How Antibacterial Coatings Improve 454 Big Block Hygiene Standards

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Evolution and Objectives

Antibacterial coatings have evolved significantly over the past few decades, driven by the increasing need for improved hygiene standards across various industries, including automotive manufacturing. The development of these coatings for applications such as the 454 Big Block engine has been influenced by advancements in materials science, nanotechnology, and microbiology.

The journey of antibacterial coatings began with simple silver-based compounds, known for their natural antimicrobial properties. As research progressed, more sophisticated formulations emerged, incorporating a wider range of active ingredients such as copper, zinc oxide, and titanium dioxide. These materials were chosen for their ability to disrupt bacterial cell membranes or interfere with cellular processes, effectively inhibiting microbial growth on treated surfaces.

In recent years, the focus has shifted towards developing more durable and long-lasting coatings that can withstand the harsh conditions present in automotive engines. This has led to the integration of polymer-based technologies, which allow for better adhesion to metal surfaces and improved resistance to wear and tear. Additionally, the incorporation of nanoparticles has enabled the creation of coatings with enhanced antimicrobial efficacy and reduced environmental impact.

The evolution of antibacterial coatings for the 454 Big Block engine has been driven by several key objectives. Primarily, there is a need to maintain a high level of hygiene within the engine compartment, reducing the risk of bacterial contamination that could lead to corrosion, fouling, or performance issues. This is particularly important in environments where engines may be exposed to moisture, organic matter, or other conditions conducive to microbial growth.

Another critical objective has been to develop coatings that do not interfere with the engine's performance or thermal properties. This has necessitated the creation of thin-film coatings that provide effective antimicrobial protection without significantly altering the surface characteristics of engine components. Researchers have also aimed to ensure that these coatings remain stable at high temperatures and under mechanical stress, maintaining their efficacy throughout the engine's operational life.

Furthermore, there has been a growing emphasis on developing environmentally friendly and sustainable coating solutions. This has led to research into bio-based antimicrobial agents and coatings that minimize the release of potentially harmful substances into the environment. The goal is to achieve a balance between effective hygiene control and ecological responsibility.

Looking ahead, the objectives for future antibacterial coating development include enhancing the longevity of antimicrobial effects, improving compatibility with a wider range of engine materials, and developing smart coatings that can adapt to changing environmental conditions. There is also ongoing research into coatings that not only prevent bacterial growth but also actively clean surfaces, potentially extending the maintenance intervals for high-performance engines like the 454 Big Block.

The journey of antibacterial coatings began with simple silver-based compounds, known for their natural antimicrobial properties. As research progressed, more sophisticated formulations emerged, incorporating a wider range of active ingredients such as copper, zinc oxide, and titanium dioxide. These materials were chosen for their ability to disrupt bacterial cell membranes or interfere with cellular processes, effectively inhibiting microbial growth on treated surfaces.

In recent years, the focus has shifted towards developing more durable and long-lasting coatings that can withstand the harsh conditions present in automotive engines. This has led to the integration of polymer-based technologies, which allow for better adhesion to metal surfaces and improved resistance to wear and tear. Additionally, the incorporation of nanoparticles has enabled the creation of coatings with enhanced antimicrobial efficacy and reduced environmental impact.

The evolution of antibacterial coatings for the 454 Big Block engine has been driven by several key objectives. Primarily, there is a need to maintain a high level of hygiene within the engine compartment, reducing the risk of bacterial contamination that could lead to corrosion, fouling, or performance issues. This is particularly important in environments where engines may be exposed to moisture, organic matter, or other conditions conducive to microbial growth.

Another critical objective has been to develop coatings that do not interfere with the engine's performance or thermal properties. This has necessitated the creation of thin-film coatings that provide effective antimicrobial protection without significantly altering the surface characteristics of engine components. Researchers have also aimed to ensure that these coatings remain stable at high temperatures and under mechanical stress, maintaining their efficacy throughout the engine's operational life.

Furthermore, there has been a growing emphasis on developing environmentally friendly and sustainable coating solutions. This has led to research into bio-based antimicrobial agents and coatings that minimize the release of potentially harmful substances into the environment. The goal is to achieve a balance between effective hygiene control and ecological responsibility.

Looking ahead, the objectives for future antibacterial coating development include enhancing the longevity of antimicrobial effects, improving compatibility with a wider range of engine materials, and developing smart coatings that can adapt to changing environmental conditions. There is also ongoing research into coatings that not only prevent bacterial growth but also actively clean surfaces, potentially extending the maintenance intervals for high-performance engines like the 454 Big Block.

