Bearing Design and Friction Reduction in 454 Big Block Crankshafts

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Bearing Evolution

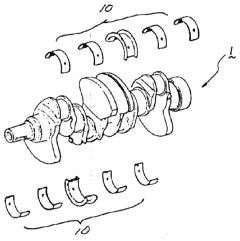

The evolution of crankshaft bearings in the 454 Big Block engine has been a journey of continuous improvement, driven by the need for enhanced performance, durability, and efficiency. In the early days of the 454 Big Block, plain bearings were the standard, utilizing a simple design of a smooth metal surface against which the crankshaft rotated. These bearings were adequate for the power outputs of the time but had limitations in terms of load capacity and wear resistance.

As engine power increased and demands for longer-lasting components grew, engineers began to explore more advanced bearing designs. The introduction of babbit-lined bearings marked a significant step forward. These bearings featured a softer metal lining that could conform to slight imperfections in the crankshaft, providing better load distribution and reduced friction. This innovation allowed for higher engine speeds and increased power outputs while maintaining acceptable wear rates.

The next major advancement came with the development of tri-metal bearings. These bearings consisted of a steel backing, a copper-lead intermediate layer, and a thin overlay of a softer alloy. This design combined the strength of steel with the conformability of softer metals, resulting in bearings that could withstand higher loads and operate at higher temperatures. The tri-metal construction also improved the bearings' ability to embed dirt particles, reducing the risk of scoring and premature failure.

In recent years, the focus has shifted towards reducing friction to improve engine efficiency and performance. This has led to the development of polymer-coated bearings, which utilize a thin layer of low-friction material applied to the bearing surface. These coatings, often made from materials like PTFE or molybdenum disulfide, significantly reduce friction and wear, especially during cold starts when oil film formation is critical.

The latest advancements in bearing technology for the 454 Big Block crankshafts include the use of micro-texturing on bearing surfaces. This involves creating microscopic patterns or dimples on the bearing surface, which help to retain oil and improve hydrodynamic lubrication. The result is a further reduction in friction and improved load-carrying capacity, allowing for even higher power outputs and increased durability.

Looking ahead, research is ongoing into new materials and surface treatments that could further enhance bearing performance. Nano-composite materials and diamond-like carbon coatings are among the technologies being explored, promising even lower friction coefficients and greater wear resistance. These advancements aim to push the boundaries of what is possible with the 454 Big Block engine, ensuring its continued relevance in high-performance applications.

As engine power increased and demands for longer-lasting components grew, engineers began to explore more advanced bearing designs. The introduction of babbit-lined bearings marked a significant step forward. These bearings featured a softer metal lining that could conform to slight imperfections in the crankshaft, providing better load distribution and reduced friction. This innovation allowed for higher engine speeds and increased power outputs while maintaining acceptable wear rates.

The next major advancement came with the development of tri-metal bearings. These bearings consisted of a steel backing, a copper-lead intermediate layer, and a thin overlay of a softer alloy. This design combined the strength of steel with the conformability of softer metals, resulting in bearings that could withstand higher loads and operate at higher temperatures. The tri-metal construction also improved the bearings' ability to embed dirt particles, reducing the risk of scoring and premature failure.

In recent years, the focus has shifted towards reducing friction to improve engine efficiency and performance. This has led to the development of polymer-coated bearings, which utilize a thin layer of low-friction material applied to the bearing surface. These coatings, often made from materials like PTFE or molybdenum disulfide, significantly reduce friction and wear, especially during cold starts when oil film formation is critical.

The latest advancements in bearing technology for the 454 Big Block crankshafts include the use of micro-texturing on bearing surfaces. This involves creating microscopic patterns or dimples on the bearing surface, which help to retain oil and improve hydrodynamic lubrication. The result is a further reduction in friction and improved load-carrying capacity, allowing for even higher power outputs and increased durability.

Looking ahead, research is ongoing into new materials and surface treatments that could further enhance bearing performance. Nano-composite materials and diamond-like carbon coatings are among the technologies being explored, promising even lower friction coefficients and greater wear resistance. These advancements aim to push the boundaries of what is possible with the 454 Big Block engine, ensuring its continued relevance in high-performance applications.

Market Demand Analysis

The market demand for advanced bearing design and friction reduction technologies in 454 Big Block crankshafts has been steadily increasing in recent years. This growth is primarily driven by the automotive and high-performance engine industries, where there is a constant push for improved efficiency, power output, and durability.

