Transitioning to Modular Battery Management Systems: Challenges and Benefits

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Evolution and Goals

Battery Management Systems (BMS) have undergone significant evolution since their inception, driven by the rapid advancement of electric vehicle (EV) technology and the growing demand for more efficient and reliable energy storage solutions. The primary goal of BMS development has been to enhance the safety, performance, and longevity of battery systems while reducing costs and complexity.

In the early stages of BMS development, the focus was primarily on basic monitoring and protection functions. These systems were designed to prevent overcharging, over-discharging, and overheating of battery cells. As the EV market expanded and battery technology improved, the goals of BMS evolved to include more sophisticated features such as cell balancing, state of charge (SOC) estimation, and state of health (SOH) monitoring.

The transition towards modular BMS represents a significant shift in the industry's approach to battery management. This evolution is driven by the need for more flexible, scalable, and cost-effective solutions that can adapt to various battery configurations and applications. Modular BMS aims to overcome the limitations of traditional centralized systems by distributing intelligence and control across multiple modules.

One of the key objectives of modular BMS is to improve system reliability and fault tolerance. By dividing the BMS into smaller, independent modules, the risk of complete system failure is reduced. If one module malfunctions, the others can continue to operate, ensuring the overall stability of the battery system. This approach aligns with the automotive industry's stringent safety requirements and the need for robust, fail-safe solutions in electric vehicles.

Another important goal of modular BMS is to enhance scalability and adaptability. As battery pack sizes and configurations continue to evolve, modular systems allow for easier customization and upgrades. This flexibility is crucial for manufacturers looking to optimize their battery systems for different vehicle models or to quickly adapt to new battery technologies without redesigning the entire BMS architecture.

Improving energy efficiency and extending battery life are also central objectives in the evolution of modular BMS. Advanced algorithms and distributed processing capabilities enable more accurate cell monitoring and precise control of charging and discharging processes. This level of granular management can lead to better utilization of battery capacity and potentially longer overall battery lifespan.

Cost reduction remains a critical goal in the transition to modular BMS. While initial implementation costs may be higher, the long-term benefits of modularity, including easier maintenance, reduced downtime, and simplified manufacturing processes, are expected to contribute to overall cost savings in battery system production and operation.

As the automotive industry moves towards more sustainable and efficient transportation solutions, the evolution of BMS technology plays a crucial role in realizing the full potential of electric vehicles. The transition to modular BMS represents a significant step towards achieving these goals, promising to deliver more reliable, flexible, and cost-effective battery management solutions for the next generation of electric vehicles.

In the early stages of BMS development, the focus was primarily on basic monitoring and protection functions. These systems were designed to prevent overcharging, over-discharging, and overheating of battery cells. As the EV market expanded and battery technology improved, the goals of BMS evolved to include more sophisticated features such as cell balancing, state of charge (SOC) estimation, and state of health (SOH) monitoring.

The transition towards modular BMS represents a significant shift in the industry's approach to battery management. This evolution is driven by the need for more flexible, scalable, and cost-effective solutions that can adapt to various battery configurations and applications. Modular BMS aims to overcome the limitations of traditional centralized systems by distributing intelligence and control across multiple modules.

One of the key objectives of modular BMS is to improve system reliability and fault tolerance. By dividing the BMS into smaller, independent modules, the risk of complete system failure is reduced. If one module malfunctions, the others can continue to operate, ensuring the overall stability of the battery system. This approach aligns with the automotive industry's stringent safety requirements and the need for robust, fail-safe solutions in electric vehicles.

Another important goal of modular BMS is to enhance scalability and adaptability. As battery pack sizes and configurations continue to evolve, modular systems allow for easier customization and upgrades. This flexibility is crucial for manufacturers looking to optimize their battery systems for different vehicle models or to quickly adapt to new battery technologies without redesigning the entire BMS architecture.

Improving energy efficiency and extending battery life are also central objectives in the evolution of modular BMS. Advanced algorithms and distributed processing capabilities enable more accurate cell monitoring and precise control of charging and discharging processes. This level of granular management can lead to better utilization of battery capacity and potentially longer overall battery lifespan.

