V8 Engine Role in Reducing Environmental Footprint

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Eco-Goals

The V8 engine, a stalwart of automotive engineering, has undergone significant evolution since its inception, particularly in response to growing environmental concerns. Initially designed for power and performance, the V8's development trajectory has shifted towards balancing these attributes with improved fuel efficiency and reduced emissions. This evolution reflects the automotive industry's broader commitment to sustainability and environmental responsibility.

In recent years, the primary eco-goal for V8 engines has been to substantially reduce their environmental footprint without compromising the power and performance that define this engine configuration. Manufacturers have set ambitious targets for decreasing carbon dioxide emissions, improving fuel economy, and enhancing overall engine efficiency. These objectives align with increasingly stringent global emissions standards and a growing consumer demand for more environmentally friendly vehicles.

The evolution of V8 engines towards these eco-goals has been marked by several key technological advancements. Variable valve timing and lift systems have been refined to optimize engine breathing across a wider range of operating conditions, improving both power output and fuel efficiency. Direct fuel injection technology has been widely adopted, allowing for more precise fuel metering and combustion control, which contributes to reduced fuel consumption and lower emissions.

Cylinder deactivation, or dynamic skip fire technology, has emerged as a significant innovation in V8 engine design. This system allows the engine to operate on fewer cylinders under light load conditions, dramatically improving fuel efficiency during cruising or low-demand driving scenarios. When full power is required, all cylinders can be instantly reactivated, preserving the V8's characteristic performance.

Turbocharging and supercharging technologies have also played a crucial role in the V8's eco-evolution. These forced induction systems enable engine downsizing while maintaining or even increasing power output. Smaller displacement V8 engines equipped with turbochargers or superchargers can deliver the performance expected of larger naturally aspirated engines while consuming less fuel and producing fewer emissions.

The integration of hybrid and mild-hybrid systems with V8 engines represents another significant step in reducing their environmental impact. These electrification strategies allow for energy recovery during braking, electric assist during acceleration, and extended engine-off periods, all contributing to improved fuel economy and reduced emissions in urban driving conditions.

Looking forward, the eco-goals for V8 engines continue to evolve. Future developments are likely to focus on further improvements in thermal efficiency, advanced materials for weight reduction, and more sophisticated engine management systems. Additionally, the exploration of alternative fuels, such as hydrogen or synthetic fuels, may open new avenues for V8 engines to remain relevant in an increasingly eco-conscious automotive landscape.

In recent years, the primary eco-goal for V8 engines has been to substantially reduce their environmental footprint without compromising the power and performance that define this engine configuration. Manufacturers have set ambitious targets for decreasing carbon dioxide emissions, improving fuel economy, and enhancing overall engine efficiency. These objectives align with increasingly stringent global emissions standards and a growing consumer demand for more environmentally friendly vehicles.

The evolution of V8 engines towards these eco-goals has been marked by several key technological advancements. Variable valve timing and lift systems have been refined to optimize engine breathing across a wider range of operating conditions, improving both power output and fuel efficiency. Direct fuel injection technology has been widely adopted, allowing for more precise fuel metering and combustion control, which contributes to reduced fuel consumption and lower emissions.

Cylinder deactivation, or dynamic skip fire technology, has emerged as a significant innovation in V8 engine design. This system allows the engine to operate on fewer cylinders under light load conditions, dramatically improving fuel efficiency during cruising or low-demand driving scenarios. When full power is required, all cylinders can be instantly reactivated, preserving the V8's characteristic performance.

Turbocharging and supercharging technologies have also played a crucial role in the V8's eco-evolution. These forced induction systems enable engine downsizing while maintaining or even increasing power output. Smaller displacement V8 engines equipped with turbochargers or superchargers can deliver the performance expected of larger naturally aspirated engines while consuming less fuel and producing fewer emissions.

The integration of hybrid and mild-hybrid systems with V8 engines represents another significant step in reducing their environmental impact. These electrification strategies allow for energy recovery during braking, electric assist during acceleration, and extended engine-off periods, all contributing to improved fuel economy and reduced emissions in urban driving conditions.

