V8 Engine Design: Impact on Vehicle Dynamics

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Design Objectives

The V8 engine has been a cornerstone of automotive engineering since its inception in the early 20th century. Its evolution has been driven by the constant pursuit of increased power, improved efficiency, and enhanced performance. The V8 configuration, with its two banks of four cylinders arranged in a V-shape, has proven to be a versatile and enduring design, capable of meeting diverse automotive needs across various vehicle segments.

The development of V8 engines has been marked by several key milestones. Early V8s were primarily focused on raw power output, with little regard for fuel efficiency or emissions. As environmental concerns grew and fuel prices fluctuated, engine designers shifted their focus towards creating more efficient V8s without sacrificing performance. This led to innovations such as variable valve timing, direct fuel injection, and cylinder deactivation technologies.

In recent years, the trend towards downsizing and turbocharging has significantly impacted V8 engine design. Many manufacturers have reduced engine displacement while implementing forced induction to maintain or even increase power output. This approach has allowed V8 engines to remain relevant in an era of increasingly stringent emissions regulations and fuel economy standards.

The objectives of modern V8 engine design are multifaceted, balancing performance, efficiency, and environmental considerations. Engineers strive to maximize power density, aiming for higher specific output (horsepower per liter) while minimizing engine weight and size. Simultaneously, there is a push to reduce friction losses and improve thermal efficiency to enhance fuel economy and reduce emissions.

Another critical design objective is the optimization of torque delivery across a wide range of engine speeds. This is particularly important for vehicle dynamics, as it directly influences acceleration, towing capacity, and overall drivability. Advanced engine management systems and variable geometry turbochargers are employed to achieve a broad, flat torque curve that enhances vehicle responsiveness and performance.

Noise, vibration, and harshness (NVH) characteristics are also key considerations in V8 engine design. Engineers must balance the desire for a powerful, emotive engine sound with the need for passenger comfort and regulatory compliance. This has led to the development of sophisticated engine mounting systems, active noise cancellation technologies, and carefully tuned exhaust systems.

As the automotive industry moves towards electrification, the role of V8 engines is evolving. Some manufacturers are exploring hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and efficiency. This approach aims to preserve the distinctive character of V8 engines while meeting future emissions targets and consumer expectations for sustainable mobility solutions.

The development of V8 engines has been marked by several key milestones. Early V8s were primarily focused on raw power output, with little regard for fuel efficiency or emissions. As environmental concerns grew and fuel prices fluctuated, engine designers shifted their focus towards creating more efficient V8s without sacrificing performance. This led to innovations such as variable valve timing, direct fuel injection, and cylinder deactivation technologies.

In recent years, the trend towards downsizing and turbocharging has significantly impacted V8 engine design. Many manufacturers have reduced engine displacement while implementing forced induction to maintain or even increase power output. This approach has allowed V8 engines to remain relevant in an era of increasingly stringent emissions regulations and fuel economy standards.

The objectives of modern V8 engine design are multifaceted, balancing performance, efficiency, and environmental considerations. Engineers strive to maximize power density, aiming for higher specific output (horsepower per liter) while minimizing engine weight and size. Simultaneously, there is a push to reduce friction losses and improve thermal efficiency to enhance fuel economy and reduce emissions.

Another critical design objective is the optimization of torque delivery across a wide range of engine speeds. This is particularly important for vehicle dynamics, as it directly influences acceleration, towing capacity, and overall drivability. Advanced engine management systems and variable geometry turbochargers are employed to achieve a broad, flat torque curve that enhances vehicle responsiveness and performance.

Noise, vibration, and harshness (NVH) characteristics are also key considerations in V8 engine design. Engineers must balance the desire for a powerful, emotive engine sound with the need for passenger comfort and regulatory compliance. This has led to the development of sophisticated engine mounting systems, active noise cancellation technologies, and carefully tuned exhaust systems.

As the automotive industry moves towards electrification, the role of V8 engines is evolving. Some manufacturers are exploring hybrid V8 powertrains, combining traditional internal combustion with electric motors to boost performance and efficiency. This approach aims to preserve the distinctive character of V8 engines while meeting future emissions targets and consumer expectations for sustainable mobility solutions.

