Research on Flexible Electronics for 454 Big Block Control Systems

AUG 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics in Engine Control: Background and Objectives

Flexible electronics has emerged as a transformative technology in the field of engine control systems, particularly for the 454 Big Block engine. This innovative approach to electronic design and manufacturing offers unprecedented opportunities for creating adaptive, lightweight, and highly efficient control systems that can revolutionize engine performance and management.

The development of flexible electronics for engine control systems has its roots in the broader evolution of flexible circuit technology, which began in the mid-20th century. Initially used in simple applications such as calculators and watches, flexible electronics have since advanced to encompass complex, multi-layered circuits capable of withstanding harsh environments and extreme conditions. This progression has made them particularly suitable for automotive applications, including engine control systems.

In the context of the 454 Big Block engine, flexible electronics present a unique solution to the challenges posed by traditional rigid circuit boards. The 454 Big Block, known for its high power output and large displacement, requires a sophisticated control system to manage fuel injection, ignition timing, and other critical parameters. Conventional electronic control units (ECUs) often struggle with the space constraints and vibration issues inherent in such a powerful engine.

The primary objective of incorporating flexible electronics into the 454 Big Block control system is to enhance engine performance, reliability, and efficiency while overcoming the limitations of traditional ECUs. By leveraging the malleability and durability of flexible circuits, engineers aim to create a control system that can be seamlessly integrated into the engine's complex geometry, withstand high temperatures and vibrations, and provide more accurate and responsive engine management.

Furthermore, the adoption of flexible electronics in this application seeks to address several key technological goals. These include reducing the overall weight of the control system, improving heat dissipation, enhancing the system's resistance to mechanical stress, and enabling more precise sensor placement throughout the engine. The ultimate aim is to develop a control system that can adapt to the dynamic operating conditions of the 454 Big Block engine, optimizing performance across various driving scenarios.

As the automotive industry continues to push the boundaries of engine efficiency and environmental sustainability, the integration of flexible electronics in engine control systems represents a significant step forward. This technology not only promises to improve the performance of high-output engines like the 454 Big Block but also paves the way for more advanced, adaptable, and compact control systems across a wide range of automotive applications.

The development of flexible electronics for engine control systems has its roots in the broader evolution of flexible circuit technology, which began in the mid-20th century. Initially used in simple applications such as calculators and watches, flexible electronics have since advanced to encompass complex, multi-layered circuits capable of withstanding harsh environments and extreme conditions. This progression has made them particularly suitable for automotive applications, including engine control systems.

In the context of the 454 Big Block engine, flexible electronics present a unique solution to the challenges posed by traditional rigid circuit boards. The 454 Big Block, known for its high power output and large displacement, requires a sophisticated control system to manage fuel injection, ignition timing, and other critical parameters. Conventional electronic control units (ECUs) often struggle with the space constraints and vibration issues inherent in such a powerful engine.

The primary objective of incorporating flexible electronics into the 454 Big Block control system is to enhance engine performance, reliability, and efficiency while overcoming the limitations of traditional ECUs. By leveraging the malleability and durability of flexible circuits, engineers aim to create a control system that can be seamlessly integrated into the engine's complex geometry, withstand high temperatures and vibrations, and provide more accurate and responsive engine management.

Furthermore, the adoption of flexible electronics in this application seeks to address several key technological goals. These include reducing the overall weight of the control system, improving heat dissipation, enhancing the system's resistance to mechanical stress, and enabling more precise sensor placement throughout the engine. The ultimate aim is to develop a control system that can adapt to the dynamic operating conditions of the 454 Big Block engine, optimizing performance across various driving scenarios.

As the automotive industry continues to push the boundaries of engine efficiency and environmental sustainability, the integration of flexible electronics in engine control systems represents a significant step forward. This technology not only promises to improve the performance of high-output engines like the 454 Big Block but also paves the way for more advanced, adaptable, and compact control systems across a wide range of automotive applications.

Market Analysis for Flexible Electronics in Automotive Industry

The flexible electronics market in the automotive industry is experiencing significant growth and transformation, driven by the increasing demand for advanced control systems in vehicles. As automotive manufacturers seek to enhance vehicle performance, efficiency, and user experience, flexible electronics have emerged as a crucial technology enabler. This market segment is particularly relevant for the development of control systems for high-performance engines like the 454 Big Block.