Looking forward, the eco-goals for V8 engines continue to evolve. Future developments are likely to focus on further improvements in thermal efficiency, advanced materials for weight reduction, and more sophisticated engine management systems. Additionally, the exploration of alternative fuels, such as hydrogen or synthetic fuels, may open new avenues for V8 engines to remain relevant in an increasingly eco-conscious automotive landscape.

Market Demand for Green Engines

The market demand for green engines, particularly V8 engines with reduced environmental footprint, has been steadily increasing in recent years. This trend is driven by a combination of factors, including stricter environmental regulations, growing consumer awareness, and corporate sustainability initiatives.

Environmental regulations worldwide are becoming increasingly stringent, with many countries implementing stricter emissions standards and fuel efficiency requirements. The European Union's Euro 6 standards and the United States' Corporate Average Fuel Economy (CAFE) regulations are prime examples of these regulatory pressures. These standards are pushing automakers to develop cleaner, more efficient engines, including V8 engines that can meet these stringent requirements while still delivering the power and performance expected from this engine configuration.

Consumer awareness of environmental issues has also played a significant role in driving demand for greener engines. A growing segment of consumers is actively seeking vehicles that offer reduced environmental impact without compromising on performance. This has led to increased interest in V8 engines that incorporate advanced technologies to minimize emissions and improve fuel efficiency.

The automotive industry has responded to these market demands by investing heavily in research and development of cleaner V8 engine technologies. Innovations such as direct injection, variable valve timing, cylinder deactivation, and start-stop systems have been incorporated into modern V8 engines to reduce their environmental footprint. Additionally, the integration of hybrid and mild-hybrid systems with V8 engines has opened up new possibilities for combining power with efficiency.

Market research indicates that the demand for green V8 engines is particularly strong in certain segments of the automotive market. Luxury vehicles, high-performance sports cars, and premium SUVs are key areas where consumers are willing to pay a premium for environmentally friendly V8 engines. These segments value the balance of power, prestige, and reduced environmental impact that advanced V8 engines can offer.

The commercial vehicle sector has also shown increasing interest in greener V8 engines. Fleet operators and logistics companies are looking for ways to reduce their carbon footprint while maintaining the power and reliability needed for heavy-duty applications. This has created a niche market for V8 engines that can deliver improved fuel efficiency and lower emissions in trucks and other commercial vehicles.

As the automotive industry continues to evolve towards electrification, the market for green V8 engines is expected to undergo significant changes. While there is a clear trend towards full electrification in many vehicle segments, there remains a substantial market for high-performance internal combustion engines, particularly in regions where the infrastructure for electric vehicles is still developing. This presents both challenges and opportunities for V8 engine manufacturers to innovate and adapt their technologies to meet evolving market demands and environmental standards.

Environmental regulations worldwide are becoming increasingly stringent, with many countries implementing stricter emissions standards and fuel efficiency requirements. The European Union's Euro 6 standards and the United States' Corporate Average Fuel Economy (CAFE) regulations are prime examples of these regulatory pressures. These standards are pushing automakers to develop cleaner, more efficient engines, including V8 engines that can meet these stringent requirements while still delivering the power and performance expected from this engine configuration.

Consumer awareness of environmental issues has also played a significant role in driving demand for greener engines. A growing segment of consumers is actively seeking vehicles that offer reduced environmental impact without compromising on performance. This has led to increased interest in V8 engines that incorporate advanced technologies to minimize emissions and improve fuel efficiency.

The automotive industry has responded to these market demands by investing heavily in research and development of cleaner V8 engine technologies. Innovations such as direct injection, variable valve timing, cylinder deactivation, and start-stop systems have been incorporated into modern V8 engines to reduce their environmental footprint. Additionally, the integration of hybrid and mild-hybrid systems with V8 engines has opened up new possibilities for combining power with efficiency.

Market research indicates that the demand for green V8 engines is particularly strong in certain segments of the automotive market. Luxury vehicles, high-performance sports cars, and premium SUVs are key areas where consumers are willing to pay a premium for environmentally friendly V8 engines. These segments value the balance of power, prestige, and reduced environmental impact that advanced V8 engines can offer.

