Sensor Fusion Techniques for Enhanced 454 Big Block Diagnostics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

454 Big Block Diagnostics Evolution and Objectives

The 454 Big Block engine, a legendary powerhouse in automotive history, has undergone significant evolution in diagnostics since its inception. Initially, diagnostics were limited to basic mechanical measurements and visual inspections. As technology advanced, electronic sensors were introduced, providing more accurate data on engine performance.

The evolution of 454 Big Block diagnostics can be traced through several key phases. In the early years, mechanics relied on timing lights, compression testers, and vacuum gauges to assess engine health. The introduction of onboard diagnostics (OBD) systems in the 1980s marked a significant leap forward, allowing for real-time monitoring of engine parameters and the storage of fault codes.

As computerization became more prevalent, advanced diagnostic tools emerged, capable of interfacing with the engine's electronic control unit (ECU). These tools provided detailed insights into fuel injection, ignition timing, and emissions control systems. The advent of OBD-II in the mid-1990s further standardized diagnostic protocols, making it easier to identify and address issues across different vehicle models.

Recent years have seen a shift towards more sophisticated diagnostic techniques, incorporating machine learning algorithms and predictive maintenance strategies. These advancements aim to detect potential issues before they manifest as failures, thereby improving engine longevity and performance.

The primary objective of modern 454 Big Block diagnostics is to enhance engine efficiency, reliability, and performance while minimizing emissions and fuel consumption. This involves real-time monitoring of various engine parameters, including temperature, pressure, fuel mixture, and exhaust composition. Advanced diagnostics also seek to optimize engine tuning for different driving conditions and load requirements.

Another crucial objective is to improve the accuracy and speed of fault detection and diagnosis. This includes the development of more sensitive sensors, faster data processing capabilities, and more intuitive user interfaces for diagnostic tools. The integration of wireless connectivity and cloud-based analytics further aims to enable remote diagnostics and over-the-air updates.

Looking ahead, the future objectives of 454 Big Block diagnostics include the implementation of artificial intelligence and machine learning algorithms to predict engine wear and potential failures with greater accuracy. There is also a focus on developing non-invasive diagnostic techniques that can provide detailed insights into engine health without the need for disassembly or intrusive testing procedures.

The evolution of 454 Big Block diagnostics can be traced through several key phases. In the early years, mechanics relied on timing lights, compression testers, and vacuum gauges to assess engine health. The introduction of onboard diagnostics (OBD) systems in the 1980s marked a significant leap forward, allowing for real-time monitoring of engine parameters and the storage of fault codes.

As computerization became more prevalent, advanced diagnostic tools emerged, capable of interfacing with the engine's electronic control unit (ECU). These tools provided detailed insights into fuel injection, ignition timing, and emissions control systems. The advent of OBD-II in the mid-1990s further standardized diagnostic protocols, making it easier to identify and address issues across different vehicle models.

Recent years have seen a shift towards more sophisticated diagnostic techniques, incorporating machine learning algorithms and predictive maintenance strategies. These advancements aim to detect potential issues before they manifest as failures, thereby improving engine longevity and performance.

The primary objective of modern 454 Big Block diagnostics is to enhance engine efficiency, reliability, and performance while minimizing emissions and fuel consumption. This involves real-time monitoring of various engine parameters, including temperature, pressure, fuel mixture, and exhaust composition. Advanced diagnostics also seek to optimize engine tuning for different driving conditions and load requirements.

Another crucial objective is to improve the accuracy and speed of fault detection and diagnosis. This includes the development of more sensitive sensors, faster data processing capabilities, and more intuitive user interfaces for diagnostic tools. The integration of wireless connectivity and cloud-based analytics further aims to enable remote diagnostics and over-the-air updates.

Looking ahead, the future objectives of 454 Big Block diagnostics include the implementation of artificial intelligence and machine learning algorithms to predict engine wear and potential failures with greater accuracy. There is also a focus on developing non-invasive diagnostic techniques that can provide detailed insights into engine health without the need for disassembly or intrusive testing procedures.

