Exploring the Use of Atmospheric Water Generators in 454 Big Blocks

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AWG Technology Evolution

Atmospheric Water Generators (AWGs) have undergone significant technological evolution since their inception. Initially developed as simple devices to extract water from humid air, AWGs have transformed into sophisticated systems capable of producing substantial quantities of potable water from various atmospheric conditions.

The early stages of AWG technology primarily relied on basic condensation principles, similar to those found in air conditioning units. These early models were inefficient and limited in their water production capacity, especially in low humidity environments. As research progressed, more advanced cooling and condensation techniques were incorporated, improving the efficiency and reliability of AWGs.

A major breakthrough came with the integration of desiccant-based systems. These systems use materials that absorb moisture from the air, which is then extracted through heating processes. This innovation allowed AWGs to operate effectively in a wider range of humidity conditions, expanding their potential applications.

The advent of smart technology and IoT integration marked another significant milestone in AWG evolution. Modern AWGs now incorporate sensors and automated control systems that optimize water production based on real-time atmospheric conditions. This has led to substantial improvements in energy efficiency and water output consistency.

Recent advancements have focused on addressing the energy-intensive nature of AWG systems. Solar-powered AWGs have emerged as a promising solution, particularly for remote or off-grid applications. These systems combine photovoltaic technology with efficient water generation processes, making them more sustainable and environmentally friendly.

Nanotechnology has also played a crucial role in enhancing AWG performance. The development of nanostructured materials with superior water-attracting properties has significantly improved water extraction efficiency. These materials can capture moisture from the air even in extremely low humidity conditions, expanding the viability of AWGs in arid regions.

The integration of AWG technology with 454 Big Blocks represents a novel approach to scaling up water production. This combination leverages the high-performance characteristics of Big Block engines to power larger, more efficient AWG systems. The robust power output of 454 Big Blocks allows for the operation of industrial-scale AWGs, potentially revolutionizing water production in water-scarce areas.

Looking ahead, the evolution of AWG technology is likely to continue focusing on improving energy efficiency, increasing water production capacity, and enhancing adaptability to diverse environmental conditions. Research into new materials, such as metal-organic frameworks (MOFs) and advanced polymers, promises to further boost the efficiency of moisture capture and water extraction processes.

The early stages of AWG technology primarily relied on basic condensation principles, similar to those found in air conditioning units. These early models were inefficient and limited in their water production capacity, especially in low humidity environments. As research progressed, more advanced cooling and condensation techniques were incorporated, improving the efficiency and reliability of AWGs.

A major breakthrough came with the integration of desiccant-based systems. These systems use materials that absorb moisture from the air, which is then extracted through heating processes. This innovation allowed AWGs to operate effectively in a wider range of humidity conditions, expanding their potential applications.

The advent of smart technology and IoT integration marked another significant milestone in AWG evolution. Modern AWGs now incorporate sensors and automated control systems that optimize water production based on real-time atmospheric conditions. This has led to substantial improvements in energy efficiency and water output consistency.

Recent advancements have focused on addressing the energy-intensive nature of AWG systems. Solar-powered AWGs have emerged as a promising solution, particularly for remote or off-grid applications. These systems combine photovoltaic technology with efficient water generation processes, making them more sustainable and environmentally friendly.

Nanotechnology has also played a crucial role in enhancing AWG performance. The development of nanostructured materials with superior water-attracting properties has significantly improved water extraction efficiency. These materials can capture moisture from the air even in extremely low humidity conditions, expanding the viability of AWGs in arid regions.

The integration of AWG technology with 454 Big Blocks represents a novel approach to scaling up water production. This combination leverages the high-performance characteristics of Big Block engines to power larger, more efficient AWG systems. The robust power output of 454 Big Blocks allows for the operation of industrial-scale AWGs, potentially revolutionizing water production in water-scarce areas.

Looking ahead, the evolution of AWG technology is likely to continue focusing on improving energy efficiency, increasing water production capacity, and enhancing adaptability to diverse environmental conditions. Research into new materials, such as metal-organic frameworks (MOFs) and advanced polymers, promises to further boost the efficiency of moisture capture and water extraction processes.