The commercial vehicle sector has also shown increasing interest in greener V8 engines. Fleet operators and logistics companies are looking for ways to reduce their carbon footprint while maintaining the power and reliability needed for heavy-duty applications. This has created a niche market for V8 engines that can deliver improved fuel efficiency and lower emissions in trucks and other commercial vehicles.

As the automotive industry continues to evolve towards electrification, the market for green V8 engines is expected to undergo significant changes. While there is a clear trend towards full electrification in many vehicle segments, there remains a substantial market for high-performance internal combustion engines, particularly in regions where the infrastructure for electric vehicles is still developing. This presents both challenges and opportunities for V8 engine manufacturers to innovate and adapt their technologies to meet evolving market demands and environmental standards.

V8 Engine Eco-Challenges

The V8 engine, a stalwart of automotive engineering, faces significant eco-challenges in the modern era of environmental consciousness. One of the primary concerns is its high fuel consumption, which directly correlates to increased carbon dioxide emissions. As global regulations tighten around greenhouse gas emissions, V8 engines struggle to meet increasingly stringent standards, particularly in urban environments where air quality is a pressing issue.

Another major challenge is the V8's inherent inefficiency in converting fuel energy into mechanical power. A substantial portion of the energy from combustion is lost as heat, contributing to thermal pollution and reducing overall engine efficiency. This inefficiency not only impacts the environment but also affects the vehicle's range and operating costs, making V8-powered vehicles less attractive in a market increasingly focused on fuel economy.

The production and disposal of V8 engines also present environmental concerns. The manufacturing process requires significant resources and energy, contributing to industrial pollution. Additionally, the complex nature of these engines, with their numerous components, makes recycling and end-of-life management more challenging compared to simpler powertrains.

Noise pollution is another eco-challenge associated with V8 engines. Their characteristic roar, while appealing to enthusiasts, contributes to urban noise levels, which can have detrimental effects on human health and wildlife. As cities implement stricter noise regulations, V8 engines may face restrictions in certain areas.

The weight of V8 engines poses an additional environmental challenge. Their substantial mass increases the overall weight of vehicles, leading to higher energy requirements for acceleration and maintaining speed. This increased energy demand translates to higher fuel consumption and, consequently, greater emissions.

Lastly, the V8 engine's reliance on fossil fuels presents a long-term sustainability issue. As the world moves towards renewable energy sources, engines that depend solely on non-renewable resources face an uncertain future. The automotive industry's shift towards electrification and alternative fuels further highlights the environmental limitations of traditional V8 engines.

These eco-challenges collectively put pressure on manufacturers to innovate and adapt V8 technology or consider alternative powertrains that can deliver similar performance with a reduced environmental impact. The future of the V8 engine in an eco-conscious world depends on addressing these challenges through technological advancements and creative engineering solutions.

Another major challenge is the V8's inherent inefficiency in converting fuel energy into mechanical power. A substantial portion of the energy from combustion is lost as heat, contributing to thermal pollution and reducing overall engine efficiency. This inefficiency not only impacts the environment but also affects the vehicle's range and operating costs, making V8-powered vehicles less attractive in a market increasingly focused on fuel economy.

The production and disposal of V8 engines also present environmental concerns. The manufacturing process requires significant resources and energy, contributing to industrial pollution. Additionally, the complex nature of these engines, with their numerous components, makes recycling and end-of-life management more challenging compared to simpler powertrains.

Noise pollution is another eco-challenge associated with V8 engines. Their characteristic roar, while appealing to enthusiasts, contributes to urban noise levels, which can have detrimental effects on human health and wildlife. As cities implement stricter noise regulations, V8 engines may face restrictions in certain areas.

The weight of V8 engines poses an additional environmental challenge. Their substantial mass increases the overall weight of vehicles, leading to higher energy requirements for acceleration and maintaining speed. This increased energy demand translates to higher fuel consumption and, consequently, greater emissions.

Lastly, the V8 engine's reliance on fossil fuels presents a long-term sustainability issue. As the world moves towards renewable energy sources, engines that depend solely on non-renewable resources face an uncertain future. The automotive industry's shift towards electrification and alternative fuels further highlights the environmental limitations of traditional V8 engines.

