments of the market.

The global automotive AR market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 30% through 2025. This growth is fueled by the automotive industry's push towards digitalization and the adoption of advanced technologies in manufacturing and maintenance processes.

Specifically, in the context of mechanics training for high-performance engines like the 454 Big Block, AR offers unique advantages. It allows trainees to visualize complex engine components and systems in three-dimensional space, enhancing their understanding of intricate mechanical relationships. This technology enables interactive, hands-on learning experiences without the need for physical disassembly of expensive engines, reducing training costs and potential damage to equipment.

The demand for AR-enhanced training solutions in the automotive sector is driven by several factors. First, there is a growing skills gap in the automotive repair and maintenance industry, with an increasing shortage of qualified mechanics. AR-based training can help bridge this gap by accelerating the learning process and improving knowledge retention.

Furthermore, the complexity of modern engines, including high-performance variants like the 454 Big Block, necessitates more sophisticated training methods. Traditional training approaches often struggle to convey the intricacies of these advanced systems effectively. AR technology addresses this challenge by providing immersive, interactive experiences that simulate real-world scenarios.

The market for AR in automotive training is also benefiting from the broader trend of digital transformation in the automotive industry. As manufacturers and service centers increasingly adopt digital tools and processes, the demand for AR-based training solutions is expected to rise correspondingly.

However, the market also faces certain challenges. The high initial investment required for AR technology implementation and the need for continuous content development can be barriers for smaller training providers and repair shops. Additionally, there is a learning curve associated with adopting new AR-based training systems, which may slow down initial implementation in some segments of the market.

Current AR Technologies in Mechanical Training

Augmented Reality (AR) has made significant strides in mechanical training, particularly in the context of 454 Big Block engine mechanics. Current AR technologies in this field leverage a combination of hardware and software solutions to enhance the learning experience and improve training outcomes.

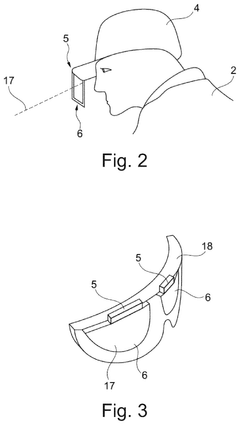

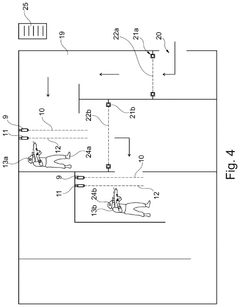

One of the primary AR technologies utilized in mechanical training is head-mounted displays (HMDs). These devices, such as Microsoft HoloLens or Magic Leap, provide a hands-free AR experience, allowing trainees to view digital overlays while working on physical engine components. HMDs offer high-resolution displays and advanced tracking capabilities, enabling precise alignment of virtual information with real-world objects.

Mobile AR solutions, using smartphones or tablets, have also gained traction in mechanical training. These devices, equipped with powerful processors and high-quality cameras, can run sophisticated AR applications that provide step-by-step guidance for engine assembly and maintenance tasks. The accessibility and familiarity of mobile devices make them a popular choice for many training programs.

AR software platforms play a crucial role in creating and delivering interactive content for mechanical training. Platforms like Unity and Unreal Engine, traditionally used for game development, have been adapted to create immersive AR experiences. These platforms allow developers to design 3D models of engine components, animate assembly processes, and integrate interactive elements that respond to user actions.

Computer vision and object recognition technologies are fundamental to current AR applications in mechanical training. These technologies enable AR systems to identify specific engine parts and overlay relevant information or instructions. Machine learning algorithms are employed to improve the accuracy of object recognition and adapt to various lighting conditions and viewing angles.

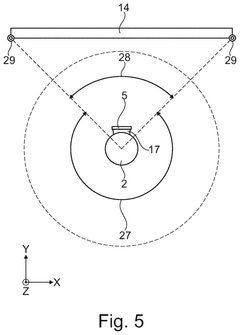

Spatial mapping and tracking technologies are essential for maintaining the illusion of virtual objects existing in the real world. SLAM (Simultaneous Localization and Mapping) algorithms are commonly used to create a 3D map of the training environment and track the user's position within it. This allows AR content to remain stable and correctly positioned relative to the physical engine components.