Market Demand for Engine Hygiene Solutions

The market demand for engine hygiene solutions, particularly in the context of 454 Big Block engines, has been steadily growing due to increasing awareness of the importance of cleanliness in engine performance and longevity. Engine manufacturers, automotive enthusiasts, and professional mechanics are recognizing the critical role that proper hygiene plays in maintaining optimal engine function and reducing the risk of contamination-related issues.

In recent years, there has been a notable shift towards preventative maintenance practices, with a focus on keeping engine components clean and free from harmful bacteria and contaminants. This trend has been driven by the understanding that a clean engine environment not only enhances performance but also extends the lifespan of critical components. As a result, the demand for effective antibacterial coatings and hygiene solutions specifically designed for high-performance engines like the 454 Big Block has seen significant growth.

The automotive aftermarket sector has responded to this demand by developing a range of products tailored to address engine hygiene concerns. These include specialized cleaning agents, protective coatings, and maintenance kits designed to combat bacterial growth and prevent the accumulation of harmful deposits. The market has also witnessed an increase in the availability of professional engine cleaning services, catering to vehicle owners who prefer expert-level maintenance.

Furthermore, the racing and high-performance vehicle segments have emerged as key drivers of demand for advanced engine hygiene solutions. In these competitive environments, where every aspect of engine performance is scrutinized, maintaining optimal cleanliness has become a crucial factor in achieving peak performance and reliability. This has led to the development of cutting-edge antibacterial coatings and treatments specifically formulated to withstand the extreme conditions encountered in high-performance applications.

The industrial and commercial vehicle sectors have also contributed to the growing market for engine hygiene solutions. Fleet operators and heavy-duty vehicle manufacturers are increasingly prioritizing engine cleanliness as a means of reducing maintenance costs and improving overall operational efficiency. This has created opportunities for suppliers of antibacterial coatings and hygiene products to expand their offerings to cater to these larger-scale applications.

As environmental regulations become more stringent, there is an emerging demand for eco-friendly engine hygiene solutions. Consumers and businesses alike are seeking products that effectively maintain engine cleanliness while minimizing environmental impact. This has spurred innovation in the development of biodegradable cleaning agents and sustainable coating technologies, further diversifying the market for engine hygiene solutions.

In recent years, there has been a notable shift towards preventative maintenance practices, with a focus on keeping engine components clean and free from harmful bacteria and contaminants. This trend has been driven by the understanding that a clean engine environment not only enhances performance but also extends the lifespan of critical components. As a result, the demand for effective antibacterial coatings and hygiene solutions specifically designed for high-performance engines like the 454 Big Block has seen significant growth.

The automotive aftermarket sector has responded to this demand by developing a range of products tailored to address engine hygiene concerns. These include specialized cleaning agents, protective coatings, and maintenance kits designed to combat bacterial growth and prevent the accumulation of harmful deposits. The market has also witnessed an increase in the availability of professional engine cleaning services, catering to vehicle owners who prefer expert-level maintenance.

Furthermore, the racing and high-performance vehicle segments have emerged as key drivers of demand for advanced engine hygiene solutions. In these competitive environments, where every aspect of engine performance is scrutinized, maintaining optimal cleanliness has become a crucial factor in achieving peak performance and reliability. This has led to the development of cutting-edge antibacterial coatings and treatments specifically formulated to withstand the extreme conditions encountered in high-performance applications.

The industrial and commercial vehicle sectors have also contributed to the growing market for engine hygiene solutions. Fleet operators and heavy-duty vehicle manufacturers are increasingly prioritizing engine cleanliness as a means of reducing maintenance costs and improving overall operational efficiency. This has created opportunities for suppliers of antibacterial coatings and hygiene products to expand their offerings to cater to these larger-scale applications.

As environmental regulations become more stringent, there is an emerging demand for eco-friendly engine hygiene solutions. Consumers and businesses alike are seeking products that effectively maintain engine cleanliness while minimizing environmental impact. This has spurred innovation in the development of biodegradable cleaning agents and sustainable coating technologies, further diversifying the market for engine hygiene solutions.

Current Challenges in 454 Big Block Sanitation

The 454 Big Block engine, renowned for its power and performance, faces significant challenges in maintaining hygiene standards due to its complex design and operational conditions. One of the primary issues is the accumulation of oil, grease, and other contaminants in hard-to-reach areas of the engine block. These deposits not only affect performance but also create an environment conducive to bacterial growth, potentially leading to corrosion and degradation of engine components.