Cost reduction remains a critical goal in the transition to modular BMS. While initial implementation costs may be higher, the long-term benefits of modularity, including easier maintenance, reduced downtime, and simplified manufacturing processes, are expected to contribute to overall cost savings in battery system production and operation.

As the automotive industry moves towards more sustainable and efficient transportation solutions, the evolution of BMS technology plays a crucial role in realizing the full potential of electric vehicles. The transition to modular BMS represents a significant step towards achieving these goals, promising to deliver more reliable, flexible, and cost-effective battery management solutions for the next generation of electric vehicles.

Market Demand Analysis

The transition to modular Battery Management Systems (BMS) is driven by a growing market demand for more efficient, flexible, and cost-effective energy storage solutions. As the electric vehicle (EV) market continues to expand rapidly, there is an increasing need for advanced BMS technologies that can optimize battery performance, extend lifespan, and enhance safety.

The global EV market is experiencing exponential growth, with sales projected to reach 26.8 million units by 2030. This surge in EV adoption is creating a substantial demand for modular BMS solutions that can adapt to various battery configurations and vehicle types. Modular BMS offers the flexibility to scale battery systems according to specific vehicle requirements, enabling manufacturers to streamline production processes and reduce costs.

In addition to the automotive sector, the renewable energy industry is also driving demand for modular BMS. As grid-scale energy storage systems become more prevalent, there is a growing need for scalable and efficient battery management solutions. Modular BMS can effectively manage large-scale battery arrays, optimizing performance and extending the lifespan of energy storage installations.

The industrial sector is another key market for modular BMS, with applications in robotics, material handling equipment, and backup power systems. These industries require reliable and adaptable battery management solutions to ensure optimal performance and safety in diverse operating environments.

Consumer electronics manufacturers are also showing interest in modular BMS technologies. As portable devices become more power-hungry and incorporate larger battery capacities, there is a need for more sophisticated battery management solutions that can be easily integrated into various product designs.

Market research indicates that the global BMS market is expected to grow at a CAGR of 19.5% from 2021 to 2028, reaching a value of $17.2 billion by the end of the forecast period. The modular BMS segment is anticipated to experience even higher growth rates due to its advantages in scalability and customization.

The demand for modular BMS is further fueled by stringent regulations and safety standards in the automotive and energy storage industries. Modular systems offer enhanced monitoring and control capabilities, helping manufacturers comply with evolving safety requirements and improve overall battery performance.

As the market for electric and hybrid vehicles continues to mature, there is an increasing focus on second-life battery applications. Modular BMS solutions are well-suited for repurposing EV batteries for stationary energy storage, creating new market opportunities and addressing sustainability concerns.

In conclusion, the market demand for modular Battery Management Systems is robust and diverse, driven by the rapid growth of the EV industry, renewable energy adoption, and the need for more efficient and flexible energy storage solutions across various sectors. The ability of modular BMS to offer scalability, improved performance, and enhanced safety positions it as a critical technology in the evolving energy landscape.

The global EV market is experiencing exponential growth, with sales projected to reach 26.8 million units by 2030. This surge in EV adoption is creating a substantial demand for modular BMS solutions that can adapt to various battery configurations and vehicle types. Modular BMS offers the flexibility to scale battery systems according to specific vehicle requirements, enabling manufacturers to streamline production processes and reduce costs.

In addition to the automotive sector, the renewable energy industry is also driving demand for modular BMS. As grid-scale energy storage systems become more prevalent, there is a growing need for scalable and efficient battery management solutions. Modular BMS can effectively manage large-scale battery arrays, optimizing performance and extending the lifespan of energy storage installations.

The industrial sector is another key market for modular BMS, with applications in robotics, material handling equipment, and backup power systems. These industries require reliable and adaptable battery management solutions to ensure optimal performance and safety in diverse operating environments.

Consumer electronics manufacturers are also showing interest in modular BMS technologies. As portable devices become more power-hungry and incorporate larger battery capacities, there is a need for more sophisticated battery management solutions that can be easily integrated into various product designs.

