Accelerating V12 Engine Innovations with Digital Twins

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Digital Twin Background and Objectives

The concept of digital twins has revolutionized the automotive industry, particularly in the realm of high-performance engines like the V12. This technology has emerged as a powerful tool for accelerating innovation and optimizing engine design, performance, and maintenance. Digital twins create virtual replicas of physical V12 engines, enabling engineers to simulate, analyze, and predict their behavior under various conditions.

The evolution of V12 engine technology has been marked by continuous efforts to enhance power output, fuel efficiency, and reliability. However, traditional development methods often involve time-consuming and costly physical prototyping and testing. The introduction of digital twins represents a paradigm shift in this process, offering a more efficient and cost-effective approach to engine innovation.

The primary objective of implementing digital twins for V12 engines is to streamline the development cycle and improve overall engine performance. By creating accurate virtual models, engineers can conduct extensive simulations and tests without the need for physical prototypes. This approach significantly reduces development time and costs while allowing for more comprehensive analysis and optimization.

Another key goal is to enhance the predictive maintenance capabilities of V12 engines. Digital twins enable real-time monitoring of engine performance, allowing for early detection of potential issues and more precise scheduling of maintenance activities. This proactive approach can significantly improve engine reliability and longevity, crucial factors for high-performance vehicles and luxury automobiles that often feature V12 engines.

Furthermore, digital twins aim to facilitate more rapid iterations in engine design. Engineers can quickly test and evaluate multiple design variations in the virtual environment, accelerating the process of identifying optimal configurations. This capability is particularly valuable for V12 engines, where small improvements can lead to significant gains in performance and efficiency.

The technology also supports the trend towards more sustainable and environmentally friendly engine designs. By enabling more accurate simulations of fuel consumption and emissions, digital twins help engineers develop V12 engines that meet increasingly stringent environmental regulations without compromising on performance.

In the broader context of automotive innovation, the application of digital twins to V12 engines serves as a testbed for advanced simulation and modeling techniques. The insights gained from this high-end application can potentially be applied to a wide range of engine types and vehicle systems, driving innovation across the entire automotive industry.

The evolution of V12 engine technology has been marked by continuous efforts to enhance power output, fuel efficiency, and reliability. However, traditional development methods often involve time-consuming and costly physical prototyping and testing. The introduction of digital twins represents a paradigm shift in this process, offering a more efficient and cost-effective approach to engine innovation.

The primary objective of implementing digital twins for V12 engines is to streamline the development cycle and improve overall engine performance. By creating accurate virtual models, engineers can conduct extensive simulations and tests without the need for physical prototypes. This approach significantly reduces development time and costs while allowing for more comprehensive analysis and optimization.

Another key goal is to enhance the predictive maintenance capabilities of V12 engines. Digital twins enable real-time monitoring of engine performance, allowing for early detection of potential issues and more precise scheduling of maintenance activities. This proactive approach can significantly improve engine reliability and longevity, crucial factors for high-performance vehicles and luxury automobiles that often feature V12 engines.

Furthermore, digital twins aim to facilitate more rapid iterations in engine design. Engineers can quickly test and evaluate multiple design variations in the virtual environment, accelerating the process of identifying optimal configurations. This capability is particularly valuable for V12 engines, where small improvements can lead to significant gains in performance and efficiency.

The technology also supports the trend towards more sustainable and environmentally friendly engine designs. By enabling more accurate simulations of fuel consumption and emissions, digital twins help engineers develop V12 engines that meet increasingly stringent environmental regulations without compromising on performance.

In the broader context of automotive innovation, the application of digital twins to V12 engines serves as a testbed for advanced simulation and modeling techniques. The insights gained from this high-end application can potentially be applied to a wide range of engine types and vehicle systems, driving innovation across the entire automotive industry.

Market Analysis for Advanced V12 Engine Technologies

The market for advanced V12 engine technologies is experiencing significant growth and transformation, driven by the increasing demand for high-performance luxury vehicles and the need for more efficient and environmentally friendly powertrains. The global luxury car market, where V12 engines are predominantly used, is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth is particularly strong in emerging markets such as China and India, where rising disposable incomes and a growing appetite for premium vehicles are fueling demand.

Within this broader market, the demand for V12 engines is evolving. While traditional applications in supercars and ultra-luxury vehicles remain strong, there is a growing interest in V12 engines for specialized applications such as marine propulsion and high-end motorsports. This diversification is expanding the potential market for advanced V12 technologies beyond the automotive sector.