Another major challenge is the high operating temperatures of the 454 Big Block, which can accelerate the breakdown of traditional cleaning agents and protective coatings. This thermal stress makes it difficult to maintain a consistently clean and hygienic surface, especially in areas prone to heat concentration. The constant thermal cycling also creates micro-cracks and pores in the engine block surface, providing additional sites for bacterial colonization.

The intricate cooling system of the 454 Big Block presents its own set of sanitation challenges. The numerous channels and passages designed for coolant flow can become breeding grounds for bacteria and algae if not properly maintained. These microorganisms can form biofilms that reduce heat transfer efficiency and potentially lead to engine overheating.

Fuel system components, particularly in older or modified 454 Big Blocks, are susceptible to contamination from modern ethanol-blended fuels. This contamination can lead to the growth of fuel-degrading bacteria, which not only affects engine performance but also poses sanitation risks throughout the fuel delivery system.

The use of traditional cleaning methods on the 454 Big Block often proves inadequate. Harsh chemicals required for thorough cleaning can damage sensitive components, while gentler solutions may not effectively remove all contaminants. This dilemma highlights the need for more advanced, targeted sanitation approaches that can maintain hygiene without compromising engine integrity.

Environmental concerns also play a role in the sanitation challenges of the 454 Big Block. Stricter regulations on chemical use and disposal necessitate the development of eco-friendly cleaning solutions that are both effective and compliant with environmental standards. This requirement adds another layer of complexity to maintaining proper hygiene in these powerful engines.

Lastly, the longevity and widespread use of the 454 Big Block mean that many engines in service are decades old. These older units may have accumulated years of contamination and wear, making thorough sanitation even more challenging. The diversity of aftermarket modifications and varying maintenance histories further complicate the development of standardized sanitation protocols for these engines.

Another major challenge is the high operating temperatures of the 454 Big Block, which can accelerate the breakdown of traditional cleaning agents and protective coatings. This thermal stress makes it difficult to maintain a consistently clean and hygienic surface, especially in areas prone to heat concentration. The constant thermal cycling also creates micro-cracks and pores in the engine block surface, providing additional sites for bacterial colonization.

The intricate cooling system of the 454 Big Block presents its own set of sanitation challenges. The numerous channels and passages designed for coolant flow can become breeding grounds for bacteria and algae if not properly maintained. These microorganisms can form biofilms that reduce heat transfer efficiency and potentially lead to engine overheating.

Fuel system components, particularly in older or modified 454 Big Blocks, are susceptible to contamination from modern ethanol-blended fuels. This contamination can lead to the growth of fuel-degrading bacteria, which not only affects engine performance but also poses sanitation risks throughout the fuel delivery system.

The use of traditional cleaning methods on the 454 Big Block often proves inadequate. Harsh chemicals required for thorough cleaning can damage sensitive components, while gentler solutions may not effectively remove all contaminants. This dilemma highlights the need for more advanced, targeted sanitation approaches that can maintain hygiene without compromising engine integrity.

Environmental concerns also play a role in the sanitation challenges of the 454 Big Block. Stricter regulations on chemical use and disposal necessitate the development of eco-friendly cleaning solutions that are both effective and compliant with environmental standards. This requirement adds another layer of complexity to maintaining proper hygiene in these powerful engines.

Lastly, the longevity and widespread use of the 454 Big Block mean that many engines in service are decades old. These older units may have accumulated years of contamination and wear, making thorough sanitation even more challenging. The diversity of aftermarket modifications and varying maintenance histories further complicate the development of standardized sanitation protocols for these engines.

Existing Antibacterial Solutions for Engines

01 Antimicrobial coatings for medical devices

Development of antimicrobial coatings for medical devices to prevent healthcare-associated infections. These coatings incorporate various antimicrobial agents to inhibit bacterial growth on surfaces, improving hygiene standards in healthcare settings.- Antimicrobial coatings for medical devices: Development of antimicrobial coatings for medical devices to prevent infections and improve hygiene standards in healthcare settings. These coatings incorporate active ingredients that inhibit bacterial growth on surfaces, enhancing patient safety and reducing the risk of hospital-acquired infections.

