The Role of Thermoelectric Generators in 454 Big Block Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG in 454 Big Block: Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for improving the efficiency and performance of 454 Big Block engines. These powerful V8 engines, known for their high displacement and torque output, have been a staple in automotive and marine applications for decades. However, they are also notorious for their high fuel consumption and heat generation.

The development of TEGs for use in 454 Big Block engines represents a significant technological advancement in the field of automotive engineering. These devices leverage the Seebeck effect to convert waste heat from the engine into usable electrical energy, potentially improving overall engine efficiency and reducing fuel consumption.

The evolution of TEG technology in the context of 454 Big Block engines can be traced back to the early 2000s when researchers began exploring ways to harness waste heat from internal combustion engines. Initial experiments focused on small-scale applications, but as the technology matured, attention shifted to larger engines like the 454 Big Block, where the potential for energy recovery is more substantial due to the greater amount of waste heat generated.

The primary objective of integrating TEGs into 454 Big Block engines is to capture a portion of the thermal energy that would otherwise be lost to the environment. By converting this waste heat into electricity, TEGs can potentially power various vehicle systems, reducing the load on the alternator and ultimately improving fuel efficiency. Additionally, the use of TEGs may help in meeting increasingly stringent emissions regulations by enabling more efficient engine operation.

Another key goal is to enhance the overall performance of the 454 Big Block engine without compromising its legendary power output. TEGs offer the possibility of achieving this by providing an additional source of electrical power that can be used to support advanced engine management systems, electric turbochargers, or other performance-enhancing technologies.

The integration of TEGs into 454 Big Block engines also aligns with broader industry trends towards electrification and improved energy efficiency. As the automotive industry moves towards hybrid and electric powertrains, the development of TEG technology for traditional high-performance engines like the 454 Big Block represents an important bridge between conventional and future propulsion systems.

Furthermore, the successful implementation of TEGs in 454 Big Block engines could pave the way for wider adoption of this technology across various engine types and sizes. This could lead to significant advancements in engine efficiency and emissions reduction across the automotive and marine industries, contributing to global efforts to reduce carbon emissions and combat climate change.

The development of TEGs for use in 454 Big Block engines represents a significant technological advancement in the field of automotive engineering. These devices leverage the Seebeck effect to convert waste heat from the engine into usable electrical energy, potentially improving overall engine efficiency and reducing fuel consumption.

The evolution of TEG technology in the context of 454 Big Block engines can be traced back to the early 2000s when researchers began exploring ways to harness waste heat from internal combustion engines. Initial experiments focused on small-scale applications, but as the technology matured, attention shifted to larger engines like the 454 Big Block, where the potential for energy recovery is more substantial due to the greater amount of waste heat generated.

The primary objective of integrating TEGs into 454 Big Block engines is to capture a portion of the thermal energy that would otherwise be lost to the environment. By converting this waste heat into electricity, TEGs can potentially power various vehicle systems, reducing the load on the alternator and ultimately improving fuel efficiency. Additionally, the use of TEGs may help in meeting increasingly stringent emissions regulations by enabling more efficient engine operation.

Another key goal is to enhance the overall performance of the 454 Big Block engine without compromising its legendary power output. TEGs offer the possibility of achieving this by providing an additional source of electrical power that can be used to support advanced engine management systems, electric turbochargers, or other performance-enhancing technologies.

The integration of TEGs into 454 Big Block engines also aligns with broader industry trends towards electrification and improved energy efficiency. As the automotive industry moves towards hybrid and electric powertrains, the development of TEG technology for traditional high-performance engines like the 454 Big Block represents an important bridge between conventional and future propulsion systems.

Furthermore, the successful implementation of TEGs in 454 Big Block engines could pave the way for wider adoption of this technology across various engine types and sizes. This could lead to significant advancements in engine efficiency and emissions reduction across the automotive and marine industries, contributing to global efforts to reduce carbon emissions and combat climate change.