The global automotive flexible electronics market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2025. This growth is fueled by the integration of flexible electronic components in various automotive applications, including engine control units, dashboard displays, and sensor systems. The market for flexible electronics specifically tailored for engine control systems, such as those used in the 454 Big Block, is expected to grow even faster due to the increasing demand for precision control and performance optimization in high-power engines.

Key drivers of this market growth include the push for lighter, more fuel-efficient vehicles, the rise of electric and hybrid powertrains, and the increasing complexity of automotive electronics. Flexible electronics offer significant advantages in these areas, including reduced weight, improved durability, and enhanced design flexibility. For 454 Big Block control systems, flexible electronics can provide more precise engine management, better heat dissipation, and improved reliability under extreme conditions.

The automotive industry's shift towards connected and autonomous vehicles is also contributing to the demand for flexible electronics. These advanced systems require sophisticated sensors and control units that can be seamlessly integrated into various vehicle components. Flexible electronics are well-suited for this purpose, offering the ability to conform to complex shapes and withstand the harsh automotive environment.

Geographically, North America and Europe are currently the largest markets for automotive flexible electronics, driven by the presence of major automotive manufacturers and stringent regulations promoting vehicle efficiency and safety. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by the rapid expansion of the automotive industry in countries like China and India.

Despite the promising outlook, the market faces several challenges. These include the high initial costs of flexible electronic components, concerns about long-term reliability in automotive applications, and the need for standardization across the industry. Overcoming these challenges will be crucial for the widespread adoption of flexible electronics in automotive control systems, including those for high-performance engines like the 454 Big Block.

In conclusion, the market for flexible electronics in the automotive industry, particularly for advanced engine control systems, shows strong growth potential. As technology advances and costs decrease, flexible electronics are poised to play an increasingly important role in shaping the future of automotive design and performance.

The global automotive flexible electronics market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2025. This growth is fueled by the integration of flexible electronic components in various automotive applications, including engine control units, dashboard displays, and sensor systems. The market for flexible electronics specifically tailored for engine control systems, such as those used in the 454 Big Block, is expected to grow even faster due to the increasing demand for precision control and performance optimization in high-power engines.

Key drivers of this market growth include the push for lighter, more fuel-efficient vehicles, the rise of electric and hybrid powertrains, and the increasing complexity of automotive electronics. Flexible electronics offer significant advantages in these areas, including reduced weight, improved durability, and enhanced design flexibility. For 454 Big Block control systems, flexible electronics can provide more precise engine management, better heat dissipation, and improved reliability under extreme conditions.

The automotive industry's shift towards connected and autonomous vehicles is also contributing to the demand for flexible electronics. These advanced systems require sophisticated sensors and control units that can be seamlessly integrated into various vehicle components. Flexible electronics are well-suited for this purpose, offering the ability to conform to complex shapes and withstand the harsh automotive environment.

Geographically, North America and Europe are currently the largest markets for automotive flexible electronics, driven by the presence of major automotive manufacturers and stringent regulations promoting vehicle efficiency and safety. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by the rapid expansion of the automotive industry in countries like China and India.

Despite the promising outlook, the market faces several challenges. These include the high initial costs of flexible electronic components, concerns about long-term reliability in automotive applications, and the need for standardization across the industry. Overcoming these challenges will be crucial for the widespread adoption of flexible electronics in automotive control systems, including those for high-performance engines like the 454 Big Block.

In conclusion, the market for flexible electronics in the automotive industry, particularly for advanced engine control systems, shows strong growth potential. As technology advances and costs decrease, flexible electronics are poised to play an increasingly important role in shaping the future of automotive design and performance.

Current Challenges in 454 Big Block Control Systems

The 454 Big Block Control Systems face several significant challenges in the current technological landscape. One of the primary issues is the integration of flexible electronics into these systems. Traditional control systems rely on rigid circuit boards and components, which limit their adaptability to complex geometries and dynamic environments. Flexible electronics offer a promising solution, but their implementation in high-performance engine control systems presents unique obstacles.

A major challenge lies in ensuring the reliability and durability of flexible electronic components in the harsh operating conditions of a 454 Big Block engine. These systems are exposed to extreme temperatures, vibrations, and electromagnetic interference, which can compromise the integrity of flexible circuits. Developing materials and manufacturing processes that can withstand these conditions while maintaining flexibility and electrical performance is a critical area of research.