Market research indicates that the global BMS market is expected to grow at a CAGR of 19.5% from 2021 to 2028, reaching a value of $17.2 billion by the end of the forecast period. The modular BMS segment is anticipated to experience even higher growth rates due to its advantages in scalability and customization.

The demand for modular BMS is further fueled by stringent regulations and safety standards in the automotive and energy storage industries. Modular systems offer enhanced monitoring and control capabilities, helping manufacturers comply with evolving safety requirements and improve overall battery performance.

As the market for electric and hybrid vehicles continues to mature, there is an increasing focus on second-life battery applications. Modular BMS solutions are well-suited for repurposing EV batteries for stationary energy storage, creating new market opportunities and addressing sustainability concerns.

In conclusion, the market demand for modular Battery Management Systems is robust and diverse, driven by the rapid growth of the EV industry, renewable energy adoption, and the need for more efficient and flexible energy storage solutions across various sectors. The ability of modular BMS to offer scalability, improved performance, and enhanced safety positions it as a critical technology in the evolving energy landscape.

Modular BMS Challenges

The transition to modular Battery Management Systems (BMS) presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the complexity of system integration. Modular BMS requires seamless communication and coordination between multiple independent modules, which can be challenging to achieve without introducing latency or data inconsistencies. This integration complexity extends to both hardware and software components, necessitating robust protocols and interfaces to ensure reliable operation.

Another major challenge lies in the realm of thermal management. As battery modules are distributed across the system, maintaining uniform temperature control becomes more difficult. Uneven thermal distribution can lead to reduced battery performance, accelerated degradation, and potential safety risks. Developing effective cooling strategies for modular BMS configurations requires innovative approaches to heat dissipation and temperature monitoring.

Standardization poses yet another hurdle in the adoption of modular BMS. The lack of industry-wide standards for module interfaces, communication protocols, and performance metrics can hinder interoperability between different manufacturers' components. This absence of standardization may lead to increased development costs and limited flexibility in system design, potentially slowing down widespread adoption.

Cost considerations also present a significant challenge. While modular BMS offers long-term benefits in terms of scalability and maintenance, the initial investment required for transitioning from traditional centralized systems can be substantial. This includes not only the cost of new hardware but also expenses related to redesigning existing battery systems, retraining personnel, and potentially disrupting current production processes.

Ensuring the reliability and fault tolerance of modular BMS is another critical challenge. With multiple independent modules, the system must be designed to handle potential failures in individual units without compromising overall performance. This requires sophisticated fault detection, isolation, and recovery mechanisms, adding another layer of complexity to the system design.

Lastly, the regulatory landscape presents its own set of challenges. As modular BMS represents a significant shift in battery management technology, existing regulations and safety standards may need to be updated or reinterpreted. Navigating this evolving regulatory environment while ensuring compliance across different markets and applications can be a complex and time-consuming process for manufacturers and system integrators.

Another major challenge lies in the realm of thermal management. As battery modules are distributed across the system, maintaining uniform temperature control becomes more difficult. Uneven thermal distribution can lead to reduced battery performance, accelerated degradation, and potential safety risks. Developing effective cooling strategies for modular BMS configurations requires innovative approaches to heat dissipation and temperature monitoring.

Standardization poses yet another hurdle in the adoption of modular BMS. The lack of industry-wide standards for module interfaces, communication protocols, and performance metrics can hinder interoperability between different manufacturers' components. This absence of standardization may lead to increased development costs and limited flexibility in system design, potentially slowing down widespread adoption.

Cost considerations also present a significant challenge. While modular BMS offers long-term benefits in terms of scalability and maintenance, the initial investment required for transitioning from traditional centralized systems can be substantial. This includes not only the cost of new hardware but also expenses related to redesigning existing battery systems, retraining personnel, and potentially disrupting current production processes.

Ensuring the reliability and fault tolerance of modular BMS is another critical challenge. With multiple independent modules, the system must be designed to handle potential failures in individual units without compromising overall performance. This requires sophisticated fault detection, isolation, and recovery mechanisms, adding another layer of complexity to the system design.

