What is HDPE?

HDPE Background and Objectives

High-density polyethylene (HDPE) is a versatile thermoplastic polymer that has become an integral part of modern manufacturing and consumer products. Developed in the 1950s, HDPE has since evolved to become one of the most widely used plastics globally, owing to its unique combination of properties and cost-effectiveness.

The journey of HDPE began with the discovery of catalysts that allowed for the polymerization of ethylene at lower pressures and temperatures. This breakthrough, pioneered by Karl Ziegler and Giulio Natta, led to the production of a more linear and densely packed polymer structure, resulting in superior mechanical properties compared to its low-density counterpart.

Over the decades, HDPE has undergone continuous refinement in its production processes and formulations. The primary objective in HDPE development has been to enhance its performance characteristics while maintaining its economic viability. This has led to the creation of various grades of HDPE tailored for specific applications, ranging from packaging to construction materials.

The technical evolution of HDPE has focused on improving key attributes such as tensile strength, impact resistance, and chemical inertness. Researchers have explored methods to optimize the molecular weight distribution and crystallinity of HDPE, resulting in materials with enhanced durability and processing characteristics.

In recent years, the objectives in HDPE research and development have shifted towards sustainability and environmental considerations. There is a growing emphasis on developing bio-based HDPE alternatives and improving the recyclability of HDPE products. This aligns with global efforts to reduce plastic waste and minimize the environmental impact of polymer production.

The current landscape of HDPE technology is characterized by a balance between performance optimization and environmental responsibility. Manufacturers are investing in advanced catalyst systems and process technologies to produce HDPE with improved mechanical properties and reduced energy consumption. Simultaneously, there is a push towards incorporating recycled content into HDPE products without compromising their quality.

Looking ahead, the future objectives for HDPE technology are likely to focus on further enhancing its sustainability profile. This includes developing more efficient recycling methods, exploring bio-based feedstocks, and creating HDPE formulations that are easier to recycle or biodegrade. Additionally, there is ongoing research into expanding HDPE's application range, particularly in high-performance sectors such as automotive and aerospace industries.

As we move forward, the evolution of HDPE technology will continue to be driven by the dual imperatives of performance enhancement and environmental stewardship. The challenge lies in maintaining HDPE's position as a versatile and cost-effective material while addressing the growing demand for sustainable plastic solutions in a circular economy.

Market Demand Analysis for HDPE

The global market demand for High-Density Polyethylene (HDPE) has been steadily increasing over the past decade, driven by its versatile properties and wide range of applications across various industries. HDPE's excellent strength-to-density ratio, chemical resistance, and durability have made it a preferred material in packaging, construction, automotive, and consumer goods sectors.

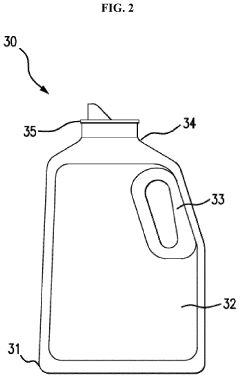

In the packaging industry, HDPE is extensively used for producing bottles, containers, and films. The growing e-commerce sector and increasing demand for packaged food and beverages have significantly contributed to the market growth. The construction industry also relies heavily on HDPE for pipes, fittings, and geomembranes, with the material's resistance to corrosion and weathering making it ideal for long-term infrastructure projects.

The automotive sector has been adopting HDPE for fuel tanks, interior components, and under-the-hood applications due to its lightweight nature and ability to reduce overall vehicle weight, thus improving fuel efficiency. This trend aligns with the global push for more environmentally friendly transportation solutions.

Consumer goods manufacturers have been incorporating HDPE into a wide array of products, from toys and household items to personal care packaging. The material's recyclability has become increasingly important as consumers and regulators focus on sustainability and circular economy principles.

Geographically, Asia-Pacific has emerged as the largest market for HDPE, with China and India leading the demand. The rapid industrialization, urbanization, and growing middle-class population in these countries have been key drivers. North America and Europe follow, with mature markets focusing on technological advancements and sustainable HDPE solutions.

