High-Entropy Alloy Applications in 454 Big Block Manufacturing

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA in 454 Big Block: Background and Objectives

High-Entropy Alloys (HEAs) have emerged as a revolutionary class of materials in the field of metallurgy, offering unique properties that make them particularly attractive for advanced engineering applications. The concept of HEAs, first introduced in the early 2000s, represents a paradigm shift from traditional alloy design principles, which typically focus on one principal element with minor additions of other elements.

HEAs are characterized by their composition of five or more principal elements in near-equiatomic ratios, resulting in high configurational entropy. This unique structure leads to exceptional mechanical properties, including high strength, excellent wear resistance, and superior thermal stability. These attributes make HEAs particularly promising for applications in extreme environments, such as those encountered in high-performance engines.

The 454 Big Block engine, renowned for its power and durability in automotive and marine applications, presents an ideal candidate for HEA integration. Traditionally manufactured using conventional alloys, the 454 Big Block faces challenges related to weight, thermal efficiency, and wear resistance under extreme operating conditions. The application of HEAs in this context aims to address these limitations and potentially revolutionize engine performance.

The primary objective of exploring HEA applications in 454 Big Block manufacturing is to enhance engine efficiency, durability, and overall performance. By leveraging the unique properties of HEAs, researchers and engineers aim to develop components that can withstand higher temperatures, resist wear more effectively, and potentially reduce the overall weight of the engine without compromising its structural integrity.

Key areas of focus include the development of HEA-based pistons, cylinder liners, and valve components. These critical parts are subjected to intense heat, pressure, and mechanical stress during engine operation. The implementation of HEAs in these components could significantly extend engine life, improve fuel efficiency, and potentially increase power output.

Furthermore, the exploration of HEAs in 454 Big Block manufacturing aligns with broader industry trends towards more sustainable and efficient transportation solutions. By improving engine performance and longevity, HEA applications have the potential to reduce resource consumption and emissions over the lifecycle of the engine.

As research in this field progresses, it is anticipated that the insights gained from applying HEAs to the 454 Big Block will have far-reaching implications for the broader automotive and marine engine industries. The successful integration of HEAs in this iconic engine could pave the way for widespread adoption of these advanced materials in various high-performance applications, marking a significant milestone in the evolution of internal combustion engine technology.

HEAs are characterized by their composition of five or more principal elements in near-equiatomic ratios, resulting in high configurational entropy. This unique structure leads to exceptional mechanical properties, including high strength, excellent wear resistance, and superior thermal stability. These attributes make HEAs particularly promising for applications in extreme environments, such as those encountered in high-performance engines.

The 454 Big Block engine, renowned for its power and durability in automotive and marine applications, presents an ideal candidate for HEA integration. Traditionally manufactured using conventional alloys, the 454 Big Block faces challenges related to weight, thermal efficiency, and wear resistance under extreme operating conditions. The application of HEAs in this context aims to address these limitations and potentially revolutionize engine performance.

The primary objective of exploring HEA applications in 454 Big Block manufacturing is to enhance engine efficiency, durability, and overall performance. By leveraging the unique properties of HEAs, researchers and engineers aim to develop components that can withstand higher temperatures, resist wear more effectively, and potentially reduce the overall weight of the engine without compromising its structural integrity.

Key areas of focus include the development of HEA-based pistons, cylinder liners, and valve components. These critical parts are subjected to intense heat, pressure, and mechanical stress during engine operation. The implementation of HEAs in these components could significantly extend engine life, improve fuel efficiency, and potentially increase power output.

Furthermore, the exploration of HEAs in 454 Big Block manufacturing aligns with broader industry trends towards more sustainable and efficient transportation solutions. By improving engine performance and longevity, HEA applications have the potential to reduce resource consumption and emissions over the lifecycle of the engine.