The push for sustainability and stricter emissions regulations are reshaping the V12 engine market. Manufacturers are investing heavily in technologies to improve fuel efficiency and reduce emissions without compromising performance. This has led to a surge in demand for advanced materials, precision engineering, and innovative combustion technologies specific to V12 engines.

Digital twin technology is emerging as a game-changer in the V12 engine market. By creating virtual replicas of physical engines, manufacturers can optimize design, reduce development time, and enhance performance. The global digital twin market in the automotive sector is expected to grow at a CAGR of 32.5% from 2021 to 2026, indicating substantial potential for digital twin applications in V12 engine development.

Consumer preferences are also influencing the market. There is a growing demand for V12 engines that offer not just raw power, but also refined performance, improved fuel economy, and reduced environmental impact. This shift is driving innovation in areas such as variable valve timing, advanced turbocharging, and hybrid integration for V12 engines.

The competitive landscape of the V12 engine market is intensifying. Traditional luxury automakers are facing competition from new entrants, particularly in the electric and hybrid supercar segments. This competition is spurring increased R&D investment in V12 technologies, as manufacturers seek to maintain their market position and brand prestige.

In conclusion, the market for advanced V12 engine technologies is dynamic and multifaceted. While facing challenges from electrification and environmental regulations, it continues to thrive through innovation, diversification, and the integration of cutting-edge technologies like digital twins. The future of this market will likely be shaped by the successful balance of performance, efficiency, and sustainability in V12 engine design and manufacturing.

Within this broader market, the demand for V12 engines is evolving. While traditional applications in supercars and ultra-luxury vehicles remain strong, there is a growing interest in V12 engines for specialized applications such as marine propulsion and high-end motorsports. This diversification is expanding the potential market for advanced V12 technologies beyond the automotive sector.

The push for sustainability and stricter emissions regulations are reshaping the V12 engine market. Manufacturers are investing heavily in technologies to improve fuel efficiency and reduce emissions without compromising performance. This has led to a surge in demand for advanced materials, precision engineering, and innovative combustion technologies specific to V12 engines.

Digital twin technology is emerging as a game-changer in the V12 engine market. By creating virtual replicas of physical engines, manufacturers can optimize design, reduce development time, and enhance performance. The global digital twin market in the automotive sector is expected to grow at a CAGR of 32.5% from 2021 to 2026, indicating substantial potential for digital twin applications in V12 engine development.

Consumer preferences are also influencing the market. There is a growing demand for V12 engines that offer not just raw power, but also refined performance, improved fuel economy, and reduced environmental impact. This shift is driving innovation in areas such as variable valve timing, advanced turbocharging, and hybrid integration for V12 engines.

The competitive landscape of the V12 engine market is intensifying. Traditional luxury automakers are facing competition from new entrants, particularly in the electric and hybrid supercar segments. This competition is spurring increased R&D investment in V12 technologies, as manufacturers seek to maintain their market position and brand prestige.

In conclusion, the market for advanced V12 engine technologies is dynamic and multifaceted. While facing challenges from electrification and environmental regulations, it continues to thrive through innovation, diversification, and the integration of cutting-edge technologies like digital twins. The future of this market will likely be shaped by the successful balance of performance, efficiency, and sustainability in V12 engine design and manufacturing.

Current State and Challenges in V12 Engine Digital Twinning

Digital twin technology has made significant strides in the automotive industry, particularly in the realm of V12 engine development. The current state of digital twinning for V12 engines represents a convergence of advanced simulation techniques, real-time data analytics, and high-fidelity modeling. These digital replicas offer unprecedented insights into engine performance, wear patterns, and potential failure modes.

Leading automotive manufacturers and research institutions have successfully implemented digital twins for V12 engines, enabling them to conduct virtual testing, optimize designs, and predict maintenance needs with remarkable accuracy. The technology has proven particularly valuable in reducing development cycles and costs associated with physical prototyping.

However, despite these advancements, several challenges persist in the field of V12 engine digital twinning. One of the primary obstacles is the complexity of accurately modeling the intricate interactions within a V12 engine. The sheer number of components and the sophisticated nature of their interplay make it difficult to create a truly comprehensive digital representation.

Data integration and synchronization pose another significant challenge. Ensuring that the digital twin accurately reflects the real-world engine in real-time requires robust data collection systems and seamless integration of various data sources. This becomes even more challenging when considering the dynamic nature of engine performance under varying conditions.

The computational demands of running high-fidelity simulations for V12 engines are substantial. Current hardware and software limitations can result in trade-offs between simulation accuracy and processing speed, potentially compromising the digital twin's effectiveness in real-time applications.

