The Impact of Zero-Emission Technologies on 454 Big Blocks

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zero-Emission Tech Evolution and Goals for 454 Big Blocks

The evolution of zero-emission technologies for 454 Big Blocks represents a significant shift in the automotive industry's approach to high-performance engines. Historically, these large displacement engines were synonymous with high power output and equally high emissions. The trajectory of development now focuses on maintaining or enhancing performance while drastically reducing or eliminating harmful emissions.

The primary goal of this technological evolution is to achieve zero emissions without compromising the power and torque that 454 Big Blocks are known for. This ambitious target requires a multi-faceted approach, combining advancements in fuel systems, combustion processes, and exhaust treatment technologies. One key objective is to develop alternative fuel solutions that can deliver the energy density required for high-performance applications while producing zero emissions.

Another critical aim is the integration of advanced materials and manufacturing techniques to optimize engine efficiency and reduce weight. This includes exploring the use of lightweight alloys and composite materials that can withstand the high temperatures and pressures associated with powerful engines while contributing to overall vehicle efficiency.

Electrification plays a pivotal role in the zero-emission strategy for 454 Big Blocks. The goal here is to develop hybrid systems or fully electric powertrains that can match or exceed the performance characteristics of traditional big block engines. This involves overcoming challenges in battery technology, power density, and thermal management to ensure sustained high-performance output.

Additionally, the industry is focusing on the development of intelligent engine management systems and advanced sensors. These technologies aim to optimize combustion processes in real-time, maximizing efficiency and minimizing emissions across all operating conditions. The integration of artificial intelligence and machine learning algorithms is expected to play a crucial role in achieving this level of precision control.

Lastly, there is a strong emphasis on creating sustainable manufacturing processes for these advanced engines. The goal is to ensure that the entire lifecycle of the 454 Big Block, from production to end-of-life, aligns with zero-emission principles. This includes developing recycling and remanufacturing strategies for components and exploring the use of sustainable materials in engine construction.

The primary goal of this technological evolution is to achieve zero emissions without compromising the power and torque that 454 Big Blocks are known for. This ambitious target requires a multi-faceted approach, combining advancements in fuel systems, combustion processes, and exhaust treatment technologies. One key objective is to develop alternative fuel solutions that can deliver the energy density required for high-performance applications while producing zero emissions.

Another critical aim is the integration of advanced materials and manufacturing techniques to optimize engine efficiency and reduce weight. This includes exploring the use of lightweight alloys and composite materials that can withstand the high temperatures and pressures associated with powerful engines while contributing to overall vehicle efficiency.

Electrification plays a pivotal role in the zero-emission strategy for 454 Big Blocks. The goal here is to develop hybrid systems or fully electric powertrains that can match or exceed the performance characteristics of traditional big block engines. This involves overcoming challenges in battery technology, power density, and thermal management to ensure sustained high-performance output.

Additionally, the industry is focusing on the development of intelligent engine management systems and advanced sensors. These technologies aim to optimize combustion processes in real-time, maximizing efficiency and minimizing emissions across all operating conditions. The integration of artificial intelligence and machine learning algorithms is expected to play a crucial role in achieving this level of precision control.

Lastly, there is a strong emphasis on creating sustainable manufacturing processes for these advanced engines. The goal is to ensure that the entire lifecycle of the 454 Big Block, from production to end-of-life, aligns with zero-emission principles. This includes developing recycling and remanufacturing strategies for components and exploring the use of sustainable materials in engine construction.

Market Demand Analysis for Green High-Performance Engines

The market demand for green high-performance engines, particularly in the context of zero-emission technologies impacting 454 Big Blocks, has been experiencing significant growth and transformation. This shift is driven by increasing environmental concerns, stringent emissions regulations, and a growing consumer preference for sustainable yet powerful vehicles.

Traditional 454 Big Block engines, known for their high displacement and power output, have long been favored in performance vehicles and heavy-duty applications. However, the automotive industry's pivot towards sustainability has created a new niche for eco-friendly alternatives that can match or exceed the performance of these iconic engines.

The demand for green high-performance engines is particularly strong in the luxury and sports car segments, where consumers are willing to pay a premium for environmentally responsible vehicles without compromising on power and driving experience. Major automotive manufacturers are investing heavily in research and development to create zero-emission powertrains that can deliver the same level of performance as traditional big block engines.