Market Analysis for V8-Powered Vehicles

The market for V8-powered vehicles has undergone significant shifts in recent years, driven by changing consumer preferences, environmental regulations, and technological advancements. Despite the growing trend towards electrification and downsizing, V8 engines continue to maintain a strong presence in specific market segments, particularly in high-performance vehicles, luxury cars, and certain truck categories.

In the performance car segment, V8 engines remain highly sought after by enthusiasts and collectors. Brands like Ferrari, Lamborghini, and Aston Martin continue to offer V8 options in their flagship models, catering to customers who prioritize power, sound, and driving experience. The market for these vehicles, while niche, remains robust, with steady demand from affluent buyers and collectors.

The luxury car market also maintains a significant demand for V8-powered vehicles. Brands such as Mercedes-Benz, BMW, and Audi offer V8 engines in their high-end models, appealing to customers who value smooth power delivery and prestige. However, this segment has seen increased competition from high-output six-cylinder engines and hybrid powertrains, which offer comparable performance with improved fuel efficiency.

In the truck and SUV market, V8 engines continue to play a crucial role, particularly in full-size pickup trucks and large SUVs. These vehicles often require high towing capacities and payload capabilities, which V8 engines are well-suited to provide. Major manufacturers like Ford, General Motors, and Dodge continue to offer V8 options in their truck lineups, catering to both commercial and recreational users.

The market for V8-powered vehicles faces challenges from increasingly stringent emissions regulations and fuel economy standards. This has led to a decline in V8 offerings in mid-size sedans and entry-level luxury vehicles, where manufacturers are shifting towards turbocharged four and six-cylinder engines. However, advancements in engine technology, such as cylinder deactivation and direct injection, have allowed V8 engines to remain competitive in terms of efficiency and emissions in their core market segments.

Looking ahead, the market for V8-powered vehicles is expected to evolve further. While the overall volume may decrease, V8 engines are likely to maintain their position in specialized applications where their unique characteristics are highly valued. This includes high-performance sports cars, luxury flagships, and heavy-duty trucks. Additionally, there is potential for V8 engines to adapt to future regulations through hybridization or alternative fuel technologies, allowing them to continue serving their dedicated market segments while meeting environmental requirements.

In the performance car segment, V8 engines remain highly sought after by enthusiasts and collectors. Brands like Ferrari, Lamborghini, and Aston Martin continue to offer V8 options in their flagship models, catering to customers who prioritize power, sound, and driving experience. The market for these vehicles, while niche, remains robust, with steady demand from affluent buyers and collectors.

The luxury car market also maintains a significant demand for V8-powered vehicles. Brands such as Mercedes-Benz, BMW, and Audi offer V8 engines in their high-end models, appealing to customers who value smooth power delivery and prestige. However, this segment has seen increased competition from high-output six-cylinder engines and hybrid powertrains, which offer comparable performance with improved fuel efficiency.

In the truck and SUV market, V8 engines continue to play a crucial role, particularly in full-size pickup trucks and large SUVs. These vehicles often require high towing capacities and payload capabilities, which V8 engines are well-suited to provide. Major manufacturers like Ford, General Motors, and Dodge continue to offer V8 options in their truck lineups, catering to both commercial and recreational users.

The market for V8-powered vehicles faces challenges from increasingly stringent emissions regulations and fuel economy standards. This has led to a decline in V8 offerings in mid-size sedans and entry-level luxury vehicles, where manufacturers are shifting towards turbocharged four and six-cylinder engines. However, advancements in engine technology, such as cylinder deactivation and direct injection, have allowed V8 engines to remain competitive in terms of efficiency and emissions in their core market segments.

Looking ahead, the market for V8-powered vehicles is expected to evolve further. While the overall volume may decrease, V8 engines are likely to maintain their position in specialized applications where their unique characteristics are highly valued. This includes high-performance sports cars, luxury flagships, and heavy-duty trucks. Additionally, there is potential for V8 engines to adapt to future regulations through hybridization or alternative fuel technologies, allowing them to continue serving their dedicated market segments while meeting environmental requirements.

Current V8 Technology and Engineering Challenges

The current state of V8 engine technology represents a pinnacle of automotive engineering, balancing power, efficiency, and performance. Modern V8 engines typically feature advanced materials, precision manufacturing techniques, and sophisticated electronic control systems. These engines often incorporate direct fuel injection, variable valve timing, and cylinder deactivation technologies to optimize performance and fuel economy.