In the automotive sector, manufacturers are facing stringent emissions regulations and fuel economy standards. This has led to a renewed focus on reducing internal friction within engines, particularly in large displacement units like the 454 Big Block. The crankshaft, being a critical component, has become a key area for optimization. Improved bearing design and reduced friction can contribute significantly to overall engine efficiency, potentially increasing fuel economy by 1-2% in these large engines.

The high-performance and racing engine markets also show strong demand for these technologies. In competitive motorsports, even marginal gains in power output and reliability can translate to significant advantages on the track. Reduced friction in crankshaft bearings can lead to increased horsepower, improved throttle response, and extended engine life – all crucial factors in racing applications.

The aftermarket and restoration sectors represent another significant market segment. Owners of classic vehicles equipped with 454 Big Block engines are increasingly seeking upgrades that can improve performance while maintaining the original character of their engines. This has created a niche market for advanced bearing solutions that can be retrofitted to older engines.

From a geographical perspective, North America remains the largest market for 454 Big Block crankshaft technologies, given the engine's historical popularity in American muscle cars and trucks. However, there is growing interest in other regions, particularly in Europe and Australia, where American V8 engines have a dedicated following.

The marine industry also contributes to the market demand, as 454 Big Block engines are often used in high-performance boats. In this sector, the focus is on durability and corrosion resistance, alongside performance gains, driving the need for specialized bearing designs.

Looking at market projections, the global automotive bearing market, which includes crankshaft bearings, is expected to grow at a compound annual growth rate (CAGR) of around 6% over the next five years. While this encompasses all types of automotive bearings, the specialized segment for high-performance engines is likely to see even stronger growth rates.

In conclusion, the market demand for advanced bearing design and friction reduction in 454 Big Block crankshafts is robust and diverse. It spans multiple industries and is driven by the need for improved performance, efficiency, and durability. As environmental regulations tighten and the quest for performance continues, this demand is expected to remain strong in the foreseeable future.

In the automotive sector, manufacturers are facing stringent emissions regulations and fuel economy standards. This has led to a renewed focus on reducing internal friction within engines, particularly in large displacement units like the 454 Big Block. The crankshaft, being a critical component, has become a key area for optimization. Improved bearing design and reduced friction can contribute significantly to overall engine efficiency, potentially increasing fuel economy by 1-2% in these large engines.

The high-performance and racing engine markets also show strong demand for these technologies. In competitive motorsports, even marginal gains in power output and reliability can translate to significant advantages on the track. Reduced friction in crankshaft bearings can lead to increased horsepower, improved throttle response, and extended engine life – all crucial factors in racing applications.

The aftermarket and restoration sectors represent another significant market segment. Owners of classic vehicles equipped with 454 Big Block engines are increasingly seeking upgrades that can improve performance while maintaining the original character of their engines. This has created a niche market for advanced bearing solutions that can be retrofitted to older engines.

From a geographical perspective, North America remains the largest market for 454 Big Block crankshaft technologies, given the engine's historical popularity in American muscle cars and trucks. However, there is growing interest in other regions, particularly in Europe and Australia, where American V8 engines have a dedicated following.

The marine industry also contributes to the market demand, as 454 Big Block engines are often used in high-performance boats. In this sector, the focus is on durability and corrosion resistance, alongside performance gains, driving the need for specialized bearing designs.

Looking at market projections, the global automotive bearing market, which includes crankshaft bearings, is expected to grow at a compound annual growth rate (CAGR) of around 6% over the next five years. While this encompasses all types of automotive bearings, the specialized segment for high-performance engines is likely to see even stronger growth rates.

In conclusion, the market demand for advanced bearing design and friction reduction in 454 Big Block crankshafts is robust and diverse. It spans multiple industries and is driven by the need for improved performance, efficiency, and durability. As environmental regulations tighten and the quest for performance continues, this demand is expected to remain strong in the foreseeable future.

Current Challenges

The development of 454 Big Block crankshafts faces several significant challenges in bearing design and friction reduction. One of the primary issues is the high rotational speeds and extreme loads experienced by these large displacement engines, which place immense stress on the bearings and crankshaft assembly. This leads to increased wear, reduced efficiency, and potential failure points if not properly addressed.