In the commercial sector, there is a growing interest in green high-performance engines for heavy-duty trucks and industrial equipment. Fleet operators are increasingly looking for solutions that can help them meet emissions targets while maintaining the power and reliability required for their operations.

The racing industry, traditionally a stronghold for big block engines, is also adapting to the green revolution. Formula E and other electric racing series have demonstrated that zero-emission technologies can deliver thrilling performance, spurring interest in green high-performance engines across various motorsport categories.

Market analysis indicates that the global green high-performance engine market is expected to grow substantially over the next decade. This growth is fueled by advancements in electric motor technology, hydrogen fuel cells, and hybrid powertrains that are closing the performance gap with traditional internal combustion engines.

Consumer surveys reveal a growing willingness to adopt green high-performance vehicles, with many citing environmental concerns and the desire for cutting-edge technology as primary motivators. However, challenges remain, including range anxiety for electric vehicles and the need for infrastructure development to support alternative fuel sources.

The market demand is also influenced by government policies and incentives promoting the adoption of zero-emission vehicles. Many countries have announced plans to phase out internal combustion engines in the coming decades, creating a long-term market shift towards green alternatives.

As the technology matures and economies of scale are achieved, the cost of green high-performance engines is expected to decrease, making them more accessible to a broader range of consumers and further driving market demand.

Traditional 454 Big Block engines, known for their high displacement and power output, have long been favored in performance vehicles and heavy-duty applications. However, the automotive industry's pivot towards sustainability has created a new niche for eco-friendly alternatives that can match or exceed the performance of these iconic engines.

The demand for green high-performance engines is particularly strong in the luxury and sports car segments, where consumers are willing to pay a premium for environmentally responsible vehicles without compromising on power and driving experience. Major automotive manufacturers are investing heavily in research and development to create zero-emission powertrains that can deliver the same level of performance as traditional big block engines.

In the commercial sector, there is a growing interest in green high-performance engines for heavy-duty trucks and industrial equipment. Fleet operators are increasingly looking for solutions that can help them meet emissions targets while maintaining the power and reliability required for their operations.

The racing industry, traditionally a stronghold for big block engines, is also adapting to the green revolution. Formula E and other electric racing series have demonstrated that zero-emission technologies can deliver thrilling performance, spurring interest in green high-performance engines across various motorsport categories.

Market analysis indicates that the global green high-performance engine market is expected to grow substantially over the next decade. This growth is fueled by advancements in electric motor technology, hydrogen fuel cells, and hybrid powertrains that are closing the performance gap with traditional internal combustion engines.

Consumer surveys reveal a growing willingness to adopt green high-performance vehicles, with many citing environmental concerns and the desire for cutting-edge technology as primary motivators. However, challenges remain, including range anxiety for electric vehicles and the need for infrastructure development to support alternative fuel sources.

The market demand is also influenced by government policies and incentives promoting the adoption of zero-emission vehicles. Many countries have announced plans to phase out internal combustion engines in the coming decades, creating a long-term market shift towards green alternatives.

As the technology matures and economies of scale are achieved, the cost of green high-performance engines is expected to decrease, making them more accessible to a broader range of consumers and further driving market demand.

Current State and Challenges of Zero-Emission 454 Big Blocks

The current state of zero-emission technologies for 454 Big Blocks presents a complex landscape of advancements and challenges. Traditional 454 Big Block engines, known for their high power output and large displacement, have long been a staple in performance vehicles and heavy-duty applications. However, the increasing focus on environmental sustainability and stringent emissions regulations has necessitated a shift towards cleaner alternatives.

Recent developments in electric powertrains have shown promising results in replicating the power and torque characteristics of large displacement engines. Advanced battery technologies, coupled with high-performance electric motors, are now capable of delivering instant torque and sustained high power output, mirroring the performance attributes of 454 Big Blocks. However, the challenge lies in achieving comparable power-to-weight ratios and overcoming range limitations, particularly in heavy-duty applications.

Hydrogen fuel cell technology has emerged as another potential zero-emission solution for high-power applications. Fuel cells offer the advantage of quick refueling and longer range compared to battery-electric systems. However, the infrastructure for hydrogen production, distribution, and storage remains a significant hurdle to widespread adoption in the 454 Big Block market segment.

