How Future Mobility Trends Influence V12 Engines

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury and high-performance vehicles, the V12 engine has been a symbol of power, smoothness, and prestige in the automotive world. Its development has been closely tied to advancements in materials science, fuel efficiency, and emission control technologies.

In the early stages, V12 engines were primarily used in racing cars and luxury vehicles, prized for their ability to produce high power output while maintaining smooth operation. The 1930s and 1940s saw the introduction of V12 engines in iconic vehicles such as the Packard Twin Six and the Ferrari 125 S, setting new standards for performance and refinement.

The 1960s and 1970s marked a period of significant advancement in V12 engine technology. Manufacturers like Ferrari, Lamborghini, and Jaguar pushed the boundaries of performance, developing engines that could produce increasingly higher power outputs while maintaining reliability. This era also saw the introduction of fuel injection systems and improved cooling technologies, which enhanced the efficiency and reliability of V12 engines.

The 1980s and 1990s brought new challenges and opportunities for V12 engine development. Stricter emission regulations and a growing focus on fuel efficiency led to the integration of electronic engine management systems and catalytic converters. These advancements allowed V12 engines to maintain their performance characteristics while meeting increasingly stringent environmental standards.

In the 21st century, V12 engines have continued to evolve, incorporating cutting-edge technologies to improve performance, efficiency, and environmental compatibility. Modern V12 engines often feature direct fuel injection, variable valve timing, and cylinder deactivation systems. These technologies allow for optimized fuel consumption and reduced emissions without compromising the power and smoothness that V12 engines are known for.

Recent years have seen a shift towards electrification and hybridization in the automotive industry, which has influenced V12 engine development. Some manufacturers have begun integrating electric motors with V12 engines to create hybrid powertrains, combining the traditional appeal of the V12 with the efficiency and instant torque of electric propulsion.

As the automotive industry continues to evolve, the future of V12 engines faces both challenges and opportunities. While there is increasing pressure to reduce emissions and improve fuel efficiency, the unique characteristics of V12 engines ensure their continued relevance in certain market segments, particularly in ultra-luxury and high-performance vehicles.

In the early stages, V12 engines were primarily used in racing cars and luxury vehicles, prized for their ability to produce high power output while maintaining smooth operation. The 1930s and 1940s saw the introduction of V12 engines in iconic vehicles such as the Packard Twin Six and the Ferrari 125 S, setting new standards for performance and refinement.

The 1960s and 1970s marked a period of significant advancement in V12 engine technology. Manufacturers like Ferrari, Lamborghini, and Jaguar pushed the boundaries of performance, developing engines that could produce increasingly higher power outputs while maintaining reliability. This era also saw the introduction of fuel injection systems and improved cooling technologies, which enhanced the efficiency and reliability of V12 engines.

The 1980s and 1990s brought new challenges and opportunities for V12 engine development. Stricter emission regulations and a growing focus on fuel efficiency led to the integration of electronic engine management systems and catalytic converters. These advancements allowed V12 engines to maintain their performance characteristics while meeting increasingly stringent environmental standards.

In the 21st century, V12 engines have continued to evolve, incorporating cutting-edge technologies to improve performance, efficiency, and environmental compatibility. Modern V12 engines often feature direct fuel injection, variable valve timing, and cylinder deactivation systems. These technologies allow for optimized fuel consumption and reduced emissions without compromising the power and smoothness that V12 engines are known for.

Recent years have seen a shift towards electrification and hybridization in the automotive industry, which has influenced V12 engine development. Some manufacturers have begun integrating electric motors with V12 engines to create hybrid powertrains, combining the traditional appeal of the V12 with the efficiency and instant torque of electric propulsion.

As the automotive industry continues to evolve, the future of V12 engines faces both challenges and opportunities. While there is increasing pressure to reduce emissions and improve fuel efficiency, the unique characteristics of V12 engines ensure their continued relevance in certain market segments, particularly in ultra-luxury and high-performance vehicles.