Lastly, the regulatory landscape presents its own set of challenges. As modular BMS represents a significant shift in battery management technology, existing regulations and safety standards may need to be updated or reinterpreted. Navigating this evolving regulatory environment while ensuring compliance across different markets and applications can be a complex and time-consuming process for manufacturers and system integrators.

Current Modular Solutions

01 Modular architecture for battery management

Modular battery management systems utilize a flexible architecture that allows for easy scalability and customization. This approach enables the system to be adapted to various battery configurations and sizes, improving overall efficiency and reducing costs. The modular design also facilitates easier maintenance and upgrades of individual components without affecting the entire system.- Modular architecture for battery management systems: Modular battery management systems utilize a flexible architecture that allows for easy scalability and customization. This approach enables the system to be adapted to various battery configurations and sizes, improving overall efficiency and reducing costs. The modular design also facilitates easier maintenance and upgrades of individual components without affecting the entire system.

- Distributed control and monitoring in battery management: Distributed control and monitoring systems in modular battery management allow for more efficient and accurate management of individual battery cells or modules. This approach enables real-time monitoring of battery parameters, such as voltage, temperature, and state of charge, at a granular level. It also allows for localized decision-making and control, improving overall system responsiveness and reliability.

- Integration of advanced communication protocols: Modern modular battery management systems incorporate advanced communication protocols to facilitate seamless data exchange between various components and external systems. These protocols enable efficient coordination between battery modules, power converters, and higher-level control systems. This integration enhances system performance, enables remote monitoring and control, and supports the implementation of smart grid technologies.

- Adaptive balancing and charge management techniques: Modular battery management systems employ adaptive balancing and charge management techniques to optimize battery performance and longevity. These techniques dynamically adjust charging and discharging parameters based on individual cell characteristics and operating conditions. This approach ensures uniform charge distribution across cells, prevents overcharging or undercharging, and extends the overall lifespan of the battery system.

- Fault detection and mitigation strategies: Advanced fault detection and mitigation strategies are implemented in modular battery management systems to enhance safety and reliability. These systems continuously monitor for potential issues such as short circuits, overheating, or cell degradation. Upon detection of a fault, the system can isolate affected modules, reroute power, or implement other mitigation measures to prevent cascading failures and ensure continued operation of the battery system.

02 Distributed control and monitoring

These systems employ distributed control and monitoring techniques, where multiple modules work together to manage different aspects of battery performance. This approach allows for more precise control over individual cells or battery packs, enhancing overall system reliability and efficiency. It also enables real-time monitoring of battery health, state of charge, and other critical parameters.Expand Specific Solutions03 Integration with energy management systems

Modular battery management systems are designed to integrate seamlessly with broader energy management systems. This integration allows for optimized energy distribution, load balancing, and improved grid stability in applications such as renewable energy storage and electric vehicle charging infrastructure. The modular approach facilitates easier integration with various energy sources and consumption patterns.Expand Specific Solutions04 Advanced diagnostics and predictive maintenance

These systems incorporate advanced diagnostic capabilities and predictive maintenance features. By continuously analyzing battery performance data, the system can predict potential issues before they occur, schedule maintenance proactively, and optimize battery life. This approach reduces downtime and extends the overall lifespan of the battery system.Expand Specific Solutions05 Adaptive power management algorithms

Modular battery management systems utilize adaptive power management algorithms that can adjust to changing conditions and usage patterns. These algorithms optimize charging and discharging cycles, balance loads across multiple battery modules, and adapt to varying environmental conditions. This results in improved energy efficiency, extended battery life, and enhanced overall system performance.Expand Specific Solutions

Key BMS Manufacturers

The transition to Modular Battery Management Systems (BMS) is currently in its growth phase, with the market expanding rapidly due to increasing demand for electric vehicles and renewable energy storage solutions. Major players like Robert Bosch GmbH, Samsung SDI Co., Ltd., and LG Energy Solution Ltd. are driving technological advancements, indicating a maturing industry. The market size is projected to grow significantly in the coming years, fueled by automotive and energy storage applications. While the technology is evolving, it has reached a level of maturity where commercial applications are viable, with companies like BYD Co., Ltd. and Exro Technologies, Inc. implementing modular BMS in their products, showcasing the technology's readiness for widespread adoption.