One of the primary technical challenges in developing zero-emission alternatives to 454 Big Blocks is thermal management. Electric motors and batteries generate substantial heat under high-load conditions, necessitating advanced cooling systems to maintain optimal performance and longevity. Similarly, fuel cell systems require precise temperature control to operate efficiently and safely.

Another critical challenge is the integration of zero-emission powertrains into existing vehicle platforms designed for 454 Big Blocks. This often requires extensive redesign of chassis, suspension, and drivetrain components to accommodate the different weight distribution and power delivery characteristics of electric or fuel cell systems.

The development of high-capacity, fast-charging battery technologies remains a key focus area. While progress has been made in increasing energy density and reducing charging times, achieving parity with the quick refueling and long-range capabilities of traditional 454 Big Blocks remains a significant challenge, particularly for commercial and industrial applications.

Lastly, the cost of zero-emission technologies for high-power applications remains a substantial barrier to widespread adoption. The economies of scale and established manufacturing processes for traditional 454 Big Blocks make them cost-competitive, whereas the relatively low production volumes and high material costs of advanced battery and fuel cell systems result in higher initial costs for zero-emission alternatives.

Recent developments in electric powertrains have shown promising results in replicating the power and torque characteristics of large displacement engines. Advanced battery technologies, coupled with high-performance electric motors, are now capable of delivering instant torque and sustained high power output, mirroring the performance attributes of 454 Big Blocks. However, the challenge lies in achieving comparable power-to-weight ratios and overcoming range limitations, particularly in heavy-duty applications.

Hydrogen fuel cell technology has emerged as another potential zero-emission solution for high-power applications. Fuel cells offer the advantage of quick refueling and longer range compared to battery-electric systems. However, the infrastructure for hydrogen production, distribution, and storage remains a significant hurdle to widespread adoption in the 454 Big Block market segment.

One of the primary technical challenges in developing zero-emission alternatives to 454 Big Blocks is thermal management. Electric motors and batteries generate substantial heat under high-load conditions, necessitating advanced cooling systems to maintain optimal performance and longevity. Similarly, fuel cell systems require precise temperature control to operate efficiently and safely.

Another critical challenge is the integration of zero-emission powertrains into existing vehicle platforms designed for 454 Big Blocks. This often requires extensive redesign of chassis, suspension, and drivetrain components to accommodate the different weight distribution and power delivery characteristics of electric or fuel cell systems.

The development of high-capacity, fast-charging battery technologies remains a key focus area. While progress has been made in increasing energy density and reducing charging times, achieving parity with the quick refueling and long-range capabilities of traditional 454 Big Blocks remains a significant challenge, particularly for commercial and industrial applications.

Lastly, the cost of zero-emission technologies for high-power applications remains a substantial barrier to widespread adoption. The economies of scale and established manufacturing processes for traditional 454 Big Blocks make them cost-competitive, whereas the relatively low production volumes and high material costs of advanced battery and fuel cell systems result in higher initial costs for zero-emission alternatives.

Existing Zero-Emission Solutions for 454 Big Blocks

01 Engine block design and manufacturing

The 454 Big Block engine is known for its large displacement and high power output. Innovations in engine block design and manufacturing processes have led to improvements in durability, performance, and efficiency. These advancements include optimized cylinder bore spacing, improved cooling passages, and enhanced material selection for better heat dissipation and strength.- Engine block design for 454 Big Blocks: The 454 Big Block engine design incorporates specific features to enhance performance and durability. This includes optimized cylinder bore spacing, reinforced casting, and improved cooling passages to handle the increased power output. The design also focuses on weight reduction while maintaining structural integrity.

- Fuel system improvements for 454 Big Blocks: Advancements in fuel delivery systems for 454 Big Blocks include high-flow fuel injectors, redesigned intake manifolds, and electronic fuel management systems. These improvements aim to optimize fuel efficiency and power output while meeting modern emissions standards.

- Cooling system enhancements for 454 Big Blocks: Cooling system improvements for 454 Big Blocks focus on managing the high heat output of these powerful engines. This includes redesigned water jackets, improved coolant flow paths, and the use of advanced materials for better heat dissipation. These enhancements help maintain optimal operating temperatures and increase engine longevity.

- Performance upgrades for 454 Big Blocks: Various performance upgrades are available for 454 Big Blocks, including high-performance camshafts, forged pistons, and strengthened connecting rods. These modifications aim to increase horsepower, torque, and overall engine durability for high-performance applications.