Market Demand Analysis

The market demand for atmospheric water generators (AWGs) in 454 Big Blocks is driven by several key factors, including water scarcity, environmental concerns, and the need for sustainable water solutions in various industries. As global water resources become increasingly strained, there is a growing interest in alternative water sources, particularly in regions facing water stress or limited access to clean water.

The automotive industry, specifically the 454 Big Block engine market, presents a unique opportunity for AWG integration. These high-performance engines, known for their power and reliability, are often used in applications where access to traditional water sources may be limited, such as off-road vehicles, marine vessels, and industrial equipment. By incorporating AWGs into 454 Big Block systems, manufacturers can address water-related challenges while enhancing the overall functionality and sustainability of their products.

The potential market for AWGs in 454 Big Blocks extends beyond the automotive sector. Industries such as agriculture, construction, and disaster relief could benefit from vehicles equipped with these water-generating capabilities. For example, agricultural machinery fitted with 454 Big Blocks and AWGs could provide irrigation solutions in remote areas, while construction equipment could generate water for dust suppression and concrete mixing on-site.

Market analysis indicates a growing awareness of water conservation and sustainability among consumers and businesses alike. This shift in mindset is driving demand for innovative water solutions across various sectors. The integration of AWGs in 454 Big Blocks aligns with this trend, offering a compelling value proposition for environmentally conscious customers and organizations seeking to reduce their water footprint.

The market size for AWGs in 454 Big Blocks is expected to expand as technological advancements improve the efficiency and cost-effectiveness of these systems. Early adopters in niche markets, such as luxury off-road vehicles and specialized industrial applications, are likely to pave the way for broader adoption. As the technology matures and production scales up, the potential for mass-market integration in commercial and consumer vehicles becomes increasingly feasible.

Regulatory factors also play a crucial role in shaping market demand. Stricter environmental regulations and water conservation policies in many countries are encouraging the adoption of water-efficient technologies. This regulatory landscape creates a favorable environment for the development and implementation of AWGs in 454 Big Blocks, potentially accelerating market growth.

However, challenges such as initial costs, system complexity, and integration hurdles may impact market adoption rates. Overcoming these barriers through continued research and development, as well as strategic partnerships between engine manufacturers and AWG technology providers, will be crucial for realizing the full market potential of this innovative solution.

The automotive industry, specifically the 454 Big Block engine market, presents a unique opportunity for AWG integration. These high-performance engines, known for their power and reliability, are often used in applications where access to traditional water sources may be limited, such as off-road vehicles, marine vessels, and industrial equipment. By incorporating AWGs into 454 Big Block systems, manufacturers can address water-related challenges while enhancing the overall functionality and sustainability of their products.

The potential market for AWGs in 454 Big Blocks extends beyond the automotive sector. Industries such as agriculture, construction, and disaster relief could benefit from vehicles equipped with these water-generating capabilities. For example, agricultural machinery fitted with 454 Big Blocks and AWGs could provide irrigation solutions in remote areas, while construction equipment could generate water for dust suppression and concrete mixing on-site.

Market analysis indicates a growing awareness of water conservation and sustainability among consumers and businesses alike. This shift in mindset is driving demand for innovative water solutions across various sectors. The integration of AWGs in 454 Big Blocks aligns with this trend, offering a compelling value proposition for environmentally conscious customers and organizations seeking to reduce their water footprint.

The market size for AWGs in 454 Big Blocks is expected to expand as technological advancements improve the efficiency and cost-effectiveness of these systems. Early adopters in niche markets, such as luxury off-road vehicles and specialized industrial applications, are likely to pave the way for broader adoption. As the technology matures and production scales up, the potential for mass-market integration in commercial and consumer vehicles becomes increasingly feasible.

Regulatory factors also play a crucial role in shaping market demand. Stricter environmental regulations and water conservation policies in many countries are encouraging the adoption of water-efficient technologies. This regulatory landscape creates a favorable environment for the development and implementation of AWGs in 454 Big Blocks, potentially accelerating market growth.

However, challenges such as initial costs, system complexity, and integration hurdles may impact market adoption rates. Overcoming these barriers through continued research and development, as well as strategic partnerships between engine manufacturers and AWG technology providers, will be crucial for realizing the full market potential of this innovative solution.