Robert Bosch GmbH

Technical Solution: Bosch has developed a modular Battery Management System (BMS) that can be scaled for various battery sizes and configurations. Their system utilizes advanced algorithms for cell balancing and state-of-charge estimation, improving overall battery performance and longevity. The modular design allows for easy integration with different battery chemistries and vehicle platforms, making it adaptable to evolving EV market needs[1]. Bosch's BMS incorporates wireless communication protocols, reducing wiring complexity and weight while enhancing diagnostic capabilities[2]. The system also features predictive maintenance algorithms that can forecast potential battery issues before they occur, minimizing downtime and improving safety[3].

Strengths: Scalability, adaptability to different battery types, advanced diagnostics. Weaknesses: Potential higher initial cost, complexity in implementation for smaller manufacturers.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has introduced a modular BMS that focuses on high-density energy storage and rapid charging capabilities. Their system employs a distributed architecture, with intelligent modules monitoring individual cell clusters[4]. This approach allows for more precise control and faster response times to temperature and voltage fluctuations. Samsung's BMS incorporates machine learning algorithms to optimize charging patterns and extend battery life, adapting to user behavior and environmental conditions[5]. The company has also developed a unique thermal management system integrated with the BMS, using phase-change materials to efficiently regulate battery temperature during fast charging and high-load operations[6].

Strengths: High-density energy storage, advanced thermal management, AI-driven optimization. Weaknesses: Potentially higher cost due to advanced features, may require specialized training for maintenance.

Core Modular BMS Tech

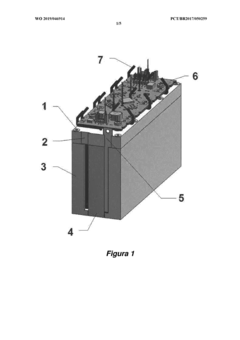

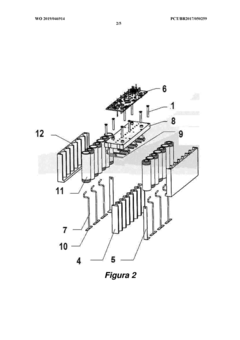

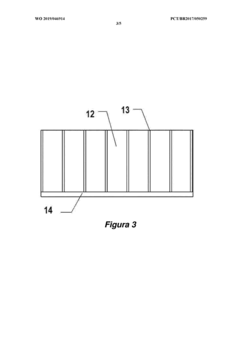

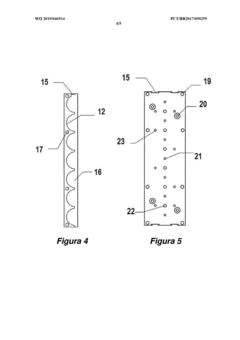

Modular battery for a temperature management and monitoring system

PatentWO2019046914A1

Innovation

- A modular battery system with a mechanical arrangement of lithium-ion cells connected to a semiconductor device for charge management, featuring a thermal management solution through convection and conduction cooling, and an integrated BMS for voltage and temperature monitoring, allowing for scalable configurations and individual cell charging.