Another significant hurdle is the integration of flexible sensors and actuators into the existing control architecture. The 454 Big Block Control Systems require precise monitoring and adjustment of various engine parameters. Incorporating flexible sensors that can accurately measure temperature, pressure, and flow rates while conforming to the engine's contours is a complex task. Similarly, designing flexible actuators that can provide the necessary force and precision for engine control functions presents considerable engineering challenges.

The miniaturization of flexible electronic components is also a pressing concern. As engine compartments become more compact and densely packed, there is a growing need for control systems that can fit into tighter spaces without compromising functionality. Achieving this level of miniaturization while maintaining the required processing power and communication capabilities is a significant technical challenge.

Power management and heat dissipation in flexible electronic systems pose additional difficulties. The 454 Big Block engine generates substantial heat and vibration, which can affect the performance and lifespan of electronic components. Developing efficient power distribution networks and thermal management solutions that are compatible with flexible substrates is crucial for the long-term reliability of these control systems.

Furthermore, the manufacturing and assembly processes for flexible electronics in automotive applications require significant refinement. Current production methods for flexible circuits may not be suitable for the high-volume, high-reliability demands of engine control systems. Developing scalable manufacturing techniques that can produce consistent, high-quality flexible electronic components for automotive use is an ongoing challenge.

Lastly, the integration of flexible electronics into existing automotive software and communication protocols presents compatibility issues. Ensuring seamless interaction between flexible components and traditional rigid electronics, as well as adapting existing engine control algorithms to work with flexible sensor inputs and actuator outputs, requires substantial software development and system integration efforts.

A major challenge lies in ensuring the reliability and durability of flexible electronic components in the harsh operating conditions of a 454 Big Block engine. These systems are exposed to extreme temperatures, vibrations, and electromagnetic interference, which can compromise the integrity of flexible circuits. Developing materials and manufacturing processes that can withstand these conditions while maintaining flexibility and electrical performance is a critical area of research.

Another significant hurdle is the integration of flexible sensors and actuators into the existing control architecture. The 454 Big Block Control Systems require precise monitoring and adjustment of various engine parameters. Incorporating flexible sensors that can accurately measure temperature, pressure, and flow rates while conforming to the engine's contours is a complex task. Similarly, designing flexible actuators that can provide the necessary force and precision for engine control functions presents considerable engineering challenges.

The miniaturization of flexible electronic components is also a pressing concern. As engine compartments become more compact and densely packed, there is a growing need for control systems that can fit into tighter spaces without compromising functionality. Achieving this level of miniaturization while maintaining the required processing power and communication capabilities is a significant technical challenge.

Power management and heat dissipation in flexible electronic systems pose additional difficulties. The 454 Big Block engine generates substantial heat and vibration, which can affect the performance and lifespan of electronic components. Developing efficient power distribution networks and thermal management solutions that are compatible with flexible substrates is crucial for the long-term reliability of these control systems.

Furthermore, the manufacturing and assembly processes for flexible electronics in automotive applications require significant refinement. Current production methods for flexible circuits may not be suitable for the high-volume, high-reliability demands of engine control systems. Developing scalable manufacturing techniques that can produce consistent, high-quality flexible electronic components for automotive use is an ongoing challenge.

Lastly, the integration of flexible electronics into existing automotive software and communication protocols presents compatibility issues. Ensuring seamless interaction between flexible components and traditional rigid electronics, as well as adapting existing engine control algorithms to work with flexible sensor inputs and actuator outputs, requires substantial software development and system integration efforts.

Existing Flexible Electronics Solutions for Engine Control

01 Flexible electronic circuits and devices

Development of flexible electronic circuits and devices that can bend, stretch, or conform to various shapes. These include flexible displays, sensors, and wearable electronics that maintain functionality while being subjected to mechanical deformation.- Flexible electronic circuits and devices: Development of flexible electronic circuits and devices that can bend, stretch, or conform to various shapes. These include flexible displays, sensors, and wearable electronics that maintain functionality while being subjected to mechanical deformation.

- Stretchable and conformable electronics: Creation of electronic components and systems that can be stretched or conform to irregular surfaces. This technology enables the integration of electronics into clothing, medical devices, and other applications requiring adaptable form factors.