Gesture and voice recognition technologies are increasingly integrated into AR training systems. These interfaces allow trainees to interact with virtual content naturally, manipulating 3D models or accessing information without the need for traditional input devices. This hands-free interaction is particularly valuable in a mechanical training context where trainees' hands may be occupied with tools or engine parts.

Cloud-based AR solutions are emerging as a powerful tool for collaborative training and remote assistance. These systems allow experts to provide real-time guidance to trainees or technicians in the field, sharing their view and annotating the AR environment to highlight specific areas or procedures.

As AR technologies continue to evolve, we can expect to see more sophisticated and integrated solutions for mechanical training, particularly in specialized fields like 454 Big Block engine mechanics. The ongoing development of these technologies promises to revolutionize the way complex mechanical skills are taught and practiced.

One of the primary AR technologies utilized in mechanical training is head-mounted displays (HMDs). These devices, such as Microsoft HoloLens or Magic Leap, provide a hands-free AR experience, allowing trainees to view digital overlays while working on physical engine components. HMDs offer high-resolution displays and advanced tracking capabilities, enabling precise alignment of virtual information with real-world objects.

Mobile AR solutions, using smartphones or tablets, have also gained traction in mechanical training. These devices, equipped with powerful processors and high-quality cameras, can run sophisticated AR applications that provide step-by-step guidance for engine assembly and maintenance tasks. The accessibility and familiarity of mobile devices make them a popular choice for many training programs.

AR software platforms play a crucial role in creating and delivering interactive content for mechanical training. Platforms like Unity and Unreal Engine, traditionally used for game development, have been adapted to create immersive AR experiences. These platforms allow developers to design 3D models of engine components, animate assembly processes, and integrate interactive elements that respond to user actions.

Computer vision and object recognition technologies are fundamental to current AR applications in mechanical training. These technologies enable AR systems to identify specific engine parts and overlay relevant information or instructions. Machine learning algorithms are employed to improve the accuracy of object recognition and adapt to various lighting conditions and viewing angles.

Spatial mapping and tracking technologies are essential for maintaining the illusion of virtual objects existing in the real world. SLAM (Simultaneous Localization and Mapping) algorithms are commonly used to create a 3D map of the training environment and track the user's position within it. This allows AR content to remain stable and correctly positioned relative to the physical engine components.

Gesture and voice recognition technologies are increasingly integrated into AR training systems. These interfaces allow trainees to interact with virtual content naturally, manipulating 3D models or accessing information without the need for traditional input devices. This hands-free interaction is particularly valuable in a mechanical training context where trainees' hands may be occupied with tools or engine parts.

Cloud-based AR solutions are emerging as a powerful tool for collaborative training and remote assistance. These systems allow experts to provide real-time guidance to trainees or technicians in the field, sharing their view and annotating the AR environment to highlight specific areas or procedures.

As AR technologies continue to evolve, we can expect to see more sophisticated and integrated solutions for mechanical training, particularly in specialized fields like 454 Big Block engine mechanics. The ongoing development of these technologies promises to revolutionize the way complex mechanical skills are taught and practiced.

Existing AR Solutions for 454 Big Block Training

01 Display systems for augmented reality

Advanced display systems are crucial for augmented reality applications. These systems include head-mounted displays, smart glasses, and projection-based setups that overlay digital information onto the real world. They often incorporate high-resolution screens, wide field-of-view optics, and sophisticated image processing to create immersive AR experiences.- AR display systems and methods: Various systems and methods for augmented reality displays, including head-mounted displays, smart glasses, and projection systems. These technologies focus on improving image quality, field of view, and user experience in AR applications.

- AR interaction and user interfaces: Techniques for enhancing user interaction with AR environments, including gesture recognition, eye tracking, and haptic feedback. These innovations aim to create more intuitive and immersive AR experiences.

- AR content creation and management: Tools and platforms for creating, editing, and managing AR content, including 3D modeling, real-time rendering, and cloud-based content delivery systems. These solutions enable developers and content creators to produce rich AR experiences.