Validation and verification of digital twin models remain ongoing challenges. Establishing the reliability and accuracy of these virtual representations requires extensive testing and correlation with physical engine data, which can be time-consuming and resource-intensive.

Furthermore, the integration of digital twins into existing manufacturing and maintenance processes presents organizational and technical hurdles. Many companies struggle with the cultural shift required to fully leverage digital twin technology, as well as the need for specialized skills and training.

Cybersecurity concerns also loom large in the digital twinning landscape. As these virtual models often contain sensitive proprietary information and are connected to real-world systems, ensuring their security against potential cyber threats is paramount.

Looking ahead, addressing these challenges will be crucial for advancing V12 engine digital twinning. Innovations in machine learning algorithms, edge computing, and sensor technologies are expected to play a significant role in overcoming current limitations and unlocking the full potential of digital twins in engine development and optimization.

Leading automotive manufacturers and research institutions have successfully implemented digital twins for V12 engines, enabling them to conduct virtual testing, optimize designs, and predict maintenance needs with remarkable accuracy. The technology has proven particularly valuable in reducing development cycles and costs associated with physical prototyping.

However, despite these advancements, several challenges persist in the field of V12 engine digital twinning. One of the primary obstacles is the complexity of accurately modeling the intricate interactions within a V12 engine. The sheer number of components and the sophisticated nature of their interplay make it difficult to create a truly comprehensive digital representation.

Data integration and synchronization pose another significant challenge. Ensuring that the digital twin accurately reflects the real-world engine in real-time requires robust data collection systems and seamless integration of various data sources. This becomes even more challenging when considering the dynamic nature of engine performance under varying conditions.

The computational demands of running high-fidelity simulations for V12 engines are substantial. Current hardware and software limitations can result in trade-offs between simulation accuracy and processing speed, potentially compromising the digital twin's effectiveness in real-time applications.

Validation and verification of digital twin models remain ongoing challenges. Establishing the reliability and accuracy of these virtual representations requires extensive testing and correlation with physical engine data, which can be time-consuming and resource-intensive.

Furthermore, the integration of digital twins into existing manufacturing and maintenance processes presents organizational and technical hurdles. Many companies struggle with the cultural shift required to fully leverage digital twin technology, as well as the need for specialized skills and training.

Cybersecurity concerns also loom large in the digital twinning landscape. As these virtual models often contain sensitive proprietary information and are connected to real-world systems, ensuring their security against potential cyber threats is paramount.

Looking ahead, addressing these challenges will be crucial for advancing V12 engine digital twinning. Innovations in machine learning algorithms, edge computing, and sensor technologies are expected to play a significant role in overcoming current limitations and unlocking the full potential of digital twins in engine development and optimization.

Existing Digital Twin Solutions for V12 Engine Development

01 Engine Management Systems

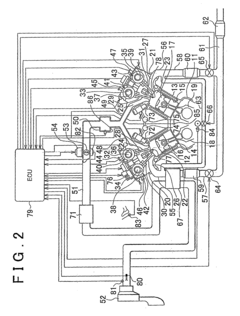

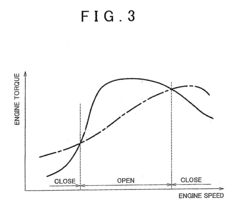

Advanced engine management systems for V12 engines, incorporating sophisticated control algorithms and sensors to optimize performance, fuel efficiency, and emissions. These systems may include real-time monitoring and adjustment of various engine parameters, such as fuel injection, ignition timing, and valve timing.- Engine Control and Management Systems: Advanced control systems for V12 engines, incorporating electronic management units that optimize performance, fuel efficiency, and emissions. These innovations include real-time monitoring and adjustment of engine parameters, as well as integration with vehicle diagnostics and telematics systems.

- Cylinder Deactivation Technology: Implementation of cylinder deactivation systems in V12 engines to improve fuel economy during partial load conditions. This technology allows the engine to operate on fewer cylinders when full power is not required, reducing fuel consumption and emissions without compromising performance when needed.

- Advanced Materials and Manufacturing Techniques: Utilization of lightweight and high-strength materials in V12 engine construction, such as advanced alloys and composites. Innovative manufacturing techniques, including 3D printing and precision machining, are employed to create more efficient and durable engine components.

- Hybrid and Electrification Integration: Integration of hybrid and electric technologies with V12 engines to enhance performance and efficiency. This includes the development of mild hybrid systems, regenerative braking, and electric turbochargers to complement the V12 powerplant.