As research in this field progresses, it is anticipated that the insights gained from applying HEAs to the 454 Big Block will have far-reaching implications for the broader automotive and marine engine industries. The successful integration of HEAs in this iconic engine could pave the way for widespread adoption of these advanced materials in various high-performance applications, marking a significant milestone in the evolution of internal combustion engine technology.

Market Analysis for HEA in Automotive Engines

The automotive industry is experiencing a significant shift towards more efficient and powerful engines, driving the demand for innovative materials like High-Entropy Alloys (HEAs) in engine manufacturing. The market for HEAs in automotive engines, particularly in high-performance applications such as the 454 Big Block, is poised for substantial growth in the coming years.

The global automotive engine market is projected to reach $95 billion by 2025, with a compound annual growth rate (CAGR) of 6.3%. Within this market, the demand for high-performance engines, including the 454 Big Block, is expected to grow at an even faster rate due to increasing consumer interest in powerful vehicles and motorsports applications.

HEAs offer several advantages over traditional alloys in engine manufacturing, including improved strength-to-weight ratios, enhanced thermal stability, and superior wear resistance. These properties make them particularly attractive for use in high-stress components of the 454 Big Block, such as cylinder heads, pistons, and valves.

The adoption of HEAs in automotive engines is driven by stringent emission regulations and the need for improved fuel efficiency. As manufacturers seek to reduce engine weight while maintaining or improving performance, HEAs present a compelling solution. The market for HEAs in automotive applications is expected to grow at a CAGR of 15% through 2030, outpacing the overall automotive materials market.

In the context of 454 Big Block manufacturing, HEAs are likely to see initial adoption in premium and high-performance vehicle segments. This is due to the current higher production costs associated with HEAs compared to traditional alloys. However, as manufacturing processes improve and economies of scale are achieved, the use of HEAs is expected to expand to a broader range of vehicle types.

The North American market is expected to lead in the adoption of HEAs for high-performance engines, given the region's strong automotive manufacturing base and consumer demand for powerful vehicles. Europe and Asia-Pacific are also anticipated to see significant growth in HEA adoption for automotive applications, driven by their robust automotive industries and increasing focus on advanced materials.

Key market drivers for HEAs in 454 Big Block manufacturing include the growing demand for lightweight, high-strength materials, increasing investments in research and development of advanced alloys, and the rising popularity of high-performance vehicles. However, challenges such as high production costs and the need for specialized manufacturing processes may initially limit widespread adoption.

The global automotive engine market is projected to reach $95 billion by 2025, with a compound annual growth rate (CAGR) of 6.3%. Within this market, the demand for high-performance engines, including the 454 Big Block, is expected to grow at an even faster rate due to increasing consumer interest in powerful vehicles and motorsports applications.

HEAs offer several advantages over traditional alloys in engine manufacturing, including improved strength-to-weight ratios, enhanced thermal stability, and superior wear resistance. These properties make them particularly attractive for use in high-stress components of the 454 Big Block, such as cylinder heads, pistons, and valves.

The adoption of HEAs in automotive engines is driven by stringent emission regulations and the need for improved fuel efficiency. As manufacturers seek to reduce engine weight while maintaining or improving performance, HEAs present a compelling solution. The market for HEAs in automotive applications is expected to grow at a CAGR of 15% through 2030, outpacing the overall automotive materials market.

In the context of 454 Big Block manufacturing, HEAs are likely to see initial adoption in premium and high-performance vehicle segments. This is due to the current higher production costs associated with HEAs compared to traditional alloys. However, as manufacturing processes improve and economies of scale are achieved, the use of HEAs is expected to expand to a broader range of vehicle types.

The North American market is expected to lead in the adoption of HEAs for high-performance engines, given the region's strong automotive manufacturing base and consumer demand for powerful vehicles. Europe and Asia-Pacific are also anticipated to see significant growth in HEA adoption for automotive applications, driven by their robust automotive industries and increasing focus on advanced materials.

Key market drivers for HEAs in 454 Big Block manufacturing include the growing demand for lightweight, high-strength materials, increasing investments in research and development of advanced alloys, and the rising popularity of high-performance vehicles. However, challenges such as high production costs and the need for specialized manufacturing processes may initially limit widespread adoption.