The market demand for HDPE is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of around 4-5% over the next five years. This growth is supported by ongoing urbanization in developing countries, infrastructure development projects, and the increasing adoption of plastic packaging in various sectors.

However, the HDPE market faces challenges from environmental concerns and regulatory pressures aimed at reducing plastic waste. This has led to increased focus on recycling technologies and the development of bio-based alternatives. The industry is responding by investing in recycling infrastructure and exploring innovative production methods to improve the material's environmental footprint.

In conclusion, the market demand for HDPE remains robust, driven by its versatility and performance characteristics. The industry's ability to address sustainability concerns and adapt to changing regulatory landscapes will be crucial in maintaining this growth momentum in the coming years.

HDPE Technical Challenges

High-density polyethylene (HDPE) has become a ubiquitous material in modern industry, yet it still faces several technical challenges that hinder its full potential. One of the primary issues is the material's susceptibility to stress cracking, particularly in applications involving long-term exposure to certain chemicals or environmental factors. This phenomenon, known as environmental stress cracking resistance (ESCR), can lead to premature failure of HDPE products, especially in high-stress environments such as pressure pipes and storage tanks.

Another significant challenge lies in improving the material's barrier properties. While HDPE offers good resistance to moisture and many chemicals, its permeability to gases like oxygen and carbon dioxide remains a limitation in certain packaging applications. This drawback restricts its use in some food and beverage packaging where extended shelf life is crucial.

The processing of HDPE also presents technical hurdles. Achieving consistent melt flow characteristics across different batches can be challenging, affecting the quality and uniformity of the final products. This variability can lead to issues in large-scale manufacturing processes, particularly in extrusion and injection molding applications.

Enhancing the mechanical properties of HDPE without compromising its other beneficial characteristics remains an ongoing challenge. While HDPE boasts excellent impact strength and chemical resistance, improving its tensile strength and stiffness without significant trade-offs in other properties is a complex task. This limitation affects its competitiveness in certain high-performance applications where materials like engineering plastics currently dominate.

The recyclability of HDPE, though generally good, faces challenges in maintaining material quality through multiple recycling cycles. The degradation of mechanical properties and potential contamination during the recycling process can limit the use of recycled HDPE in high-value applications. This issue is particularly relevant in the context of increasing environmental concerns and circular economy initiatives.

Addressing the color limitations of HDPE is another technical challenge. The material's natural milky white appearance can be difficult to alter consistently, especially when aiming for vibrant or dark colors. This limitation can affect its aesthetic appeal in certain consumer products and packaging applications.

Lastly, the development of advanced HDPE composites and blends presents both opportunities and challenges. While incorporating additives or blending with other polymers can enhance specific properties, achieving optimal compatibility and maintaining the desired balance of characteristics requires sophisticated formulation and processing techniques.

Current HDPE Production Methods

01 HDPE composition and properties

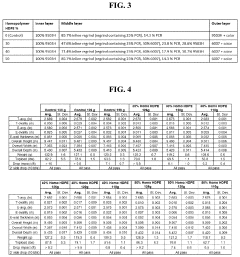

High-density polyethylene (HDPE) is a versatile thermoplastic polymer with unique properties. It is known for its high strength-to-density ratio, chemical resistance, and durability. HDPE compositions can be tailored to enhance specific properties such as impact resistance, tensile strength, and environmental stress crack resistance. Various additives and processing techniques are used to modify HDPE for different applications.- HDPE composition and properties: High-density polyethylene (HDPE) is a versatile thermoplastic polymer with excellent mechanical properties, chemical resistance, and durability. Its composition can be modified to enhance specific characteristics such as impact strength, stiffness, or processability. Various additives and fillers can be incorporated to tailor HDPE for different applications.

- HDPE processing techniques: Different processing techniques are employed to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods can be optimized to improve the material's performance and efficiency in production. Advanced processing techniques may involve the use of catalysts, controlled cooling, or specific molding conditions to achieve desired properties.

- HDPE recycling and sustainability: Recycling of HDPE is crucial for environmental sustainability. Various methods have been developed to efficiently recycle HDPE, including mechanical recycling, chemical recycling, and energy recovery. These processes aim to reduce waste, conserve resources, and minimize the environmental impact of plastic products.