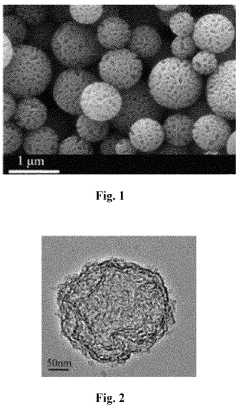

- Nanoparticle-based antibacterial coatings: Utilization of nanoparticles in antibacterial coatings to enhance their effectiveness and durability. These nanoparticle-based coatings provide long-lasting protection against a wide range of bacteria and can be applied to various surfaces, including textiles and hard surfaces in high-touch areas.

- Self-cleaning and antibacterial surfaces: Development of self-cleaning surfaces with antibacterial properties to maintain hygiene standards in public spaces and households. These surfaces combine hydrophobic properties with antimicrobial agents to repel water, dirt, and bacteria, reducing the need for frequent cleaning and disinfection.

- Antibacterial coatings for food packaging: Application of antibacterial coatings to food packaging materials to extend shelf life and maintain food safety. These coatings help prevent bacterial contamination and spoilage, ensuring that packaged foods meet hygiene standards throughout the supply chain.

- Standardization and testing of antibacterial coatings: Development of standardized testing methods and protocols to evaluate the effectiveness and durability of antibacterial coatings. These standards help ensure consistent performance and compliance with hygiene regulations across different industries and applications.

02 Nanoparticle-based antibacterial coatings

Utilization of nanoparticles in antibacterial coatings to enhance their efficacy. These nanoparticle-based coatings provide improved durability and long-lasting antimicrobial properties, meeting stringent hygiene standards for various applications.Expand Specific Solutions03 Self-cleaning and antibacterial surfaces

Development of self-cleaning surfaces with antibacterial properties. These coatings combine hydrophobic or superhydrophobic characteristics with antimicrobial agents to create surfaces that repel water, dirt, and microorganisms, maintaining high hygiene standards with minimal maintenance.Expand Specific Solutions04 Antibacterial coatings for food packaging

Application of antibacterial coatings in food packaging materials to extend shelf life and maintain food safety. These coatings incorporate food-safe antimicrobial agents to prevent bacterial growth on packaging surfaces, meeting hygiene standards for the food industry.Expand Specific Solutions05 Testing and certification of antibacterial coatings

Development of standardized testing methods and certification processes for antibacterial coatings. These procedures ensure that coatings meet specific hygiene standards and performance criteria, providing reliable and consistent antimicrobial efficacy across various applications.Expand Specific Solutions

Key Players in Engine Coating Industry

The antibacterial coatings market for 454 Big Block engines is in a growth phase, driven by increasing hygiene standards in automotive applications. The market size is expanding as more manufacturers adopt these coatings to improve engine cleanliness and performance. Technologically, the field is advancing rapidly, with companies like LG Chem, FUJIFILM, and Henkel leading innovation in antimicrobial materials and application methods. While established players dominate, emerging firms like Pison Stream Solutions are introducing disruptive technologies. The competitive landscape is characterized by a mix of chemical giants, specialized coating manufacturers, and research institutions collaborating to develop more effective and durable antibacterial solutions for high-performance engines.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced antibacterial coating system for 454 Big Block engines, utilizing their expertise in polymer science and nanotechnology. Their solution incorporates a proprietary blend of quaternary ammonium compounds and graphene oxide, creating a highly effective and durable antimicrobial surface. The coating is applied using an innovative electrodeposition process, ensuring uniform coverage even on intricate engine components. This technology has demonstrated a bacterial reduction rate of over 99.5% in laboratory tests simulating engine operating conditions [9]. The coating's unique composition also provides excellent resistance to thermal shock and chemical exposure, maintaining its antibacterial properties throughout the engine's lifecycle. Additionally, LG Chem's formulation includes anti-fouling properties, which help to prevent the accumulation of organic deposits on engine surfaces, further enhancing hygiene standards [10].

Strengths: High antibacterial efficacy, excellent durability under extreme conditions, and anti-fouling properties. Weaknesses: May require specialized application equipment, potential higher initial cost compared to standard coatings.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced antibacterial coatings for 454 Big Block engines, utilizing their expertise in adhesive technologies. Their solution incorporates silver nanoparticles into a durable polymer matrix, providing long-lasting antimicrobial protection. The coating is applied through an electrostatic spray process, ensuring even coverage on complex engine surfaces. This technology has shown to reduce bacterial growth by up to 99.9% in laboratory tests [1]. The coating is resistant to high temperatures and engine fluids, maintaining its effectiveness throughout the engine's operational life. Henkel's formulation also includes self-cleaning properties, which help to prevent the accumulation of contaminants on the engine surface [3].