Market Analysis for Advanced Engine Diagnostics

The market for advanced engine diagnostics, particularly for high-performance engines like the 454 Big Block, has been experiencing significant growth in recent years. This expansion is driven by the increasing complexity of modern engines, stricter emission regulations, and the growing demand for improved fuel efficiency and performance. The global automotive diagnostics market, which encompasses advanced engine diagnostics, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other automotive sectors.

The demand for sensor fusion techniques in engine diagnostics is particularly strong in the performance and racing segments, where the 454 Big Block engine is widely used. These markets require highly accurate and real-time diagnostic capabilities to optimize engine performance, predict potential failures, and minimize downtime. The integration of multiple sensor data streams through fusion techniques allows for more comprehensive and precise diagnostics, which is crucial in high-stakes racing environments and for enthusiasts who demand peak engine performance.

In the commercial vehicle sector, where durability and reliability are paramount, the market for advanced diagnostics is also expanding. Fleet operators are increasingly recognizing the value of predictive maintenance enabled by sophisticated diagnostic tools, which can significantly reduce operational costs and vehicle downtime. This trend is expected to drive further adoption of sensor fusion techniques in engine diagnostics across various vehicle classes.

The aftermarket segment for advanced engine diagnostics is showing robust growth as well. As vehicles become more complex, independent repair shops and DIY enthusiasts are investing in advanced diagnostic tools to remain competitive and capable of servicing modern engines. This has created a burgeoning market for user-friendly, yet sophisticated diagnostic equipment that incorporates sensor fusion technologies.

Geographically, North America and Europe lead in the adoption of advanced engine diagnostic technologies, owing to their mature automotive industries and stringent emission norms. However, emerging markets in Asia-Pacific and Latin America are expected to show rapid growth in the coming years, driven by increasing vehicle production and a growing awareness of the benefits of advanced diagnostics in improving vehicle longevity and performance.

The market is characterized by a mix of established automotive technology providers and innovative startups specializing in diagnostic software and hardware. Competition is intense, with companies vying to offer the most comprehensive and user-friendly diagnostic solutions. As the technology continues to evolve, there is a growing trend towards cloud-based diagnostic platforms and the integration of artificial intelligence to enhance the capabilities of sensor fusion techniques.

The demand for sensor fusion techniques in engine diagnostics is particularly strong in the performance and racing segments, where the 454 Big Block engine is widely used. These markets require highly accurate and real-time diagnostic capabilities to optimize engine performance, predict potential failures, and minimize downtime. The integration of multiple sensor data streams through fusion techniques allows for more comprehensive and precise diagnostics, which is crucial in high-stakes racing environments and for enthusiasts who demand peak engine performance.

In the commercial vehicle sector, where durability and reliability are paramount, the market for advanced diagnostics is also expanding. Fleet operators are increasingly recognizing the value of predictive maintenance enabled by sophisticated diagnostic tools, which can significantly reduce operational costs and vehicle downtime. This trend is expected to drive further adoption of sensor fusion techniques in engine diagnostics across various vehicle classes.

The aftermarket segment for advanced engine diagnostics is showing robust growth as well. As vehicles become more complex, independent repair shops and DIY enthusiasts are investing in advanced diagnostic tools to remain competitive and capable of servicing modern engines. This has created a burgeoning market for user-friendly, yet sophisticated diagnostic equipment that incorporates sensor fusion technologies.

Geographically, North America and Europe lead in the adoption of advanced engine diagnostic technologies, owing to their mature automotive industries and stringent emission norms. However, emerging markets in Asia-Pacific and Latin America are expected to show rapid growth in the coming years, driven by increasing vehicle production and a growing awareness of the benefits of advanced diagnostics in improving vehicle longevity and performance.

