V8 Engine Impact on Lowering Maintenance Costs

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a revolutionary powerplant in automotive history, has undergone significant evolution since its inception. This technological marvel has consistently aimed to enhance performance while simultaneously reducing maintenance costs. The journey of V8 engine development reflects a continuous pursuit of efficiency, power, and reliability.

Initially introduced in the early 20th century, V8 engines quickly gained popularity due to their compact design and impressive power output. As automotive technology progressed, engineers focused on refining the V8 to meet changing market demands and regulatory requirements. The primary objectives driving V8 engine evolution have been increased fuel efficiency, reduced emissions, improved durability, and lower maintenance costs.

One of the key milestones in V8 engine development was the introduction of overhead valve (OHV) designs, which significantly improved engine breathing and overall efficiency. This advancement paved the way for higher compression ratios and increased power output while maintaining reasonable fuel consumption. Subsequently, the adoption of fuel injection systems further enhanced performance and reduced maintenance requirements by eliminating carburetor-related issues.

The integration of electronic engine management systems marked another crucial step in V8 evolution. These sophisticated control units optimized fuel delivery, ignition timing, and other critical parameters in real-time, resulting in improved efficiency and reduced wear on engine components. This technological leap not only boosted performance but also extended service intervals, directly contributing to lower maintenance costs.

Material science advancements have played a pivotal role in enhancing V8 engine durability and reducing maintenance needs. The use of lightweight alloys, such as aluminum, for engine blocks and heads has led to improved heat dissipation and reduced overall weight. Additionally, the development of more robust internal components, including forged crankshafts and connecting rods, has significantly increased engine longevity and reliability.

Recent years have seen a focus on variable valve timing and lift systems in V8 engines. These innovations allow for optimized engine performance across a wide range of operating conditions, resulting in improved fuel efficiency and reduced emissions. Furthermore, the implementation of cylinder deactivation technology enables V8 engines to operate on fewer cylinders during light load conditions, substantially reducing fuel consumption without compromising power availability when needed.

The ongoing evolution of V8 engines continues to prioritize the reduction of maintenance costs. Modern designs incorporate features such as extended-life spark plugs, long-lasting synthetic oils, and improved cooling systems. These advancements have significantly increased service intervals and reduced the frequency of routine maintenance tasks, directly impacting the overall cost of ownership for V8-powered vehicles.

Initially introduced in the early 20th century, V8 engines quickly gained popularity due to their compact design and impressive power output. As automotive technology progressed, engineers focused on refining the V8 to meet changing market demands and regulatory requirements. The primary objectives driving V8 engine evolution have been increased fuel efficiency, reduced emissions, improved durability, and lower maintenance costs.

One of the key milestones in V8 engine development was the introduction of overhead valve (OHV) designs, which significantly improved engine breathing and overall efficiency. This advancement paved the way for higher compression ratios and increased power output while maintaining reasonable fuel consumption. Subsequently, the adoption of fuel injection systems further enhanced performance and reduced maintenance requirements by eliminating carburetor-related issues.

The integration of electronic engine management systems marked another crucial step in V8 evolution. These sophisticated control units optimized fuel delivery, ignition timing, and other critical parameters in real-time, resulting in improved efficiency and reduced wear on engine components. This technological leap not only boosted performance but also extended service intervals, directly contributing to lower maintenance costs.

Material science advancements have played a pivotal role in enhancing V8 engine durability and reducing maintenance needs. The use of lightweight alloys, such as aluminum, for engine blocks and heads has led to improved heat dissipation and reduced overall weight. Additionally, the development of more robust internal components, including forged crankshafts and connecting rods, has significantly increased engine longevity and reliability.

Recent years have seen a focus on variable valve timing and lift systems in V8 engines. These innovations allow for optimized engine performance across a wide range of operating conditions, resulting in improved fuel efficiency and reduced emissions. Furthermore, the implementation of cylinder deactivation technology enables V8 engines to operate on fewer cylinders during light load conditions, substantially reducing fuel consumption without compromising power availability when needed.