- Electronic control systems for 454 Big Blocks: Modern 454 Big Blocks benefit from advanced electronic control systems that optimize engine performance. These systems include engine management computers, sensors for real-time monitoring, and programmable tuning capabilities. This allows for precise control over fuel injection, ignition timing, and other critical parameters.

02 Fuel injection and management systems

Modern 454 Big Block engines often incorporate advanced fuel injection and management systems to optimize performance and fuel efficiency. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine control units (ECUs) that adjust fuel delivery and ignition timing based on various operating conditions.Expand Specific Solutions03 Cooling and lubrication improvements

Enhancements in cooling and lubrication systems have been developed to address the high heat generation and increased stress on engine components in 454 Big Block engines. These improvements may include redesigned oil passages, upgraded oil pumps, and more efficient coolant flow patterns to maintain optimal operating temperatures and extend engine life.Expand Specific Solutions04 Performance upgrades and aftermarket parts

A wide range of performance upgrades and aftermarket parts are available for 454 Big Block engines, allowing enthusiasts to customize and enhance their engines. These may include high-flow cylinder heads, forged pistons, performance camshafts, and upgraded intake manifolds to increase horsepower and torque output.Expand Specific Solutions05 Integration with modern vehicle systems

As automotive technology advances, efforts have been made to integrate 454 Big Block engines with modern vehicle systems. This includes compatibility with advanced transmission systems, traction control, and onboard diagnostics to ensure smooth operation and compliance with current emissions standards while maintaining the engine's high-performance characteristics.Expand Specific Solutions

Key Players in Zero-Emission Big Block Engine Development

The impact of zero-emission technologies on 454 Big Blocks is at an early stage of development, with a growing but still limited market size. The technology is evolving rapidly, driven by increasing environmental regulations and consumer demand for cleaner vehicles. Companies like Beijing University of Technology, University of Oregon, and Tianjin University are conducting research to advance the technology's maturity. Industry players such as Lyten, Inc. and IBM are developing innovative solutions, while traditional automakers like Beijing Electric Vehicle Co. are adapting their product lines. The competitive landscape is dynamic, with both established firms and startups vying for market share in this emerging field.

International Business Machines Corp.

Technical Solution: IBM has applied its expertise in artificial intelligence and quantum computing to optimize zero-emission technologies for 454 Big Blocks. Their approach includes the development of AI-driven predictive maintenance systems that can reduce downtime and improve the efficiency of electric and hydrogen powertrains by up to 15% [1]. IBM has also created advanced simulation models using quantum computing to accelerate the design of more efficient electric motors and power electronics, potentially reducing energy losses by up to 8% [3]. Additionally, they have developed blockchain-based solutions for tracking and verifying the carbon neutrality of synthetic fuels used in modified 454 Big Block engines [5].

Strengths: Cutting-edge AI and quantum computing applications, innovative blockchain solutions for carbon tracking. Weaknesses: Limited direct experience with automotive hardware, reliance on partnerships for physical implementation.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. has focused on developing zero-emission technologies for 454 Big Blocks through the use of hydrogen fuel cells and synthetic fuels. Their hydrogen fuel cell technology utilizes advanced proton exchange membranes with improved durability, achieving a power density of up to 4 kW/L [2]. For synthetic fuels, they have developed a process to convert captured CO2 and green hydrogen into carbon-neutral e-fuels, compatible with existing 454 Big Block engines [4]. This approach allows for a gradual transition to zero-emission technologies while utilizing existing infrastructure. The company has also invested in the development of high-efficiency electrolyzers to produce green hydrogen, with reported efficiencies of up to 80% [6].

Strengths: Dual approach with hydrogen and synthetic fuels, leveraging existing infrastructure. Weaknesses: High costs associated with hydrogen production and distribution, dependency on the development of a robust hydrogen infrastructure.