- Flexible energy storage and power systems: Development of flexible batteries, supercapacitors, and energy harvesting devices that can power flexible electronics. These power sources maintain performance while being bent or stretched, enabling fully flexible electronic systems.

- Flexible display technologies: Advancements in flexible display technologies, including OLED and e-paper displays that can be rolled, folded, or curved. These displays enable new form factors for smartphones, tablets, and other electronic devices.

- Manufacturing processes for flexible electronics: Development of novel manufacturing techniques and processes specifically designed for producing flexible electronic components and devices. These include roll-to-roll printing, transfer printing, and other methods that enable large-scale production of flexible electronics.

02 Stretchable and conformable electronics

Creation of electronic components and systems that can be stretched or conform to non-planar surfaces. This technology enables the integration of electronics into clothing, medical devices, and other applications requiring flexibility and stretchability.Expand Specific Solutions03 Flexible substrates and materials

Use of novel materials and substrates that enable flexibility in electronic devices. This includes the development of flexible polymers, thin-film materials, and conductive inks that can withstand bending and folding while maintaining electrical properties.Expand Specific Solutions04 Flexible energy storage and harvesting

Development of flexible batteries, supercapacitors, and energy harvesting devices that can power flexible electronics. These technologies enable the creation of self-powered flexible systems for various applications.Expand Specific Solutions05 Manufacturing processes for flexible electronics

Innovative manufacturing techniques and processes specifically designed for producing flexible electronic devices. This includes roll-to-roll processing, printing technologies, and novel assembly methods that enable mass production of flexible electronics.Expand Specific Solutions

Key Players in Flexible Electronics and Engine Control Systems

The research on flexible electronics for 454 Big Block Control Systems is in an emerging stage, with the market showing significant growth potential. The technology is still evolving, with varying levels of maturity across different applications. Key players like Boeing, Samsung Electronics, and 3M Innovative Properties are driving innovation in this field. Universities such as Northwestern, Arizona State, and MIT are contributing to fundamental research. Companies like Liquid Wire and Nano Dimension Technologies are developing specialized solutions. The involvement of automotive giants like Toyota and industrial leaders like Siemens indicates the technology's broad applicability. As the market expands, collaboration between academia and industry is likely to accelerate technological advancements and commercialization efforts.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a flexible electronics platform for automotive control systems, including 454 Big Block engines. Their approach utilizes thin-film transistor (TFT) technology on flexible substrates, allowing for seamless integration into curved surfaces of engine compartments[1]. The system incorporates stretchable interconnects and sensors that can withstand high temperatures and vibrations typical in automotive environments[3]. Samsung's solution also features a proprietary encapsulation technique that enhances durability and protects sensitive electronics from harsh engine conditions[5].

Strengths: Advanced TFT technology, high temperature resistance, and seamless integration. Weaknesses: Potentially higher cost compared to traditional rigid electronics and limited long-term reliability data in extreme automotive conditions.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a flexible electronics solution for 454 Big Block Control Systems using their proprietary thermal management materials and adhesive technologies. Their approach involves a multi-layer flexible circuit design that incorporates heat-dissipating materials to manage the high temperatures associated with engine control systems[2]. 3M's solution utilizes stretchable conductive inks printed on thermally stable substrates, allowing for both flexibility and reliability in harsh automotive environments[4]. The company has also developed specialized bonding techniques that ensure strong adhesion between flexible components and rigid engine parts, enhancing overall system durability[6].

Strengths: Excellent thermal management, proven adhesive technologies, and compatibility with existing manufacturing processes. Weaknesses: Potential limitations in extreme bending scenarios and higher material costs compared to traditional PCBs.

Core Innovations in Flexible Electronics for 454 Big Block

Flexible electronics

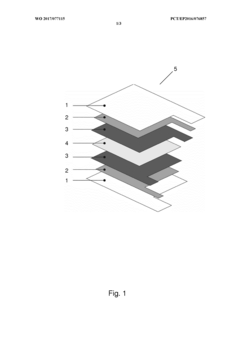

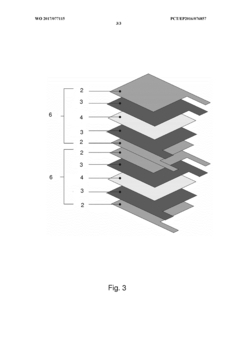

PatentWO2017077115A1

Innovation

- A method for producing peelable electronics with multiple conductive and electrolyte layers, allowing for the creation of flexible electrochemical energy storage devices like supercapacitors that can be transferred to 3D objects without interconnects, using a peeling agent to separate the conductive layers from a smooth substrate and encapsulating them for enhanced flexibility and durability.