The ongoing evolution of V8 engines continues to prioritize the reduction of maintenance costs. Modern designs incorporate features such as extended-life spark plugs, long-lasting synthetic oils, and improved cooling systems. These advancements have significantly increased service intervals and reduced the frequency of routine maintenance tasks, directly impacting the overall cost of ownership for V8-powered vehicles.

Market Demand Analysis for V8 Engines

The market demand for V8 engines has been evolving significantly in recent years, driven by a complex interplay of factors including environmental regulations, fuel efficiency concerns, and changing consumer preferences. Despite the general trend towards downsizing and electrification in the automotive industry, V8 engines continue to maintain a strong presence in certain market segments, particularly in luxury vehicles, high-performance sports cars, and heavy-duty trucks.

In the luxury vehicle segment, V8 engines remain a symbol of prestige and power. Brands such as Mercedes-Benz, BMW, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and status. The demand for these engines in luxury SUVs has been particularly resilient, as consumers seek vehicles that combine comfort with robust towing capabilities.

The sports car market continues to value V8 engines for their distinctive sound and performance characteristics. Iconic models from manufacturers like Ford, Chevrolet, and Dodge maintain strong sales figures, appealing to enthusiasts who appreciate the raw power and emotional connection associated with V8 powerplants.

In the commercial sector, V8 engines are still in high demand for heavy-duty trucks and large SUVs. These vehicles often require the torque and power output that V8 engines provide, especially for towing and hauling applications. The construction, agriculture, and logistics industries contribute significantly to this demand.

However, the market for V8 engines is not without challenges. Stringent emissions regulations in many countries have forced manufacturers to invest heavily in improving the efficiency and reducing the environmental impact of these engines. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, which aim to maintain performance while lowering fuel consumption and emissions.

The potential for lower maintenance costs associated with V8 engines has emerged as a key factor influencing market demand. As manufacturers develop more durable and efficient V8 designs, the total cost of ownership for vehicles equipped with these engines becomes more competitive. This aspect is particularly important for fleet operators and businesses that rely on vehicles for their operations.

Looking ahead, the market for V8 engines is expected to become more niche but remain stable in certain sectors. The focus on reducing maintenance costs through improved engineering and materials could help sustain demand, especially in markets where the infrastructure for alternative powertrains is still developing. Additionally, the emotional appeal and performance characteristics of V8 engines are likely to ensure a dedicated customer base for the foreseeable future.

In the luxury vehicle segment, V8 engines remain a symbol of prestige and power. Brands such as Mercedes-Benz, BMW, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and status. The demand for these engines in luxury SUVs has been particularly resilient, as consumers seek vehicles that combine comfort with robust towing capabilities.

The sports car market continues to value V8 engines for their distinctive sound and performance characteristics. Iconic models from manufacturers like Ford, Chevrolet, and Dodge maintain strong sales figures, appealing to enthusiasts who appreciate the raw power and emotional connection associated with V8 powerplants.

In the commercial sector, V8 engines are still in high demand for heavy-duty trucks and large SUVs. These vehicles often require the torque and power output that V8 engines provide, especially for towing and hauling applications. The construction, agriculture, and logistics industries contribute significantly to this demand.

However, the market for V8 engines is not without challenges. Stringent emissions regulations in many countries have forced manufacturers to invest heavily in improving the efficiency and reducing the environmental impact of these engines. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, which aim to maintain performance while lowering fuel consumption and emissions.

The potential for lower maintenance costs associated with V8 engines has emerged as a key factor influencing market demand. As manufacturers develop more durable and efficient V8 designs, the total cost of ownership for vehicles equipped with these engines becomes more competitive. This aspect is particularly important for fleet operators and businesses that rely on vehicles for their operations.

Looking ahead, the market for V8 engines is expected to become more niche but remain stable in certain sectors. The focus on reducing maintenance costs through improved engineering and materials could help sustain demand, especially in markets where the infrastructure for alternative powertrains is still developing. Additionally, the emotional appeal and performance characteristics of V8 engines are likely to ensure a dedicated customer base for the foreseeable future.