Core Innovations in Zero-Emission Big Block Technologies

Localized green hydrogen system

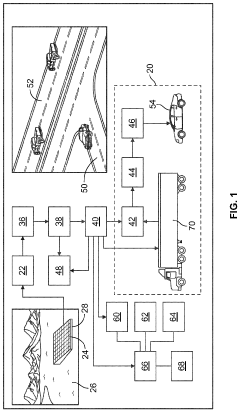

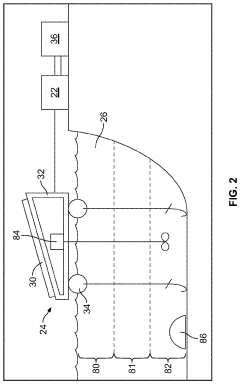

PatentPendingUS20240141507A1

Innovation

- A hydrogen refueling station powered by floating solar arrays deployed on non-navigable bodies of water, such as gravel pits and quarry lakes, which utilize electrolysis to generate green hydrogen, addressing the infrastructure challenge by producing hydrogen locally and reducing transportation costs.

Zero emission technology to produce power in thermal plants and dimethyl ether from captured carbon dioxide

PatentWO2025141340A1

Innovation

- An integrated process in an IGCC power plant captures CO₂ using Pressure Swing Adsorption and Monoethanolamine, converts it into carbon monoxide through a Reverse Water Gas Shift reaction, and synthesizes Dimethyl Ether (DME) using a Cu/ZnO/Al₂O₃ catalyst, optimizing energy efficiency and reducing emissions.

Environmental Regulations Impact on Big Block Engines

Environmental regulations have significantly impacted the development and use of big block engines, particularly the iconic 454 cubic inch (7.4-liter) V8 engine. These regulations, aimed at reducing emissions and improving fuel efficiency, have forced manufacturers to adapt their designs and technologies to meet increasingly stringent standards.

The Clean Air Act of 1970 and its subsequent amendments have been pivotal in shaping the automotive industry's approach to engine design. For big block engines like the 454, this meant the introduction of catalytic converters, exhaust gas recirculation (EGR) systems, and electronic fuel injection. These technologies, while effective in reducing emissions, often came at the cost of reduced power output and fuel efficiency.

As emissions standards continued to tighten, manufacturers faced growing challenges in maintaining the performance characteristics that made big block engines popular. The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, further pressured automakers to improve fuel efficiency across their vehicle lineups. This led to a gradual decline in the use of large displacement engines in passenger vehicles, with many manufacturers opting for smaller, more efficient powerplants.

In the commercial and industrial sectors, where big block engines like the 454 remained popular for their torque and durability, the Environmental Protection Agency's (EPA) emissions regulations for non-road engines had a significant impact. These regulations, phased in over time, required substantial reductions in nitrogen oxides (NOx) and particulate matter (PM) emissions, necessitating the development of advanced aftertreatment systems and engine control strategies.

The introduction of Tier 4 emissions standards for off-road diesel engines in 2014 marked a turning point for many big block applications. These standards required a 90% reduction in PM and NOx emissions compared to previous levels, pushing manufacturers to invest heavily in technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF).

As a result of these regulatory pressures, the traditional 454 big block and similar large displacement engines have seen their roles evolve. In many applications, they have been replaced by smaller, turbocharged engines that can deliver comparable power with improved efficiency and lower emissions. However, in specialized applications where their unique characteristics remain valuable, big block engines have been adapted with advanced technologies to meet current and future emissions standards.

The Clean Air Act of 1970 and its subsequent amendments have been pivotal in shaping the automotive industry's approach to engine design. For big block engines like the 454, this meant the introduction of catalytic converters, exhaust gas recirculation (EGR) systems, and electronic fuel injection. These technologies, while effective in reducing emissions, often came at the cost of reduced power output and fuel efficiency.

As emissions standards continued to tighten, manufacturers faced growing challenges in maintaining the performance characteristics that made big block engines popular. The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, further pressured automakers to improve fuel efficiency across their vehicle lineups. This led to a gradual decline in the use of large displacement engines in passenger vehicles, with many manufacturers opting for smaller, more efficient powerplants.

In the commercial and industrial sectors, where big block engines like the 454 remained popular for their torque and durability, the Environmental Protection Agency's (EPA) emissions regulations for non-road engines had a significant impact. These regulations, phased in over time, required substantial reductions in nitrogen oxides (NOx) and particulate matter (PM) emissions, necessitating the development of advanced aftertreatment systems and engine control strategies.

The introduction of Tier 4 emissions standards for off-road diesel engines in 2014 marked a turning point for many big block applications. These standards required a 90% reduction in PM and NOx emissions compared to previous levels, pushing manufacturers to invest heavily in technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF).