The market is characterized by a mix of established automotive technology providers and innovative startups specializing in diagnostic software and hardware. Competition is intense, with companies vying to offer the most comprehensive and user-friendly diagnostic solutions. As the technology continues to evolve, there is a growing trend towards cloud-based diagnostic platforms and the integration of artificial intelligence to enhance the capabilities of sensor fusion techniques.

Current Sensor Fusion Challenges in Engine Diagnostics

Sensor fusion techniques in engine diagnostics, particularly for the 454 Big Block engine, face several significant challenges in the current technological landscape. One of the primary obstacles is the integration of diverse sensor data streams. The 454 Big Block engine, known for its high performance and complex operation, requires a multitude of sensors to monitor various parameters such as temperature, pressure, fuel flow, and exhaust composition. Harmonizing these disparate data sources into a coherent and actionable diagnostic output remains a formidable task.

The issue of data synchronization presents another major hurdle. Different sensors often operate at varying sampling rates and with distinct latencies. Ensuring that the data from all sensors is properly time-aligned is crucial for accurate diagnostics, yet achieving this synchronization in real-time poses significant technical challenges. This is particularly evident in transient engine conditions, where rapid changes in engine state demand precise temporal correlation of sensor data.

Sensor reliability and fault tolerance represent ongoing concerns in the field of engine diagnostics. The harsh operating environment of a 454 Big Block engine, characterized by high temperatures, vibrations, and potential contamination, can lead to sensor degradation or failure. Developing robust sensor fusion algorithms that can detect and compensate for faulty sensor readings is essential for maintaining diagnostic accuracy and reliability.

The computational demands of real-time sensor fusion pose another significant challenge. Processing and analyzing large volumes of sensor data with minimal latency requires substantial computing power. Balancing the need for comprehensive diagnostics with the practical limitations of onboard computing resources in vehicle applications remains a key area of focus for researchers and engineers.

Furthermore, the challenge of sensor calibration and cross-validation cannot be overlooked. Each sensor in the diagnostic system may have its own calibration requirements and potential biases. Ensuring that the fusion algorithm can account for these individual sensor characteristics while maintaining overall system accuracy is a complex task that demands sophisticated calibration and validation methodologies.

Lastly, the integration of machine learning and artificial intelligence techniques into sensor fusion algorithms presents both opportunities and challenges. While these advanced techniques offer the potential for more accurate and predictive diagnostics, they also introduce new complexities in terms of algorithm training, validation, and real-world performance consistency. Striking the right balance between traditional sensor fusion methods and AI-driven approaches remains an active area of research and development in the field of engine diagnostics.

The issue of data synchronization presents another major hurdle. Different sensors often operate at varying sampling rates and with distinct latencies. Ensuring that the data from all sensors is properly time-aligned is crucial for accurate diagnostics, yet achieving this synchronization in real-time poses significant technical challenges. This is particularly evident in transient engine conditions, where rapid changes in engine state demand precise temporal correlation of sensor data.

Sensor reliability and fault tolerance represent ongoing concerns in the field of engine diagnostics. The harsh operating environment of a 454 Big Block engine, characterized by high temperatures, vibrations, and potential contamination, can lead to sensor degradation or failure. Developing robust sensor fusion algorithms that can detect and compensate for faulty sensor readings is essential for maintaining diagnostic accuracy and reliability.

The computational demands of real-time sensor fusion pose another significant challenge. Processing and analyzing large volumes of sensor data with minimal latency requires substantial computing power. Balancing the need for comprehensive diagnostics with the practical limitations of onboard computing resources in vehicle applications remains a key area of focus for researchers and engineers.

Furthermore, the challenge of sensor calibration and cross-validation cannot be overlooked. Each sensor in the diagnostic system may have its own calibration requirements and potential biases. Ensuring that the fusion algorithm can account for these individual sensor characteristics while maintaining overall system accuracy is a complex task that demands sophisticated calibration and validation methodologies.