V8 Engine Technology Status and Challenges

The V8 engine, a pinnacle of automotive engineering, has undergone significant advancements in recent years. However, it still faces several challenges in terms of maintenance costs and overall efficiency. Currently, V8 engines are widely used in high-performance vehicles, luxury cars, and some trucks, offering impressive power and torque. The technology has evolved to incorporate direct fuel injection, variable valve timing, and cylinder deactivation, all aimed at improving fuel economy and reducing emissions.

One of the primary challenges facing V8 engines is the ongoing pressure to meet increasingly stringent emissions regulations. Manufacturers are constantly working to develop cleaner-burning V8 engines without sacrificing performance. This has led to the integration of complex emission control systems, which, while effective, can increase maintenance complexity and costs.

Another significant challenge is the push for improved fuel efficiency. Despite advancements, V8 engines are still generally less fuel-efficient than their smaller counterparts. This has prompted research into lightweight materials and advanced combustion techniques to enhance efficiency without compromising power output.

Maintenance costs remain a concern for V8 engine owners. The complexity of modern V8 engines, with their sophisticated electronic systems and precision components, often requires specialized knowledge and tools for servicing. This can lead to higher maintenance expenses compared to simpler engine configurations.

Reliability and durability are areas where V8 engines have made substantial progress, but there is still room for improvement. The high-stress nature of these powerful engines can lead to increased wear on certain components, potentially resulting in more frequent maintenance intervals or premature failures if not properly maintained.

The advent of electric and hybrid technologies poses a significant challenge to the future of V8 engines. As the automotive industry shifts towards electrification, there is increasing pressure to justify the continued development and use of V8 engines in mainstream vehicles. This has led to research into hybrid V8 systems that combine traditional internal combustion with electric motors to improve efficiency and reduce emissions.

Geographically, the development and production of V8 engines are concentrated in regions with a strong automotive industry presence, such as North America, Germany, and Japan. However, emerging markets like China are also becoming increasingly involved in V8 engine technology, particularly in the luxury and performance vehicle segments.

In conclusion, while V8 engines continue to offer unparalleled performance and prestige, they face significant challenges in terms of emissions, fuel efficiency, and maintenance costs. The future of V8 technology will likely depend on innovative solutions that address these challenges while preserving the power and character that enthusiasts cherish.

One of the primary challenges facing V8 engines is the ongoing pressure to meet increasingly stringent emissions regulations. Manufacturers are constantly working to develop cleaner-burning V8 engines without sacrificing performance. This has led to the integration of complex emission control systems, which, while effective, can increase maintenance complexity and costs.

Another significant challenge is the push for improved fuel efficiency. Despite advancements, V8 engines are still generally less fuel-efficient than their smaller counterparts. This has prompted research into lightweight materials and advanced combustion techniques to enhance efficiency without compromising power output.

Maintenance costs remain a concern for V8 engine owners. The complexity of modern V8 engines, with their sophisticated electronic systems and precision components, often requires specialized knowledge and tools for servicing. This can lead to higher maintenance expenses compared to simpler engine configurations.

Reliability and durability are areas where V8 engines have made substantial progress, but there is still room for improvement. The high-stress nature of these powerful engines can lead to increased wear on certain components, potentially resulting in more frequent maintenance intervals or premature failures if not properly maintained.

The advent of electric and hybrid technologies poses a significant challenge to the future of V8 engines. As the automotive industry shifts towards electrification, there is increasing pressure to justify the continued development and use of V8 engines in mainstream vehicles. This has led to research into hybrid V8 systems that combine traditional internal combustion with electric motors to improve efficiency and reduce emissions.

Geographically, the development and production of V8 engines are concentrated in regions with a strong automotive industry presence, such as North America, Germany, and Japan. However, emerging markets like China are also becoming increasingly involved in V8 engine technology, particularly in the luxury and performance vehicle segments.

In conclusion, while V8 engines continue to offer unparalleled performance and prestige, they face significant challenges in terms of emissions, fuel efficiency, and maintenance costs. The future of V8 technology will likely depend on innovative solutions that address these challenges while preserving the power and character that enthusiasts cherish.