- Innovative Cooling and Lubrication Systems: Development of advanced cooling and lubrication systems specifically designed for high-performance V12 engines. These innovations focus on improving heat management, reducing friction, and enhancing overall engine efficiency and longevity.

02 Cylinder Deactivation Technology

Innovative cylinder deactivation systems specifically designed for V12 engines, allowing for selective shutdown of cylinders during low-load conditions. This technology aims to improve fuel economy and reduce emissions without compromising performance when full power is needed.Expand Specific Solutions03 Turbocharging and Supercharging Advancements

Novel turbocharging and supercharging solutions tailored for V12 engines, enhancing power output and efficiency. These may include electric turbochargers, variable geometry turbos, or advanced multi-stage forced induction systems designed to minimize turbo lag and maximize performance across the entire RPM range.Expand Specific Solutions04 Lightweight Materials and Construction

Use of advanced lightweight materials and innovative construction techniques in V12 engine design to reduce overall weight while maintaining strength and durability. This may involve the use of composite materials, advanced alloys, or novel manufacturing processes to create lighter engine components without sacrificing performance or reliability.Expand Specific Solutions05 Hybrid and Electrification Integration

Integration of hybrid and electric technologies with V12 engines to create high-performance hybrid powertrains. This may include the development of mild hybrid systems, plug-in hybrid configurations, or even fully electric assist systems designed to complement the V12 engine's power characteristics while improving efficiency and reducing emissions.Expand Specific Solutions

Key Players in V12 Engine and Digital Twin Industries

The digital twin technology for V12 engine innovations is in its early growth stage, with a rapidly expanding market driven by increasing demand for high-performance engines and fuel efficiency. The global digital twin market is projected to reach $48.2 billion by 2026, with automotive applications showing significant potential. While the technology is maturing, it's not yet fully mature, as evidenced by ongoing research and development efforts. Key players in this space include Ford Global Technologies LLC, leveraging their automotive expertise, and IBM, bringing advanced AI and cloud computing capabilities. Universities like Beihang University and Xi'an Jiaotong University are contributing to academic research, while companies such as Applied Materials, Inc. and Cummins Power Generation Ltd. are exploring industrial applications, indicating a diverse and competitive landscape.

Ford Global Technologies LLC

Technical Solution: Ford's digital twin technology for V12 engine innovation focuses on creating highly accurate virtual models of their engines. These models integrate real-time sensor data, historical performance metrics, and advanced simulation algorithms to predict engine behavior under various conditions. Ford utilizes high-fidelity 3D modeling and computational fluid dynamics (CFD) to analyze combustion processes, thermal management, and overall engine efficiency[1]. The digital twin platform incorporates machine learning algorithms to continuously improve predictive accuracy based on real-world data collected from test engines and vehicles on the road[2]. This allows for rapid iteration and optimization of engine designs, reducing the need for physical prototypes and accelerating the development cycle[3].

Strengths: Reduced development time and costs, improved engine performance optimization, and enhanced predictive maintenance capabilities. Weaknesses: High initial investment in technology and expertise, potential cybersecurity risks associated with connected digital systems.

Cummins Power Generation Ltd.

Technical Solution: Cummins employs advanced digital twin technology to accelerate V12 engine innovations. Their approach involves creating detailed virtual replicas of their engines, incorporating real-time operational data from sensors and IoT devices. The digital twin system utilizes AI and machine learning algorithms to analyze engine performance, predict maintenance needs, and optimize fuel efficiency[4]. Cummins' platform integrates multi-physics simulation models to accurately represent the complex interactions within the engine, including combustion dynamics, thermal management, and structural integrity[5]. The company leverages cloud computing resources to run sophisticated simulations and scenario analyses, enabling rapid design iterations and performance optimizations without the need for extensive physical testing[6].

Strengths: Comprehensive engine lifecycle management, improved reliability predictions, and enhanced fuel efficiency optimization. Weaknesses: Dependency on robust data collection infrastructure, potential challenges in data integration from diverse sources.

Core Innovations in V12 Engine Digital Twin Technology

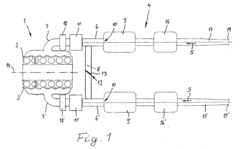

Internal combustion engine

PatentInactiveEP1338772A3

Innovation

- The implementation of separate engine intake manifolds for each cylinder bank connected by a transverse channel reduces noise by minimizing air filter size and flow resistance, allowing for a more compact design and adjustable acoustic behavior through a limiting element like a diaphragm or flap, which can be adjusted based on operating parameters.