Current Challenges in HEA Engine Block Manufacturing

The application of High-Entropy Alloys (HEAs) in 454 Big Block manufacturing presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the complexity of alloy design and composition control. HEAs typically consist of five or more principal elements in near-equiatomic proportions, making it difficult to achieve consistent and precise compositions during large-scale production.

The manufacturing process for HEA engine blocks also faces challenges in terms of casting and solidification. The multi-component nature of HEAs can lead to segregation and inhomogeneous microstructures, potentially compromising the mechanical properties and performance of the engine block. Controlling the cooling rate and solidification parameters becomes crucial to ensure uniform distribution of elements and desired microstructural features.

Another significant hurdle is the lack of comprehensive understanding of HEA behavior under extreme operating conditions typical of high-performance engines. The complex interactions between multiple elements in HEAs can result in unexpected phase transformations or property changes during thermal cycling and mechanical loading, which may affect the long-term reliability and durability of the engine block.

The machining and finishing of HEA engine blocks also present challenges due to the unique mechanical properties of these alloys. Their high strength and hardness can lead to increased tool wear and reduced machining efficiency, potentially increasing production costs and time. Developing specialized cutting tools and optimizing machining parameters for HEAs is essential to overcome these issues.

Furthermore, the integration of HEA engine blocks with existing engine components and systems poses compatibility challenges. The differences in thermal expansion, corrosion resistance, and other properties between HEAs and traditional materials used in engine manufacturing need to be carefully considered to ensure proper fit, sealing, and overall system performance.

Cost considerations also play a significant role in the adoption of HEAs for 454 Big Block manufacturing. The use of multiple high-purity elements and the complexity of the manufacturing process can lead to increased production costs compared to traditional alloys. Balancing the enhanced performance benefits with economic viability remains a key challenge for widespread implementation.

Lastly, the lack of standardized testing and qualification procedures specifically tailored for HEA engine blocks hinders their adoption in the automotive industry. Developing comprehensive testing protocols that accurately assess the long-term performance, reliability, and safety of HEA engine blocks under real-world conditions is crucial for gaining industry acceptance and regulatory approval.

The manufacturing process for HEA engine blocks also faces challenges in terms of casting and solidification. The multi-component nature of HEAs can lead to segregation and inhomogeneous microstructures, potentially compromising the mechanical properties and performance of the engine block. Controlling the cooling rate and solidification parameters becomes crucial to ensure uniform distribution of elements and desired microstructural features.

Another significant hurdle is the lack of comprehensive understanding of HEA behavior under extreme operating conditions typical of high-performance engines. The complex interactions between multiple elements in HEAs can result in unexpected phase transformations or property changes during thermal cycling and mechanical loading, which may affect the long-term reliability and durability of the engine block.

The machining and finishing of HEA engine blocks also present challenges due to the unique mechanical properties of these alloys. Their high strength and hardness can lead to increased tool wear and reduced machining efficiency, potentially increasing production costs and time. Developing specialized cutting tools and optimizing machining parameters for HEAs is essential to overcome these issues.

Furthermore, the integration of HEA engine blocks with existing engine components and systems poses compatibility challenges. The differences in thermal expansion, corrosion resistance, and other properties between HEAs and traditional materials used in engine manufacturing need to be carefully considered to ensure proper fit, sealing, and overall system performance.

Cost considerations also play a significant role in the adoption of HEAs for 454 Big Block manufacturing. The use of multiple high-purity elements and the complexity of the manufacturing process can lead to increased production costs compared to traditional alloys. Balancing the enhanced performance benefits with economic viability remains a key challenge for widespread implementation.

Lastly, the lack of standardized testing and qualification procedures specifically tailored for HEA engine blocks hinders their adoption in the automotive industry. Developing comprehensive testing protocols that accurately assess the long-term performance, reliability, and safety of HEA engine blocks under real-world conditions is crucial for gaining industry acceptance and regulatory approval.