- HDPE applications in packaging: HDPE is widely used in packaging applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used for bottles, containers, and films. Innovations in HDPE packaging focus on improving barrier properties, reducing material usage, and enhancing recyclability while maintaining product integrity and shelf life.

- HDPE blends and composites: HDPE can be blended with other polymers or reinforced with various materials to create composites with enhanced properties. These blends and composites can offer improved mechanical strength, thermal stability, or specific functional characteristics. Research in this area focuses on developing novel combinations to meet specialized application requirements.

02 HDPE processing and manufacturing

The processing and manufacturing of HDPE involve various techniques such as extrusion, injection molding, and blow molding. These processes can be optimized to improve the material's performance and efficiency. Advanced manufacturing methods, including the use of catalysts and controlled polymerization conditions, are employed to produce HDPE with specific characteristics. Post-processing treatments may also be applied to enhance the final product's properties.Expand Specific Solutions03 HDPE applications and products

HDPE finds extensive use in various industries due to its versatile properties. It is commonly used in packaging, construction, automotive, and consumer goods. Specific applications include pipes, containers, bottles, food packaging, and industrial components. The material's recyclability and durability make it a popular choice for sustainable product design. Innovations in HDPE applications continue to expand its use in new markets and technologies.Expand Specific Solutions04 HDPE blends and composites

HDPE can be blended with other polymers or reinforced with various materials to create composites with enhanced properties. These blends and composites offer improved mechanical strength, thermal stability, or specific functional characteristics. Nanocomposites incorporating HDPE are also being developed for advanced applications. The combination of HDPE with other materials opens up new possibilities for tailored material solutions in various industries.Expand Specific Solutions05 HDPE recycling and sustainability

The recycling of HDPE is a crucial aspect of its lifecycle, contributing to sustainability efforts. Various recycling methods and technologies are being developed to improve the efficiency and quality of recycled HDPE. Innovations in sorting, cleaning, and reprocessing HDPE waste are enhancing the circular economy of this material. Additionally, research is ongoing to develop more environmentally friendly production methods and biodegradable alternatives to traditional HDPE.Expand Specific Solutions

Key HDPE Industry Players

The High-Density Polyethylene (HDPE) market is in a mature stage, with steady growth driven by diverse applications across industries. The global HDPE market size is substantial, expected to reach billions of dollars in the coming years. Technologically, HDPE is well-established, with ongoing innovations focusing on enhancing properties and sustainability. Key players like Dow Global Technologies, ExxonMobil, and DuPont de Nemours are at the forefront of HDPE technology development, while companies such as Chevron Phillips Chemical and NOVA Chemicals are also significant contributors. The competitive landscape is characterized by these major petrochemical companies, along with specialized polymer manufacturers like Celanese Polymers, all striving for market share through product differentiation and technological advancements.

Dow Global Technologies LLC

ExxonMobil Technology & Engineering Co.

HDPE Material Properties Analysis

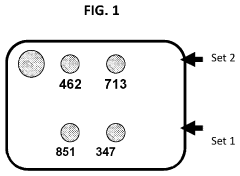

- A composition comprising an olefin-based polymer with 0.15 wt % to 15 wt % of an odor suppressant, including 0.05 wt % to 2 wt % of a metal oxide with a band gap greater than 5.0 eV and 0.1 wt % to 13 wt % of an acid copolymer, which synergistically reduces volatile hetero-carbonyl species without compromising processability or film properties.

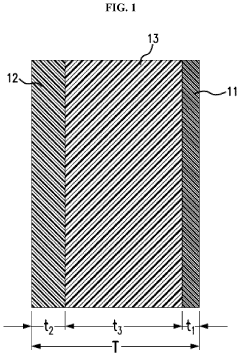

- A molded multilayer polymer structure comprising a body wall with a first layer of copolymer HDPE, a second layer of homopolymer HDPE, and a third layer that combines both, with a total weight content of homopolymer HDPE at least 30 wt-%, including regrind and post-consumer resin, to achieve improved mechanical and ESCR properties without costly processes.