Current V8 Engine Maintenance Solutions

01 Engine monitoring and diagnostics

Advanced monitoring systems and diagnostic tools are used to track V8 engine performance and predict maintenance needs. These systems can analyze engine data in real-time, detect potential issues early, and optimize maintenance schedules, potentially reducing overall maintenance costs.- Engine monitoring and diagnostics: Advanced monitoring systems and diagnostic tools are used to track V8 engine performance and predict maintenance needs. These systems can analyze various engine parameters in real-time, helping to identify potential issues before they become major problems. This proactive approach can significantly reduce maintenance costs by preventing unexpected breakdowns and optimizing service intervals.

- Improved lubrication systems: Enhanced lubrication systems are designed to extend the life of V8 engine components and reduce friction-related wear. These systems may include advanced oil filtration, precise oil distribution, and temperature management features. By maintaining optimal lubrication, these systems can help reduce maintenance frequency and costs associated with engine wear.

- Modular engine design: Modular V8 engine designs allow for easier maintenance and component replacement. This approach enables technicians to access and service specific parts of the engine without the need for extensive disassembly. The modular design can lead to reduced labor costs and shorter maintenance times, ultimately lowering overall maintenance expenses.

- Predictive maintenance scheduling: Implementing predictive maintenance scheduling systems for V8 engines can optimize service intervals based on actual usage and operating conditions. These systems use data analytics and machine learning algorithms to predict when maintenance is needed, avoiding unnecessary servicing and reducing overall maintenance costs while ensuring engine reliability.

- Advanced materials and coatings: The use of advanced materials and protective coatings in V8 engine components can significantly improve durability and reduce wear. These innovations may include ceramic coatings, high-strength alloys, and composite materials that can withstand higher temperatures and pressures. By extending component life and reducing the frequency of replacements, these advancements can lead to lower long-term maintenance costs.

02 Improved engine components and materials

Development of more durable and efficient engine components using advanced materials and manufacturing techniques. These improvements can extend the lifespan of engine parts, reduce wear and tear, and ultimately lower maintenance frequency and costs for V8 engines.Expand Specific Solutions03 Predictive maintenance strategies

Implementation of predictive maintenance strategies using artificial intelligence and machine learning algorithms. These approaches analyze historical data and current engine performance to predict when maintenance is needed, optimizing maintenance schedules and reducing unnecessary interventions.Expand Specific Solutions04 Cost-effective lubrication systems

Development of advanced lubrication systems and high-performance lubricants specifically designed for V8 engines. These innovations can improve engine efficiency, reduce friction, and extend the intervals between oil changes, contributing to lower maintenance costs.Expand Specific Solutions05 Modular engine design for easier maintenance

Implementation of modular engine designs that allow for easier access to components and simplified replacement of parts. This approach can reduce labor costs associated with maintenance and repairs, as well as minimize downtime for V8 engines.Expand Specific Solutions

Major V8 Engine Manufacturers and Competition

The V8 Engine's impact on lowering maintenance costs is at a mature stage in the automotive industry, with significant market size and technological advancements. Major players like Honda Motor Co., Ltd., Ford Global Technologies LLC, GM Global Technology Operations LLC, and Toyota Motor Corp. have extensively developed and implemented V8 engine technologies. These companies have invested in research and development to optimize V8 engines for improved efficiency and reduced maintenance requirements. The competitive landscape is characterized by ongoing innovation in materials, design, and manufacturing processes to further enhance V8 engine performance and longevity, ultimately contributing to lower maintenance costs for vehicle owners.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced V8 engine with cylinder deactivation technology, which can shut off four cylinders during light load conditions. This system, known as Dynamic Fuel Management, uses sophisticated algorithms to determine when to activate or deactivate cylinders based on driving conditions[1]. The engine also incorporates a high-pressure direct injection system and dual overhead camshafts with variable valve timing, optimizing fuel efficiency and performance[2]. Ford's V8 engines feature a compact graphite iron cylinder block, reducing weight while maintaining strength, contributing to overall vehicle efficiency[3].

