Assessing V12 Engine Mass Production Technologies

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has a rich history dating back to the early 20th century. Initially developed for luxury automobiles and racing cars, it has evolved significantly over the decades. The V12 configuration, with its smooth power delivery and distinctive sound, has been a hallmark of high-performance vehicles.

In the 1920s and 1930s, V12 engines were primarily found in prestigious marques like Packard, Cadillac, and Lincoln. These early V12s were large displacement engines, often exceeding 7 liters, and were known for their refinement rather than outright power.

The post-World War II era saw a shift in V12 engine development. European manufacturers, particularly Ferrari and Lamborghini, began to focus on high-performance V12 engines for their sports cars. These engines were smaller in displacement but produced higher power outputs through advanced engineering and higher revving capabilities.

The 1960s and 1970s marked a golden age for V12 engines in motorsports. Iconic cars like the Ferrari 250 GTO and the Jaguar E-Type showcased the potential of V12 power. During this period, advancements in metallurgy and engine design allowed for increased reliability and performance.

The 1980s and 1990s brought significant technological advancements to V12 engines. Electronic fuel injection, variable valve timing, and improved engine management systems enhanced both power output and efficiency. Luxury car manufacturers like BMW and Mercedes-Benz introduced V12 engines to their flagship models, emphasizing smoothness and refinement.

In the 21st century, V12 engines have faced challenges due to increasing environmental regulations and a focus on fuel efficiency. However, they have adapted through the implementation of technologies such as direct injection, turbocharging, and hybrid systems. Modern V12 engines, found in supercars and ultra-luxury vehicles, now combine high performance with improved fuel economy and reduced emissions.

The evolution of V12 engines has also seen advancements in manufacturing techniques. Computer-aided design and precision machining have allowed for tighter tolerances and more complex engine designs. These improvements have contributed to increased power density and reliability in modern V12 engines.

Looking towards the future, the role of V12 engines in mass production faces uncertainty. While they continue to represent the pinnacle of internal combustion engine technology, the automotive industry's shift towards electrification poses challenges. However, some manufacturers are exploring ways to preserve the V12's legacy through hybrid powertrains and limited production runs, ensuring that this iconic engine configuration maintains its place in automotive history.

In the 1920s and 1930s, V12 engines were primarily found in prestigious marques like Packard, Cadillac, and Lincoln. These early V12s were large displacement engines, often exceeding 7 liters, and were known for their refinement rather than outright power.

The post-World War II era saw a shift in V12 engine development. European manufacturers, particularly Ferrari and Lamborghini, began to focus on high-performance V12 engines for their sports cars. These engines were smaller in displacement but produced higher power outputs through advanced engineering and higher revving capabilities.

The 1960s and 1970s marked a golden age for V12 engines in motorsports. Iconic cars like the Ferrari 250 GTO and the Jaguar E-Type showcased the potential of V12 power. During this period, advancements in metallurgy and engine design allowed for increased reliability and performance.

The 1980s and 1990s brought significant technological advancements to V12 engines. Electronic fuel injection, variable valve timing, and improved engine management systems enhanced both power output and efficiency. Luxury car manufacturers like BMW and Mercedes-Benz introduced V12 engines to their flagship models, emphasizing smoothness and refinement.

In the 21st century, V12 engines have faced challenges due to increasing environmental regulations and a focus on fuel efficiency. However, they have adapted through the implementation of technologies such as direct injection, turbocharging, and hybrid systems. Modern V12 engines, found in supercars and ultra-luxury vehicles, now combine high performance with improved fuel economy and reduced emissions.

The evolution of V12 engines has also seen advancements in manufacturing techniques. Computer-aided design and precision machining have allowed for tighter tolerances and more complex engine designs. These improvements have contributed to increased power density and reliability in modern V12 engines.

Looking towards the future, the role of V12 engines in mass production faces uncertainty. While they continue to represent the pinnacle of internal combustion engine technology, the automotive industry's shift towards electrification poses challenges. However, some manufacturers are exploring ways to preserve the V12's legacy through hybrid powertrains and limited production runs, ensuring that this iconic engine configuration maintains its place in automotive history.

Market Demand Analysis

The market demand for V12 engines has been experiencing a significant shift in recent years. While traditionally associated with luxury and high-performance vehicles, the V12 engine market has been facing challenges due to increasing environmental regulations and a global push towards more fuel-efficient and sustainable transportation solutions.