Future Mobility Market

The future mobility market is undergoing a significant transformation, driven by technological advancements, changing consumer preferences, and environmental concerns. This shift is reshaping the automotive industry and challenging traditional powertrain technologies, including V12 engines.

Electric vehicles (EVs) are gaining substantial market share, with global EV sales reaching 10.5 million units in 2022, representing a 55% year-over-year increase. This growth is expected to continue, with projections suggesting EVs could account for 30% of all vehicle sales by 2030. The rise of EVs is primarily fueled by improvements in battery technology, decreasing costs, and increasing charging infrastructure.

Autonomous driving technology is another key trend shaping the future mobility market. While fully autonomous vehicles are not yet widespread, advanced driver assistance systems (ADAS) are becoming increasingly common. The global ADAS market is projected to grow at a CAGR of 11.9% from 2021 to 2030, reaching a value of $74.9 billion by the end of the forecast period.

Shared mobility services, including ride-hailing and car-sharing platforms, are also influencing the future mobility landscape. These services are changing the way people think about car ownership and transportation. The global shared mobility market size was valued at $99.5 billion in 2021 and is expected to expand at a CAGR of 25.1% from 2022 to 2030.

Connectivity is becoming a crucial feature in modern vehicles, with the connected car market projected to grow from $53.9 billion in 2020 to $166 billion by 2025, at a CAGR of 25.2%. This trend is driving demand for vehicles with advanced infotainment systems, over-the-air updates, and vehicle-to-everything (V2X) communication capabilities.

Environmental regulations and sustainability concerns are pushing the industry towards cleaner technologies. Many countries have announced plans to phase out internal combustion engines, with some targeting bans on new gasoline and diesel vehicle sales by 2030 or 2035. This regulatory pressure is accelerating the shift towards electrification and other alternative powertrains.

These trends are collectively reshaping the future mobility market, creating both challenges and opportunities for traditional automotive technologies like V12 engines. As the market evolves, manufacturers will need to adapt their strategies and product offerings to remain competitive in this rapidly changing landscape.

Electric vehicles (EVs) are gaining substantial market share, with global EV sales reaching 10.5 million units in 2022, representing a 55% year-over-year increase. This growth is expected to continue, with projections suggesting EVs could account for 30% of all vehicle sales by 2030. The rise of EVs is primarily fueled by improvements in battery technology, decreasing costs, and increasing charging infrastructure.

Autonomous driving technology is another key trend shaping the future mobility market. While fully autonomous vehicles are not yet widespread, advanced driver assistance systems (ADAS) are becoming increasingly common. The global ADAS market is projected to grow at a CAGR of 11.9% from 2021 to 2030, reaching a value of $74.9 billion by the end of the forecast period.

Shared mobility services, including ride-hailing and car-sharing platforms, are also influencing the future mobility landscape. These services are changing the way people think about car ownership and transportation. The global shared mobility market size was valued at $99.5 billion in 2021 and is expected to expand at a CAGR of 25.1% from 2022 to 2030.

Connectivity is becoming a crucial feature in modern vehicles, with the connected car market projected to grow from $53.9 billion in 2020 to $166 billion by 2025, at a CAGR of 25.2%. This trend is driving demand for vehicles with advanced infotainment systems, over-the-air updates, and vehicle-to-everything (V2X) communication capabilities.

Environmental regulations and sustainability concerns are pushing the industry towards cleaner technologies. Many countries have announced plans to phase out internal combustion engines, with some targeting bans on new gasoline and diesel vehicle sales by 2030 or 2035. This regulatory pressure is accelerating the shift towards electrification and other alternative powertrains.

These trends are collectively reshaping the future mobility market, creating both challenges and opportunities for traditional automotive technologies like V12 engines. As the market evolves, manufacturers will need to adapt their strategies and product offerings to remain competitive in this rapidly changing landscape.