As a result of these regulatory pressures, the traditional 454 big block and similar large displacement engines have seen their roles evolve. In many applications, they have been replaced by smaller, turbocharged engines that can deliver comparable power with improved efficiency and lower emissions. However, in specialized applications where their unique characteristics remain valuable, big block engines have been adapted with advanced technologies to meet current and future emissions standards.

Economic Implications of Zero-Emission Big Block Adoption

The adoption of zero-emission technologies in 454 Big Blocks presents significant economic implications for various stakeholders in the automotive industry and beyond. As manufacturers transition towards cleaner propulsion systems, the initial costs associated with research, development, and production of zero-emission big blocks are expected to be substantial. This investment may lead to higher prices for vehicles equipped with these engines in the short term, potentially impacting consumer demand and market penetration rates.

However, as economies of scale are achieved and production processes are optimized, the cost of zero-emission big blocks is likely to decrease over time. This cost reduction could eventually lead to price parity with traditional internal combustion engines, making zero-emission vehicles more accessible to a broader range of consumers. The shift towards zero-emission technologies may also create new job opportunities in the clean energy sector, potentially offsetting job losses in traditional automotive manufacturing.

From a macroeconomic perspective, the widespread adoption of zero-emission big blocks could contribute to reduced dependence on fossil fuels, potentially impacting oil-producing economies and reshaping global trade dynamics. Conversely, countries and regions with abundant renewable energy resources may see economic benefits as demand for clean energy increases.

The aftermarket and service sectors are also likely to experience significant changes. As zero-emission big blocks require different maintenance procedures and components compared to traditional engines, service centers and parts suppliers will need to adapt their offerings and retrain their workforce. This transition may create new business opportunities for companies specializing in zero-emission technology maintenance and repair.

Government policies and incentives will play a crucial role in shaping the economic landscape for zero-emission big blocks. Tax credits, subsidies, and regulatory requirements can accelerate adoption rates and influence investment decisions. These policies may also impact international competitiveness, as countries with supportive frameworks for zero-emission technologies may gain advantages in the global automotive market.

The insurance industry may also see shifts in risk assessment and pricing models for vehicles equipped with zero-emission big blocks. Factors such as reduced fire risk and potentially different accident profiles could lead to adjustments in insurance premiums, affecting both consumers and insurers.

In conclusion, the economic implications of zero-emission big block adoption are far-reaching and complex, involving multiple sectors and stakeholders. While initial costs and disruptions are expected, the long-term economic benefits of cleaner transportation and reduced environmental impact could outweigh these challenges, driving innovation and creating new economic opportunities in the automotive industry and related sectors.

However, as economies of scale are achieved and production processes are optimized, the cost of zero-emission big blocks is likely to decrease over time. This cost reduction could eventually lead to price parity with traditional internal combustion engines, making zero-emission vehicles more accessible to a broader range of consumers. The shift towards zero-emission technologies may also create new job opportunities in the clean energy sector, potentially offsetting job losses in traditional automotive manufacturing.

From a macroeconomic perspective, the widespread adoption of zero-emission big blocks could contribute to reduced dependence on fossil fuels, potentially impacting oil-producing economies and reshaping global trade dynamics. Conversely, countries and regions with abundant renewable energy resources may see economic benefits as demand for clean energy increases.

The aftermarket and service sectors are also likely to experience significant changes. As zero-emission big blocks require different maintenance procedures and components compared to traditional engines, service centers and parts suppliers will need to adapt their offerings and retrain their workforce. This transition may create new business opportunities for companies specializing in zero-emission technology maintenance and repair.

Government policies and incentives will play a crucial role in shaping the economic landscape for zero-emission big blocks. Tax credits, subsidies, and regulatory requirements can accelerate adoption rates and influence investment decisions. These policies may also impact international competitiveness, as countries with supportive frameworks for zero-emission technologies may gain advantages in the global automotive market.

The insurance industry may also see shifts in risk assessment and pricing models for vehicles equipped with zero-emission big blocks. Factors such as reduced fire risk and potentially different accident profiles could lead to adjustments in insurance premiums, affecting both consumers and insurers.

In conclusion, the economic implications of zero-emission big block adoption are far-reaching and complex, involving multiple sectors and stakeholders. While initial costs and disruptions are expected, the long-term economic benefits of cleaner transportation and reduced environmental impact could outweigh these challenges, driving innovation and creating new economic opportunities in the automotive industry and related sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!