In the luxury automotive sector, V12 engines continue to hold a niche but prestigious position. Brands like Rolls-Royce, Ferrari, and Lamborghini still offer V12 engines in their flagship models, catering to a select clientele who prioritize performance and exclusivity over fuel efficiency. However, the market size for these vehicles remains limited, with annual production numbers typically in the low thousands for each manufacturer.

The high-performance sports car segment also maintains a demand for V12 engines, particularly in limited edition and track-focused models. These vehicles often serve as halo products for automotive brands, showcasing their engineering prowess and attracting enthusiasts. However, the trend towards downsizing and electrification is gradually impacting this sector as well.

In the commercial and industrial sectors, V12 engines find applications in marine propulsion, power generation, and heavy machinery. These markets show more stability in demand, as the power and reliability of V12 engines are still valued in these applications. However, even in these sectors, there is a growing interest in alternative power sources and more efficient engine designs.

The global market for V12 engines is influenced by regional differences in regulations and consumer preferences. While stricter emission standards in Europe and North America are putting pressure on V12 engine production, emerging markets in Asia and the Middle East still show a stronger appetite for high-displacement engines in luxury vehicles.

Looking at future trends, the market for V12 engines is expected to face continued challenges. The automotive industry's shift towards electrification and the increasing focus on reducing carbon emissions are likely to further constrain the demand for large displacement engines. Many manufacturers are exploring hybrid technologies as a transitional solution, combining V12 engines with electric motors to improve efficiency while maintaining performance.

Despite these challenges, there remains a core group of enthusiasts and collectors who value the unique characteristics of V12 engines, ensuring a small but persistent demand in the foreseeable future. This niche market may sustain limited production runs of V12 engines, particularly for special edition vehicles and in motorsport applications.

In the luxury automotive sector, V12 engines continue to hold a niche but prestigious position. Brands like Rolls-Royce, Ferrari, and Lamborghini still offer V12 engines in their flagship models, catering to a select clientele who prioritize performance and exclusivity over fuel efficiency. However, the market size for these vehicles remains limited, with annual production numbers typically in the low thousands for each manufacturer.

The high-performance sports car segment also maintains a demand for V12 engines, particularly in limited edition and track-focused models. These vehicles often serve as halo products for automotive brands, showcasing their engineering prowess and attracting enthusiasts. However, the trend towards downsizing and electrification is gradually impacting this sector as well.

In the commercial and industrial sectors, V12 engines find applications in marine propulsion, power generation, and heavy machinery. These markets show more stability in demand, as the power and reliability of V12 engines are still valued in these applications. However, even in these sectors, there is a growing interest in alternative power sources and more efficient engine designs.

The global market for V12 engines is influenced by regional differences in regulations and consumer preferences. While stricter emission standards in Europe and North America are putting pressure on V12 engine production, emerging markets in Asia and the Middle East still show a stronger appetite for high-displacement engines in luxury vehicles.

Looking at future trends, the market for V12 engines is expected to face continued challenges. The automotive industry's shift towards electrification and the increasing focus on reducing carbon emissions are likely to further constrain the demand for large displacement engines. Many manufacturers are exploring hybrid technologies as a transitional solution, combining V12 engines with electric motors to improve efficiency while maintaining performance.

Despite these challenges, there remains a core group of enthusiasts and collectors who value the unique characteristics of V12 engines, ensuring a small but persistent demand in the foreseeable future. This niche market may sustain limited production runs of V12 engines, particularly for special edition vehicles and in motorsport applications.

Current Challenges

The mass production of V12 engines presents several significant challenges that manufacturers must overcome to ensure efficiency, quality, and cost-effectiveness. One of the primary hurdles is the complexity of the engine design itself. With twelve cylinders, the V12 engine requires precise manufacturing and assembly processes to maintain tight tolerances and ensure proper functioning of all components.

Achieving consistent quality across large production volumes is another major challenge. The intricate nature of V12 engines demands stringent quality control measures throughout the production line. Even minor variations in component specifications or assembly procedures can lead to performance issues or reliability concerns in the final product.

Cost management is a critical factor in V12 engine mass production. The high-end materials and advanced technologies required for these engines contribute to elevated production costs. Balancing the need for premium components with cost-effective manufacturing processes is an ongoing challenge for manufacturers seeking to maintain profitability while meeting market demands.