Market Analysis for TEG-Enhanced Engines

The market for thermoelectric generator (TEG) enhanced 454 big block engines is poised for significant growth, driven by increasing demand for fuel-efficient and environmentally friendly power solutions in the automotive and industrial sectors. The integration of TEGs into these large displacement engines addresses key market needs for improved energy recovery and reduced emissions, aligning with global trends towards sustainability and energy conservation.

In the automotive sector, the market potential for TEG-enhanced 454 big block engines is particularly promising. These engines are commonly used in high-performance vehicles, trucks, and marine applications, where fuel efficiency and power output are critical factors. The addition of TEGs can significantly improve overall engine efficiency by converting waste heat into usable electrical energy, thereby reducing fuel consumption and emissions. This aligns with stringent environmental regulations and consumer preferences for greener technologies, creating a strong market pull for TEG-enhanced engines.

The industrial sector also presents substantial opportunities for TEG-enhanced 454 big block engines. In applications such as power generation, oil and gas, and manufacturing, where large engines are used for continuous operation, the benefits of TEGs become even more pronounced. The ability to recover waste heat and convert it into electricity can lead to significant cost savings and improved energy efficiency, making TEG-enhanced engines an attractive option for industrial users looking to optimize their operations and reduce their carbon footprint.

Market analysis indicates a growing awareness among end-users about the benefits of TEG technology, which is expected to drive adoption rates in the coming years. The potential for fuel savings, reduced maintenance costs, and improved environmental performance are key factors influencing purchasing decisions. Additionally, government incentives and regulations promoting energy efficiency and emissions reduction are likely to further stimulate market growth for TEG-enhanced engines.

The market size for TEG-enhanced 454 big block engines is expected to expand significantly over the next decade. While precise figures are challenging to determine due to the emerging nature of this technology, industry experts project substantial year-over-year growth rates. This growth is anticipated to be driven by both retrofitting existing engines with TEG systems and the integration of TEGs into new engine designs.

Geographically, North America and Europe are expected to be the leading markets for TEG-enhanced 454 big block engines, due to their strong automotive and industrial sectors, as well as stringent environmental regulations. However, emerging economies in Asia-Pacific and Latin America are also showing increasing interest in this technology, particularly in industries where large engines are widely used, such as mining and power generation.

In the automotive sector, the market potential for TEG-enhanced 454 big block engines is particularly promising. These engines are commonly used in high-performance vehicles, trucks, and marine applications, where fuel efficiency and power output are critical factors. The addition of TEGs can significantly improve overall engine efficiency by converting waste heat into usable electrical energy, thereby reducing fuel consumption and emissions. This aligns with stringent environmental regulations and consumer preferences for greener technologies, creating a strong market pull for TEG-enhanced engines.

The industrial sector also presents substantial opportunities for TEG-enhanced 454 big block engines. In applications such as power generation, oil and gas, and manufacturing, where large engines are used for continuous operation, the benefits of TEGs become even more pronounced. The ability to recover waste heat and convert it into electricity can lead to significant cost savings and improved energy efficiency, making TEG-enhanced engines an attractive option for industrial users looking to optimize their operations and reduce their carbon footprint.

Market analysis indicates a growing awareness among end-users about the benefits of TEG technology, which is expected to drive adoption rates in the coming years. The potential for fuel savings, reduced maintenance costs, and improved environmental performance are key factors influencing purchasing decisions. Additionally, government incentives and regulations promoting energy efficiency and emissions reduction are likely to further stimulate market growth for TEG-enhanced engines.

The market size for TEG-enhanced 454 big block engines is expected to expand significantly over the next decade. While precise figures are challenging to determine due to the emerging nature of this technology, industry experts project substantial year-over-year growth rates. This growth is anticipated to be driven by both retrofitting existing engines with TEG systems and the integration of TEGs into new engine designs.

Geographically, North America and Europe are expected to be the leading markets for TEG-enhanced 454 big block engines, due to their strong automotive and industrial sectors, as well as stringent environmental regulations. However, emerging economies in Asia-Pacific and Latin America are also showing increasing interest in this technology, particularly in industries where large engines are widely used, such as mining and power generation.