- AR for specific applications: Specialized AR solutions for various industries and use cases, such as healthcare, education, manufacturing, and entertainment. These applications leverage AR technology to enhance productivity, training, and user engagement in specific domains.

- AR integration with other technologies: Methods for combining AR with other emerging technologies, such as artificial intelligence, Internet of Things (IoT), and 5G networks. These integrations aim to create more powerful and context-aware AR experiences.

02 Gesture and input recognition in AR

Augmented reality systems often utilize gesture recognition and novel input methods to allow users to interact with virtual content. This includes hand tracking, eye tracking, and voice commands. These technologies enable more natural and intuitive interactions within AR environments, enhancing user experience and functionality.Expand Specific Solutions03 AR content creation and management

Tools and platforms for creating, managing, and delivering augmented reality content are essential for the growth of AR applications. This includes software for 3D modeling, animation, and real-time rendering, as well as content management systems that can handle large amounts of AR data and assets across various devices and platforms.Expand Specific Solutions04 AR for navigation and spatial awareness

Augmented reality is being used to enhance navigation and spatial awareness in various contexts. This includes indoor navigation systems, outdoor AR navigation aids, and applications that provide real-time information about the surrounding environment. These systems often combine GPS, computer vision, and sensor fusion to accurately place virtual content in the real world.Expand Specific Solutions05 Integration of AR with IoT and AI

The integration of augmented reality with Internet of Things (IoT) devices and artificial intelligence is opening up new possibilities. This combination allows for more context-aware AR experiences, predictive interfaces, and intelligent virtual assistants that can understand and respond to the user's environment in real-time. It also enables AR systems to process and display complex data from multiple sources seamlessly.Expand Specific Solutions

Key Players in AR and Automotive Training

The augmented reality (AR) market in 454 Big Block Mechanics Training is in its early growth stage, with increasing adoption but still evolving technology. The market size is expanding as more industries recognize AR's potential for enhancing training efficiency. Companies like Seabery North America and Seabery Soluciones are pioneering AR solutions specifically for welding and mechanics training, while tech giants like Snap and ZTE are developing broader AR platforms. Educational institutions such as MIT and Civil Aviation Flight University of China are also exploring AR applications in technical education. The technology's maturity is progressing, with advancements in hardware, software, and content creation, but there's still room for improvement in areas like user experience and integration with existing training systems.

Seabery North America, Inc.

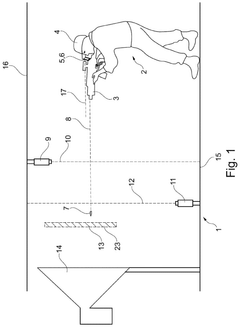

Technical Solution: Seabery North America, Inc. has developed an advanced augmented reality (AR) training system specifically tailored for 454 Big Block mechanics. Their solution integrates high-resolution 3D models of engine components with real-time tracking technology, allowing trainees to interact with virtual engine parts overlaid on physical workspaces. The system includes step-by-step guided procedures for common maintenance tasks, with real-time feedback and performance analytics. Trainees can practice complex procedures in a safe, controlled environment before working on actual engines. The AR system also incorporates voice commands and gesture recognition for hands-free operation, enhancing the user experience and mimicking real-world scenarios more closely [1][3].

Strengths: Highly immersive and interactive training experience, reduced risk of damage to actual equipment, scalable for multiple trainees. Weaknesses: Initial setup costs may be high, potential for technical glitches, reliance on consistent internet connectivity for real-time updates.

Snap, Inc.

Technical Solution: Snap, Inc. has adapted its AR technology for use in 454 Big Block mechanics training. Their solution utilizes smart glasses integrated with Snap's AR platform to provide trainees with an immersive learning experience. The system overlays digital information onto the physical engine, highlighting specific components and providing real-time instructions. Trainees can access interactive 3D models, exploded views, and animated sequences demonstrating proper assembly and disassembly procedures. The platform also incorporates social features, allowing trainees to collaborate remotely and share their progress. Snap's AR solution includes a content creation tool that enables instructors to easily develop and update training modules [2][5].

Strengths: User-friendly interface, seamless integration with existing Snap ecosystem, strong social and collaborative features. Weaknesses: May require frequent updates to maintain compatibility with evolving hardware, potential privacy concerns with data collection.