Lastly, the integration of machine learning and artificial intelligence techniques into sensor fusion algorithms presents both opportunities and challenges. While these advanced techniques offer the potential for more accurate and predictive diagnostics, they also introduce new complexities in terms of algorithm training, validation, and real-world performance consistency. Striking the right balance between traditional sensor fusion methods and AI-driven approaches remains an active area of research and development in the field of engine diagnostics.

Existing Sensor Fusion Solutions for 454 Big Block

01 Multi-sensor fusion for medical diagnostics

Sensor fusion techniques are applied in medical diagnostics to combine data from multiple sensors, improving accuracy and reliability of diagnostic results. This approach can integrate various physiological parameters and imaging modalities to provide a comprehensive health assessment.- Multi-sensor fusion for diagnostic applications: Sensor fusion techniques are employed in diagnostic systems to combine data from multiple sensors, improving accuracy and reliability of diagnostics. This approach enables more comprehensive analysis by integrating diverse sensor inputs, leading to enhanced detection and identification of various conditions or anomalies.

- Machine learning algorithms in sensor fusion diagnostics: Advanced machine learning algorithms are utilized to process and interpret data from multiple sensors in diagnostic applications. These algorithms can identify patterns, correlations, and anomalies that may not be apparent through traditional analysis methods, thereby improving diagnostic accuracy and efficiency.

- Real-time sensor fusion for continuous monitoring: Real-time sensor fusion techniques are implemented in diagnostic systems to enable continuous monitoring of various parameters. This approach allows for immediate detection of changes or anomalies, facilitating rapid response and intervention in critical situations.

- Sensor fusion for medical diagnostics: In medical applications, sensor fusion techniques are employed to combine data from various diagnostic tools and sensors. This integration of multiple data sources enhances the accuracy of diagnoses, enables early detection of diseases, and supports personalized treatment strategies.

- Sensor fusion in industrial diagnostics and predictive maintenance: Sensor fusion techniques are applied in industrial settings for diagnostics and predictive maintenance. By combining data from multiple sensors monitoring different aspects of machinery or processes, these systems can detect potential failures or inefficiencies before they become critical, improving overall operational efficiency and reducing downtime.

02 Sensor fusion in automotive diagnostics

Automotive systems utilize sensor fusion techniques to integrate data from multiple sensors for enhanced vehicle diagnostics. This approach improves fault detection, performance monitoring, and predictive maintenance in vehicles.Expand Specific Solutions03 Sensor fusion for industrial process diagnostics

Industrial processes employ sensor fusion techniques to combine data from various sensors for improved process monitoring and fault diagnosis. This approach enhances the reliability and efficiency of industrial operations by providing a more comprehensive view of system performance.Expand Specific Solutions04 Sensor fusion in wearable health monitoring devices

Wearable health monitoring devices utilize sensor fusion techniques to integrate data from multiple sensors for comprehensive health diagnostics. This approach enables continuous monitoring of various physiological parameters and early detection of health issues.Expand Specific Solutions05 AI-enhanced sensor fusion for diagnostics

Artificial intelligence techniques are combined with sensor fusion to enhance diagnostic capabilities across various fields. Machine learning algorithms process and analyze data from multiple sensors to improve accuracy, speed, and reliability of diagnostic results.Expand Specific Solutions

Key Players in Engine Diagnostics and Sensor Fusion

The sensor fusion techniques for enhanced 454 Big Block diagnostics market is in its growth stage, with increasing adoption across automotive and industrial sectors. The market size is expanding rapidly, driven by the demand for more accurate and reliable diagnostic systems. Technologically, the field is advancing quickly, with companies like Analog Devices, Carl Zeiss, and Continental Teves leading innovation. Universities such as Nanjing University of Aeronautics & Astronautics and Southeast University are contributing significant research. While the technology is maturing, there's still room for improvement in areas like real-time processing and integration with AI systems, indicating a competitive landscape with opportunities for both established players and new entrants.

Analog Devices International Unlimited Co.