However, V8 engines face significant engineering challenges in the contemporary automotive landscape. One of the primary concerns is meeting increasingly stringent emissions regulations while maintaining the power output and driving characteristics that V8 enthusiasts expect. This has led to the development of complex exhaust after-treatment systems and the exploration of hybrid technologies to supplement V8 powertrains.

Another major challenge is the ongoing pursuit of improved fuel efficiency. While V8 engines have made substantial gains in this area, they still lag behind smaller displacement engines in terms of overall fuel economy. Engineers are constantly working to reduce internal friction, improve thermal management, and optimize combustion processes to extract maximum efficiency from these large displacement engines.

The impact of V8 engines on vehicle dynamics presents both opportunities and challenges. The substantial weight of these engines, typically positioned at the front of the vehicle, can affect weight distribution and handling characteristics. This has led to innovative solutions in chassis design and the use of lightweight materials to counterbalance the engine's mass and maintain optimal vehicle dynamics.

Noise, vibration, and harshness (NVH) management is another critical area of focus for V8 engine designers. The inherent balance of the V8 configuration provides a good starting point, but achieving the refined operation expected in luxury vehicles requires advanced isolation techniques and precise manufacturing tolerances.

As the automotive industry shifts towards electrification, V8 engine designers face the challenge of remaining relevant in a changing market. This has spurred research into integrating V8 engines with electric powertrains to create high-performance hybrid systems that can deliver both the emotional appeal of a V8 and the efficiency benefits of electrification.

The packaging of V8 engines in modern vehicle designs also presents challenges, particularly as aerodynamics and pedestrian safety regulations influence vehicle shapes. Engineers must work closely with vehicle designers to ensure that V8 engines can be accommodated within these constraints without compromising performance or safety.

However, V8 engines face significant engineering challenges in the contemporary automotive landscape. One of the primary concerns is meeting increasingly stringent emissions regulations while maintaining the power output and driving characteristics that V8 enthusiasts expect. This has led to the development of complex exhaust after-treatment systems and the exploration of hybrid technologies to supplement V8 powertrains.

Another major challenge is the ongoing pursuit of improved fuel efficiency. While V8 engines have made substantial gains in this area, they still lag behind smaller displacement engines in terms of overall fuel economy. Engineers are constantly working to reduce internal friction, improve thermal management, and optimize combustion processes to extract maximum efficiency from these large displacement engines.

The impact of V8 engines on vehicle dynamics presents both opportunities and challenges. The substantial weight of these engines, typically positioned at the front of the vehicle, can affect weight distribution and handling characteristics. This has led to innovative solutions in chassis design and the use of lightweight materials to counterbalance the engine's mass and maintain optimal vehicle dynamics.

Noise, vibration, and harshness (NVH) management is another critical area of focus for V8 engine designers. The inherent balance of the V8 configuration provides a good starting point, but achieving the refined operation expected in luxury vehicles requires advanced isolation techniques and precise manufacturing tolerances.

As the automotive industry shifts towards electrification, V8 engine designers face the challenge of remaining relevant in a changing market. This has spurred research into integrating V8 engines with electric powertrains to create high-performance hybrid systems that can deliver both the emotional appeal of a V8 and the efficiency benefits of electrification.

The packaging of V8 engines in modern vehicle designs also presents challenges, particularly as aerodynamics and pedestrian safety regulations influence vehicle shapes. Engineers must work closely with vehicle designers to ensure that V8 engines can be accommodated within these constraints without compromising performance or safety.

Contemporary V8 Engine Design Solutions

01 Engine performance optimization for vehicle dynamics

V8 engine performance is optimized to enhance vehicle dynamics. This includes adjusting engine parameters, improving fuel efficiency, and managing power output to achieve better overall vehicle performance and handling characteristics.- Engine performance optimization: V8 engine vehicle dynamics can be improved through various performance optimization techniques. These may include adjusting fuel injection timing, optimizing valve timing, and enhancing combustion efficiency. Such optimizations can lead to increased power output, improved fuel economy, and better overall vehicle performance.

- Vehicle stability control: Implementing advanced stability control systems specifically designed for V8 engine vehicles can significantly enhance their dynamics. These systems may incorporate sensors to monitor vehicle behavior, adjusting power distribution and braking to maintain stability during cornering, acceleration, and deceleration.