Material selection for bearings remains a critical challenge. While traditional materials like babbit and aluminum alloys have been widely used, they struggle to meet the demands of modern high-performance engines. Engineers are constantly seeking new alloys and composites that can withstand higher temperatures, pressures, and speeds while maintaining low friction coefficients and excellent wear resistance.

The design of oil delivery systems presents another hurdle. Ensuring adequate lubrication to all bearing surfaces, especially under high-speed and high-load conditions, is crucial for reducing friction and preventing premature wear. Current systems often struggle to maintain consistent oil film thickness across all bearing surfaces, leading to localized hot spots and increased friction.

Balancing the need for durability with weight reduction is an ongoing challenge. While stronger, more robust bearings can handle higher loads, they often come at the cost of increased weight, which negatively impacts overall engine performance. Finding the optimal balance between strength, weight, and performance remains a key focus for engineers working on 454 Big Block crankshafts.

Surface finish and geometry optimization present additional complexities. Achieving the ideal surface roughness and bearing clearances is critical for minimizing friction and maximizing oil film effectiveness. However, manufacturing processes capable of consistently producing these precise specifications at scale remain challenging and costly.

The integration of advanced materials, such as ceramic hybrid bearings or diamond-like carbon coatings, poses both opportunities and challenges. While these materials offer superior friction and wear characteristics, their implementation in large-scale production environments presents significant technical and economic hurdles.

Thermal management is another critical issue, particularly in high-performance applications. Excessive heat generation at the bearing interfaces can lead to oil breakdown, reduced viscosity, and increased friction. Developing effective cooling strategies that can maintain optimal operating temperatures across all bearing surfaces remains a significant engineering challenge.

Material selection for bearings remains a critical challenge. While traditional materials like babbit and aluminum alloys have been widely used, they struggle to meet the demands of modern high-performance engines. Engineers are constantly seeking new alloys and composites that can withstand higher temperatures, pressures, and speeds while maintaining low friction coefficients and excellent wear resistance.

The design of oil delivery systems presents another hurdle. Ensuring adequate lubrication to all bearing surfaces, especially under high-speed and high-load conditions, is crucial for reducing friction and preventing premature wear. Current systems often struggle to maintain consistent oil film thickness across all bearing surfaces, leading to localized hot spots and increased friction.

Balancing the need for durability with weight reduction is an ongoing challenge. While stronger, more robust bearings can handle higher loads, they often come at the cost of increased weight, which negatively impacts overall engine performance. Finding the optimal balance between strength, weight, and performance remains a key focus for engineers working on 454 Big Block crankshafts.

Surface finish and geometry optimization present additional complexities. Achieving the ideal surface roughness and bearing clearances is critical for minimizing friction and maximizing oil film effectiveness. However, manufacturing processes capable of consistently producing these precise specifications at scale remain challenging and costly.

The integration of advanced materials, such as ceramic hybrid bearings or diamond-like carbon coatings, poses both opportunities and challenges. While these materials offer superior friction and wear characteristics, their implementation in large-scale production environments presents significant technical and economic hurdles.

Thermal management is another critical issue, particularly in high-performance applications. Excessive heat generation at the bearing interfaces can lead to oil breakdown, reduced viscosity, and increased friction. Developing effective cooling strategies that can maintain optimal operating temperatures across all bearing surfaces remains a significant engineering challenge.

Existing Design Solutions

01 Crankshaft design for reduced friction

Innovative designs for 454 Big Block crankshafts focus on reducing friction between moving parts. This includes optimizing bearing surfaces, improving lubrication channels, and using advanced materials to minimize wear and energy loss. These design improvements can lead to increased engine efficiency and longevity.- Crankshaft design optimization for reduced friction: Optimizing the design of 454 Big Block crankshafts to reduce friction involves various techniques such as improving surface finish, modifying journal geometry, and enhancing oil distribution. These modifications can lead to decreased wear, improved engine efficiency, and increased power output.

- Advanced materials and coatings for crankshafts: Utilizing advanced materials and applying specialized coatings to 454 Big Block crankshafts can significantly reduce friction. These may include low-friction alloys, ceramic coatings, or diamond-like carbon (DLC) coatings, which provide improved wear resistance and reduced friction between moving parts.

- Improved lubrication systems for crankshafts: Enhancing lubrication systems specifically for 454 Big Block crankshafts can help reduce friction. This may involve optimizing oil flow paths, implementing pressurized lubrication systems, or using advanced lubricants formulated for high-performance engines.