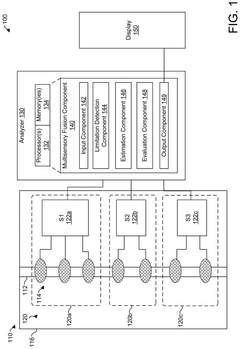

Technical Solution: Analog Devices has developed advanced sensor fusion techniques for enhanced 454 Big Block diagnostics. Their approach combines data from multiple sensors, including accelerometers, gyroscopes, and temperature sensors, to provide a comprehensive view of engine performance. The company utilizes proprietary algorithms to process and integrate sensor data in real-time, enabling more accurate and reliable diagnostics[1]. Their system employs adaptive filtering techniques to reduce noise and improve signal quality, resulting in more precise measurements of engine parameters such as vibration, temperature, and pressure[2]. Additionally, Analog Devices has implemented machine learning algorithms to detect anomalies and predict potential engine issues before they become critical[3].

Strengths: High accuracy and reliability due to multi-sensor integration; Real-time processing capabilities; Predictive maintenance features. Weaknesses: May require specialized hardware; Potentially higher implementation costs compared to simpler diagnostic systems.

Continental Teves AG & Co. oHG

Technical Solution: Continental has developed a sensor fusion system for 454 Big Block diagnostics that integrates data from various engine sensors and vehicle systems. Their approach uses a centralized Electronic Control Unit (ECU) to process inputs from multiple sources, including engine speed sensors, crankshaft position sensors, and exhaust gas sensors[4]. The system employs advanced signal processing techniques to synchronize and correlate data from different sensors, providing a holistic view of engine performance. Continental's solution also incorporates machine learning algorithms to adapt to individual engine characteristics over time, improving diagnostic accuracy[5]. The company has implemented a distributed architecture that allows for scalability and easy integration with existing vehicle systems[6].

Strengths: Comprehensive integration with vehicle systems; Adaptive learning capabilities; Scalable architecture. Weaknesses: May require significant computing power; Potential complexity in initial setup and calibration.

Core Innovations in Engine Diagnostic Sensor Fusion

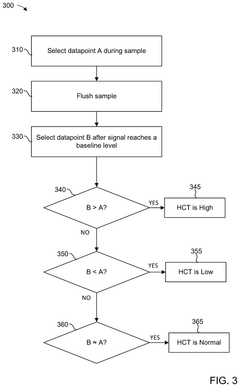

Data fusion method to improve accuracy of algorithmic performance in multisensory devices

PatentPendingUS20250120615A1

Innovation

- The implementation of data fusion methods in multisensory devices to improve accuracy by analyzing traces of signals from one sensor to estimate levels of other analytes and confirm measurements through comparison with dedicated sensors.

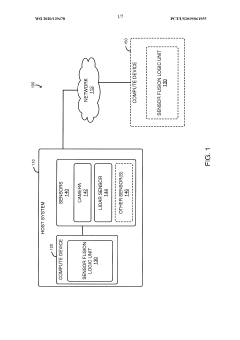

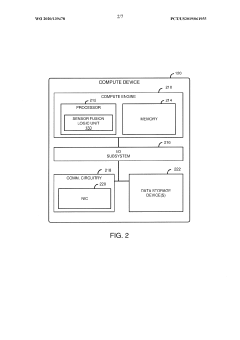

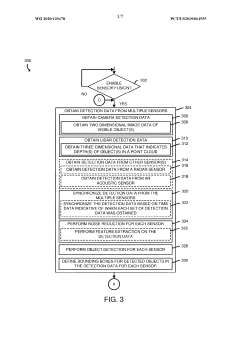

Technologies for fusing data from multiple sensors to improve object detection, identification, and localization

PatentWO2020139478A1

Innovation

- A system that includes a compute device with a sensor fusion logic unit, which selectively applies weights to data from multiple sensors like cameras and lidar based on context and sensor attributes, and applies user-defined rules to merge bounding boxes, determining degrees of belief for object representation, and performs object localization using depth information from 3D sensors.