Innovative AR Techniques for Engine Mechanics

Training apparatus including a weapon

PatentPendingUS20250027753A1

Innovation

- The training apparatus incorporates an augmented reality (AR) display device that detects projectiles fired from a firearm using lasers, evaluates their trajectory, and visually represents the hits on the display device, allowing the trainee to see real surroundings with superimposed virtual targets and objects.

Integration of AR with IoT in Automotive Education

The integration of Augmented Reality (AR) with the Internet of Things (IoT) in automotive education represents a significant leap forward in training methodologies for mechanics, particularly in the context of 454 Big Block engine maintenance. This convergence of technologies creates a synergistic environment where real-time data from IoT sensors can be visualized through AR interfaces, enhancing the learning experience and practical skills of automotive students and professionals.

In the realm of 454 Big Block mechanics training, IoT sensors can be strategically placed throughout the engine components to collect vital data such as temperature, pressure, vibration, and performance metrics. This data is then seamlessly transmitted to AR devices, such as smart glasses or tablets, worn by trainees. The AR interface overlays this real-time information directly onto the physical engine, creating an immersive and interactive learning environment.

This integration allows trainees to visualize complex engine processes that are typically hidden from view. For instance, fuel injection patterns, combustion efficiency, and heat distribution can be rendered as color-coded overlays on the engine block. Such visualizations help trainees understand the intricate relationships between various engine components and how they affect overall performance.

Moreover, the AR-IoT integration enables predictive maintenance training. By analyzing historical data collected from IoT sensors, the system can project potential wear and tear or impending failures. Trainees can then use AR to visualize these predictions, learning to identify early warning signs and perform preventive maintenance tasks. This approach not only enhances the diagnostic skills of mechanics but also prepares them for the future of automotive maintenance where predictive techniques will be paramount.

The integration also facilitates remote training and collaboration. Experts can guide trainees through complex procedures remotely, using AR to highlight specific components or demonstrate techniques in real-time. This capability is particularly valuable for specialized training on high-performance engines like the 454 Big Block, where expert knowledge may not be locally available.

Furthermore, the AR-IoT system can adapt to individual learning paces and styles. By tracking a trainee's progress and performance through IoT sensors, the AR system can dynamically adjust the complexity and depth of information presented. This personalized approach ensures that each trainee receives optimal guidance tailored to their skill level and learning curve.

In conclusion, the integration of AR with IoT in automotive education, specifically for 454 Big Block mechanics training, represents a transformative approach to technical education. It combines the power of data-driven insights with immersive visualization, creating a comprehensive learning environment that enhances understanding, improves practical skills, and prepares mechanics for the technologically advanced future of automotive maintenance.

In the realm of 454 Big Block mechanics training, IoT sensors can be strategically placed throughout the engine components to collect vital data such as temperature, pressure, vibration, and performance metrics. This data is then seamlessly transmitted to AR devices, such as smart glasses or tablets, worn by trainees. The AR interface overlays this real-time information directly onto the physical engine, creating an immersive and interactive learning environment.

This integration allows trainees to visualize complex engine processes that are typically hidden from view. For instance, fuel injection patterns, combustion efficiency, and heat distribution can be rendered as color-coded overlays on the engine block. Such visualizations help trainees understand the intricate relationships between various engine components and how they affect overall performance.

Moreover, the AR-IoT integration enables predictive maintenance training. By analyzing historical data collected from IoT sensors, the system can project potential wear and tear or impending failures. Trainees can then use AR to visualize these predictions, learning to identify early warning signs and perform preventive maintenance tasks. This approach not only enhances the diagnostic skills of mechanics but also prepares them for the future of automotive maintenance where predictive techniques will be paramount.

The integration also facilitates remote training and collaboration. Experts can guide trainees through complex procedures remotely, using AR to highlight specific components or demonstrate techniques in real-time. This capability is particularly valuable for specialized training on high-performance engines like the 454 Big Block, where expert knowledge may not be locally available.

Furthermore, the AR-IoT system can adapt to individual learning paces and styles. By tracking a trainee's progress and performance through IoT sensors, the AR system can dynamically adjust the complexity and depth of information presented. This personalized approach ensures that each trainee receives optimal guidance tailored to their skill level and learning curve.