V12 Tech Challenges

The V12 engine, long revered for its power, smoothness, and prestige, faces significant challenges in the rapidly evolving landscape of future mobility. As the automotive industry shifts towards electrification, autonomy, and sustainability, V12 engines must adapt to remain relevant or risk becoming obsolete.

One of the primary challenges for V12 engines is meeting increasingly stringent emissions regulations. With many countries and regions implementing strict CO2 emission targets and planning to phase out internal combustion engines, V12 manufacturers must invest heavily in advanced technologies to reduce their environmental impact. This includes developing more efficient combustion processes, implementing sophisticated exhaust after-treatment systems, and exploring hybrid powertrains to complement the V12's output.

Fuel efficiency is another critical hurdle for V12 engines. As consumers and regulators demand better fuel economy, the inherently thirsty nature of these large-displacement engines becomes a significant liability. Engineers must find innovative ways to improve efficiency without compromising the performance characteristics that define the V12 experience. This may involve technologies such as cylinder deactivation, advanced thermal management, and intelligent engine control systems.

The shift towards electric powertrains poses an existential threat to V12 engines. As battery technology improves and electric motors become more powerful and efficient, the performance gap between electric vehicles and traditional high-performance engines narrows. V12 manufacturers must contend with the superior torque delivery and instant acceleration of electric powertrains while justifying the continued development of complex, expensive internal combustion engines.

Weight reduction is another challenge facing V12 engines. As vehicles incorporate more technology and safety features, keeping overall weight in check becomes crucial for performance and efficiency. The substantial mass of a V12 engine can negatively impact vehicle dynamics and fuel consumption, requiring innovative materials and design solutions to mitigate these effects.

The complexity and cost of V12 engines present additional hurdles in a market increasingly focused on simplification and cost reduction. The intricate nature of these powerplants results in higher manufacturing and maintenance costs, which can be difficult to justify in an era of downsizing and electrification. Manufacturers must find ways to streamline production and reduce complexity without sacrificing the qualities that make V12 engines special.

Lastly, the changing perception of luxury and performance in the automotive world challenges the traditional appeal of V12 engines. As silent, vibration-free electric powertrains become associated with premium experiences, V12 manufacturers must redefine the value proposition of their engines to maintain their allure in high-end vehicles.

One of the primary challenges for V12 engines is meeting increasingly stringent emissions regulations. With many countries and regions implementing strict CO2 emission targets and planning to phase out internal combustion engines, V12 manufacturers must invest heavily in advanced technologies to reduce their environmental impact. This includes developing more efficient combustion processes, implementing sophisticated exhaust after-treatment systems, and exploring hybrid powertrains to complement the V12's output.

Fuel efficiency is another critical hurdle for V12 engines. As consumers and regulators demand better fuel economy, the inherently thirsty nature of these large-displacement engines becomes a significant liability. Engineers must find innovative ways to improve efficiency without compromising the performance characteristics that define the V12 experience. This may involve technologies such as cylinder deactivation, advanced thermal management, and intelligent engine control systems.

The shift towards electric powertrains poses an existential threat to V12 engines. As battery technology improves and electric motors become more powerful and efficient, the performance gap between electric vehicles and traditional high-performance engines narrows. V12 manufacturers must contend with the superior torque delivery and instant acceleration of electric powertrains while justifying the continued development of complex, expensive internal combustion engines.

Weight reduction is another challenge facing V12 engines. As vehicles incorporate more technology and safety features, keeping overall weight in check becomes crucial for performance and efficiency. The substantial mass of a V12 engine can negatively impact vehicle dynamics and fuel consumption, requiring innovative materials and design solutions to mitigate these effects.

The complexity and cost of V12 engines present additional hurdles in a market increasingly focused on simplification and cost reduction. The intricate nature of these powerplants results in higher manufacturing and maintenance costs, which can be difficult to justify in an era of downsizing and electrification. Manufacturers must find ways to streamline production and reduce complexity without sacrificing the qualities that make V12 engines special.