Production scalability poses another significant hurdle. As demand for V12 engines can fluctuate based on market trends and economic conditions, manufacturers must develop flexible production systems that can adapt to varying production volumes without compromising quality or efficiency.

The environmental impact of V12 engine production is an increasing concern. Stringent emissions regulations and growing pressure for sustainable manufacturing practices require producers to invest in cleaner technologies and more eco-friendly production methods. This necessitates continuous innovation in both engine design and manufacturing processes.

Skilled labor shortage is another pressing issue in V12 engine mass production. The complexity of these engines demands highly skilled technicians and engineers, who are often in short supply. Training and retaining a qualified workforce capable of handling the intricacies of V12 engine production is an ongoing challenge for manufacturers.

Supply chain management presents its own set of difficulties. The production of V12 engines relies on a complex network of suppliers providing specialized components. Ensuring a stable and efficient supply chain, particularly for rare or custom parts, is crucial for maintaining consistent production schedules and quality standards.

Lastly, the integration of advanced technologies such as automation and robotics into the production process presents both opportunities and challenges. While these technologies can enhance precision and efficiency, their implementation requires significant investment and can be complex to integrate seamlessly into existing production lines.

Achieving consistent quality across large production volumes is another major challenge. The intricate nature of V12 engines demands stringent quality control measures throughout the production line. Even minor variations in component specifications or assembly procedures can lead to performance issues or reliability concerns in the final product.

Cost management is a critical factor in V12 engine mass production. The high-end materials and advanced technologies required for these engines contribute to elevated production costs. Balancing the need for premium components with cost-effective manufacturing processes is an ongoing challenge for manufacturers seeking to maintain profitability while meeting market demands.

Production scalability poses another significant hurdle. As demand for V12 engines can fluctuate based on market trends and economic conditions, manufacturers must develop flexible production systems that can adapt to varying production volumes without compromising quality or efficiency.

The environmental impact of V12 engine production is an increasing concern. Stringent emissions regulations and growing pressure for sustainable manufacturing practices require producers to invest in cleaner technologies and more eco-friendly production methods. This necessitates continuous innovation in both engine design and manufacturing processes.

Skilled labor shortage is another pressing issue in V12 engine mass production. The complexity of these engines demands highly skilled technicians and engineers, who are often in short supply. Training and retaining a qualified workforce capable of handling the intricacies of V12 engine production is an ongoing challenge for manufacturers.

Supply chain management presents its own set of difficulties. The production of V12 engines relies on a complex network of suppliers providing specialized components. Ensuring a stable and efficient supply chain, particularly for rare or custom parts, is crucial for maintaining consistent production schedules and quality standards.

Lastly, the integration of advanced technologies such as automation and robotics into the production process presents both opportunities and challenges. While these technologies can enhance precision and efficiency, their implementation requires significant investment and can be complex to integrate seamlessly into existing production lines.

Mass Production Methods

01 V12 Engine Design and Configuration

V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine layout while providing high power output and smooth operation. The design often includes features for improved performance, fuel efficiency, and reduced vibration.- V12 Engine Design and Configuration: V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine design while providing high power output and smooth operation. The V12 layout is often used in high-performance and luxury vehicles due to its balance of power and refinement.

- V12 Engine Control Systems: Advanced control systems are crucial for optimizing V12 engine performance. These systems manage fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Electronic control units (ECUs) play a key role in coordinating various engine functions and adapting to different driving conditions.

- V12 Engine Cooling and Lubrication: Effective cooling and lubrication systems are essential for V12 engines due to their high power output and heat generation. Advanced cooling systems may include multiple radiators, oil coolers, and precision-engineered coolant passages. Lubrication systems are designed to ensure proper oil distribution to all critical engine components, even under high-performance conditions.

- V12 Engine Materials and Manufacturing: The use of advanced materials and manufacturing techniques is crucial in V12 engine production. Lightweight alloys, such as aluminum and magnesium, are often used to reduce engine weight while maintaining strength. Precision manufacturing processes, including computer-controlled machining and advanced casting techniques, ensure tight tolerances and high-quality components.

- V12 Engine Applications and Integration: V12 engines are integrated into various high-performance and luxury vehicles, including sports cars, luxury sedans, and some marine applications. The integration process involves careful consideration of vehicle packaging, weight distribution, and powertrain mounting to optimize performance and handling characteristics. Customized exhaust systems and transmission pairings are often developed to complement the V12 engine's power output and characteristics.