Current TEG Integration Challenges in Big Block Engines

The integration of Thermoelectric Generators (TEGs) in 454 Big Block Engines presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the thermal management of the system. Big block engines generate substantial heat, and while this is beneficial for TEG operation, it also poses risks of overheating and potential damage to the TEG components.

Efficient heat transfer from the engine to the TEG is crucial, but achieving this without compromising engine performance or adding excessive weight is complex. The design of heat exchangers that can withstand the high temperatures and vibrations of a big block engine while maintaining optimal thermal contact with the TEG modules is a significant engineering challenge.

Another major hurdle is the integration of TEGs into the limited space available in the engine compartment. Big block engines are already space-intensive, and finding suitable locations for TEG placement without interfering with other critical components or affecting the engine's center of gravity is problematic. This spatial constraint also impacts the potential power output of the TEG system, as the number and size of TEG modules are limited by available space.

The durability and longevity of TEGs in the harsh environment of a big block engine pose additional challenges. TEGs must withstand extreme temperature fluctuations, constant vibrations, and potential exposure to engine fluids and contaminants. Developing TEG materials and protective enclosures that can endure these conditions while maintaining performance over the engine's lifespan is a significant materials science challenge.

Electrical integration is another complex aspect of TEG implementation in big block engines. The variable and often unpredictable power output of TEGs necessitates sophisticated power management systems to effectively utilize the generated electricity. These systems must be capable of handling fluctuating inputs while providing stable power to the vehicle's electrical systems or storage devices.

Cost-effectiveness remains a significant barrier to widespread adoption of TEGs in big block engines. The current high cost of thermoelectric materials and the complexity of integration make it challenging to justify the investment, particularly when compared to traditional alternator systems. Improving the efficiency of TEGs and reducing manufacturing costs are crucial for making this technology economically viable in automotive applications.

Lastly, the impact on engine performance and fuel efficiency must be carefully considered. While TEGs have the potential to improve overall engine efficiency by recovering waste heat, any additional weight or changes to the engine's thermal characteristics could potentially offset these gains. Striking the right balance between TEG integration and maintaining or enhancing engine performance is a delicate engineering task that requires extensive testing and optimization.

Efficient heat transfer from the engine to the TEG is crucial, but achieving this without compromising engine performance or adding excessive weight is complex. The design of heat exchangers that can withstand the high temperatures and vibrations of a big block engine while maintaining optimal thermal contact with the TEG modules is a significant engineering challenge.

Another major hurdle is the integration of TEGs into the limited space available in the engine compartment. Big block engines are already space-intensive, and finding suitable locations for TEG placement without interfering with other critical components or affecting the engine's center of gravity is problematic. This spatial constraint also impacts the potential power output of the TEG system, as the number and size of TEG modules are limited by available space.

The durability and longevity of TEGs in the harsh environment of a big block engine pose additional challenges. TEGs must withstand extreme temperature fluctuations, constant vibrations, and potential exposure to engine fluids and contaminants. Developing TEG materials and protective enclosures that can endure these conditions while maintaining performance over the engine's lifespan is a significant materials science challenge.

Electrical integration is another complex aspect of TEG implementation in big block engines. The variable and often unpredictable power output of TEGs necessitates sophisticated power management systems to effectively utilize the generated electricity. These systems must be capable of handling fluctuating inputs while providing stable power to the vehicle's electrical systems or storage devices.

Cost-effectiveness remains a significant barrier to widespread adoption of TEGs in big block engines. The current high cost of thermoelectric materials and the complexity of integration make it challenging to justify the investment, particularly when compared to traditional alternator systems. Improving the efficiency of TEGs and reducing manufacturing costs are crucial for making this technology economically viable in automotive applications.

Lastly, the impact on engine performance and fuel efficiency must be carefully considered. While TEGs have the potential to improve overall engine efficiency by recovering waste heat, any additional weight or changes to the engine's thermal characteristics could potentially offset these gains. Striking the right balance between TEG integration and maintaining or enhancing engine performance is a delicate engineering task that requires extensive testing and optimization.