- Suspension and chassis tuning: Optimizing suspension systems and chassis design for V8 engine vehicles can greatly improve their dynamic performance. This may involve adjusting spring rates, damper settings, and implementing adaptive suspension technologies to balance comfort and handling characteristics across various driving conditions.

- Drivetrain and transmission enhancements: Improving drivetrain components and transmission systems can optimize power delivery in V8 engine vehicles. This may include developing advanced gearbox technologies, implementing torque vectoring systems, and enhancing driveshaft designs to minimize power loss and improve overall vehicle dynamics.

- Aerodynamic improvements: Enhancing the aerodynamic properties of V8 engine vehicles can significantly impact their dynamics at high speeds. This may involve optimizing body shapes, implementing active aerodynamic elements, and refining underbody designs to reduce drag and improve stability.

02 Suspension and chassis control systems for V8 vehicles

Advanced suspension and chassis control systems are developed specifically for V8-powered vehicles to improve stability, handling, and ride comfort. These systems may include adaptive damping, active roll control, and electronic stability control tailored for high-performance V8 engines.Expand Specific Solutions03 Drivetrain and transmission optimization for V8 engines

Specialized drivetrain and transmission systems are designed to handle the power and torque characteristics of V8 engines. This includes advanced gearbox designs, torque vectoring systems, and intelligent all-wheel-drive configurations to enhance traction and vehicle dynamics.Expand Specific Solutions04 Aerodynamic enhancements for V8-powered vehicles

Aerodynamic features are developed to improve the stability and performance of V8-powered vehicles at high speeds. This includes active aerodynamic elements, underbody designs, and airflow management systems to reduce drag and increase downforce.Expand Specific Solutions05 Vehicle dynamics control and driver assistance systems

Advanced control systems and driver assistance technologies are implemented to enhance the dynamics of V8-powered vehicles. These may include torque vectoring, dynamic stability control, and adaptive driving modes that adjust vehicle behavior based on driving conditions and driver input.Expand Specific Solutions

Major Manufacturers in V8 Engine Production

The V8 engine design's impact on vehicle dynamics represents a mature technology in the automotive industry, with a significant market presence and ongoing refinement. The competitive landscape is characterized by established players like Honda, Ford, Toyota, and BMW, who have extensively developed V8 engines for high-performance vehicles. These companies continue to innovate, focusing on improving power output, fuel efficiency, and emissions reduction. Emerging players such as Chery and Leapmotor are also entering the market, particularly in the context of electrification and hybrid powertrains. The technology's maturity suggests a shift towards integration with new propulsion systems rather than radical redesigns of the V8 concept itself.

Honda Motor Co., Ltd.

Technical Solution: Honda's V8 engine design focuses on optimizing vehicle dynamics through advanced technologies. Their Earth Dreams V8 engine incorporates direct injection, variable cylinder management, and a two-stage intake system[1]. This design allows for seamless transition between power and efficiency modes, enhancing overall vehicle performance. Honda's V8 engines typically feature a 90-degree V configuration, which provides natural balance and smooth operation[2]. The company has also implemented active engine mounts to minimize vibration transmission to the vehicle chassis, further improving ride quality and handling[3]. Honda's V8 engines often utilize lightweight materials such as aluminum alloys for the block and heads, contributing to a favorable power-to-weight ratio and improved vehicle agility[4].

Strengths: Excellent balance between power and efficiency, smooth operation, and advanced vibration control. Weaknesses: Limited application in Honda's predominantly four-cylinder lineup, potentially higher production costs compared to more common engine configurations.

Ford Global Technologies LLC

Technical Solution: Ford's V8 engine design philosophy emphasizes both performance and efficiency in relation to vehicle dynamics. Their Coyote V8 engine, used in various high-performance models, features dual overhead camshafts, variable camshaft timing, and high-flow cylinder heads[1]. Ford has implemented plasma transferred wire arc spray-bore technology in some V8 engines, reducing weight and improving heat dissipation[2]. The company's modular V8 design allows for flexibility in displacement and output, catering to different vehicle dynamics requirements across their lineup[3]. Ford's V8 engines often incorporate advanced electronic throttle control and variable valve timing systems, enabling precise power delivery and improved responsiveness[4]. In recent years, Ford has also explored cylinder deactivation technology in their V8 engines to enhance fuel efficiency without compromising performance when full power is needed[5].