02 V12 Engine Control Systems

Advanced control systems are implemented in V12 engines to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and engine management units that adjust various parameters based on driving conditions and user input.Expand Specific Solutions03 V12 Engine Applications

V12 engines are commonly used in high-performance vehicles, luxury cars, marine vessels, and some aircraft. Their application extends to various industries where high power output and smooth operation are required, such as in racing, aerospace, and heavy machinery.Expand Specific Solutions04 V12 Engine Cooling and Lubrication

Efficient cooling and lubrication systems are crucial for V12 engines due to their high power output and complex design. These systems often incorporate advanced technologies to manage heat dissipation and ensure proper lubrication throughout the engine, enhancing durability and performance.Expand Specific Solutions05 V12 Engine Exhaust Systems

Specialized exhaust systems are designed for V12 engines to optimize performance, reduce back pressure, and meet emissions standards. These systems may include features such as variable valve exhaust, catalytic converters, and tuned exhaust manifolds to enhance engine efficiency and sound characteristics.Expand Specific Solutions

Key Industry Players

The V12 engine mass production technology market is in a mature stage, with established players dominating the landscape. The global market size for V12 engines is relatively small but stable, primarily catering to luxury and high-performance vehicle segments. Technologically, V12 engines have reached a high level of sophistication, with companies like Toyota Motor Corp., Ford Global Technologies, and Volkswagen AG leading innovation. These firms, along with others such as BMW and Mercedes-Benz, have developed advanced manufacturing processes and materials to enhance performance and efficiency. However, the industry faces challenges from stricter emissions regulations and the shift towards electrification, prompting manufacturers to explore hybrid V12 powertrains and alternative technologies to maintain relevance in the evolving automotive landscape.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced V12 engine mass production technologies, focusing on precision manufacturing and efficiency. Their approach includes high-precision casting and machining processes, utilizing computer-controlled robotic systems for consistent quality[1]. Toyota's V12 engines feature a dual overhead camshaft (DOHC) design with variable valve timing (VVT) for improved performance and fuel efficiency[2]. The company has also implemented a modular production system, allowing for flexible manufacturing of different engine variants on the same production line[3]. Toyota's V12 engines incorporate advanced materials such as aluminum alloys for the block and heads, reducing weight while maintaining durability[4]. The mass production process integrates real-time quality control measures, using sensors and data analytics to ensure each engine meets strict performance and emissions standards[5].

Strengths: High precision manufacturing, flexible production system, advanced materials usage. Weaknesses: Higher production costs, limited market demand for V12 engines in current automotive trends.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V12 engine mass production technologies focuses on balancing performance with efficiency. Their production process incorporates advanced computer-aided design (CAD) and simulation tools to optimize engine components before physical prototyping[1]. Ford utilizes a combination of high-pressure die casting and precision CNC machining to produce engine blocks and heads with tight tolerances[2]. The company has developed a modular engine architecture that allows for shared components across different engine configurations, reducing production complexity and costs[3]. Ford's V12 engines feature direct fuel injection and variable camshaft timing to enhance power output and fuel efficiency[4]. The mass production line incorporates automated assembly systems and advanced robotics for consistent quality and reduced labor costs[5]. Ford also employs advanced testing and quality control measures, including acoustic analysis and dynamometer testing for each engine produced[6].

Strengths: Modular engine architecture, advanced simulation and design tools, automated production processes. Weaknesses: Limited market for V12 engines, high development and tooling costs.