Lastly, the changing perception of luxury and performance in the automotive world challenges the traditional appeal of V12 engines. As silent, vibration-free electric powertrains become associated with premium experiences, V12 manufacturers must redefine the value proposition of their engines to maintain their allure in high-end vehicles.

Current V12 Solutions

01 V12 Engine Design and Configuration

V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine design while providing high power output and smooth operation. The V12 layout is often used in high-performance and luxury vehicles due to its balance of power and refinement.- V12 Engine Design and Configuration: V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design allows for smooth operation, high power output, and balanced performance. The V12 layout is often used in high-performance and luxury vehicles due to its ability to produce significant horsepower while maintaining relatively compact dimensions.

- Fuel Efficiency and Emissions Control in V12 Engines: Modern V12 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, and cylinder deactivation systems. Manufacturers are continually developing new methods to optimize the performance of V12 engines while meeting increasingly stringent environmental regulations.

- V12 Engine Control Systems: Sophisticated electronic control systems are crucial for managing the complex operations of V12 engines. These systems monitor and adjust various parameters such as fuel injection, ignition timing, and air-fuel mixture to optimize performance, efficiency, and emissions. Advanced engine management software and sensors play a key role in fine-tuning V12 engine operation.

- V12 Engine Applications in Various Industries: While commonly associated with high-end automobiles, V12 engines find applications in various industries. They are used in marine propulsion systems, aviation, and even in some industrial power generation units. The versatility of V12 engines makes them suitable for applications requiring high power output and reliability.

- Historical Development of V12 Engines: The development of V12 engines has a rich history dating back to the early 20th century. Early designs were primarily used in luxury automobiles and aircraft. Over time, advancements in materials, manufacturing techniques, and engineering have led to significant improvements in V12 engine performance, efficiency, and reliability. The evolution of V12 engines reflects broader trends in automotive and mechanical engineering.

02 Engine Control Systems for V12 Engines

Advanced control systems are crucial for optimizing the performance and efficiency of V12 engines. These systems manage fuel injection, ignition timing, and other parameters to ensure optimal engine operation across various driving conditions. Modern V12 engines often incorporate sophisticated electronic control units (ECUs) to fine-tune engine performance.Expand Specific Solutions03 Fuel Efficiency Improvements in V12 Engines

Despite their high power output, modern V12 engines incorporate various technologies to improve fuel efficiency. These may include direct fuel injection, variable valve timing, and cylinder deactivation systems. Such advancements help reduce fuel consumption while maintaining the performance characteristics expected from a V12 engine.Expand Specific Solutions04 Historical Development of V12 Engines

The development of V12 engines has a rich history dating back to the early 20th century. Early designs were often used in luxury automobiles and aircraft. Over time, V12 engines have evolved significantly, incorporating new materials, manufacturing techniques, and technologies to improve performance, reliability, and efficiency.Expand Specific Solutions05 Applications of V12 Engines

V12 engines find applications in various fields beyond automotive use. They are employed in marine vessels, stationary power generation, and even some aircraft. In the automotive sector, V12 engines are typically reserved for high-end luxury cars, sports cars, and racing vehicles where their power, smoothness, and prestige are highly valued.Expand Specific Solutions

Key V12 Manufacturers

The future mobility trends influencing V12 engines present a complex competitive landscape. The industry is in a transitional phase, with traditional automotive giants like Toyota, Ford, and GM competing against emerging players in electric and hybrid technologies. The market for high-performance engines remains significant, but is facing pressure from environmental regulations and shifting consumer preferences. Technologically, companies like Yamaha, Caterpillar, and Ballard Power Systems are advancing engine efficiency and exploring alternative powertrains. Luxury brands such as Jaguar Land Rover continue to invest in V12 development, while others like BorgWarner and AVL List focus on innovative powertrain solutions. This dynamic environment is driving rapid innovation and strategic partnerships across the automotive sector.

Toyota Motor Corp.