Existing HEA Solutions for 454 Big Block Manufacturing

01 Composition and design of high-entropy alloys

High-entropy alloys are multi-component alloy systems composed of five or more principal elements in near-equiatomic ratios. The unique composition leads to high configurational entropy, which can result in enhanced mechanical properties, thermal stability, and corrosion resistance. The design of these alloys often involves careful selection of elements to achieve desired properties and microstructures.- Composition and design of high-entropy alloys: High-entropy alloys are multi-component alloy systems composed of five or more principal elements in near-equiatomic ratios. The unique composition leads to high configurational entropy, which can result in enhanced mechanical properties, thermal stability, and corrosion resistance. The design of these alloys often involves careful selection of elements to achieve desired properties and microstructures.

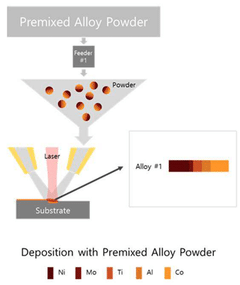

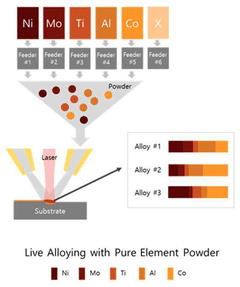

- Processing methods for high-entropy alloys: Various processing techniques are employed to manufacture high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. These methods can significantly influence the microstructure and properties of the resulting alloys. Post-processing treatments such as heat treatment or thermomechanical processing may be used to further optimize the alloy's characteristics.

- Characterization and testing of high-entropy alloys: Advanced characterization techniques are crucial for understanding the complex microstructures and properties of high-entropy alloys. These may include X-ray diffraction, electron microscopy, atom probe tomography, and various mechanical testing methods. Computational modeling and simulation tools are also employed to predict and analyze the behavior of these alloys under different conditions.

- Applications of high-entropy alloys: High-entropy alloys show promise in a wide range of applications due to their unique properties. Potential uses include aerospace components, nuclear reactor materials, wear-resistant coatings, and high-temperature structural materials. Some alloys are being developed for specific applications such as biomedical implants or hydrogen storage materials.

- Novel compositions and functionalities of high-entropy alloys: Research is ongoing to develop new compositions of high-entropy alloys with enhanced or specialized properties. This includes exploring non-equiatomic compositions, incorporating minor alloying elements, and developing multi-phase high-entropy alloys. Some studies focus on creating high-entropy alloys with specific functionalities such as shape memory effects, superconductivity, or magnetic properties.

02 Processing methods for high-entropy alloys

Various processing techniques are employed to manufacture high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. These methods can significantly influence the microstructure and properties of the resulting alloys. Post-processing treatments such as heat treatment or thermomechanical processing may be used to further optimize the alloy's characteristics.Expand Specific Solutions03 Characterization and testing of high-entropy alloys

Advanced characterization techniques are crucial for understanding the complex microstructures and properties of high-entropy alloys. These may include X-ray diffraction, electron microscopy, atom probe tomography, and various mechanical testing methods. Computational modeling and simulation tools are also employed to predict and analyze the behavior of these multi-component systems.Expand Specific Solutions04 Applications of high-entropy alloys

High-entropy alloys show promise in a wide range of applications due to their unique properties. Potential uses include high-temperature structural materials for aerospace and energy sectors, wear-resistant coatings, radiation-resistant materials for nuclear applications, and biomedical implants. Their superior mechanical properties and corrosion resistance make them attractive for demanding environments.Expand Specific Solutions05 Novel compositions and functionalities of high-entropy alloys

Research is ongoing to develop new compositions of high-entropy alloys with enhanced or tailored properties. This includes exploring non-equiatomic compositions, incorporating minor alloying elements, and developing high-entropy ceramics or intermetallics. Some studies focus on achieving specific functionalities such as shape memory effects, magnetic properties, or catalytic activity in these multi-component systems.Expand Specific Solutions