Environmental Impact of Advanced Engine Diagnostics

The environmental impact of advanced engine diagnostics, particularly in the context of sensor fusion techniques for enhanced 454 Big Block diagnostics, is a multifaceted issue with significant implications for sustainability and emissions control. As automotive technology continues to evolve, the integration of sophisticated diagnostic systems has become crucial in optimizing engine performance and reducing harmful emissions.

Advanced diagnostic techniques, such as those employed in sensor fusion for the 454 Big Block engine, contribute to more precise monitoring and control of engine parameters. This enhanced accuracy leads to improved fuel efficiency and reduced emissions. By continuously analyzing data from multiple sensors, these systems can detect and correct inefficiencies in real-time, resulting in a cleaner combustion process and lower overall environmental impact.

The implementation of sensor fusion techniques allows for a more comprehensive understanding of engine behavior under various operating conditions. This holistic approach enables engineers to fine-tune engine performance, leading to reduced fuel consumption and, consequently, lower carbon dioxide emissions. Additionally, the ability to detect and diagnose potential issues early on helps prevent catastrophic failures that could result in sudden increases in emissions or the release of harmful substances into the environment.

Moreover, advanced diagnostics play a crucial role in ensuring compliance with increasingly stringent environmental regulations. By providing accurate, real-time data on engine performance and emissions, these systems enable manufacturers to demonstrate adherence to emission standards and facilitate the development of cleaner engine technologies. This proactive approach to emissions control contributes to improved air quality and reduced environmental impact in urban areas where vehicle emissions are a significant concern.

The long-term environmental benefits of advanced engine diagnostics extend beyond immediate emissions reduction. By optimizing engine performance and extending the lifespan of vehicle components, these systems contribute to a reduction in the overall environmental footprint of automotive manufacturing and disposal. Fewer replacement parts and longer-lasting engines translate to reduced resource consumption and waste generation throughout the vehicle's lifecycle.

However, it is important to consider the potential environmental trade-offs associated with the production and disposal of advanced diagnostic systems. The manufacturing of sophisticated sensors and electronic components may involve the use of rare earth elements and other materials with their own environmental implications. As such, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of implementing these advanced diagnostic technologies.

In conclusion, while advanced engine diagnostics, including sensor fusion techniques for the 454 Big Block, offer significant potential for reducing the environmental impact of automotive engines, a holistic approach is required to ensure that these benefits are not offset by unintended consequences in other areas of the vehicle's life cycle. Continued research and development in this field will be crucial in maximizing the positive environmental outcomes of these technologies while minimizing any potential negative impacts.

Advanced diagnostic techniques, such as those employed in sensor fusion for the 454 Big Block engine, contribute to more precise monitoring and control of engine parameters. This enhanced accuracy leads to improved fuel efficiency and reduced emissions. By continuously analyzing data from multiple sensors, these systems can detect and correct inefficiencies in real-time, resulting in a cleaner combustion process and lower overall environmental impact.

The implementation of sensor fusion techniques allows for a more comprehensive understanding of engine behavior under various operating conditions. This holistic approach enables engineers to fine-tune engine performance, leading to reduced fuel consumption and, consequently, lower carbon dioxide emissions. Additionally, the ability to detect and diagnose potential issues early on helps prevent catastrophic failures that could result in sudden increases in emissions or the release of harmful substances into the environment.

Moreover, advanced diagnostics play a crucial role in ensuring compliance with increasingly stringent environmental regulations. By providing accurate, real-time data on engine performance and emissions, these systems enable manufacturers to demonstrate adherence to emission standards and facilitate the development of cleaner engine technologies. This proactive approach to emissions control contributes to improved air quality and reduced environmental impact in urban areas where vehicle emissions are a significant concern.