Existing TEG Solutions for 454 Big Block Engines

01 Thermoelectric material composition and structure

Advancements in thermoelectric materials focus on improving their composition and structure to enhance energy conversion efficiency. This includes developing novel semiconductor materials, nanostructured materials, and composite structures that can effectively convert temperature differences into electrical energy.- Thermoelectric material composition and structure: Advancements in thermoelectric materials focus on improving their composition and structure to enhance energy conversion efficiency. This includes developing novel semiconductor materials, nanostructured materials, and composite structures that can effectively convert temperature differences into electrical energy.

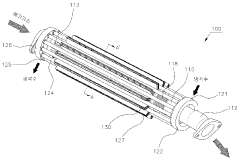

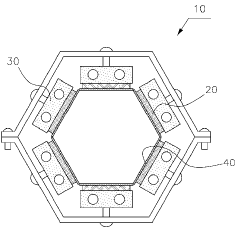

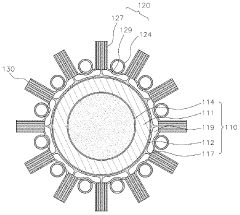

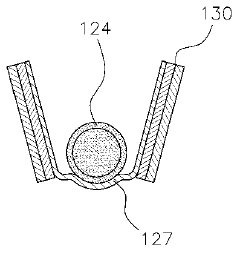

- Device design and optimization: Innovations in thermoelectric generator design aim to optimize heat flow, reduce thermal resistance, and improve overall system efficiency. This involves developing new geometries, heat exchanger designs, and integration techniques to maximize power output and minimize losses.

- Integration with other energy systems: Thermoelectric generators are being integrated with other energy systems to create hybrid solutions. This includes combining them with solar panels, waste heat recovery systems, or other renewable energy sources to improve overall energy efficiency and utilization.

- Flexible and wearable thermoelectric devices: Development of flexible and wearable thermoelectric generators for powering portable electronics and medical devices. These innovations focus on creating thin-film thermoelectric materials and flexible substrates that can conform to various shapes and be integrated into clothing or accessories.

- Micro and nano-scale thermoelectric systems: Research into micro and nano-scale thermoelectric systems for applications in microelectronics and IoT devices. This includes developing miniaturized thermoelectric modules, improving thermal management at small scales, and enhancing the power density of thermoelectric generators.

02 Device design and optimization

Innovations in thermoelectric generator design aim to optimize heat flow, reduce thermal resistance, and improve overall system efficiency. This involves developing new geometries, heat exchanger designs, and integration techniques to maximize power output and minimize losses.Expand Specific Solutions03 Application-specific thermoelectric generators

Tailoring thermoelectric generators for specific applications such as waste heat recovery in industrial processes, automotive exhaust systems, and wearable devices. This includes developing flexible, thin-film, and miniaturized thermoelectric generators for diverse use cases.Expand Specific Solutions04 Integration with other energy harvesting technologies

Combining thermoelectric generators with other energy harvesting technologies like photovoltaics or piezoelectrics to create hybrid systems. This approach aims to increase overall energy generation and improve system reliability in various environmental conditions.Expand Specific Solutions05 Modeling and simulation techniques

Development of advanced modeling and simulation techniques to predict and optimize thermoelectric generator performance. This includes computational methods for material property prediction, device-level simulations, and system-level performance analysis to guide design and development processes.Expand Specific Solutions