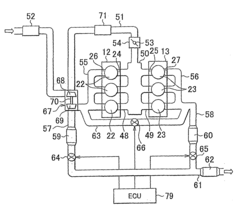

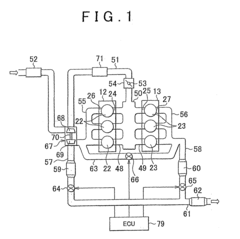

Internal combustion engine and control method thereof

PatentInactiveUS20100011762A1

Innovation

- The implementation of a communication control valve in the communicating passage, which adjusts the flowrate of exhaust gas and is controlled based on the engine's operating state, including load and air-fuel ratios, to reduce pulsations and optimize bank control, thereby ensuring stoichiometric conditions for the NOX storage reduction catalyst.

Environmental Impact and Sustainability Considerations

The integration of digital twin technology in V12 engine development presents significant opportunities for enhancing environmental sustainability and reducing ecological impact. By creating virtual replicas of physical engines, manufacturers can optimize performance, reduce emissions, and improve fuel efficiency without the need for extensive physical prototyping. This approach substantially decreases material waste and energy consumption associated with traditional development processes.

Digital twins enable engineers to simulate various operating conditions and test different configurations virtually, leading to more environmentally friendly designs. Through advanced modeling and real-time data analysis, developers can identify areas of inefficiency and implement solutions that minimize fuel consumption and exhaust emissions. This proactive approach aligns with increasingly stringent environmental regulations and consumer demands for greener transportation options.

Furthermore, digital twin technology facilitates predictive maintenance strategies, extending the lifespan of V12 engines and reducing the need for premature replacements. By monitoring engine performance in real-time and anticipating potential issues, maintenance can be scheduled more efficiently, minimizing downtime and resource consumption. This not only improves the overall sustainability of the engine but also reduces the environmental impact associated with manufacturing replacement parts and disposing of worn components.

The application of digital twins in V12 engine development also contributes to the circular economy concept. By providing detailed insights into engine performance throughout its lifecycle, manufacturers can design for easier disassembly, reuse, and recycling. This approach promotes the efficient use of resources and minimizes waste, aligning with broader sustainability goals in the automotive industry.

Additionally, digital twin technology enables more accurate lifecycle assessments of V12 engines. By simulating the entire product lifecycle, from raw material extraction to end-of-life disposal, manufacturers can make informed decisions to reduce environmental impact at every stage. This holistic approach to sustainability considers not only the operational efficiency of the engine but also its overall ecological footprint.

As the automotive industry transitions towards more sustainable practices, the role of digital twins in V12 engine development becomes increasingly crucial. By leveraging this technology, manufacturers can accelerate the innovation of cleaner, more efficient engines while simultaneously reducing the environmental impact of the development process itself. This synergy between technological advancement and environmental stewardship positions digital twin-enabled V12 engine development as a key driver in the pursuit of sustainable transportation solutions.

Digital twins enable engineers to simulate various operating conditions and test different configurations virtually, leading to more environmentally friendly designs. Through advanced modeling and real-time data analysis, developers can identify areas of inefficiency and implement solutions that minimize fuel consumption and exhaust emissions. This proactive approach aligns with increasingly stringent environmental regulations and consumer demands for greener transportation options.

Furthermore, digital twin technology facilitates predictive maintenance strategies, extending the lifespan of V12 engines and reducing the need for premature replacements. By monitoring engine performance in real-time and anticipating potential issues, maintenance can be scheduled more efficiently, minimizing downtime and resource consumption. This not only improves the overall sustainability of the engine but also reduces the environmental impact associated with manufacturing replacement parts and disposing of worn components.

The application of digital twins in V12 engine development also contributes to the circular economy concept. By providing detailed insights into engine performance throughout its lifecycle, manufacturers can design for easier disassembly, reuse, and recycling. This approach promotes the efficient use of resources and minimizes waste, aligning with broader sustainability goals in the automotive industry.

Additionally, digital twin technology enables more accurate lifecycle assessments of V12 engines. By simulating the entire product lifecycle, from raw material extraction to end-of-life disposal, manufacturers can make informed decisions to reduce environmental impact at every stage. This holistic approach to sustainability considers not only the operational efficiency of the engine but also its overall ecological footprint.