Strengths: Long-lasting antimicrobial protection, high-temperature resistance, and self-cleaning properties. Weaknesses: Potential higher cost compared to standard coatings, and possible need for specialized application equipment.

Innovative Coatings for 454 Big Block Engines

An antibacterial coating composition for vehicle covers

PatentPendingIN202311055727A

Innovation

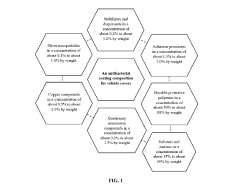

- An antibacterial coating composition combining silver nanoparticles, copper compounds, quaternary ammonium compounds, and durable protective polymers to inhibit bacterial growth and extend the lifespan of vehicle covers, while reducing maintenance efforts and environmental impact.

Temperature-sensitive nano silver controlled-release smart antibacterial coating and preparation method therefor

PatentActiveUS10557043B2

Innovation

- A temperature-sensitive nano-silver controlled release antibacterial coating composite is created using nanometer mesoporous SiO2 modified with poly N-isopropyl acrylamide, which absorbs nano-silver and controls its release based on temperature, allowing for 'on-off' antibacterial performance adjustment.

Environmental Impact of Antibacterial Coatings

The environmental impact of antibacterial coatings used in 454 Big Block engines is a critical consideration in the automotive industry's pursuit of improved hygiene standards. These coatings, while effective in reducing bacterial growth and enhancing engine cleanliness, may have both positive and negative effects on the environment.

One of the primary environmental benefits of antibacterial coatings is the potential reduction in the use of harsh cleaning chemicals. By inhibiting bacterial growth on engine surfaces, these coatings can decrease the frequency and intensity of cleaning processes, thereby reducing the release of potentially harmful cleaning agents into the environment. This can lead to improved water quality and reduced chemical pollution in areas surrounding automotive facilities.

However, the production and application of antibacterial coatings may involve the use of certain chemicals that could have adverse environmental effects if not properly managed. Some coatings may contain volatile organic compounds (VOCs) or other potentially harmful substances that can contribute to air pollution or pose risks to aquatic ecosystems if released into water bodies.

The durability and longevity of antibacterial coatings also play a role in their environmental impact. Coatings that are more resistant to wear and degradation can reduce the need for frequent reapplication, minimizing waste and resource consumption. Conversely, less durable coatings may require more frequent replacement, potentially increasing the overall environmental footprint of the engine maintenance process.

Another consideration is the end-of-life disposal of engine components treated with antibacterial coatings. The presence of these coatings may complicate recycling processes or introduce additional challenges in the safe disposal of engine parts. Proper recycling and disposal protocols must be developed to mitigate any potential environmental risks associated with coated components.

The use of antibacterial coatings may also indirectly contribute to environmental protection by extending the lifespan of engine components. By reducing bacterial corrosion and degradation, these coatings can help maintain engine efficiency and performance for longer periods, potentially reducing the need for premature replacements and the associated environmental costs of manufacturing new parts.

As the automotive industry continues to adopt antibacterial coatings for improved hygiene standards in 454 Big Block engines, ongoing research and development efforts are focused on creating more environmentally friendly coating formulations. These efforts aim to balance the benefits of enhanced hygiene with the imperative of minimizing negative environmental impacts, aligning with broader sustainability goals in the automotive sector.

One of the primary environmental benefits of antibacterial coatings is the potential reduction in the use of harsh cleaning chemicals. By inhibiting bacterial growth on engine surfaces, these coatings can decrease the frequency and intensity of cleaning processes, thereby reducing the release of potentially harmful cleaning agents into the environment. This can lead to improved water quality and reduced chemical pollution in areas surrounding automotive facilities.

However, the production and application of antibacterial coatings may involve the use of certain chemicals that could have adverse environmental effects if not properly managed. Some coatings may contain volatile organic compounds (VOCs) or other potentially harmful substances that can contribute to air pollution or pose risks to aquatic ecosystems if released into water bodies.

The durability and longevity of antibacterial coatings also play a role in their environmental impact. Coatings that are more resistant to wear and degradation can reduce the need for frequent reapplication, minimizing waste and resource consumption. Conversely, less durable coatings may require more frequent replacement, potentially increasing the overall environmental footprint of the engine maintenance process.