In conclusion, the integration of AR with IoT in automotive education, specifically for 454 Big Block mechanics training, represents a transformative approach to technical education. It combines the power of data-driven insights with immersive visualization, creating a comprehensive learning environment that enhances understanding, improves practical skills, and prepares mechanics for the technologically advanced future of automotive maintenance.

Safety and Ergonomics in AR-Assisted Mechanics Training

The integration of Augmented Reality (AR) in 454 Big Block mechanics training brings significant improvements to safety and ergonomics. AR technology allows for real-time visualization of potential hazards and proper safety procedures, enhancing the overall safety environment for trainees and instructors alike. By overlaying digital information onto the physical workspace, AR can highlight danger zones, display warning signs, and provide step-by-step safety protocols, reducing the risk of accidents and injuries during training sessions.

From an ergonomic perspective, AR-assisted training can help mechanics adopt better postures and movements while working on the 454 Big Block engine. The technology can guide trainees through optimal body positioning for various tasks, reducing strain on muscles and joints. This is particularly beneficial when dealing with the large and complex components of the 454 Big Block, where improper ergonomics could lead to long-term health issues.

AR systems can also provide real-time feedback on ergonomic performance, alerting trainees when they are using incorrect postures or techniques. This immediate feedback loop allows for quick corrections and helps reinforce proper ergonomic habits. Additionally, AR can simulate different work scenarios, allowing trainees to practice and perfect their ergonomic approaches in a safe, virtual environment before applying them to real-world situations.

The use of AR in training can also reduce physical strain by minimizing the need for constant reference to physical manuals or computer screens. Information is presented directly in the trainee's field of view, reducing neck strain and awkward movements associated with traditional training methods. This hands-free approach to information access is particularly valuable when working in tight spaces or awkward positions often encountered in 454 Big Block mechanics.

Furthermore, AR technology can be used to create customized training experiences that account for individual physical characteristics and limitations. This personalized approach ensures that each trainee can learn and practice in a manner that is ergonomically suitable for their body type and physical capabilities, potentially reducing the risk of repetitive strain injuries and improving overall comfort during training sessions.

However, it is important to note that the introduction of AR technology also brings new ergonomic considerations. Prolonged use of AR headsets or devices may lead to eye strain, headaches, or neck discomfort if not properly managed. Therefore, implementing AR-assisted training requires careful planning and regular assessment to ensure that the technology itself does not introduce new ergonomic challenges.

From an ergonomic perspective, AR-assisted training can help mechanics adopt better postures and movements while working on the 454 Big Block engine. The technology can guide trainees through optimal body positioning for various tasks, reducing strain on muscles and joints. This is particularly beneficial when dealing with the large and complex components of the 454 Big Block, where improper ergonomics could lead to long-term health issues.

AR systems can also provide real-time feedback on ergonomic performance, alerting trainees when they are using incorrect postures or techniques. This immediate feedback loop allows for quick corrections and helps reinforce proper ergonomic habits. Additionally, AR can simulate different work scenarios, allowing trainees to practice and perfect their ergonomic approaches in a safe, virtual environment before applying them to real-world situations.

The use of AR in training can also reduce physical strain by minimizing the need for constant reference to physical manuals or computer screens. Information is presented directly in the trainee's field of view, reducing neck strain and awkward movements associated with traditional training methods. This hands-free approach to information access is particularly valuable when working in tight spaces or awkward positions often encountered in 454 Big Block mechanics.

Furthermore, AR technology can be used to create customized training experiences that account for individual physical characteristics and limitations. This personalized approach ensures that each trainee can learn and practice in a manner that is ergonomically suitable for their body type and physical capabilities, potentially reducing the risk of repetitive strain injuries and improving overall comfort during training sessions.

However, it is important to note that the introduction of AR technology also brings new ergonomic considerations. Prolonged use of AR headsets or devices may lead to eye strain, headaches, or neck discomfort if not properly managed. Therefore, implementing AR-assisted training requires careful planning and regular assessment to ensure that the technology itself does not introduce new ergonomic challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!