The long-term environmental benefits of advanced engine diagnostics extend beyond immediate emissions reduction. By optimizing engine performance and extending the lifespan of vehicle components, these systems contribute to a reduction in the overall environmental footprint of automotive manufacturing and disposal. Fewer replacement parts and longer-lasting engines translate to reduced resource consumption and waste generation throughout the vehicle's lifecycle.

However, it is important to consider the potential environmental trade-offs associated with the production and disposal of advanced diagnostic systems. The manufacturing of sophisticated sensors and electronic components may involve the use of rare earth elements and other materials with their own environmental implications. As such, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of implementing these advanced diagnostic technologies.

In conclusion, while advanced engine diagnostics, including sensor fusion techniques for the 454 Big Block, offer significant potential for reducing the environmental impact of automotive engines, a holistic approach is required to ensure that these benefits are not offset by unintended consequences in other areas of the vehicle's life cycle. Continued research and development in this field will be crucial in maximizing the positive environmental outcomes of these technologies while minimizing any potential negative impacts.

Data Privacy in Connected Vehicle Diagnostics

As connected vehicles become increasingly prevalent, the issue of data privacy in vehicle diagnostics has emerged as a critical concern for both manufacturers and consumers. The integration of advanced sensor technologies and connectivity features in modern vehicles has led to the collection and transmission of vast amounts of data, including sensitive information about vehicle performance, driver behavior, and location history. This data is invaluable for diagnostic purposes, enabling more accurate and timely maintenance, as well as improving overall vehicle performance and safety. However, it also raises significant privacy concerns that must be addressed to ensure consumer trust and compliance with data protection regulations.

The challenge lies in striking a balance between the need for comprehensive diagnostic data and the protection of individual privacy rights. Vehicle manufacturers and service providers must implement robust data protection measures to safeguard sensitive information from unauthorized access, use, or disclosure. This includes employing encryption techniques for data transmission and storage, implementing secure authentication protocols, and establishing clear data retention and deletion policies.

Furthermore, the concept of data minimization is crucial in this context. Diagnostic systems should be designed to collect only the data that is absolutely necessary for their intended purpose, avoiding the accumulation of excessive personal information. This approach not only helps to protect privacy but also reduces the potential impact of data breaches.

Transparency and user control are also key components of data privacy in connected vehicle diagnostics. Manufacturers must provide clear and accessible information to vehicle owners about what data is being collected, how it is being used, and with whom it may be shared. Additionally, offering granular control options that allow users to manage their data preferences can help build trust and ensure compliance with evolving privacy regulations.

The regulatory landscape surrounding data privacy in connected vehicles is rapidly evolving, with frameworks such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States setting new standards for data protection. Vehicle manufacturers and service providers must stay abreast of these regulations and ensure their diagnostic systems and data handling practices are compliant across different jurisdictions.

The challenge lies in striking a balance between the need for comprehensive diagnostic data and the protection of individual privacy rights. Vehicle manufacturers and service providers must implement robust data protection measures to safeguard sensitive information from unauthorized access, use, or disclosure. This includes employing encryption techniques for data transmission and storage, implementing secure authentication protocols, and establishing clear data retention and deletion policies.

Furthermore, the concept of data minimization is crucial in this context. Diagnostic systems should be designed to collect only the data that is absolutely necessary for their intended purpose, avoiding the accumulation of excessive personal information. This approach not only helps to protect privacy but also reduces the potential impact of data breaches.

Transparency and user control are also key components of data privacy in connected vehicle diagnostics. Manufacturers must provide clear and accessible information to vehicle owners about what data is being collected, how it is being used, and with whom it may be shared. Additionally, offering granular control options that allow users to manage their data preferences can help build trust and ensure compliance with evolving privacy regulations.

The regulatory landscape surrounding data privacy in connected vehicles is rapidly evolving, with frameworks such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States setting new standards for data protection. Vehicle manufacturers and service providers must stay abreast of these regulations and ensure their diagnostic systems and data handling practices are compliant across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!