Environmental Impact of HDPE

The environmental impact of High-Density Polyethylene (HDPE) is a complex issue that requires careful consideration. HDPE, while widely used for its durability and versatility, poses significant challenges to the environment throughout its lifecycle.

During production, HDPE manufacturing processes contribute to air and water pollution. The extraction and refining of petroleum, the primary raw material for HDPE, release greenhouse gases and other pollutants. Additionally, the polymerization process itself consumes substantial energy, further increasing the carbon footprint of HDPE production.

Once in use, HDPE products generally have a low direct environmental impact due to their inert nature. However, the longevity of HDPE becomes problematic at the end of its lifecycle. HDPE can take hundreds of years to decompose naturally, leading to long-term accumulation in landfills and natural environments.

The most significant environmental concern associated with HDPE is marine pollution. Due to its buoyancy and durability, HDPE products often end up in oceans and waterways, contributing to the growing problem of plastic pollution. This pollution has severe consequences for marine ecosystems, affecting wildlife through ingestion and entanglement.

Recycling offers a partial solution to HDPE's environmental impact. HDPE is one of the most commonly recycled plastics, with established recycling processes in many countries. Recycling HDPE reduces the need for virgin material production and helps mitigate waste accumulation. However, recycling rates remain suboptimal globally, and the quality of recycled HDPE can degrade over multiple recycling cycles.

Efforts to address the environmental impact of HDPE include improved waste management systems, increased recycling initiatives, and the development of biodegradable alternatives. Some researchers are exploring bio-based HDPE derived from renewable resources, which could potentially reduce the reliance on petroleum and decrease the overall carbon footprint.

Despite these challenges, it's important to note that HDPE's durability and lightweight nature can contribute to environmental benefits in certain applications. For instance, HDPE pipes used in water distribution systems have a longer lifespan and require less energy for transportation compared to traditional materials like concrete or metal.

In conclusion, while HDPE offers valuable properties for various applications, its environmental impact remains a significant concern. Balancing the material's benefits with its environmental costs requires ongoing research, improved recycling technologies, and a shift towards more sustainable production and consumption patterns.

HDPE Recycling Technologies

HDPE recycling technologies have evolved significantly over the years, addressing the growing need for sustainable plastic management. Mechanical recycling remains the most widely used method, involving sorting, grinding, washing, and melting HDPE waste to produce recycled pellets. This process preserves the polymer structure but may result in some quality degradation due to contaminants and thermal stress.

Advanced sorting technologies, such as near-infrared (NIR) spectroscopy and X-ray fluorescence, have improved the efficiency of separating HDPE from other plastics and removing contaminants. These technologies enable higher purity recycled HDPE, expanding its potential applications.

Chemical recycling, also known as feedstock recycling, has gained traction as a complementary approach to mechanical recycling. This process breaks down HDPE into its chemical components, allowing for the production of virgin-quality plastics. Pyrolysis and gasification are two primary chemical recycling methods for HDPE, converting the material into valuable hydrocarbons or syngas.

Solvent-based purification techniques have emerged as a promising alternative, offering a middle ground between mechanical and chemical recycling. This method uses specific solvents to dissolve and purify HDPE, removing contaminants while preserving the polymer structure. The result is high-quality recycled HDPE suitable for food-grade applications.

Additives and compatibilizers play a crucial role in enhancing the properties of recycled HDPE. These substances improve the mechanical strength, thermal stability, and processability of recycled materials, bridging the quality gap between virgin and recycled HDPE.

Emerging technologies, such as enzymatic recycling and supercritical fluid extraction, show potential for more efficient and environmentally friendly HDPE recycling. These methods aim to overcome limitations of traditional recycling processes, offering higher purity and energy efficiency.

The integration of artificial intelligence and machine learning in recycling facilities has improved sorting accuracy and process optimization. These technologies enable real-time adjustments to recycling parameters, enhancing overall efficiency and output quality.

As the demand for recycled HDPE grows, closed-loop recycling systems are gaining prominence. These systems aim to create a circular economy for HDPE, where products are designed for easy recycling and reintegration into the manufacturing process, minimizing waste and resource consumption.