Technical Challenges

The implementation of Atmospheric Water Generators (AWGs) in 454 Big Blocks faces several significant technical challenges that need to be addressed for successful integration and operation. One of the primary obstacles is the energy efficiency of the AWG systems. The process of extracting water from air, particularly in low humidity environments, requires substantial energy input, which can be problematic for large-scale applications like 454 Big Blocks.

The size and weight of AWG units pose another challenge. Traditional AWG systems are often bulky and heavy, making their integration into existing 454 Big Block designs complex and potentially compromising the vehicle's performance characteristics. Engineers must find innovative ways to miniaturize the AWG components without sacrificing their water generation capacity.

Water quality control is a critical issue that demands attention. The water produced by AWGs may contain impurities from the air, necessitating additional filtration and treatment systems. Ensuring that the generated water meets safety standards for various applications, including potential use in engine cooling systems, is crucial and technically demanding.

The variability of atmospheric conditions presents a significant hurdle. AWG performance is highly dependent on ambient temperature and humidity levels, which can fluctuate dramatically in different operating environments. Developing AWG systems that can maintain consistent water production across a wide range of climatic conditions is a complex engineering challenge.

Durability and maintenance requirements are also key concerns. AWG systems integrated into 454 Big Blocks will be subjected to harsh conditions, including vibrations, temperature extremes, and potentially corrosive environments. Designing robust AWG components that can withstand these conditions while minimizing maintenance needs is essential for practical implementation.

The integration of AWG systems with the existing 454 Big Block engine architecture presents its own set of challenges. Engineers must devise solutions for seamlessly incorporating water generation, storage, and distribution systems without compromising the engine's core functionality or performance metrics.

Lastly, the control and automation of AWG systems in a mobile application like the 454 Big Block require sophisticated software and sensor technologies. Developing intelligent control systems that can optimize water generation based on engine demands, environmental conditions, and energy availability is a complex task that requires advanced algorithms and real-time data processing capabilities.

The size and weight of AWG units pose another challenge. Traditional AWG systems are often bulky and heavy, making their integration into existing 454 Big Block designs complex and potentially compromising the vehicle's performance characteristics. Engineers must find innovative ways to miniaturize the AWG components without sacrificing their water generation capacity.

Water quality control is a critical issue that demands attention. The water produced by AWGs may contain impurities from the air, necessitating additional filtration and treatment systems. Ensuring that the generated water meets safety standards for various applications, including potential use in engine cooling systems, is crucial and technically demanding.

The variability of atmospheric conditions presents a significant hurdle. AWG performance is highly dependent on ambient temperature and humidity levels, which can fluctuate dramatically in different operating environments. Developing AWG systems that can maintain consistent water production across a wide range of climatic conditions is a complex engineering challenge.

Durability and maintenance requirements are also key concerns. AWG systems integrated into 454 Big Blocks will be subjected to harsh conditions, including vibrations, temperature extremes, and potentially corrosive environments. Designing robust AWG components that can withstand these conditions while minimizing maintenance needs is essential for practical implementation.

The integration of AWG systems with the existing 454 Big Block engine architecture presents its own set of challenges. Engineers must devise solutions for seamlessly incorporating water generation, storage, and distribution systems without compromising the engine's core functionality or performance metrics.

Lastly, the control and automation of AWG systems in a mobile application like the 454 Big Block require sophisticated software and sensor technologies. Developing intelligent control systems that can optimize water generation based on engine demands, environmental conditions, and energy availability is a complex task that requires advanced algorithms and real-time data processing capabilities.

Current AWG Solutions

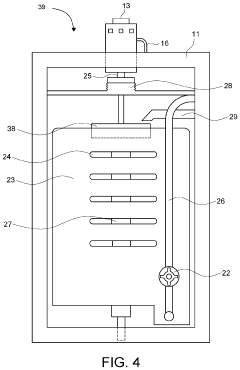

01 Condensation-based water extraction systems

These systems utilize condensation techniques to extract water from atmospheric air. They typically involve cooling air to its dew point, causing water vapor to condense into liquid form. The process may include various cooling methods and efficiency-enhancing features to optimize water production.- Condensation-based water extraction systems: These systems utilize condensation techniques to extract water from atmospheric air. They typically involve cooling air to its dew point, causing water vapor to condense into liquid form. The process may include various cooling methods and efficiency-enhancing features to optimize water production.