These eco-challenges collectively put pressure on manufacturers to innovate and adapt V8 technology or consider alternative powertrains that can deliver similar performance with a reduced environmental impact. The future of the V8 engine in an eco-conscious world depends on addressing these challenges through technological advancements and creative engineering solutions.

Current V8 Eco-Solutions

01 Emissions monitoring and reduction

V8 engines can be equipped with advanced emissions monitoring systems to track and reduce their environmental impact. These systems may include sensors and control units that optimize engine performance, reduce fuel consumption, and minimize harmful emissions. Technologies such as exhaust gas recirculation and catalytic converters can be implemented to further reduce the engine's environmental footprint.- Emission reduction technologies for V8 engines: Various technologies are being developed to reduce emissions from V8 engines, including advanced fuel injection systems, exhaust gas recirculation, and catalytic converters. These innovations aim to improve fuel efficiency and reduce harmful pollutants, thereby minimizing the environmental footprint of V8 engines.

- Environmental impact assessment of V8 engines: Methods and systems for assessing the environmental impact of V8 engines throughout their lifecycle, including production, use, and disposal. These assessments consider factors such as carbon emissions, resource consumption, and waste generation to provide a comprehensive understanding of the engine's environmental footprint.

- Optimization of V8 engine design for environmental performance: Innovative design approaches for V8 engines that focus on improving environmental performance without compromising power output. These designs may include lightweight materials, improved thermal management, and advanced combustion chamber geometries to enhance efficiency and reduce emissions.

- Alternative fuel compatibility for V8 engines: Adaptations and modifications to V8 engines to enable the use of alternative fuels such as biofuels, hydrogen, or synthetic fuels. These adaptations aim to reduce reliance on fossil fuels and decrease the overall carbon footprint of V8 engines.

- Monitoring and control systems for V8 engine environmental performance: Advanced monitoring and control systems that continuously assess and optimize the environmental performance of V8 engines during operation. These systems may include real-time emissions monitoring, adaptive engine management, and predictive maintenance features to minimize environmental impact.

02 Fuel efficiency improvements

Enhancing the fuel efficiency of V8 engines is crucial for reducing their environmental impact. This can be achieved through various methods, including advanced fuel injection systems, improved combustion chamber designs, and the use of lightweight materials. Implementing start-stop technology and cylinder deactivation can also contribute to better fuel economy, especially in urban driving conditions.Expand Specific Solutions03 Alternative fuel compatibility

Adapting V8 engines to run on alternative fuels can significantly reduce their environmental footprint. This may involve modifying the engine to use biofuels, compressed natural gas, or hydrogen. Such adaptations often require changes to the fuel delivery system, engine management software, and sometimes the internal components to ensure optimal performance and emissions reduction with the alternative fuel.Expand Specific Solutions04 Thermal management and waste heat recovery

Improving the thermal management of V8 engines can lead to better efficiency and reduced environmental impact. This includes advanced cooling systems, thermal insulation, and waste heat recovery technologies. By capturing and utilizing waste heat, the overall efficiency of the engine can be increased, leading to lower fuel consumption and emissions.Expand Specific Solutions05 Lifecycle assessment and sustainable manufacturing

Considering the entire lifecycle of V8 engines is essential for assessing and reducing their environmental footprint. This involves analyzing the environmental impact of raw material extraction, manufacturing processes, use phase, and end-of-life disposal or recycling. Implementing sustainable manufacturing practices, using recycled materials, and designing for easy disassembly and recycling can contribute to a reduced overall environmental impact.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine's role in reducing environmental footprint is at a critical juncture, with the industry transitioning towards more sustainable technologies. The market for eco-friendly V8 engines is growing, driven by stringent emissions regulations and consumer demand for greener vehicles. Major players like Ford, GM, Toyota, and Honda are investing heavily in research and development to improve V8 efficiency and reduce emissions. Emerging technologies such as hybrid V8 systems and alternative fuels are gaining traction, with companies like Corbion Biotech and Phillips 66 exploring innovative solutions. The competitive landscape is evolving, with traditional automakers facing challenges from new entrants and technology firms focused on sustainable powertrain solutions.