Strengths: Improved fuel efficiency, reduced emissions, and maintained performance. Weaknesses: Increased complexity may lead to higher initial costs and potential reliability concerns in the long term.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced engine management systems for V8 engines, focusing on predictive maintenance and real-time monitoring. Their solution incorporates IoT sensors throughout the engine, collecting data on temperature, pressure, vibration, and oil quality. This data is processed using AI algorithms to predict potential failures and optimize maintenance schedules[9]. Hitachi's system also includes adaptive control strategies that adjust engine parameters based on driving conditions and component wear, maintaining optimal performance over time. The company has implemented a cloud-based analytics platform that allows for remote diagnostics and fleet-wide performance optimization[10].

Strengths: Advanced predictive maintenance capabilities, potential for significant reduction in unexpected downtime. Weaknesses: Requires substantial initial investment in sensors and data infrastructure.

Key Innovations in V8 Engine Maintenance

V8 engine

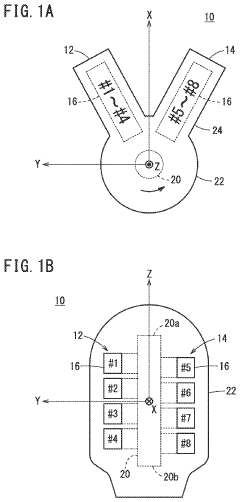

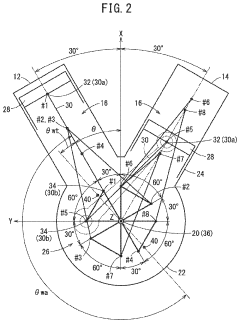

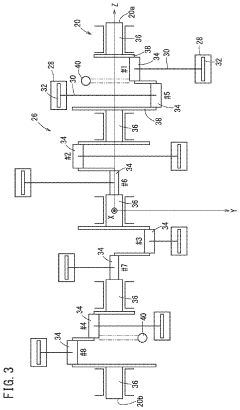

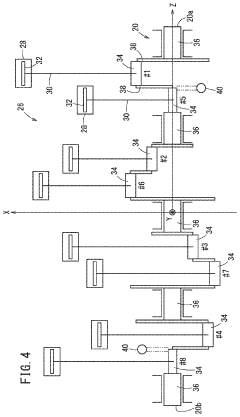

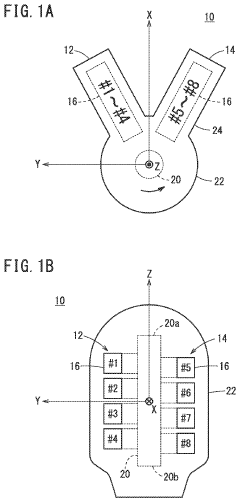

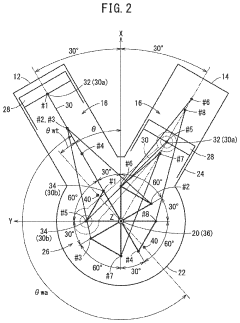

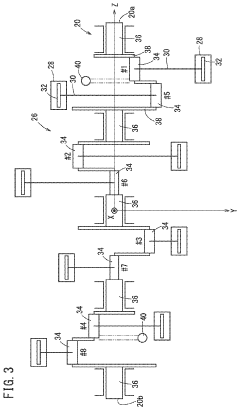

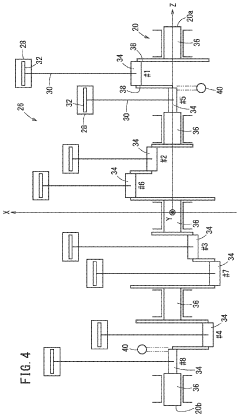

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Impact of V8 Engine Maintenance

The environmental impact of V8 engine maintenance is a critical consideration in the automotive industry, particularly as sustainability becomes increasingly important. V8 engines, known for their power and performance, have traditionally been associated with higher fuel consumption and emissions. However, advancements in maintenance practices and technologies have led to significant improvements in their environmental footprint.

One of the primary environmental concerns related to V8 engine maintenance is the disposal of used oil and other fluids. These substances can be harmful to ecosystems if not properly managed. Modern maintenance practices have implemented more efficient oil recycling programs, reducing the amount of waste oil entering the environment. Additionally, the development of synthetic oils has extended the intervals between oil changes, further decreasing the overall environmental impact.