Technical Solution: Toyota is addressing the future of V12 engines in the context of evolving mobility trends through a multi-faceted approach. While not a traditional V12 manufacturer, Toyota's luxury brand Lexus has experience with V8 engines and is applying similar principles to larger configurations. The company is focusing on hybridization, with plans to develop high-performance hybrid systems that could potentially complement or replace V12 engines in luxury and performance applications[10]. Toyota is also investing in hydrogen combustion engine technology, which could be scaled up to V12 configurations, offering a zero-emission alternative with the characteristic sound and feel of a large displacement engine[11]. Additionally, Toyota is exploring advanced materials and manufacturing techniques to reduce the weight and improve the efficiency of large engines, potentially extending the viability of V12-like powertrains in future mobility scenarios[12].

Strengths: Strong hybrid technology expertise and innovative alternative fuel solutions. Weaknesses: Limited experience with V12 engines specifically, which may affect brand perception in ultra-luxury segments.

Ford Global Technologies LLC

Technical Solution: Ford is addressing future mobility trends in relation to V12 engines by focusing on downsizing and electrification. While not traditionally known for V12 engines, Ford's approach involves developing smaller, more efficient engines with similar power outputs. They are implementing advanced turbocharging technologies and hybrid systems to achieve V12-like performance from smaller displacement engines[4]. Ford is also exploring the use of sustainable fuels and improving engine thermal efficiency to meet stricter emissions standards[5]. The company's EcoBoost technology serves as a foundation for these advancements, potentially offering V12-level power with significantly reduced fuel consumption and emissions[6].

Strengths: Cost-effective alternative to traditional V12 engines with improved fuel efficiency. Weaknesses: May not fully replicate the prestige and sound characteristics of true V12 engines.

V12 Innovations

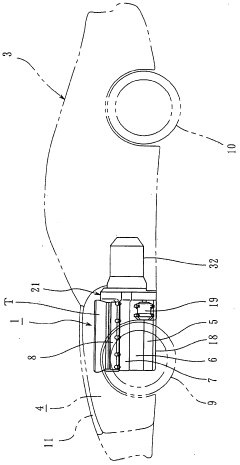

V-engine for vehicle

PatentWO2003074852A1

Innovation

- The V-type engine design incorporates auxiliary machines and transmission means on both sides of the crankshaft, with a dry sump lubrication system and strategically positioned output shafts and valve drive shafts to adjust the engine's center of gravity closer to the vehicle's center, allowing for improved power transmission and reduced height, while balancing weights for enhanced stability.