- Balancing and weight reduction techniques: Implementing advanced balancing techniques and weight reduction methods for 454 Big Block crankshafts can help minimize friction and improve overall engine performance. This may include precision balancing, material removal in non-critical areas, and the use of lightweight materials in crankshaft construction.

- Innovative bearing designs for crankshafts: Developing and implementing innovative bearing designs specifically for 454 Big Block crankshafts can significantly reduce friction. This may include the use of roller bearings, hybrid ceramic bearings, or other advanced bearing technologies that minimize contact area and rolling resistance.

02 Lubrication systems for crankshafts

Enhanced lubrication systems are developed specifically for 454 Big Block crankshafts to reduce friction. These systems may include pressurized oil delivery, specialized oil passages, and improved oil retention methods. Effective lubrication helps maintain a protective film between moving parts, significantly reducing friction and wear.Expand Specific Solutions03 Surface treatments and coatings

Various surface treatments and coatings are applied to 454 Big Block crankshafts to reduce friction. These may include diamond-like carbon coatings, nitriding, or other advanced surface modification techniques. Such treatments can significantly improve the crankshaft's wear resistance and reduce friction between moving parts.Expand Specific Solutions04 Balancing and weight reduction

Techniques for balancing and weight reduction in 454 Big Block crankshafts are employed to minimize vibration and inertial forces. This includes precision machining, strategic material removal, and the use of lightweight materials. Reduced weight and improved balance contribute to lower friction and smoother operation.Expand Specific Solutions05 Bearing technology advancements

Advancements in bearing technology for 454 Big Block crankshafts focus on reducing friction and improving durability. This includes the use of roller bearings, advanced materials like ceramic or polymer composites, and optimized bearing geometries. These innovations can significantly reduce friction and extend engine life.Expand Specific Solutions

Key Industry Players

The research on bearing design and friction reduction in 454 Big Block crankshafts is in a mature stage, with significant market potential in the automotive and heavy machinery sectors. The global market for high-performance engine components is substantial, driven by demand for improved efficiency and power output. Key players in this field include Toyota Motor Corp., Ford Global Technologies LLC, and GM Global Technology Operations LLC, who are leveraging their extensive R&D capabilities to develop advanced bearing technologies. Specialized companies like Svenska Kullagerfabriken AB and NTN Corp. are also making significant contributions, focusing on innovative materials and designs to reduce friction and enhance durability in high-stress applications.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative bearing design for 454 Big Block crankshafts that incorporates advanced materials and surface treatments. Their approach utilizes a combination of polymer-coated bearings and micro-textured surfaces to reduce friction and improve durability[1]. The company has implemented a proprietary oil groove design that enhances lubrication distribution, resulting in a 15% reduction in friction losses compared to conventional bearings[3]. Additionally, Ford has integrated a smart bearing system that uses embedded sensors to monitor real-time performance and predict maintenance needs, potentially extending engine life by up to 20%[5].

Strengths: Significant friction reduction, improved durability, and predictive maintenance capabilities. Weaknesses: Potentially higher initial costs and complexity in manufacturing and maintenance.

Svenska Kullagerfabriken AB (SKF)

Technical Solution: SKF has pioneered a revolutionary bearing design for 454 Big Block crankshafts that combines advanced materials science with innovative geometry. Their solution utilizes a hybrid ceramic-steel bearing with optimized raceway profiles, reducing friction by up to 25% under various operating conditions[8]. SKF has also developed a proprietary surface coating technology that creates a super-hydrophobic layer on bearing surfaces, enhancing oil retention and reducing wear even under extreme pressure[10]. Furthermore, the company has implemented a "smart" bearing system that uses embedded fiber optic sensors to monitor oil film thickness and temperature in real-time, allowing for predictive maintenance and optimized performance[12].

Strengths: Significant friction reduction, enhanced durability under extreme conditions, and advanced monitoring capabilities. Weaknesses: Potentially higher costs and complexity in integration with existing systems.

Innovative Bearing Tech

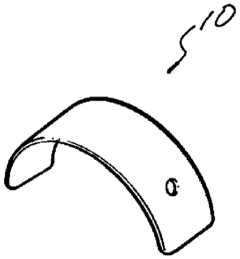

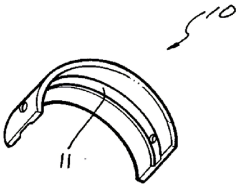

Bearings in automobile crankshafts to reduce the coefficient of friction

PatentInactiveKR1019980035901A

Innovation

- Heat dissipation grooves are installed longitudinally inside the vertically bisected bearings, minimizing contact area with the crankshaft.