As the automotive industry transitions towards more sustainable practices, the role of digital twins in V12 engine development becomes increasingly crucial. By leveraging this technology, manufacturers can accelerate the innovation of cleaner, more efficient engines while simultaneously reducing the environmental impact of the development process itself. This synergy between technological advancement and environmental stewardship positions digital twin-enabled V12 engine development as a key driver in the pursuit of sustainable transportation solutions.

Integration with IoT and AI in V12 Engine Digital Twins

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) technologies with V12 engine digital twins represents a significant leap forward in engine development and optimization. This convergence of advanced technologies enables real-time data collection, analysis, and predictive modeling, revolutionizing the way engineers design, test, and maintain high-performance V12 engines.

IoT sensors embedded throughout the physical V12 engine continuously gather data on various parameters such as temperature, pressure, vibration, and fuel consumption. This wealth of information is then transmitted to the digital twin, creating a virtual replica that accurately reflects the engine's current state and performance. The integration of IoT ensures that the digital twin remains synchronized with its physical counterpart, providing engineers with up-to-date insights into the engine's behavior under various operating conditions.

AI algorithms play a crucial role in processing and interpreting the vast amounts of data collected by IoT sensors. Machine learning models can identify patterns and anomalies in engine performance, predicting potential issues before they occur. This predictive maintenance capability significantly reduces downtime and extends the lifespan of V12 engines, particularly in high-stakes applications such as motorsports or luxury vehicles.

Furthermore, AI-powered optimization algorithms can analyze the digital twin to suggest improvements in engine design and performance. These algorithms can simulate thousands of iterations, testing various configurations and parameters to identify the optimal setup for specific performance goals, such as maximizing power output or improving fuel efficiency.

The combination of IoT and AI in V12 engine digital twins also enables advanced simulation capabilities. Engineers can run virtual tests on the digital twin, subjecting it to extreme conditions or scenarios that would be impractical or dangerous to replicate with a physical engine. This virtual testing environment accelerates the development process, reduces costs associated with physical prototyping, and allows for more comprehensive validation of design changes.

Real-time monitoring and analysis facilitated by IoT and AI integration provide valuable insights into engine performance during actual operation. This data can be used to fine-tune engine parameters on the fly, adapting to changing conditions and ensuring optimal performance at all times. For instance, in a racing scenario, engineers can use the digital twin to make informed decisions about engine settings based on current track conditions and race strategy.

As the integration of IoT and AI with V12 engine digital twins continues to evolve, we can expect to see even more sophisticated applications. Future developments may include self-learning digital twins that can autonomously optimize engine performance based on historical data and current conditions, further pushing the boundaries of V12 engine innovation and efficiency.

IoT sensors embedded throughout the physical V12 engine continuously gather data on various parameters such as temperature, pressure, vibration, and fuel consumption. This wealth of information is then transmitted to the digital twin, creating a virtual replica that accurately reflects the engine's current state and performance. The integration of IoT ensures that the digital twin remains synchronized with its physical counterpart, providing engineers with up-to-date insights into the engine's behavior under various operating conditions.

AI algorithms play a crucial role in processing and interpreting the vast amounts of data collected by IoT sensors. Machine learning models can identify patterns and anomalies in engine performance, predicting potential issues before they occur. This predictive maintenance capability significantly reduces downtime and extends the lifespan of V12 engines, particularly in high-stakes applications such as motorsports or luxury vehicles.

Furthermore, AI-powered optimization algorithms can analyze the digital twin to suggest improvements in engine design and performance. These algorithms can simulate thousands of iterations, testing various configurations and parameters to identify the optimal setup for specific performance goals, such as maximizing power output or improving fuel efficiency.

The combination of IoT and AI in V12 engine digital twins also enables advanced simulation capabilities. Engineers can run virtual tests on the digital twin, subjecting it to extreme conditions or scenarios that would be impractical or dangerous to replicate with a physical engine. This virtual testing environment accelerates the development process, reduces costs associated with physical prototyping, and allows for more comprehensive validation of design changes.

Real-time monitoring and analysis facilitated by IoT and AI integration provide valuable insights into engine performance during actual operation. This data can be used to fine-tune engine parameters on the fly, adapting to changing conditions and ensuring optimal performance at all times. For instance, in a racing scenario, engineers can use the digital twin to make informed decisions about engine settings based on current track conditions and race strategy.

As the integration of IoT and AI with V12 engine digital twins continues to evolve, we can expect to see even more sophisticated applications. Future developments may include self-learning digital twins that can autonomously optimize engine performance based on historical data and current conditions, further pushing the boundaries of V12 engine innovation and efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!