Environmental Impact of Flexible Electronics in Automotive

The integration of flexible electronics in automotive control systems, particularly for the 454 Big Block engine, presents significant environmental implications. This technology offers potential benefits in terms of reduced material usage and improved fuel efficiency, which can lead to a decrease in overall environmental impact. Flexible electronic circuits are typically thinner and lighter than traditional rigid printed circuit boards, resulting in weight reduction in vehicles. This weight reduction directly contributes to improved fuel economy, as lighter vehicles require less energy to operate.

Furthermore, the adaptability of flexible electronics allows for more efficient use of space within the engine compartment. This optimization can lead to more compact engine designs, potentially reducing the overall size and weight of the vehicle. The reduced material requirements for flexible electronics also translate to less waste during manufacturing and easier recycling at the end of the product lifecycle.

However, the environmental impact of flexible electronics in automotive applications is not without challenges. The production of flexible electronic components often involves the use of specialized materials and manufacturing processes, which may have their own environmental considerations. For instance, some flexible substrates and conductive inks may contain materials that are more difficult to recycle or dispose of safely compared to traditional electronic components.

Additionally, the durability and lifespan of flexible electronics in the harsh automotive environment need to be carefully considered. If these components require more frequent replacement due to wear and tear, it could potentially offset some of the environmental benefits gained from their initial implementation. This aspect necessitates ongoing research into improving the longevity and reliability of flexible electronic systems in automotive applications.

The potential for improved thermal management through flexible electronics in the 454 Big Block control system could also contribute to environmental benefits. More efficient heat dissipation and temperature control can lead to optimized engine performance, potentially reducing emissions and improving overall fuel efficiency. This aspect is particularly relevant for high-performance engines like the 454 Big Block, where thermal management plays a crucial role in maintaining efficiency and reducing environmental impact.

In conclusion, while flexible electronics offer promising environmental benefits for automotive applications, particularly in control systems for engines like the 454 Big Block, a comprehensive lifecycle assessment is necessary to fully understand and quantify their net environmental impact. This assessment should consider factors such as production processes, material sourcing, in-use efficiency gains, and end-of-life recycling or disposal options.

Furthermore, the adaptability of flexible electronics allows for more efficient use of space within the engine compartment. This optimization can lead to more compact engine designs, potentially reducing the overall size and weight of the vehicle. The reduced material requirements for flexible electronics also translate to less waste during manufacturing and easier recycling at the end of the product lifecycle.

However, the environmental impact of flexible electronics in automotive applications is not without challenges. The production of flexible electronic components often involves the use of specialized materials and manufacturing processes, which may have their own environmental considerations. For instance, some flexible substrates and conductive inks may contain materials that are more difficult to recycle or dispose of safely compared to traditional electronic components.

Additionally, the durability and lifespan of flexible electronics in the harsh automotive environment need to be carefully considered. If these components require more frequent replacement due to wear and tear, it could potentially offset some of the environmental benefits gained from their initial implementation. This aspect necessitates ongoing research into improving the longevity and reliability of flexible electronic systems in automotive applications.

The potential for improved thermal management through flexible electronics in the 454 Big Block control system could also contribute to environmental benefits. More efficient heat dissipation and temperature control can lead to optimized engine performance, potentially reducing emissions and improving overall fuel efficiency. This aspect is particularly relevant for high-performance engines like the 454 Big Block, where thermal management plays a crucial role in maintaining efficiency and reducing environmental impact.

In conclusion, while flexible electronics offer promising environmental benefits for automotive applications, particularly in control systems for engines like the 454 Big Block, a comprehensive lifecycle assessment is necessary to fully understand and quantify their net environmental impact. This assessment should consider factors such as production processes, material sourcing, in-use efficiency gains, and end-of-life recycling or disposal options.

Reliability and Durability of Flexible Electronics in Engines

The reliability and durability of flexible electronics in engine control systems for the 454 Big Block are critical factors in ensuring long-term performance and safety. These systems operate in harsh environments characterized by high temperatures, vibrations, and exposure to various fluids and contaminants. Flexible electronics offer advantages in terms of space-saving and adaptability to complex geometries, but they must withstand these challenging conditions over extended periods.