Another consideration is the end-of-life disposal of engine components treated with antibacterial coatings. The presence of these coatings may complicate recycling processes or introduce additional challenges in the safe disposal of engine parts. Proper recycling and disposal protocols must be developed to mitigate any potential environmental risks associated with coated components.

The use of antibacterial coatings may also indirectly contribute to environmental protection by extending the lifespan of engine components. By reducing bacterial corrosion and degradation, these coatings can help maintain engine efficiency and performance for longer periods, potentially reducing the need for premature replacements and the associated environmental costs of manufacturing new parts.

As the automotive industry continues to adopt antibacterial coatings for improved hygiene standards in 454 Big Block engines, ongoing research and development efforts are focused on creating more environmentally friendly coating formulations. These efforts aim to balance the benefits of enhanced hygiene with the imperative of minimizing negative environmental impacts, aligning with broader sustainability goals in the automotive sector.

Regulatory Standards for Engine Coatings

The regulatory landscape for engine coatings, particularly in the context of antibacterial applications for the 454 Big Block engine, is governed by a complex set of standards and guidelines. These regulations are designed to ensure the safety, efficacy, and environmental compatibility of coatings used in automotive applications.

At the forefront of these standards are the Environmental Protection Agency (EPA) regulations, which mandate strict controls on volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted during the coating process and throughout the lifecycle of the engine. Manufacturers must adhere to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Surface Coating of Automobiles and Light-Duty Trucks, which sets limits on organic HAP emissions.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating the use of antibacterial coatings in engine manufacturing. OSHA standards focus on worker safety during the application and handling of these coatings, requiring proper ventilation, personal protective equipment, and handling procedures to minimize exposure risks.

In addition to federal regulations, state-level environmental agencies often impose their own, sometimes more stringent, requirements on coating formulations and application processes. California's Air Resources Board (CARB), for instance, has established particularly rigorous standards that have influenced regulations across the United States.

International standards also come into play, especially for engines destined for global markets. The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the chemical composition of coatings used on engines exported to EU countries. Similarly, Japan's Chemical Substances Control Law (CSCL) sets its own parameters for chemical safety and environmental protection.

For antibacterial coatings specifically, the Food and Drug Administration (FDA) may have oversight if the coatings make claims related to public health or if they are used in environments where food safety is a concern. The EPA also regulates antimicrobial pesticides, which may include certain types of antibacterial coatings, under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

Compliance with these regulatory standards often requires extensive testing and documentation. Manufacturers must demonstrate that their coatings meet performance criteria while also adhering to environmental and safety regulations. This may involve third-party certification processes and ongoing quality control measures to ensure consistent compliance throughout production.

As environmental concerns and public health awareness continue to grow, regulatory standards for engine coatings are likely to evolve. Manufacturers and coating developers must stay abreast of these changes and be prepared to adapt their formulations and processes accordingly to maintain compliance and market access.

At the forefront of these standards are the Environmental Protection Agency (EPA) regulations, which mandate strict controls on volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted during the coating process and throughout the lifecycle of the engine. Manufacturers must adhere to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Surface Coating of Automobiles and Light-Duty Trucks, which sets limits on organic HAP emissions.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating the use of antibacterial coatings in engine manufacturing. OSHA standards focus on worker safety during the application and handling of these coatings, requiring proper ventilation, personal protective equipment, and handling procedures to minimize exposure risks.

In addition to federal regulations, state-level environmental agencies often impose their own, sometimes more stringent, requirements on coating formulations and application processes. California's Air Resources Board (CARB), for instance, has established particularly rigorous standards that have influenced regulations across the United States.

International standards also come into play, especially for engines destined for global markets. The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the chemical composition of coatings used on engines exported to EU countries. Similarly, Japan's Chemical Substances Control Law (CSCL) sets its own parameters for chemical safety and environmental protection.

For antibacterial coatings specifically, the Food and Drug Administration (FDA) may have oversight if the coatings make claims related to public health or if they are used in environments where food safety is a concern. The EPA also regulates antimicrobial pesticides, which may include certain types of antibacterial coatings, under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

Compliance with these regulatory standards often requires extensive testing and documentation. Manufacturers must demonstrate that their coatings meet performance criteria while also adhering to environmental and safety regulations. This may involve third-party certification processes and ongoing quality control measures to ensure consistent compliance throughout production.

As environmental concerns and public health awareness continue to grow, regulatory standards for engine coatings are likely to evolve. Manufacturers and coating developers must stay abreast of these changes and be prepared to adapt their formulations and processes accordingly to maintain compliance and market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!