Ford Global Technologies LLC

Technical Solution: Ford has made significant strides in reducing the environmental impact of their V8 engines through the implementation of their EcoBoost technology. While primarily associated with smaller engines, Ford has applied EcoBoost principles to their V8 lineup, incorporating direct fuel injection, turbocharging, and variable camshaft timing[4]. This combination allows for smaller displacement engines to produce power equivalent to larger naturally aspirated engines, while consuming less fuel and producing fewer emissions. Ford has also introduced cylinder deactivation technology in their V8 engines, which can shut down half of the cylinders during light load conditions, significantly improving fuel efficiency[5]. Furthermore, Ford has invested in advanced materials and manufacturing processes to reduce the weight of their V8 engines, contributing to overall vehicle efficiency[6].

Strengths: Efficient power delivery, reduced fuel consumption, and adaptable performance. Weaknesses: Increased complexity and potential reliability concerns with turbocharging systems.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative approach to reduce the environmental footprint of V8 engines through their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system combines direct and port fuel injection, optimizing fuel efficiency and reducing emissions[1]. Toyota's V8 engines also incorporate VVT-iE (Variable Valve Timing-intelligent by Electric motor) on the intake camshaft, which improves engine efficiency across a wider range of operating conditions[2]. Additionally, Toyota has implemented advanced thermal management systems in their V8 engines, including electric water pumps and split cooling circuits, which contribute to faster warm-up times and reduced friction, further enhancing fuel economy and lowering emissions[3].

Strengths: Advanced fuel injection technology, innovative valve timing system, and efficient thermal management. Weaknesses: Complexity of the system may lead to higher manufacturing and maintenance costs.

V8 Green Innovations

V8 engine

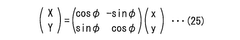

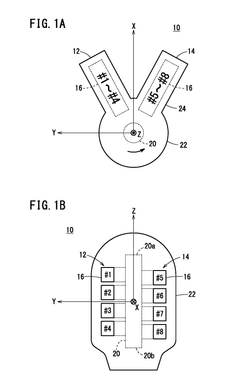

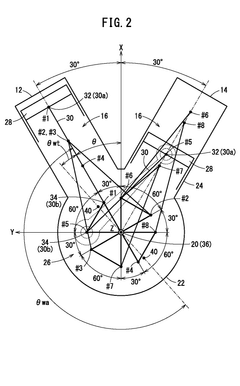

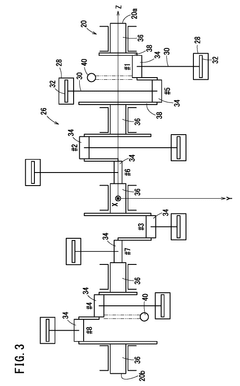

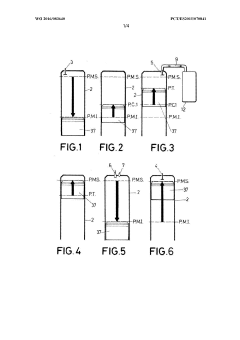

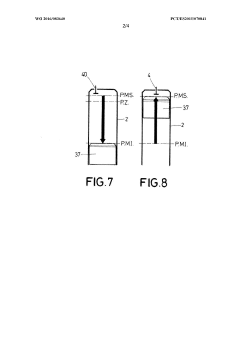

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Six-stroke internal combustion engine

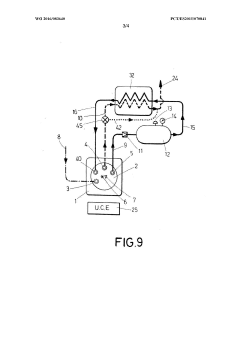

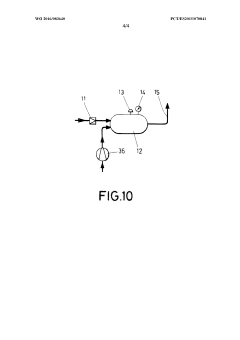

PatentWO2016083640A1

Innovation

- An eight-stroke engine design incorporating an internal combustion engine and a heat exchanger, where residual heat from exhaust gases is used to preheat air in the intake stroke, allowing for a lower cycle to absorb heat and improve thermal efficiency, with a compressed air storage tank facilitating energy recovery and reduced emissions.