Strengths: Versatile modular design, advanced manufacturing techniques for weight reduction, and strong performance characteristics. Weaknesses: Fuel efficiency challenges in some applications, potential complexity in maintenance due to advanced technologies.

Key Innovations in V8 Engine Technology

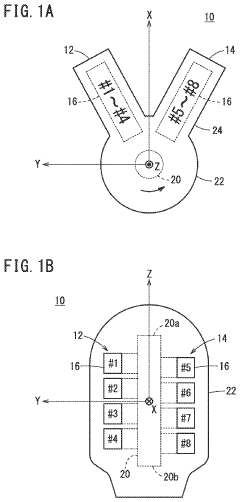

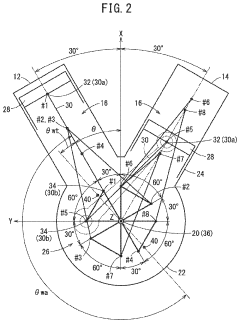

V8 engine

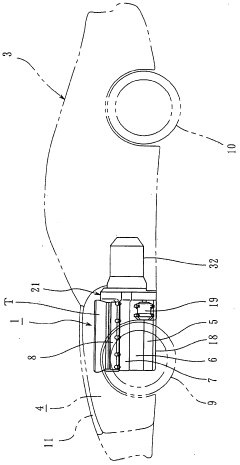

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

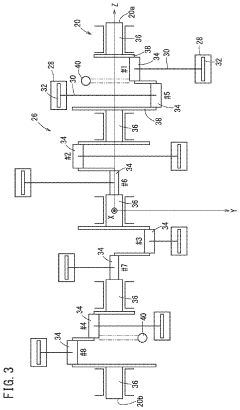

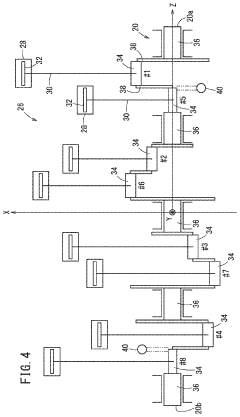

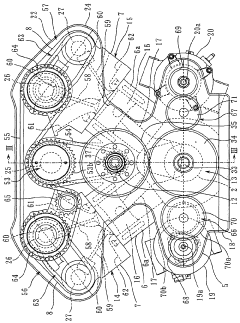

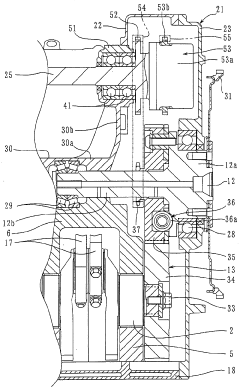

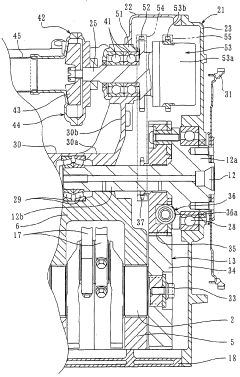

V-engine for vehicle

PatentWO2003074852A1

Innovation

- The V-type engine design incorporates auxiliary machines and transmission means on both sides of the crankshaft, with a dry sump lubrication system and strategically positioned output shafts and valve drive shafts to adjust the engine's center of gravity closer to the vehicle's center, allowing for improved power transmission and reduced height, while balancing weights for enhanced stability.

Environmental Regulations Impact on V8 Engines

Environmental regulations have significantly impacted the development and production of V8 engines in recent years. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers have been forced to adapt their V8 engine designs to meet these new regulations.

One of the primary challenges facing V8 engines is the need to reduce carbon dioxide (CO2) emissions. Many countries have implemented stringent CO2 emission targets for new vehicles, putting pressure on automakers to improve fuel efficiency and reduce overall emissions. This has led to the development of various technologies aimed at enhancing V8 engine efficiency, such as cylinder deactivation, direct fuel injection, and advanced turbocharging systems.

Cylinder deactivation, also known as variable displacement, allows V8 engines to operate on fewer cylinders during low-load conditions, effectively improving fuel economy. This technology has become increasingly common in modern V8 engines, helping manufacturers meet emissions targets while maintaining the power and performance associated with V8 configurations.