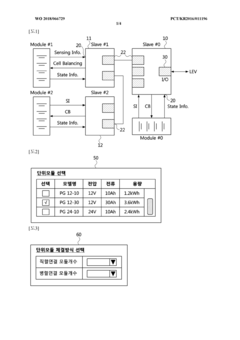

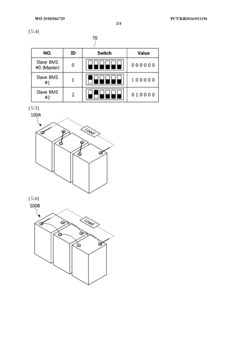

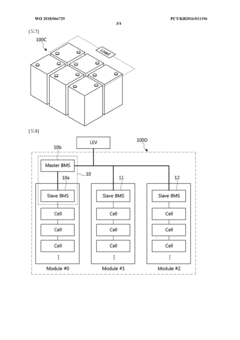

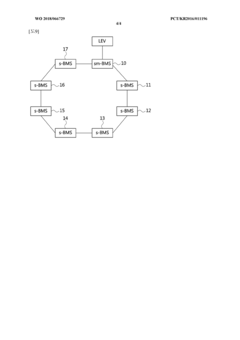

Battery management system and battery module assembly comprising same

PatentWO2018066729A1

Innovation

- A battery management system with an integrated board structure that includes a sub-BMS circuit, a main BMS circuit, and communication ports, allowing for flexible hierarchy and communication method settings through a user interface, enabling easy management and connection of multiple battery modules in series, parallel, or series-parallel configurations.

Regulatory Compliance

The transition to modular Battery Management Systems (BMS) in the automotive and energy storage sectors brings forth significant regulatory compliance challenges and considerations. As these systems become more prevalent, manufacturers and operators must navigate a complex landscape of regulations to ensure safety, performance, and environmental standards are met.

One of the primary regulatory concerns for modular BMS is safety certification. Regulatory bodies such as the United Nations Economic Commission for Europe (UNECE) and the National Highway Traffic Safety Administration (NHTSA) have established stringent safety standards for electric vehicle batteries. Modular BMS must demonstrate compliance with these standards, including thermal management, electrical safety, and crash protection requirements.

Environmental regulations also play a crucial role in the adoption of modular BMS. The European Union's Battery Directive and similar regulations in other regions mandate specific requirements for battery recycling and disposal. Modular BMS designs must incorporate features that facilitate easy disassembly and recycling of individual modules, aligning with circular economy principles and extended producer responsibility.

Electromagnetic compatibility (EMC) regulations present another compliance challenge for modular BMS. As these systems often involve high-frequency switching and complex electronic components, they must adhere to EMC standards to prevent interference with other vehicle systems and external devices. Manufacturers need to conduct extensive testing and implement appropriate shielding measures to ensure compliance.

Data privacy and cybersecurity regulations are increasingly relevant to modular BMS, especially as these systems become more connected and integrated with vehicle telematics. Regulations such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States impose strict requirements on data collection, storage, and transmission. Modular BMS designs must incorporate robust cybersecurity measures and data protection protocols to comply with these regulations.

The global nature of the automotive and energy storage markets necessitates compliance with diverse regional regulations. Manufacturers must navigate varying standards across different countries and regions, which can impact the design and implementation of modular BMS. This regulatory diversity often requires the development of adaptable systems that can be easily modified to meet specific regional requirements.

As the technology evolves, regulatory frameworks are also adapting to address the unique challenges posed by modular BMS. Industry stakeholders are actively engaging with regulatory bodies to shape future standards and ensure that regulations keep pace with technological advancements. This collaborative approach is essential for creating a regulatory environment that promotes innovation while maintaining high safety and performance standards.

One of the primary regulatory concerns for modular BMS is safety certification. Regulatory bodies such as the United Nations Economic Commission for Europe (UNECE) and the National Highway Traffic Safety Administration (NHTSA) have established stringent safety standards for electric vehicle batteries. Modular BMS must demonstrate compliance with these standards, including thermal management, electrical safety, and crash protection requirements.

Environmental regulations also play a crucial role in the adoption of modular BMS. The European Union's Battery Directive and similar regulations in other regions mandate specific requirements for battery recycling and disposal. Modular BMS designs must incorporate features that facilitate easy disassembly and recycling of individual modules, aligning with circular economy principles and extended producer responsibility.

Electromagnetic compatibility (EMC) regulations present another compliance challenge for modular BMS. As these systems often involve high-frequency switching and complex electronic components, they must adhere to EMC standards to prevent interference with other vehicle systems and external devices. Manufacturers need to conduct extensive testing and implement appropriate shielding measures to ensure compliance.