Key Players in Automotive TEG Development

The thermoelectric generator (TEG) market for 454 Big Block Engines is in its early growth stage, with increasing interest from automotive manufacturers and suppliers. The market size is relatively small but expanding, driven by the push for improved fuel efficiency and emissions reduction. Technologically, TEGs are still evolving, with companies like Robert Bosch, Denso, and Gentherm leading development efforts. These firms are focusing on enhancing TEG efficiency, durability, and cost-effectiveness for automotive applications. Major automakers such as BMW, Toyota, and Hyundai are also exploring TEG integration, indicating growing industry adoption and potential for market expansion in the coming years.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermoelectric generators (TEGs) for 454 Big Block Engines, focusing on waste heat recovery to improve overall engine efficiency. Their TEG system utilizes high-performance semiconductor materials to convert thermal energy from exhaust gases into electricity. The design incorporates a modular approach, allowing for easy integration into existing engine architectures. Bosch's TEGs are capable of generating up to 5% additional electrical power, reducing the load on the alternator and improving fuel economy[1][3]. The system also includes advanced thermal management to optimize performance across various engine operating conditions.

Strengths: Proven expertise in automotive systems, extensive R&D capabilities, and established market presence. Weaknesses: High initial costs and complexity in integrating TEGs into existing engine designs.

Toyota Motor Corp.

Technical Solution: Toyota has invested heavily in thermoelectric generator technology for its 454 Big Block Engines, focusing on maximizing energy recovery from exhaust heat. Their approach involves a novel cascaded TEG design that utilizes different thermoelectric materials optimized for specific temperature ranges along the exhaust system. This multi-stage system achieves higher overall efficiency, with reported power generation of up to 7% of the engine's output[2]. Toyota's TEGs also incorporate advanced heat exchangers and a bypass system to protect the generators during high-temperature conditions, ensuring longevity and consistent performance.

Strengths: Strong research capabilities, extensive experience in hybrid technologies, and global manufacturing scale. Weaknesses: Higher system complexity may lead to increased maintenance requirements.

Core TEG Innovations for High-Performance Engines

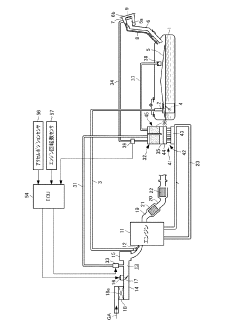

Thermoelectric generator of vehicle

PatentActiveKR1020130073411A

Innovation

- A compact thermoelectric generator design featuring a high-temperature unit with heat exchange fins and a bypass pipe, combined with a low-temperature unit using cooling water to enhance thermal energy transfer and generate electricity via a thermoelectric phenomenon, utilizing P-type and N-type semiconductors bonded to heat exchange fins and cooled by cooling water.

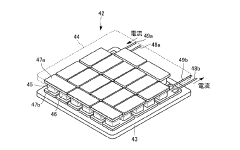

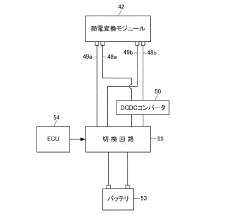

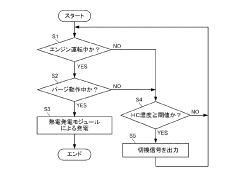

Thermoelectric generator

PatentInactiveJP2014181665A

Innovation

- A thermoelectric generator design that utilizes a high-temperature section facing a cooling water circulation portion and a low-temperature section with an adsorbent, generating power from the temperature difference between cooling water and the adsorbent, and incorporating a purge mechanism and Peltier effect for efficient fuel desorption and cooling.

Environmental Impact and Emissions Regulations

The integration of thermoelectric generators (TEGs) in 454 Big Block engines presents significant implications for environmental impact and emissions regulations. As automotive manufacturers face increasingly stringent emissions standards, the potential of TEGs to improve engine efficiency and reduce emissions becomes particularly relevant.

TEGs in 454 Big Block engines can contribute to reduced fuel consumption by harnessing waste heat and converting it into usable electrical energy. This process not only improves overall engine efficiency but also leads to a decrease in greenhouse gas emissions. The reduction in fuel consumption directly correlates with lower carbon dioxide (CO2) emissions, a primary target of environmental regulations worldwide.

Furthermore, the implementation of TEGs can assist in meeting nitrogen oxides (NOx) and particulate matter (PM) emission standards. By optimizing engine performance and reducing the load on the alternator, TEGs indirectly contribute to more efficient combustion processes, potentially leading to lower NOx and PM emissions. This aligns with the increasingly strict regulations on these pollutants, particularly in urban areas and regions with air quality concerns.