Core Innovations

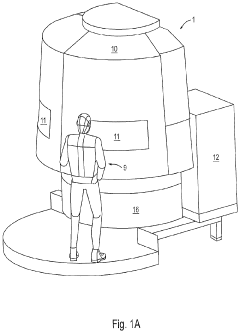

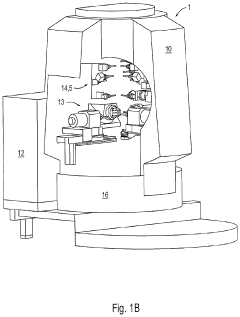

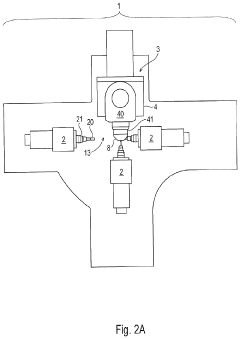

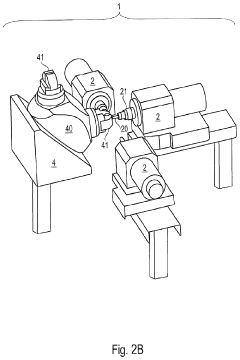

Machine Concept for the Mass Production of High-Precision Workpieces

PatentPendingUS20230398651A1

Innovation

- The machine concept optimizes machining units and technological sequences relative to workpiece characteristics, allowing for flexible expansion by adding machining centers or transferring production to a rotary transfer machine while maintaining validated production conditions, thereby minimizing resource usage and environmental impact.

Chip-size packages assembled using mass production techniques at the wafer-level

PatentInactiveUS6004867A

Innovation

- A chip-size package design featuring a semiconductor chip with exposed input/output pads, a substrate with electrically conductive traces and terminal pads, and metallic bumps that allow for flexible arrangement and mass production at the wafer level, with a barrier metal layer for enhanced bonding and a method involving wafer-level processing steps like lapping and polishing.

Environmental Impact

The environmental impact of V12 engine mass production technologies is a critical consideration in today's automotive industry. These powerful engines, while prized for their performance, face increasing scrutiny due to their potential ecological footprint. The production process of V12 engines involves significant resource consumption and energy-intensive manufacturing techniques, which contribute to greenhouse gas emissions and environmental degradation.

Material extraction and processing for V12 engines require substantial amounts of raw materials, including metals like aluminum, steel, and rare earth elements. The mining and refining of these materials can lead to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive nature of metal processing contributes to increased carbon emissions throughout the supply chain.

The manufacturing phase of V12 engines presents its own set of environmental challenges. The complex machining processes, precision engineering, and assembly techniques demand considerable energy inputs, often derived from fossil fuel sources. This reliance on non-renewable energy contributes to the overall carbon footprint of engine production. Furthermore, the use of lubricants, coolants, and other chemicals in the manufacturing process can result in hazardous waste generation, requiring careful management and disposal to prevent environmental contamination.

Transportation and logistics associated with V12 engine production also play a role in its environmental impact. The global nature of automotive supply chains means that components and finished engines often travel long distances, increasing fuel consumption and emissions from freight transport. This aspect of production further amplifies the carbon footprint of V12 engines before they even reach the end-user.

In response to these environmental concerns, manufacturers are exploring various strategies to mitigate the ecological impact of V12 engine production. Advancements in manufacturing technologies, such as more efficient CNC machining and 3D printing, offer potential for reducing material waste and energy consumption. Additionally, the implementation of closed-loop recycling systems and the use of recycled materials in engine components can help decrease the demand for virgin resources.

Efforts to improve energy efficiency in production facilities through the adoption of renewable energy sources, smart grid technologies, and energy recovery systems are becoming increasingly common. These initiatives aim to reduce the carbon intensity of V12 engine manufacturing processes. Moreover, the development of cleaner, more environmentally friendly lubricants and coolants is helping to minimize the toxic waste generated during production.

As environmental regulations become more stringent globally, V12 engine manufacturers are also focusing on end-of-life considerations. Design for disassembly and recyclability is gaining importance, with engineers working to create engines that can be more easily recycled or repurposed at the end of their lifecycle. This holistic approach to environmental impact assessment is crucial for ensuring the long-term sustainability of V12 engine production in an increasingly eco-conscious market.

Material extraction and processing for V12 engines require substantial amounts of raw materials, including metals like aluminum, steel, and rare earth elements. The mining and refining of these materials can lead to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive nature of metal processing contributes to increased carbon emissions throughout the supply chain.

The manufacturing phase of V12 engines presents its own set of environmental challenges. The complex machining processes, precision engineering, and assembly techniques demand considerable energy inputs, often derived from fossil fuel sources. This reliance on non-renewable energy contributes to the overall carbon footprint of engine production. Furthermore, the use of lubricants, coolants, and other chemicals in the manufacturing process can result in hazardous waste generation, requiring careful management and disposal to prevent environmental contamination.

Transportation and logistics associated with V12 engine production also play a role in its environmental impact. The global nature of automotive supply chains means that components and finished engines often travel long distances, increasing fuel consumption and emissions from freight transport. This aspect of production further amplifies the carbon footprint of V12 engines before they even reach the end-user.