- Desiccant-based atmospheric water generation: This approach uses desiccant materials to absorb moisture from the air. The water is then extracted from the desiccant through heating or other regeneration processes. These systems can be effective in a wide range of humidity conditions and may be more energy-efficient in certain environments.

- Integrated renewable energy and water generation systems: These innovative systems combine atmospheric water generation with renewable energy sources such as solar or wind power. This integration aims to create sustainable and off-grid solutions for water production, particularly in remote or water-scarce areas.

- Atmospheric water harvesting for agriculture: Specialized atmospheric water generators designed for agricultural applications. These systems focus on providing irrigation water or supplementing existing water sources for crop cultivation, potentially incorporating features tailored to agricultural needs such as nutrient addition or specific water quality controls.

- Portable and compact atmospheric water generators: Compact and mobile water generation units designed for personal use, emergency situations, or small-scale applications. These devices prioritize portability and ease of use, often incorporating energy-efficient technologies and user-friendly interfaces for operation in various environments.

02 Desiccant-based atmospheric water generation

This approach employs hygroscopic materials or desiccants to absorb moisture from the air. The water is then extracted from the desiccant through heating or other regeneration processes. These systems can be effective in a wide range of humidity conditions and may be more energy-efficient in certain environments.Expand Specific Solutions03 Solar-powered atmospheric water generators

These devices harness solar energy to power the water extraction process, making them suitable for off-grid applications. They may use photovoltaic panels or solar thermal collectors to drive condensation or desiccant-based systems, improving energy efficiency and sustainability.Expand Specific Solutions04 Portable and compact water generation units

Designed for personal or small-scale use, these units are compact and often mobile. They may employ various water extraction technologies optimized for portability, such as thermoelectric cooling or miniaturized condensation systems, to provide water in remote locations or emergency situations.Expand Specific Solutions05 Large-scale atmospheric water harvesting systems

These systems are designed for industrial or community-level water production. They often incorporate advanced air handling, multiple extraction stages, and water treatment processes to maximize output and ensure water quality. Such systems may be integrated with existing infrastructure or designed as standalone water production facilities.Expand Specific Solutions

Key Industry Players

The atmospheric water generation market for 454 Big Blocks is in its early development stage, characterized by emerging technologies and growing interest from various sectors. The market size is relatively small but expanding, driven by increasing water scarcity concerns and the need for sustainable water solutions. The technology's maturity is still evolving, with companies like Toyota Motor Corp., Uravu Labs Pvt Ltd., and Genesis Systems LLC leading research and development efforts. These players are focusing on improving efficiency, scalability, and cost-effectiveness of atmospheric water generators for large-scale applications. The competitive landscape is diverse, including automotive giants, specialized water technology firms, and research institutions, indicating a multidisciplinary approach to solving this complex technical challenge.

Uravu Labs Pvt Ltd.

Technical Solution: Uravu Labs has developed an innovative atmospheric water generator (AWG) technology that utilizes desiccants to extract water from air. Their system operates on a day-night cycle, absorbing moisture during the night and releasing it as clean water during the day. The technology is designed to be energy-efficient and can operate using renewable energy sources such as solar power. Uravu's AWG can produce up to 20 liters of water per day from air with relative humidity as low as 30%[1]. The company has also integrated IoT capabilities for remote monitoring and optimization of water production[2].

Strengths: Energy-efficient, works in low humidity, scalable, and can be powered by renewable energy. Weaknesses: Limited water production capacity compared to larger industrial systems, potentially higher initial costs.

Genesis Systems LLC

Technical Solution: Genesis Systems has developed the WaterCube™, an advanced atmospheric water generation system designed for large-scale water production. The technology uses a proprietary desiccant-based process to extract water from air, even in arid conditions with humidity as low as 5%. The WaterCube™ can produce up to 1,000,000 liters of water per day, making it suitable for industrial and municipal applications[3]. The system incorporates a closed-loop process that minimizes energy consumption and can be powered by various energy sources, including waste heat from industrial processes[4].