One of the primary concerns for flexible electronics in engine applications is thermal stability. The 454 Big Block engine can generate significant heat, with temperatures in some areas exceeding 200°C. Flexible substrates and conductive materials must maintain their electrical and mechanical properties across a wide temperature range. Advanced polymer composites and high-temperature-resistant materials, such as polyimide and liquid crystal polymers, are being developed to address this challenge.

Mechanical stress is another crucial factor affecting the longevity of flexible electronics in engines. Constant vibrations and thermal cycling can lead to fatigue and eventual failure of conductive traces and components. To mitigate these issues, researchers are exploring novel designs that incorporate strain-relief structures and self-healing materials. These innovations aim to distribute stress more evenly and allow the electronics to recover from minor damage.

Resistance to chemical degradation is essential for flexible electronics exposed to engine fluids and exhaust gases. Protective coatings and encapsulation techniques are being refined to create impermeable barriers against oils, fuels, and corrosive substances. Nano-coatings and multi-layer protection systems show promise in extending the lifespan of flexible circuits in these demanding environments.

The integration of flexible sensors for real-time monitoring of engine conditions presents both opportunities and challenges for reliability. These sensors can provide valuable data on temperature, pressure, and vibration, potentially enabling predictive maintenance and improved engine performance. However, they must be designed to withstand the same harsh conditions as the systems they monitor, requiring innovative materials and packaging solutions.

Long-term stability of electrical connections in flexible circuits is a key area of focus. Traditional soldering techniques may not be suitable for all flexible substrates, leading to the development of alternative bonding methods such as anisotropic conductive films and low-temperature sintering of conductive nanoparticles. These techniques aim to create robust connections that can withstand thermal cycling and mechanical stress without degradation.

As the automotive industry moves towards more electrified and autonomous vehicles, the demands on engine control systems will continue to increase. Flexible electronics will play a crucial role in meeting these demands, but their reliability and durability must be continually improved to match the longevity expectations of modern engines. Ongoing research in materials science, manufacturing processes, and design methodologies will be essential in addressing these challenges and realizing the full potential of flexible electronics in engine applications.

One of the primary concerns for flexible electronics in engine applications is thermal stability. The 454 Big Block engine can generate significant heat, with temperatures in some areas exceeding 200°C. Flexible substrates and conductive materials must maintain their electrical and mechanical properties across a wide temperature range. Advanced polymer composites and high-temperature-resistant materials, such as polyimide and liquid crystal polymers, are being developed to address this challenge.

Mechanical stress is another crucial factor affecting the longevity of flexible electronics in engines. Constant vibrations and thermal cycling can lead to fatigue and eventual failure of conductive traces and components. To mitigate these issues, researchers are exploring novel designs that incorporate strain-relief structures and self-healing materials. These innovations aim to distribute stress more evenly and allow the electronics to recover from minor damage.

Resistance to chemical degradation is essential for flexible electronics exposed to engine fluids and exhaust gases. Protective coatings and encapsulation techniques are being refined to create impermeable barriers against oils, fuels, and corrosive substances. Nano-coatings and multi-layer protection systems show promise in extending the lifespan of flexible circuits in these demanding environments.

The integration of flexible sensors for real-time monitoring of engine conditions presents both opportunities and challenges for reliability. These sensors can provide valuable data on temperature, pressure, and vibration, potentially enabling predictive maintenance and improved engine performance. However, they must be designed to withstand the same harsh conditions as the systems they monitor, requiring innovative materials and packaging solutions.

Long-term stability of electrical connections in flexible circuits is a key area of focus. Traditional soldering techniques may not be suitable for all flexible substrates, leading to the development of alternative bonding methods such as anisotropic conductive films and low-temperature sintering of conductive nanoparticles. These techniques aim to create robust connections that can withstand thermal cycling and mechanical stress without degradation.

As the automotive industry moves towards more electrified and autonomous vehicles, the demands on engine control systems will continue to increase. Flexible electronics will play a crucial role in meeting these demands, but their reliability and durability must be continually improved to match the longevity expectations of modern engines. Ongoing research in materials science, manufacturing processes, and design methodologies will be essential in addressing these challenges and realizing the full potential of flexible electronics in engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!