Another significant impact of environmental regulations on V8 engines is the widespread adoption of forced induction systems, particularly turbocharging. Turbochargers allow manufacturers to downsize engine displacement while maintaining or even increasing power output, resulting in improved fuel efficiency and reduced emissions. This trend has led to the development of smaller displacement V8 engines that can still deliver the performance expected from this engine configuration.

The implementation of start-stop technology has also become more prevalent in V8-powered vehicles as a result of environmental regulations. This system automatically shuts off the engine when the vehicle is stationary, reducing fuel consumption and emissions in urban driving conditions. While this technology presents challenges for V8 engines due to their higher inertia and fuel consumption during startup, manufacturers have developed sophisticated systems to mitigate these issues.

Exhaust gas aftertreatment systems have become increasingly complex and effective in response to tightening emissions regulations. Modern V8 engines often employ advanced catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems to reduce harmful emissions. These technologies have allowed V8 engines to meet stringent emissions standards, albeit at the cost of increased complexity and manufacturing expenses.

The push for electrification has also influenced V8 engine development, with many manufacturers incorporating hybrid systems into their V8-powered vehicles. These mild-hybrid or full-hybrid powertrains combine the traditional V8 engine with electric motors, allowing for improved fuel efficiency and reduced emissions while maintaining the characteristic performance of V8 engines.

As environmental regulations continue to evolve, the future of V8 engines remains uncertain. While some manufacturers are phasing out V8 engines in favor of smaller, more efficient powertrains, others are investing in advanced technologies to ensure the continued viability of V8 engines in an increasingly environmentally conscious automotive landscape.

One of the primary challenges facing V8 engines is the need to reduce carbon dioxide (CO2) emissions. Many countries have implemented stringent CO2 emission targets for new vehicles, putting pressure on automakers to improve fuel efficiency and reduce overall emissions. This has led to the development of various technologies aimed at enhancing V8 engine efficiency, such as cylinder deactivation, direct fuel injection, and advanced turbocharging systems.

Cylinder deactivation, also known as variable displacement, allows V8 engines to operate on fewer cylinders during low-load conditions, effectively improving fuel economy. This technology has become increasingly common in modern V8 engines, helping manufacturers meet emissions targets while maintaining the power and performance associated with V8 configurations.

Another significant impact of environmental regulations on V8 engines is the widespread adoption of forced induction systems, particularly turbocharging. Turbochargers allow manufacturers to downsize engine displacement while maintaining or even increasing power output, resulting in improved fuel efficiency and reduced emissions. This trend has led to the development of smaller displacement V8 engines that can still deliver the performance expected from this engine configuration.

The implementation of start-stop technology has also become more prevalent in V8-powered vehicles as a result of environmental regulations. This system automatically shuts off the engine when the vehicle is stationary, reducing fuel consumption and emissions in urban driving conditions. While this technology presents challenges for V8 engines due to their higher inertia and fuel consumption during startup, manufacturers have developed sophisticated systems to mitigate these issues.

Exhaust gas aftertreatment systems have become increasingly complex and effective in response to tightening emissions regulations. Modern V8 engines often employ advanced catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems to reduce harmful emissions. These technologies have allowed V8 engines to meet stringent emissions standards, albeit at the cost of increased complexity and manufacturing expenses.

The push for electrification has also influenced V8 engine development, with many manufacturers incorporating hybrid systems into their V8-powered vehicles. These mild-hybrid or full-hybrid powertrains combine the traditional V8 engine with electric motors, allowing for improved fuel efficiency and reduced emissions while maintaining the characteristic performance of V8 engines.

As environmental regulations continue to evolve, the future of V8 engines remains uncertain. While some manufacturers are phasing out V8 engines in favor of smaller, more efficient powertrains, others are investing in advanced technologies to ensure the continued viability of V8 engines in an increasingly environmentally conscious automotive landscape.

V8 Engine Integration with Vehicle Dynamics Systems

The integration of V8 engines with vehicle dynamics systems represents a critical aspect of modern automotive engineering. This integration process involves a complex interplay between the engine's power output, weight distribution, and the vehicle's overall handling characteristics. V8 engines, known for their high power output and distinctive sound, significantly influence a vehicle's dynamic behavior.