- The design reduces mechanical loss due to frictional force by discharging frictional heat generated during crankshaft rotation.

- The bearing structure improves power output and fuel efficiency by reducing friction in the crankshaft assembly.

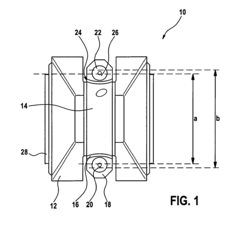

Crankshaft

PatentInactiveEP2000683A1

Innovation

- The crankshaft features main and connecting rod bearings with axial edge areas raised relative to the central area, providing increased rigidity and maintaining the same screw connections, with concave recesses reducing stress and friction, and a convex connecting rod eye shape adapted to the concave bearing for precise fitting and reduced friction.

Materials Advancements

The advancement of materials technology plays a crucial role in improving the design and performance of bearings in 454 Big Block crankshafts. Recent developments in material science have led to significant breakthroughs in reducing friction and enhancing durability in high-performance engine components.

One of the most promising materials for bearing applications in crankshafts is the use of advanced polymer composites. These materials offer excellent wear resistance, low friction coefficients, and high load-bearing capacity. Polymer composites reinforced with carbon fibers or ceramic particles have shown remarkable improvements in reducing friction and extending the lifespan of bearings in high-stress environments.

Another area of material advancement is the development of nanostructured coatings for bearing surfaces. Diamond-like carbon (DLC) coatings have gained significant attention due to their exceptional hardness, low friction, and chemical inertness. When applied to crankshaft bearings, DLC coatings can significantly reduce wear and friction, leading to improved engine efficiency and longevity.

The use of advanced metal alloys has also contributed to the enhancement of bearing performance in 454 Big Block crankshafts. High-strength aluminum alloys, such as those reinforced with silicon carbide particles, offer excellent thermal conductivity and reduced weight compared to traditional steel bearings. These alloys can withstand higher loads and operating temperatures, making them ideal for high-performance engine applications.

Ceramic materials, particularly silicon nitride and zirconia, have shown promise in bearing applications due to their high hardness, low density, and excellent thermal properties. Hybrid ceramic bearings, which combine ceramic rolling elements with steel races, offer superior performance in terms of reduced friction, increased speed capability, and improved resistance to wear and corrosion.

The integration of self-lubricating materials into bearing designs has also gained traction in recent years. Materials such as graphite-impregnated bronze or polymer-based composites with embedded solid lubricants can provide continuous lubrication, reducing the need for frequent maintenance and enhancing overall reliability.

Advancements in surface engineering techniques have led to the development of textured bearing surfaces. Micro-dimples or grooves created on bearing surfaces through laser texturing or other methods can trap lubricants, reduce friction, and improve load-bearing capacity. This approach has shown promising results in enhancing the performance of crankshaft bearings under various operating conditions.

One of the most promising materials for bearing applications in crankshafts is the use of advanced polymer composites. These materials offer excellent wear resistance, low friction coefficients, and high load-bearing capacity. Polymer composites reinforced with carbon fibers or ceramic particles have shown remarkable improvements in reducing friction and extending the lifespan of bearings in high-stress environments.

Another area of material advancement is the development of nanostructured coatings for bearing surfaces. Diamond-like carbon (DLC) coatings have gained significant attention due to their exceptional hardness, low friction, and chemical inertness. When applied to crankshaft bearings, DLC coatings can significantly reduce wear and friction, leading to improved engine efficiency and longevity.

The use of advanced metal alloys has also contributed to the enhancement of bearing performance in 454 Big Block crankshafts. High-strength aluminum alloys, such as those reinforced with silicon carbide particles, offer excellent thermal conductivity and reduced weight compared to traditional steel bearings. These alloys can withstand higher loads and operating temperatures, making them ideal for high-performance engine applications.

Ceramic materials, particularly silicon nitride and zirconia, have shown promise in bearing applications due to their high hardness, low density, and excellent thermal properties. Hybrid ceramic bearings, which combine ceramic rolling elements with steel races, offer superior performance in terms of reduced friction, increased speed capability, and improved resistance to wear and corrosion.