In response to these environmental concerns, manufacturers are exploring various strategies to mitigate the ecological impact of V12 engine production. Advancements in manufacturing technologies, such as more efficient CNC machining and 3D printing, offer potential for reducing material waste and energy consumption. Additionally, the implementation of closed-loop recycling systems and the use of recycled materials in engine components can help decrease the demand for virgin resources.

Efforts to improve energy efficiency in production facilities through the adoption of renewable energy sources, smart grid technologies, and energy recovery systems are becoming increasingly common. These initiatives aim to reduce the carbon intensity of V12 engine manufacturing processes. Moreover, the development of cleaner, more environmentally friendly lubricants and coolants is helping to minimize the toxic waste generated during production.

As environmental regulations become more stringent globally, V12 engine manufacturers are also focusing on end-of-life considerations. Design for disassembly and recyclability is gaining importance, with engineers working to create engines that can be more easily recycled or repurposed at the end of their lifecycle. This holistic approach to environmental impact assessment is crucial for ensuring the long-term sustainability of V12 engine production in an increasingly eco-conscious market.

Cost-Benefit Analysis

The cost-benefit analysis of V12 engine mass production technologies reveals a complex interplay of factors that manufacturers must carefully consider. Initial investment costs for specialized tooling and production lines are substantial, often reaching into millions of dollars. However, these costs can be offset by economies of scale as production volumes increase. The precision engineering required for V12 engines demands high-quality materials and advanced manufacturing processes, which contribute to higher per-unit costs compared to smaller engines.

Labor costs associated with V12 production are significant due to the complexity of assembly and the need for skilled technicians. However, automation and advanced robotics can help reduce labor expenses over time. Quality control measures are crucial and add to overall costs, but they are essential for maintaining the premium status and reliability expected of V12 engines.

Energy consumption during production is another considerable factor. V12 engines require more machining time and energy-intensive processes, which increase utility costs. However, modern energy-efficient manufacturing techniques and equipment can help mitigate these expenses.

On the benefit side, V12 engines command premium prices in the luxury and high-performance vehicle markets, potentially yielding higher profit margins. The exclusivity and prestige associated with V12 engines can enhance brand value and customer loyalty, indirectly benefiting other product lines within a manufacturer's portfolio.

Long-term benefits include the development of advanced manufacturing capabilities that can be applied to other engine types or components. The expertise gained in producing complex V12 engines can lead to innovations in manufacturing processes, potentially reducing costs for future projects.

However, manufacturers must also consider the limited market size for V12 engines and potential regulatory challenges related to emissions standards. These factors could impact long-term profitability and necessitate ongoing investments in engine efficiency and emissions reduction technologies.

In conclusion, while the initial costs of V12 engine mass production are high, the potential for premium pricing, brand enhancement, and technological advancements can justify the investment for manufacturers targeting the luxury and high-performance segments. Careful management of production costs and a strategic approach to market positioning are essential for maximizing the benefits of V12 engine production.

Labor costs associated with V12 production are significant due to the complexity of assembly and the need for skilled technicians. However, automation and advanced robotics can help reduce labor expenses over time. Quality control measures are crucial and add to overall costs, but they are essential for maintaining the premium status and reliability expected of V12 engines.

Energy consumption during production is another considerable factor. V12 engines require more machining time and energy-intensive processes, which increase utility costs. However, modern energy-efficient manufacturing techniques and equipment can help mitigate these expenses.

On the benefit side, V12 engines command premium prices in the luxury and high-performance vehicle markets, potentially yielding higher profit margins. The exclusivity and prestige associated with V12 engines can enhance brand value and customer loyalty, indirectly benefiting other product lines within a manufacturer's portfolio.

Long-term benefits include the development of advanced manufacturing capabilities that can be applied to other engine types or components. The expertise gained in producing complex V12 engines can lead to innovations in manufacturing processes, potentially reducing costs for future projects.

However, manufacturers must also consider the limited market size for V12 engines and potential regulatory challenges related to emissions standards. These factors could impact long-term profitability and necessitate ongoing investments in engine efficiency and emissions reduction technologies.

In conclusion, while the initial costs of V12 engine mass production are high, the potential for premium pricing, brand enhancement, and technological advancements can justify the investment for manufacturers targeting the luxury and high-performance segments. Careful management of production costs and a strategic approach to market positioning are essential for maximizing the benefits of V12 engine production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!