One of the primary considerations in this integration is the engine's placement within the vehicle chassis. Front-engine, mid-engine, and rear-engine configurations each present unique challenges and advantages for vehicle dynamics. Front-engine V8 layouts, common in many performance cars and luxury sedans, offer good weight distribution and traction but can lead to understeer in high-performance driving situations. Mid-engine V8 configurations, often seen in supercars, provide optimal weight distribution and handling balance but pose challenges in terms of packaging and heat management.

The weight of V8 engines is another crucial factor affecting vehicle dynamics. Modern V8 designs often incorporate lightweight materials such as aluminum alloys to reduce overall mass. This weight reduction not only improves the power-to-weight ratio but also enhances the vehicle's agility and responsiveness. Advanced manufacturing techniques, such as thin-wall casting, further contribute to weight reduction without compromising structural integrity.

Power delivery characteristics of V8 engines play a significant role in vehicle dynamics. The smooth power delivery and high torque output of V8s require sophisticated traction control and stability management systems. These systems must be carefully calibrated to harness the engine's power while maintaining vehicle stability across various driving conditions. Variable valve timing and cylinder deactivation technologies in modern V8s allow for more precise control over power output, further enhancing the integration with vehicle dynamics systems.

Suspension tuning is another critical aspect of V8 engine integration. The substantial power and torque produced by V8 engines necessitate robust suspension systems capable of managing weight transfer during acceleration, braking, and cornering. Adaptive suspension systems, which can adjust damping rates in real-time, are often employed to optimize ride quality and handling performance across different driving modes and conditions.

The integration process also extends to the drivetrain components. Transmission systems, particularly in high-performance applications, must be engineered to handle the V8's power output while providing smooth and responsive gear changes. Advanced dual-clutch transmissions and intelligent all-wheel-drive systems are frequently paired with V8 engines to optimize power distribution and enhance vehicle dynamics.

Aerodynamics play a crucial role in V8-powered vehicles, especially at high speeds. The integration of V8 engines often requires careful consideration of airflow management, both for engine cooling and overall vehicle stability. Features such as active aerodynamic elements and underbody diffusers are commonly employed to enhance downforce and stability without compromising the engine's cooling requirements.

One of the primary considerations in this integration is the engine's placement within the vehicle chassis. Front-engine, mid-engine, and rear-engine configurations each present unique challenges and advantages for vehicle dynamics. Front-engine V8 layouts, common in many performance cars and luxury sedans, offer good weight distribution and traction but can lead to understeer in high-performance driving situations. Mid-engine V8 configurations, often seen in supercars, provide optimal weight distribution and handling balance but pose challenges in terms of packaging and heat management.

The weight of V8 engines is another crucial factor affecting vehicle dynamics. Modern V8 designs often incorporate lightweight materials such as aluminum alloys to reduce overall mass. This weight reduction not only improves the power-to-weight ratio but also enhances the vehicle's agility and responsiveness. Advanced manufacturing techniques, such as thin-wall casting, further contribute to weight reduction without compromising structural integrity.

Power delivery characteristics of V8 engines play a significant role in vehicle dynamics. The smooth power delivery and high torque output of V8s require sophisticated traction control and stability management systems. These systems must be carefully calibrated to harness the engine's power while maintaining vehicle stability across various driving conditions. Variable valve timing and cylinder deactivation technologies in modern V8s allow for more precise control over power output, further enhancing the integration with vehicle dynamics systems.

Suspension tuning is another critical aspect of V8 engine integration. The substantial power and torque produced by V8 engines necessitate robust suspension systems capable of managing weight transfer during acceleration, braking, and cornering. Adaptive suspension systems, which can adjust damping rates in real-time, are often employed to optimize ride quality and handling performance across different driving modes and conditions.

The integration process also extends to the drivetrain components. Transmission systems, particularly in high-performance applications, must be engineered to handle the V8's power output while providing smooth and responsive gear changes. Advanced dual-clutch transmissions and intelligent all-wheel-drive systems are frequently paired with V8 engines to optimize power distribution and enhance vehicle dynamics.

Aerodynamics play a crucial role in V8-powered vehicles, especially at high speeds. The integration of V8 engines often requires careful consideration of airflow management, both for engine cooling and overall vehicle stability. Features such as active aerodynamic elements and underbody diffusers are commonly employed to enhance downforce and stability without compromising the engine's cooling requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!