The use of TEGs also supports compliance with idle reduction regulations. As TEGs can generate electricity even when the engine is idling, they reduce the need for extended idling periods to power auxiliary systems. This capability is particularly beneficial in jurisdictions with anti-idling laws, helping fleet operators and individual drivers adhere to these environmental regulations.

From a lifecycle perspective, the environmental impact of TEGs in 454 Big Block engines extends beyond operational emissions. The production and eventual disposal of TEGs must be considered in the context of environmental regulations. While the manufacturing process may have its own environmental footprint, the long-term benefits of reduced emissions and improved fuel efficiency can potentially offset these initial impacts.

As emissions regulations continue to evolve, the role of TEGs in 454 Big Block engines may become increasingly important. Future regulations may incentivize or mandate the use of waste heat recovery technologies, positioning TEGs as a key component in meeting these requirements. Additionally, the potential for TEGs to contribute to overall vehicle electrification aligns with the broader regulatory push towards low-emission and zero-emission vehicles.

In conclusion, the integration of TEGs in 454 Big Block engines represents a promising approach to addressing environmental concerns and meeting emissions regulations. As the automotive industry continues to seek innovative solutions for reducing its environmental impact, TEGs offer a pathway to improved efficiency and reduced emissions, aligning with both current and anticipated regulatory frameworks.

TEGs in 454 Big Block engines can contribute to reduced fuel consumption by harnessing waste heat and converting it into usable electrical energy. This process not only improves overall engine efficiency but also leads to a decrease in greenhouse gas emissions. The reduction in fuel consumption directly correlates with lower carbon dioxide (CO2) emissions, a primary target of environmental regulations worldwide.

Furthermore, the implementation of TEGs can assist in meeting nitrogen oxides (NOx) and particulate matter (PM) emission standards. By optimizing engine performance and reducing the load on the alternator, TEGs indirectly contribute to more efficient combustion processes, potentially leading to lower NOx and PM emissions. This aligns with the increasingly strict regulations on these pollutants, particularly in urban areas and regions with air quality concerns.

The use of TEGs also supports compliance with idle reduction regulations. As TEGs can generate electricity even when the engine is idling, they reduce the need for extended idling periods to power auxiliary systems. This capability is particularly beneficial in jurisdictions with anti-idling laws, helping fleet operators and individual drivers adhere to these environmental regulations.

From a lifecycle perspective, the environmental impact of TEGs in 454 Big Block engines extends beyond operational emissions. The production and eventual disposal of TEGs must be considered in the context of environmental regulations. While the manufacturing process may have its own environmental footprint, the long-term benefits of reduced emissions and improved fuel efficiency can potentially offset these initial impacts.

As emissions regulations continue to evolve, the role of TEGs in 454 Big Block engines may become increasingly important. Future regulations may incentivize or mandate the use of waste heat recovery technologies, positioning TEGs as a key component in meeting these requirements. Additionally, the potential for TEGs to contribute to overall vehicle electrification aligns with the broader regulatory push towards low-emission and zero-emission vehicles.

In conclusion, the integration of TEGs in 454 Big Block engines represents a promising approach to addressing environmental concerns and meeting emissions regulations. As the automotive industry continues to seek innovative solutions for reducing its environmental impact, TEGs offer a pathway to improved efficiency and reduced emissions, aligning with both current and anticipated regulatory frameworks.

Cost-Benefit Analysis of TEG Implementation

The implementation of Thermoelectric Generators (TEGs) in 454 Big Block Engines presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for TEG systems are substantial, primarily due to the high-quality materials required for efficient thermoelectric conversion and the complexity of integration with existing engine systems. These costs include the thermoelectric modules, heat exchangers, and necessary modifications to the engine structure.