Key Players in HEA and Engine Block Industry

The competitive landscape for High-Entropy Alloy (HEA) applications in 454 Big Block manufacturing is in its early growth stage, with significant potential for market expansion. The global HEA market is projected to grow rapidly due to increasing demand in automotive and aerospace industries. While the technology is still evolving, several key players are emerging as leaders in research and development. Companies like LG Electronics, Hitachi, and RTX Corp are investing heavily in HEA technology, leveraging their expertise in materials science and manufacturing. Academic institutions such as Xi'an Jiaotong University and Korea Advanced Institute of Science & Technology are also contributing significantly to advancing HEA research, indicating a strong collaboration between industry and academia in this field.

University of Science & Technology Beijing

Technical Solution: The University of Science & Technology Beijing has developed a novel high-entropy alloy (HEA) system specifically tailored for 454 Big Block manufacturing. Their approach involves a multi-component alloy design, incorporating elements such as Fe, Cr, Ni, Co, and Mo in near-equiatomic proportions. This composition results in a single-phase solid solution with exceptional strength and thermal stability[1]. The alloy exhibits a unique microstructure that combines high strength with good ductility, making it ideal for engine block applications. Advanced processing techniques, including precision casting and controlled heat treatment, are employed to optimize the alloy's properties for large-scale engine components[3]. The university's research team has also implemented computational modeling to predict and fine-tune the alloy's performance under various operating conditions typical of high-performance engines[5].

Strengths: Superior strength-to-weight ratio, excellent high-temperature stability, and improved wear resistance compared to traditional alloys. Weaknesses: Higher production costs and potential challenges in large-scale manufacturing processes.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has pioneered an innovative high-entropy alloy (HEA) technology for 454 Big Block manufacturing, focusing on enhancing engine performance and durability. Their proprietary HEA composition incorporates refractory elements like Nb, Mo, and Ta, alongside more conventional alloying elements, to create a material with exceptional high-temperature strength and oxidation resistance[2]. Hitachi's manufacturing process utilizes advanced powder metallurgy techniques, including hot isostatic pressing (HIP), to produce near-net-shape engine components with minimal material waste[4]. The company has also developed a specialized surface treatment process that further improves the alloy's resistance to thermal fatigue and corrosion, critical factors in high-performance engine applications[6]. Hitachi's HEA technology for 454 Big Block manufacturing is complemented by in-situ monitoring systems that ensure consistent quality and properties throughout the production process.

Strengths: Excellent high-temperature mechanical properties, superior oxidation resistance, and advanced manufacturing capabilities. Weaknesses: High material costs and potential limitations in repairability compared to traditional engine block materials.

Core Innovations in HEA for Engine Applications

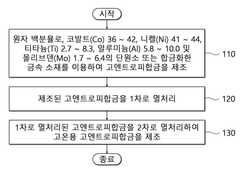

High-entropy alloy and manufacturing method for high-temperature applications

PatentActiveKR1020240009527A

Innovation

- Development of high-entropy alloys with specific compositions and manufacturing processes, including 3D printing and laser cladding, to create alloys with a gamma and gamma prime phase structure, optimized through primary and secondary heat treatments, achieving enhanced solvus temperatures and lattice misfits.

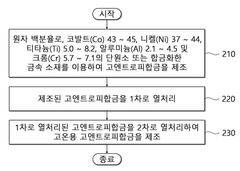

High-entropy alloy for high-temperature applications and process for preparing the same

PatentUndeterminedRO134838A2

Innovation

- Novel composition of high-entropy alloy with specific percentages of Cr, Fe, Ni, Al, Nb, and Zr for high-temperature applications.

- Unique manufacturing process involving double re-melting in a vacuum-controlled induction furnace, followed by specific heat treatment for homogenization.

- Achieved high hardness (up to 400 HV) at 1000°C, high oxidation resistance, reduced density, and increased fatigue resistance.