Emissions Regulations Impact

The impact of emissions regulations on V8 engines and their role in reducing environmental footprint has been significant and far-reaching. As governments worldwide implement increasingly stringent emissions standards, automotive manufacturers have been compelled to adapt their V8 engine designs to meet these new requirements.

One of the primary drivers of change has been the introduction of corporate average fuel economy (CAFE) standards in various countries. These regulations set targets for fleet-wide fuel efficiency, indirectly pushing manufacturers to improve the efficiency of their V8 engines or face substantial fines. This has led to the development of more fuel-efficient V8 designs, incorporating technologies such as direct injection, variable valve timing, and cylinder deactivation.

The European Union's Euro emissions standards have also played a crucial role in shaping V8 engine development. Each successive iteration of these standards has set lower limits for pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. This has necessitated the integration of advanced aftertreatment systems, including catalytic converters, diesel particulate filters, and selective catalytic reduction (SCR) systems, into V8-powered vehicles.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have implemented progressively stricter emissions regulations. These standards have forced manufacturers to invest heavily in research and development to reduce emissions from V8 engines. Technologies such as exhaust gas recirculation (EGR) and lean-burn combustion have been widely adopted to meet these requirements.

The introduction of carbon dioxide emissions targets has further intensified the pressure on V8 engine manufacturers. Many countries have implemented CO2-based vehicle taxation systems, which have made high-displacement engines less attractive to consumers. This has led to the downsizing of V8 engines and the increased use of forced induction to maintain performance while reducing fuel consumption and emissions.

Emissions regulations have also spurred innovation in alternative powertrain technologies. Many manufacturers have begun to explore hybrid and electric powertrains as a means of offsetting the emissions of their V8 engines. This has resulted in the development of hybrid V8 systems, which combine the traditional appeal of a V8 engine with improved fuel efficiency and reduced emissions.

As regulations continue to evolve, the future of V8 engines in reducing environmental footprint remains uncertain. While technological advancements have allowed V8 engines to become cleaner and more efficient, the long-term viability of these engines in an increasingly environmentally conscious market will depend on their ability to meet ever-more stringent emissions standards.

One of the primary drivers of change has been the introduction of corporate average fuel economy (CAFE) standards in various countries. These regulations set targets for fleet-wide fuel efficiency, indirectly pushing manufacturers to improve the efficiency of their V8 engines or face substantial fines. This has led to the development of more fuel-efficient V8 designs, incorporating technologies such as direct injection, variable valve timing, and cylinder deactivation.

The European Union's Euro emissions standards have also played a crucial role in shaping V8 engine development. Each successive iteration of these standards has set lower limits for pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. This has necessitated the integration of advanced aftertreatment systems, including catalytic converters, diesel particulate filters, and selective catalytic reduction (SCR) systems, into V8-powered vehicles.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have implemented progressively stricter emissions regulations. These standards have forced manufacturers to invest heavily in research and development to reduce emissions from V8 engines. Technologies such as exhaust gas recirculation (EGR) and lean-burn combustion have been widely adopted to meet these requirements.

The introduction of carbon dioxide emissions targets has further intensified the pressure on V8 engine manufacturers. Many countries have implemented CO2-based vehicle taxation systems, which have made high-displacement engines less attractive to consumers. This has led to the downsizing of V8 engines and the increased use of forced induction to maintain performance while reducing fuel consumption and emissions.

Emissions regulations have also spurred innovation in alternative powertrain technologies. Many manufacturers have begun to explore hybrid and electric powertrains as a means of offsetting the emissions of their V8 engines. This has resulted in the development of hybrid V8 systems, which combine the traditional appeal of a V8 engine with improved fuel efficiency and reduced emissions.