However, the long-term benefits of TEG implementation can potentially outweigh these initial expenses. The primary advantage is the improvement in overall engine efficiency through waste heat recovery. TEGs can convert a portion of the engine's waste heat into usable electrical energy, reducing the load on the alternator and potentially improving fuel economy. This fuel savings, when calculated over the lifespan of the engine, can result in significant cost reductions for vehicle operators.

Maintenance costs associated with TEGs are generally low, as they have no moving parts and are relatively durable. This can lead to reduced long-term operational expenses compared to traditional engine components. Additionally, the electricity generated by TEGs can power auxiliary systems, potentially reducing the size and weight of the alternator and battery systems, which could lead to further fuel savings and reduced component costs.

Environmental benefits, while not directly financial, can translate into economic advantages through compliance with emissions regulations and potential tax incentives for green technologies. The reduction in fuel consumption leads to lower CO2 emissions, which can be particularly valuable in markets with strict environmental regulations or carbon pricing mechanisms.

The scalability of TEG technology in 454 Big Block Engines also factors into the cost-benefit analysis. As production volumes increase and technology advances, the per-unit cost of TEG systems is expected to decrease, improving the overall economic viability of the technology. Furthermore, the potential for TEGs to enhance engine performance and reliability could lead to increased customer satisfaction and brand value, indirectly contributing to the financial benefits.

However, it's crucial to consider the opportunity costs associated with TEG implementation. The resources allocated to this technology could potentially be invested in alternative efficiency-improving technologies or other areas of engine development. The payback period for TEG systems must be carefully evaluated against these alternative investments to ensure optimal resource allocation.

In conclusion, while the upfront costs of implementing TEGs in 454 Big Block Engines are significant, the long-term benefits in fuel efficiency, reduced emissions, and potential regulatory advantages present a compelling case for their adoption. The ultimate cost-benefit ratio will depend on factors such as fuel prices, regulatory environment, and technological advancements in TEG efficiency. A comprehensive analysis considering these factors over the expected lifespan of the engine is essential for making informed decisions about TEG implementation.

However, the long-term benefits of TEG implementation can potentially outweigh these initial expenses. The primary advantage is the improvement in overall engine efficiency through waste heat recovery. TEGs can convert a portion of the engine's waste heat into usable electrical energy, reducing the load on the alternator and potentially improving fuel economy. This fuel savings, when calculated over the lifespan of the engine, can result in significant cost reductions for vehicle operators.

Maintenance costs associated with TEGs are generally low, as they have no moving parts and are relatively durable. This can lead to reduced long-term operational expenses compared to traditional engine components. Additionally, the electricity generated by TEGs can power auxiliary systems, potentially reducing the size and weight of the alternator and battery systems, which could lead to further fuel savings and reduced component costs.

Environmental benefits, while not directly financial, can translate into economic advantages through compliance with emissions regulations and potential tax incentives for green technologies. The reduction in fuel consumption leads to lower CO2 emissions, which can be particularly valuable in markets with strict environmental regulations or carbon pricing mechanisms.

The scalability of TEG technology in 454 Big Block Engines also factors into the cost-benefit analysis. As production volumes increase and technology advances, the per-unit cost of TEG systems is expected to decrease, improving the overall economic viability of the technology. Furthermore, the potential for TEGs to enhance engine performance and reliability could lead to increased customer satisfaction and brand value, indirectly contributing to the financial benefits.

However, it's crucial to consider the opportunity costs associated with TEG implementation. The resources allocated to this technology could potentially be invested in alternative efficiency-improving technologies or other areas of engine development. The payback period for TEG systems must be carefully evaluated against these alternative investments to ensure optimal resource allocation.

In conclusion, while the upfront costs of implementing TEGs in 454 Big Block Engines are significant, the long-term benefits in fuel efficiency, reduced emissions, and potential regulatory advantages present a compelling case for their adoption. The ultimate cost-benefit ratio will depend on factors such as fuel prices, regulatory environment, and technological advancements in TEG efficiency. A comprehensive analysis considering these factors over the expected lifespan of the engine is essential for making informed decisions about TEG implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!