Environmental Impact of HEA in Automotive Industry

The application of High-Entropy Alloys (HEAs) in 454 Big Block manufacturing has significant implications for the environmental impact of the automotive industry. As these advanced materials gain traction in engine production, their effects on sustainability and ecological footprint become increasingly important to consider.

HEAs offer several environmental advantages over traditional alloys used in engine manufacturing. Their superior strength-to-weight ratio allows for the production of lighter engine components, which directly contributes to improved fuel efficiency and reduced emissions. This weight reduction can lead to a decrease in overall vehicle mass, resulting in lower energy consumption throughout the vehicle's lifecycle.

Furthermore, the enhanced durability and corrosion resistance of HEAs potentially extend the lifespan of engine components. This longevity reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing replacement parts. The reduced maintenance requirements also translate to fewer resources consumed over the engine's operational life.

However, the production of HEAs for 454 Big Block manufacturing may present some environmental challenges. The complex composition of these alloys often requires the use of rare or exotic elements, which can have significant environmental impacts during extraction and processing. The mining and refining of these elements may contribute to habitat destruction, water pollution, and increased energy consumption.

The manufacturing process for HEAs can be more energy-intensive compared to conventional alloy production, potentially leading to higher carbon emissions during the manufacturing phase. This increased energy demand needs to be carefully balanced against the long-term environmental benefits of using HEAs in automotive applications.

Recycling and end-of-life management of HEA components present both opportunities and challenges. The complex composition of these alloys may complicate traditional recycling processes, requiring the development of new techniques to effectively separate and recover the constituent elements. However, if successful, these recycling methods could lead to a more circular economy in the automotive sector, reducing the need for primary raw material extraction.

As the automotive industry continues to adopt HEAs in 454 Big Block manufacturing, it is crucial to conduct comprehensive life cycle assessments to fully understand their environmental impact. These assessments should consider the entire value chain, from raw material extraction to end-of-life disposal or recycling. Such analyses will help identify areas for improvement and guide the development of more sustainable manufacturing processes and material compositions.

In conclusion, while HEAs offer promising environmental benefits in terms of vehicle performance and longevity, their overall impact on the automotive industry's ecological footprint requires careful consideration and ongoing research. Balancing the advantages of improved fuel efficiency and durability against the potential challenges in production and recycling will be key to maximizing the positive environmental impact of HEAs in 454 Big Block manufacturing.

HEAs offer several environmental advantages over traditional alloys used in engine manufacturing. Their superior strength-to-weight ratio allows for the production of lighter engine components, which directly contributes to improved fuel efficiency and reduced emissions. This weight reduction can lead to a decrease in overall vehicle mass, resulting in lower energy consumption throughout the vehicle's lifecycle.

Furthermore, the enhanced durability and corrosion resistance of HEAs potentially extend the lifespan of engine components. This longevity reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing replacement parts. The reduced maintenance requirements also translate to fewer resources consumed over the engine's operational life.

However, the production of HEAs for 454 Big Block manufacturing may present some environmental challenges. The complex composition of these alloys often requires the use of rare or exotic elements, which can have significant environmental impacts during extraction and processing. The mining and refining of these elements may contribute to habitat destruction, water pollution, and increased energy consumption.

The manufacturing process for HEAs can be more energy-intensive compared to conventional alloy production, potentially leading to higher carbon emissions during the manufacturing phase. This increased energy demand needs to be carefully balanced against the long-term environmental benefits of using HEAs in automotive applications.

Recycling and end-of-life management of HEA components present both opportunities and challenges. The complex composition of these alloys may complicate traditional recycling processes, requiring the development of new techniques to effectively separate and recover the constituent elements. However, if successful, these recycling methods could lead to a more circular economy in the automotive sector, reducing the need for primary raw material extraction.