Data privacy and cybersecurity regulations are increasingly relevant to modular BMS, especially as these systems become more connected and integrated with vehicle telematics. Regulations such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States impose strict requirements on data collection, storage, and transmission. Modular BMS designs must incorporate robust cybersecurity measures and data protection protocols to comply with these regulations.

The global nature of the automotive and energy storage markets necessitates compliance with diverse regional regulations. Manufacturers must navigate varying standards across different countries and regions, which can impact the design and implementation of modular BMS. This regulatory diversity often requires the development of adaptable systems that can be easily modified to meet specific regional requirements.

As the technology evolves, regulatory frameworks are also adapting to address the unique challenges posed by modular BMS. Industry stakeholders are actively engaging with regulatory bodies to shape future standards and ensure that regulations keep pace with technological advancements. This collaborative approach is essential for creating a regulatory environment that promotes innovation while maintaining high safety and performance standards.

Cost-Benefit Analysis

The transition to modular battery management systems (BMS) presents a complex cost-benefit scenario for manufacturers and end-users alike. Initial implementation costs can be substantial, encompassing hardware redesign, software development, and production line modifications. These upfront expenses may deter some companies from immediate adoption. However, the long-term financial benefits often outweigh these initial investments.

Modular BMS offers significant cost savings in maintenance and repairs. Traditional integrated systems often require complete replacement when a single component fails, whereas modular designs allow for targeted component replacement. This approach reduces downtime and replacement costs, particularly beneficial for large-scale energy storage systems and electric vehicle fleets.

Scalability is another key economic advantage of modular BMS. As battery technology evolves, modular systems can be more easily upgraded or expanded without necessitating a complete system overhaul. This flexibility allows companies to adapt to changing market demands and technological advancements more cost-effectively.

Energy efficiency improvements associated with modular BMS contribute to operational cost reductions. Advanced monitoring and control capabilities enable more precise battery management, extending battery life and optimizing performance. These factors lead to decreased energy consumption and lower long-term operational expenses.

From a manufacturing perspective, modular BMS can streamline production processes. Standardized modules can be mass-produced, potentially reducing per-unit costs and improving quality control. This standardization also simplifies inventory management and can lead to economies of scale in production.

The enhanced data collection and analysis capabilities of modular BMS provide valuable insights for product development and customer service. This data-driven approach can lead to more efficient R&D processes, faster problem resolution, and improved customer satisfaction, indirectly contributing to cost savings and revenue growth.

While the benefits are substantial, it's crucial to consider potential drawbacks. The complexity of modular systems may require additional training for maintenance personnel and could potentially increase the risk of compatibility issues between modules. These factors should be weighed against the long-term advantages when conducting a comprehensive cost-benefit analysis.

Modular BMS offers significant cost savings in maintenance and repairs. Traditional integrated systems often require complete replacement when a single component fails, whereas modular designs allow for targeted component replacement. This approach reduces downtime and replacement costs, particularly beneficial for large-scale energy storage systems and electric vehicle fleets.

Scalability is another key economic advantage of modular BMS. As battery technology evolves, modular systems can be more easily upgraded or expanded without necessitating a complete system overhaul. This flexibility allows companies to adapt to changing market demands and technological advancements more cost-effectively.

Energy efficiency improvements associated with modular BMS contribute to operational cost reductions. Advanced monitoring and control capabilities enable more precise battery management, extending battery life and optimizing performance. These factors lead to decreased energy consumption and lower long-term operational expenses.

From a manufacturing perspective, modular BMS can streamline production processes. Standardized modules can be mass-produced, potentially reducing per-unit costs and improving quality control. This standardization also simplifies inventory management and can lead to economies of scale in production.

The enhanced data collection and analysis capabilities of modular BMS provide valuable insights for product development and customer service. This data-driven approach can lead to more efficient R&D processes, faster problem resolution, and improved customer satisfaction, indirectly contributing to cost savings and revenue growth.

While the benefits are substantial, it's crucial to consider potential drawbacks. The complexity of modular systems may require additional training for maintenance personnel and could potentially increase the risk of compatibility issues between modules. These factors should be weighed against the long-term advantages when conducting a comprehensive cost-benefit analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!