The production and disposal of replacement parts also contribute to the environmental footprint of V8 engine maintenance. However, improved manufacturing techniques and materials have led to more durable components, reducing the frequency of replacements. Furthermore, the automotive industry has made strides in developing recyclable and biodegradable materials for various engine parts, minimizing waste and promoting a circular economy.

Emissions control systems play a crucial role in mitigating the environmental impact of V8 engines. Regular maintenance of these systems, including catalytic converters and oxygen sensors, ensures optimal performance and reduces harmful emissions. Advanced diagnostic tools have enabled more precise maintenance, allowing technicians to identify and address potential issues before they lead to increased emissions or decreased efficiency.

Energy consumption during maintenance procedures is another environmental consideration. The adoption of more energy-efficient tools and equipment in maintenance facilities has helped reduce the overall carbon footprint of V8 engine upkeep. Additionally, the implementation of lean maintenance practices has optimized workflows, reducing unnecessary energy expenditure and resource waste.

Water usage and contamination are also important factors in the environmental impact of V8 engine maintenance. Modern maintenance facilities have implemented water recycling systems and more efficient cleaning methods, significantly reducing water consumption and preventing contamination of local water sources. The use of environmentally friendly cleaning agents has further minimized the potential for harmful chemical runoff.

As the automotive industry continues to evolve, the environmental impact of V8 engine maintenance is likely to decrease further. The integration of predictive maintenance technologies, powered by artificial intelligence and machine learning, promises to optimize maintenance schedules and reduce unnecessary interventions. This approach not only minimizes resource consumption but also extends the lifespan of engine components, reducing the overall environmental impact of manufacturing and disposal.

One of the primary environmental concerns related to V8 engine maintenance is the disposal of used oil and other fluids. These substances can be harmful to ecosystems if not properly managed. Modern maintenance practices have implemented more efficient oil recycling programs, reducing the amount of waste oil entering the environment. Additionally, the development of synthetic oils has extended the intervals between oil changes, further decreasing the overall environmental impact.

The production and disposal of replacement parts also contribute to the environmental footprint of V8 engine maintenance. However, improved manufacturing techniques and materials have led to more durable components, reducing the frequency of replacements. Furthermore, the automotive industry has made strides in developing recyclable and biodegradable materials for various engine parts, minimizing waste and promoting a circular economy.

Emissions control systems play a crucial role in mitigating the environmental impact of V8 engines. Regular maintenance of these systems, including catalytic converters and oxygen sensors, ensures optimal performance and reduces harmful emissions. Advanced diagnostic tools have enabled more precise maintenance, allowing technicians to identify and address potential issues before they lead to increased emissions or decreased efficiency.

Energy consumption during maintenance procedures is another environmental consideration. The adoption of more energy-efficient tools and equipment in maintenance facilities has helped reduce the overall carbon footprint of V8 engine upkeep. Additionally, the implementation of lean maintenance practices has optimized workflows, reducing unnecessary energy expenditure and resource waste.

Water usage and contamination are also important factors in the environmental impact of V8 engine maintenance. Modern maintenance facilities have implemented water recycling systems and more efficient cleaning methods, significantly reducing water consumption and preventing contamination of local water sources. The use of environmentally friendly cleaning agents has further minimized the potential for harmful chemical runoff.

As the automotive industry continues to evolve, the environmental impact of V8 engine maintenance is likely to decrease further. The integration of predictive maintenance technologies, powered by artificial intelligence and machine learning, promises to optimize maintenance schedules and reduce unnecessary interventions. This approach not only minimizes resource consumption but also extends the lifespan of engine components, reducing the overall environmental impact of manufacturing and disposal.

Economic Analysis of V8 Engine Lifecycle Costs

The economic analysis of V8 engine lifecycle costs reveals significant potential for reducing maintenance expenses over the long term. V8 engines, known for their power and performance, have traditionally been associated with higher fuel consumption and maintenance costs. However, recent advancements in engine design and technology have led to improved efficiency and reliability, resulting in a more favorable economic outlook for V8 engines.