As the automotive industry continues to adopt HEAs in 454 Big Block manufacturing, it is crucial to conduct comprehensive life cycle assessments to fully understand their environmental impact. These assessments should consider the entire value chain, from raw material extraction to end-of-life disposal or recycling. Such analyses will help identify areas for improvement and guide the development of more sustainable manufacturing processes and material compositions.

In conclusion, while HEAs offer promising environmental benefits in terms of vehicle performance and longevity, their overall impact on the automotive industry's ecological footprint requires careful consideration and ongoing research. Balancing the advantages of improved fuel efficiency and durability against the potential challenges in production and recycling will be key to maximizing the positive environmental impact of HEAs in 454 Big Block manufacturing.

Cost-Benefit Analysis of HEA in Engine Manufacturing

The implementation of High-Entropy Alloys (HEAs) in 454 Big Block manufacturing presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for HEA integration are substantial, primarily due to the need for specialized equipment and processes to handle these advanced materials. The procurement of raw materials for HEAs is also more expensive compared to traditional alloys, which can significantly impact the overall production costs.

However, the long-term benefits of HEA implementation in engine manufacturing are considerable. The superior mechanical properties of HEAs, including enhanced strength, hardness, and wear resistance, contribute to improved engine performance and durability. This translates to extended engine life cycles and reduced maintenance requirements, potentially offsetting the higher initial costs over time.

The manufacturing process itself may see efficiency gains through the use of HEAs. Their unique properties allow for potential simplification of certain production steps, such as heat treatments or surface hardening processes. This streamlining can lead to reduced energy consumption and shorter production times, contributing to overall cost savings in the manufacturing pipeline.

From a market perspective, the incorporation of HEAs in 454 Big Block engines can provide a significant competitive advantage. The enhanced performance characteristics of HEA-based components can justify premium pricing strategies, potentially increasing profit margins. Additionally, the use of cutting-edge materials aligns with consumer trends towards high-performance, technologically advanced products, potentially expanding market share and brand value.

Environmental considerations also play a role in the cost-benefit analysis. The improved efficiency and longevity of HEA-based engines can contribute to reduced emissions and resource consumption over the product lifecycle. While difficult to quantify directly, these environmental benefits can translate to positive brand perception and potential regulatory advantages, indirectly impacting the bottom line.

It's crucial to consider the scalability of HEA implementation. As production volumes increase, economies of scale may help to mitigate the initial high costs associated with HEA manufacturing. Research and development investments in optimizing HEA production processes can lead to further cost reductions over time, improving the long-term economic viability of this technology in engine manufacturing.

However, the long-term benefits of HEA implementation in engine manufacturing are considerable. The superior mechanical properties of HEAs, including enhanced strength, hardness, and wear resistance, contribute to improved engine performance and durability. This translates to extended engine life cycles and reduced maintenance requirements, potentially offsetting the higher initial costs over time.

The manufacturing process itself may see efficiency gains through the use of HEAs. Their unique properties allow for potential simplification of certain production steps, such as heat treatments or surface hardening processes. This streamlining can lead to reduced energy consumption and shorter production times, contributing to overall cost savings in the manufacturing pipeline.

From a market perspective, the incorporation of HEAs in 454 Big Block engines can provide a significant competitive advantage. The enhanced performance characteristics of HEA-based components can justify premium pricing strategies, potentially increasing profit margins. Additionally, the use of cutting-edge materials aligns with consumer trends towards high-performance, technologically advanced products, potentially expanding market share and brand value.

Environmental considerations also play a role in the cost-benefit analysis. The improved efficiency and longevity of HEA-based engines can contribute to reduced emissions and resource consumption over the product lifecycle. While difficult to quantify directly, these environmental benefits can translate to positive brand perception and potential regulatory advantages, indirectly impacting the bottom line.

It's crucial to consider the scalability of HEA implementation. As production volumes increase, economies of scale may help to mitigate the initial high costs associated with HEA manufacturing. Research and development investments in optimizing HEA production processes can lead to further cost reductions over time, improving the long-term economic viability of this technology in engine manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!