Strengths: High water production capacity, operates in extremely low humidity, energy-efficient, and versatile power options. Weaknesses: Large physical footprint, high initial investment cost, and may require specialized maintenance.

Core AWG Innovations

Atmospheric Water Generator Utilizing Centrifugal Hydraulic Air Compressor

PatentInactiveUS20210230846A1

Innovation

- A centrifugal disc-based atmospheric water generator that uses water as both a sorbent and hydraulic component, eliminating the need for costly filtration and fan-powered air circulation, and utilizing dehydrated air for cooling and heat transfer to enhance efficiency and productivity.

Environmental Impact

The implementation of Atmospheric Water Generators (AWGs) in 454 Big Blocks presents both potential benefits and environmental concerns that warrant careful consideration. These devices, designed to extract water from ambient air, could significantly impact local ecosystems and climate patterns if deployed on a large scale.

One of the primary environmental advantages of AWGs is their potential to reduce pressure on traditional water sources, such as rivers, lakes, and groundwater. By tapping into atmospheric moisture, these systems could help preserve natural water bodies and aquifers, particularly in water-stressed regions. This could lead to the restoration of degraded ecosystems and the protection of biodiversity in areas where water scarcity has been a persistent issue.

However, the energy consumption of AWGs is a significant environmental concern. The process of condensing water from air requires substantial energy input, which, if sourced from fossil fuels, could contribute to increased greenhouse gas emissions. To mitigate this impact, it is crucial to pair AWGs with renewable energy sources such as solar or wind power. This integration could create a more sustainable water production system, aligning with global efforts to reduce carbon footprints.

The large-scale deployment of AWGs in 454 Big Blocks could also affect local microclimates. By extracting moisture from the air, these devices might alter humidity levels, potentially impacting plant growth, insect populations, and other moisture-dependent ecological processes. Long-term studies would be necessary to fully understand and manage these effects, ensuring that the benefits of water production do not come at the cost of ecosystem health.

Another environmental consideration is the disposal of waste products generated by AWGs. These may include filters, condensate, and other materials that require proper handling to prevent pollution. Developing efficient recycling and waste management protocols for these components would be essential to minimize environmental impact and promote a circular economy approach.

The use of AWGs could also indirectly benefit the environment by reducing the need for water transportation infrastructure. This could lead to fewer pipelines, reduced road traffic for water delivery, and decreased reliance on plastic bottles, all of which contribute to lower carbon emissions and reduced plastic waste.

In conclusion, while AWGs in 454 Big Blocks offer promising solutions for water scarcity, their environmental impact must be carefully managed. Balancing the benefits of increased water availability against potential ecological disruptions will be crucial. Ongoing research, monitoring, and adaptive management strategies will be necessary to ensure that this technology contributes positively to environmental sustainability while addressing critical water needs.

One of the primary environmental advantages of AWGs is their potential to reduce pressure on traditional water sources, such as rivers, lakes, and groundwater. By tapping into atmospheric moisture, these systems could help preserve natural water bodies and aquifers, particularly in water-stressed regions. This could lead to the restoration of degraded ecosystems and the protection of biodiversity in areas where water scarcity has been a persistent issue.

However, the energy consumption of AWGs is a significant environmental concern. The process of condensing water from air requires substantial energy input, which, if sourced from fossil fuels, could contribute to increased greenhouse gas emissions. To mitigate this impact, it is crucial to pair AWGs with renewable energy sources such as solar or wind power. This integration could create a more sustainable water production system, aligning with global efforts to reduce carbon footprints.

The large-scale deployment of AWGs in 454 Big Blocks could also affect local microclimates. By extracting moisture from the air, these devices might alter humidity levels, potentially impacting plant growth, insect populations, and other moisture-dependent ecological processes. Long-term studies would be necessary to fully understand and manage these effects, ensuring that the benefits of water production do not come at the cost of ecosystem health.

Another environmental consideration is the disposal of waste products generated by AWGs. These may include filters, condensate, and other materials that require proper handling to prevent pollution. Developing efficient recycling and waste management protocols for these components would be essential to minimize environmental impact and promote a circular economy approach.