As regulations continue to evolve, the future of V8 engines in reducing environmental footprint remains uncertain. While technological advancements have allowed V8 engines to become cleaner and more efficient, the long-term viability of these engines in an increasingly environmentally conscious market will depend on their ability to meet ever-more stringent emissions standards.

V8 Lifecycle Assessment

The V8 engine lifecycle assessment is a crucial component in evaluating its role in reducing environmental footprint. This comprehensive analysis examines the engine's impact from cradle to grave, encompassing raw material extraction, manufacturing, use phase, and end-of-life disposal. The assessment typically begins with the sourcing and processing of raw materials, including metals like aluminum and steel, as well as various plastics and composites used in engine construction.

Manufacturing processes are scrutinized next, focusing on energy consumption, emissions, and waste generation during engine production. This stage often reveals opportunities for optimization, such as implementing more efficient machining techniques or utilizing recycled materials. The use phase, generally the longest and most impactful stage of the V8 engine's lifecycle, is analyzed in depth. Fuel consumption, emissions output, and maintenance requirements are key factors considered during this phase.

Particular attention is paid to the engine's fuel efficiency and its evolution over time. Modern V8 engines often incorporate advanced technologies like direct injection, variable valve timing, and cylinder deactivation to improve fuel economy and reduce emissions. The assessment quantifies these improvements and their cumulative effect on the engine's environmental footprint throughout its operational life.

End-of-life considerations form the final stage of the lifecycle assessment. This includes evaluating the recyclability of engine components, the environmental impact of disposal methods, and the potential for remanufacturing or repurposing engine parts. The increasing use of lightweight materials in V8 engines, while beneficial for fuel efficiency, can present challenges in recycling and disposal that must be addressed.

Throughout the lifecycle assessment, various environmental impact categories are considered, including global warming potential, acidification, eutrophication, and resource depletion. These metrics provide a holistic view of the V8 engine's environmental performance and help identify areas for improvement. The assessment also often includes comparisons with alternative powertrains, such as smaller turbocharged engines or electric motors, to contextualize the V8's environmental impact within the broader automotive landscape.

By conducting a thorough lifecycle assessment, manufacturers and researchers can pinpoint the most significant environmental impacts of V8 engines and develop targeted strategies to mitigate them. This approach ensures that efforts to reduce the environmental footprint are focused on the areas that will yield the greatest benefits, leading to more sustainable V8 engine designs and production processes.

Manufacturing processes are scrutinized next, focusing on energy consumption, emissions, and waste generation during engine production. This stage often reveals opportunities for optimization, such as implementing more efficient machining techniques or utilizing recycled materials. The use phase, generally the longest and most impactful stage of the V8 engine's lifecycle, is analyzed in depth. Fuel consumption, emissions output, and maintenance requirements are key factors considered during this phase.

Particular attention is paid to the engine's fuel efficiency and its evolution over time. Modern V8 engines often incorporate advanced technologies like direct injection, variable valve timing, and cylinder deactivation to improve fuel economy and reduce emissions. The assessment quantifies these improvements and their cumulative effect on the engine's environmental footprint throughout its operational life.

End-of-life considerations form the final stage of the lifecycle assessment. This includes evaluating the recyclability of engine components, the environmental impact of disposal methods, and the potential for remanufacturing or repurposing engine parts. The increasing use of lightweight materials in V8 engines, while beneficial for fuel efficiency, can present challenges in recycling and disposal that must be addressed.

Throughout the lifecycle assessment, various environmental impact categories are considered, including global warming potential, acidification, eutrophication, and resource depletion. These metrics provide a holistic view of the V8 engine's environmental performance and help identify areas for improvement. The assessment also often includes comparisons with alternative powertrains, such as smaller turbocharged engines or electric motors, to contextualize the V8's environmental impact within the broader automotive landscape.

By conducting a thorough lifecycle assessment, manufacturers and researchers can pinpoint the most significant environmental impacts of V8 engines and develop targeted strategies to mitigate them. This approach ensures that efforts to reduce the environmental footprint are focused on the areas that will yield the greatest benefits, leading to more sustainable V8 engine designs and production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!