One of the primary factors contributing to lower maintenance costs is the enhanced durability of modern V8 engines. Manufacturers have implemented advanced materials and manufacturing techniques, such as precision casting and forging, which result in more robust engine components. This increased durability translates to fewer replacements and repairs over the engine's lifetime, significantly reducing maintenance expenses.

Improved lubrication systems play a crucial role in extending engine life and reducing maintenance needs. Modern V8 engines often feature advanced oil circulation systems that ensure better distribution of lubricants throughout the engine, minimizing wear and tear on critical components. Additionally, the use of synthetic oils with longer change intervals has further contributed to reduced maintenance frequency and costs.

The integration of advanced engine management systems has also positively impacted maintenance costs. These systems continuously monitor engine performance, adjusting parameters in real-time to optimize efficiency and prevent excessive wear. By maintaining optimal operating conditions, these systems help extend the life of engine components and reduce the likelihood of unexpected failures, thereby lowering overall maintenance expenses.

Furthermore, the adoption of modular design principles in V8 engines has simplified maintenance procedures. This approach allows for easier access to individual components, reducing labor time and costs associated with repairs and routine maintenance. The standardization of parts across different engine models has also contributed to lower replacement costs and improved availability of spare parts.

The economic benefits of these advancements extend beyond direct maintenance costs. Improved fuel efficiency in modern V8 engines, achieved through technologies such as direct injection and variable valve timing, results in lower operational costs over the engine's lifecycle. This increased efficiency not only reduces fuel expenses but also contributes to lower emissions, potentially leading to additional economic benefits in regions with strict environmental regulations.

In conclusion, the economic analysis of V8 engine lifecycle costs demonstrates a clear trend towards lower maintenance expenses. The combination of enhanced durability, advanced lubrication systems, sophisticated engine management, and modular design principles has significantly improved the long-term economic viability of V8 engines. As technology continues to evolve, it is likely that further reductions in maintenance costs will be realized, solidifying the position of V8 engines in various applications where power and performance are paramount.

One of the primary factors contributing to lower maintenance costs is the enhanced durability of modern V8 engines. Manufacturers have implemented advanced materials and manufacturing techniques, such as precision casting and forging, which result in more robust engine components. This increased durability translates to fewer replacements and repairs over the engine's lifetime, significantly reducing maintenance expenses.

Improved lubrication systems play a crucial role in extending engine life and reducing maintenance needs. Modern V8 engines often feature advanced oil circulation systems that ensure better distribution of lubricants throughout the engine, minimizing wear and tear on critical components. Additionally, the use of synthetic oils with longer change intervals has further contributed to reduced maintenance frequency and costs.

The integration of advanced engine management systems has also positively impacted maintenance costs. These systems continuously monitor engine performance, adjusting parameters in real-time to optimize efficiency and prevent excessive wear. By maintaining optimal operating conditions, these systems help extend the life of engine components and reduce the likelihood of unexpected failures, thereby lowering overall maintenance expenses.

Furthermore, the adoption of modular design principles in V8 engines has simplified maintenance procedures. This approach allows for easier access to individual components, reducing labor time and costs associated with repairs and routine maintenance. The standardization of parts across different engine models has also contributed to lower replacement costs and improved availability of spare parts.

The economic benefits of these advancements extend beyond direct maintenance costs. Improved fuel efficiency in modern V8 engines, achieved through technologies such as direct injection and variable valve timing, results in lower operational costs over the engine's lifecycle. This increased efficiency not only reduces fuel expenses but also contributes to lower emissions, potentially leading to additional economic benefits in regions with strict environmental regulations.

In conclusion, the economic analysis of V8 engine lifecycle costs demonstrates a clear trend towards lower maintenance expenses. The combination of enhanced durability, advanced lubrication systems, sophisticated engine management, and modular design principles has significantly improved the long-term economic viability of V8 engines. As technology continues to evolve, it is likely that further reductions in maintenance costs will be realized, solidifying the position of V8 engines in various applications where power and performance are paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!