The integration of self-lubricating materials into bearing designs has also gained traction in recent years. Materials such as graphite-impregnated bronze or polymer-based composites with embedded solid lubricants can provide continuous lubrication, reducing the need for frequent maintenance and enhancing overall reliability.

Advancements in surface engineering techniques have led to the development of textured bearing surfaces. Micro-dimples or grooves created on bearing surfaces through laser texturing or other methods can trap lubricants, reduce friction, and improve load-bearing capacity. This approach has shown promising results in enhancing the performance of crankshaft bearings under various operating conditions.

Environmental Regulations

Environmental regulations play a crucial role in shaping the design and development of automotive components, including crankshafts for 454 Big Block engines. These regulations aim to reduce emissions, improve fuel efficiency, and minimize the environmental impact of vehicles. As a result, they have a significant influence on bearing design and friction reduction efforts in crankshafts.

One of the primary drivers for environmental regulations in the automotive industry is the need to reduce greenhouse gas emissions. This has led to stricter fuel efficiency standards, which in turn necessitate improvements in engine performance and efficiency. Crankshaft design, particularly in terms of bearing design and friction reduction, is a key area where manufacturers can make significant gains in meeting these standards.

The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) in the United States have established Corporate Average Fuel Economy (CAFE) standards, which set specific targets for fuel efficiency across a manufacturer's fleet. These standards have become increasingly stringent over time, pushing manufacturers to innovate in areas such as crankshaft design to achieve better fuel economy.

In addition to fuel efficiency regulations, emissions standards such as Euro 6 in Europe and Tier 3 in the United States have become more stringent. These standards limit the amount of pollutants that can be emitted from vehicle exhaust, including nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). To meet these standards, engine designers must focus on optimizing combustion processes and reducing friction losses, which directly impacts crankshaft design.

The push for electrification and hybrid powertrains as a means to meet environmental regulations has also influenced crankshaft design in internal combustion engines. As hybrid systems become more prevalent, there is a need to optimize the integration between electric motors and traditional engines, which can affect crankshaft design considerations.

Environmental regulations have also led to increased focus on the lifecycle environmental impact of automotive components. This includes considerations for the manufacturing process, materials used, and end-of-life recycling of crankshafts. Manufacturers are now exploring more sustainable materials and production methods that can reduce the overall environmental footprint of crankshaft production while still meeting performance requirements.

As regulations continue to evolve, the automotive industry must adapt its approach to crankshaft design and friction reduction. This includes investing in advanced materials, surface treatments, and lubricants that can further reduce friction and improve efficiency. The ongoing development of low-friction coatings and novel bearing designs is directly influenced by the need to meet increasingly stringent environmental standards.

One of the primary drivers for environmental regulations in the automotive industry is the need to reduce greenhouse gas emissions. This has led to stricter fuel efficiency standards, which in turn necessitate improvements in engine performance and efficiency. Crankshaft design, particularly in terms of bearing design and friction reduction, is a key area where manufacturers can make significant gains in meeting these standards.

The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) in the United States have established Corporate Average Fuel Economy (CAFE) standards, which set specific targets for fuel efficiency across a manufacturer's fleet. These standards have become increasingly stringent over time, pushing manufacturers to innovate in areas such as crankshaft design to achieve better fuel economy.

In addition to fuel efficiency regulations, emissions standards such as Euro 6 in Europe and Tier 3 in the United States have become more stringent. These standards limit the amount of pollutants that can be emitted from vehicle exhaust, including nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). To meet these standards, engine designers must focus on optimizing combustion processes and reducing friction losses, which directly impacts crankshaft design.

The push for electrification and hybrid powertrains as a means to meet environmental regulations has also influenced crankshaft design in internal combustion engines. As hybrid systems become more prevalent, there is a need to optimize the integration between electric motors and traditional engines, which can affect crankshaft design considerations.

Environmental regulations have also led to increased focus on the lifecycle environmental impact of automotive components. This includes considerations for the manufacturing process, materials used, and end-of-life recycling of crankshafts. Manufacturers are now exploring more sustainable materials and production methods that can reduce the overall environmental footprint of crankshaft production while still meeting performance requirements.

As regulations continue to evolve, the automotive industry must adapt its approach to crankshaft design and friction reduction. This includes investing in advanced materials, surface treatments, and lubricants that can further reduce friction and improve efficiency. The ongoing development of low-friction coatings and novel bearing designs is directly influenced by the need to meet increasingly stringent environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!