The use of AWGs could also indirectly benefit the environment by reducing the need for water transportation infrastructure. This could lead to fewer pipelines, reduced road traffic for water delivery, and decreased reliance on plastic bottles, all of which contribute to lower carbon emissions and reduced plastic waste.

In conclusion, while AWGs in 454 Big Blocks offer promising solutions for water scarcity, their environmental impact must be carefully managed. Balancing the benefits of increased water availability against potential ecological disruptions will be crucial. Ongoing research, monitoring, and adaptive management strategies will be necessary to ensure that this technology contributes positively to environmental sustainability while addressing critical water needs.

Regulatory Compliance

The implementation of Atmospheric Water Generators (AWGs) in 454 Big Blocks must adhere to a complex web of regulatory requirements spanning environmental, safety, and health standards. At the federal level, the Environmental Protection Agency (EPA) oversees air quality and water safety regulations that directly impact AWG operations. The Clean Air Act and Safe Drinking Water Act provide the primary regulatory framework, setting standards for air emissions and water quality respectively.

State-level regulations add another layer of complexity, with varying requirements for water treatment, distribution, and monitoring. Many states have adopted more stringent standards than federal baselines, necessitating careful consideration of local regulations during AWG implementation. Additionally, local municipalities may impose their own ordinances regarding water production and distribution, particularly in drought-prone areas.

The Food and Drug Administration (FDA) also plays a role in regulating AWGs when the produced water is intended for human consumption. Compliance with FDA guidelines on water quality, packaging, and labeling is essential for AWG systems in 454 Big Blocks that may supply drinking water.

Occupational Safety and Health Administration (OSHA) standards must be met to ensure worker safety during the installation, operation, and maintenance of AWGs. This includes regulations on electrical safety, fall protection, and exposure to potential contaminants.

Energy efficiency standards, set by the Department of Energy, apply to the operation of AWGs, particularly when integrated into large-scale systems like 454 Big Blocks. Compliance with these standards is crucial for both regulatory adherence and operational cost management.

International standards, such as those set by the International Organization for Standardization (ISO), may also be relevant, especially for AWG systems manufactured abroad or implemented in multinational projects. These standards often address quality management, environmental management, and energy management systems.

Regulatory compliance for AWGs in 454 Big Blocks extends to waste management and disposal. The handling of filters, condensate, and other byproducts must align with local and federal waste management regulations, including those set by the EPA under the Resource Conservation and Recovery Act.

As the technology evolves, regulatory frameworks are likely to adapt. Staying abreast of proposed regulations and participating in public comment periods can help shape future compliance requirements. Engaging with industry associations and regulatory bodies can provide valuable insights into upcoming changes and best practices for compliance.

State-level regulations add another layer of complexity, with varying requirements for water treatment, distribution, and monitoring. Many states have adopted more stringent standards than federal baselines, necessitating careful consideration of local regulations during AWG implementation. Additionally, local municipalities may impose their own ordinances regarding water production and distribution, particularly in drought-prone areas.

The Food and Drug Administration (FDA) also plays a role in regulating AWGs when the produced water is intended for human consumption. Compliance with FDA guidelines on water quality, packaging, and labeling is essential for AWG systems in 454 Big Blocks that may supply drinking water.

Occupational Safety and Health Administration (OSHA) standards must be met to ensure worker safety during the installation, operation, and maintenance of AWGs. This includes regulations on electrical safety, fall protection, and exposure to potential contaminants.

Energy efficiency standards, set by the Department of Energy, apply to the operation of AWGs, particularly when integrated into large-scale systems like 454 Big Blocks. Compliance with these standards is crucial for both regulatory adherence and operational cost management.

International standards, such as those set by the International Organization for Standardization (ISO), may also be relevant, especially for AWG systems manufactured abroad or implemented in multinational projects. These standards often address quality management, environmental management, and energy management systems.

Regulatory compliance for AWGs in 454 Big Blocks extends to waste management and disposal. The handling of filters, condensate, and other byproducts must align with local and federal waste management regulations, including those set by the EPA under the Resource Conservation and Recovery Act.

As the technology evolves, regulatory frameworks are likely to adapt. Staying abreast of proposed regulations and participating in public comment periods can help shape future compliance requirements. Engaging with industry associations and regulatory bodies can provide valuable insights into upcoming changes and best practices for compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!