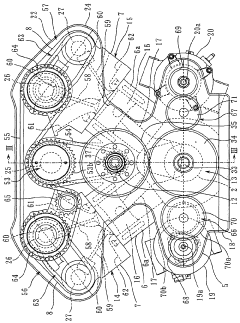

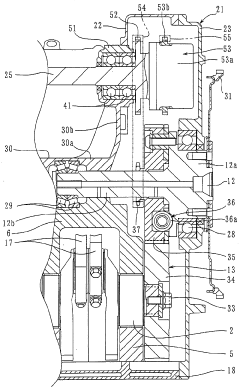

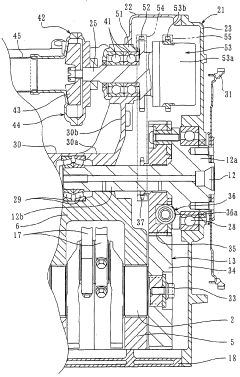

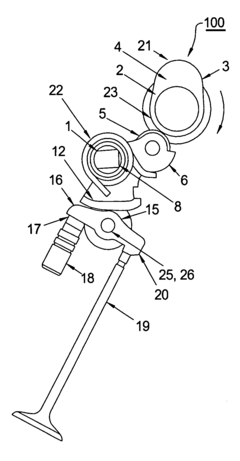

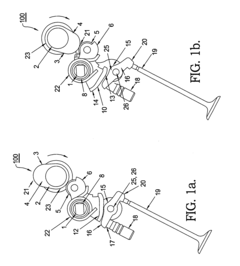

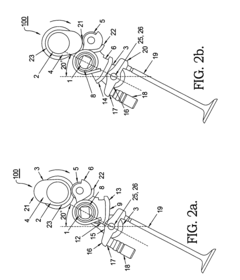

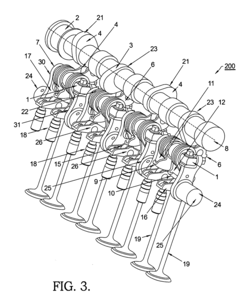

Variable valve actuation system having a crank-based actuation transmission

PatentInactiveUS20080141960A1

Innovation

- A simplified mechanical VVA system using a single electrical rotary actuator and a secondary crank mechanism with an eccentric transmission to vary valve lift, duration, and phasing, eliminating the need for multiple frame structures and parasitic loads, and reducing the number of mechanical parts for easier assembly and reduced power consumption.

Emissions Regulations

Emissions regulations have become a critical factor shaping the future of V12 engines in the automotive industry. As global concerns about climate change and air quality intensify, governments worldwide are implementing increasingly stringent emissions standards. These regulations aim to reduce greenhouse gas emissions and improve air quality in urban areas, directly impacting the viability of high-performance, large-displacement engines like the V12.

The European Union, for instance, has set ambitious targets for reducing CO2 emissions from new cars. By 2030, the EU aims to reduce CO2 emissions from new cars by 37.5% compared to 2021 levels. This presents a significant challenge for manufacturers of V12 engines, as these powerplants typically produce higher levels of CO2 emissions due to their larger displacement and fuel consumption.

In the United States, the Corporate Average Fuel Economy (CAFE) standards continue to evolve, pushing automakers to improve overall fleet efficiency. While some exemptions exist for low-volume manufacturers, the general trend towards stricter fuel economy requirements poses challenges for V12 engines, which are often found in luxury and high-performance vehicles.

China, the world's largest automotive market, has also implemented stringent emissions regulations. The China 6 standard, equivalent to Euro 6, sets strict limits on pollutants such as nitrogen oxides (NOx) and particulate matter. These regulations have forced manufacturers to invest heavily in advanced emission control technologies or consider alternative powertrains.

To comply with these regulations, manufacturers are exploring various strategies. Some are implementing advanced technologies such as cylinder deactivation, direct injection, and improved thermal management to enhance the efficiency of V12 engines. Others are turning to hybridization, combining V12 engines with electric motors to reduce overall emissions while maintaining performance.

However, the long-term viability of V12 engines in the face of tightening emissions regulations remains uncertain. Many automakers are shifting their focus towards smaller, turbocharged engines or fully electric powertrains. This shift is driven not only by regulatory pressures but also by changing consumer preferences and the need to future-proof their product lines.

As emissions regulations continue to evolve, the future of V12 engines will likely depend on technological advancements and the ability of manufacturers to balance performance with environmental compliance. While some niche markets may continue to support V12 engines, their widespread use in mainstream vehicles is likely to diminish as the automotive industry transitions towards more sustainable mobility solutions.

The European Union, for instance, has set ambitious targets for reducing CO2 emissions from new cars. By 2030, the EU aims to reduce CO2 emissions from new cars by 37.5% compared to 2021 levels. This presents a significant challenge for manufacturers of V12 engines, as these powerplants typically produce higher levels of CO2 emissions due to their larger displacement and fuel consumption.

In the United States, the Corporate Average Fuel Economy (CAFE) standards continue to evolve, pushing automakers to improve overall fleet efficiency. While some exemptions exist for low-volume manufacturers, the general trend towards stricter fuel economy requirements poses challenges for V12 engines, which are often found in luxury and high-performance vehicles.

China, the world's largest automotive market, has also implemented stringent emissions regulations. The China 6 standard, equivalent to Euro 6, sets strict limits on pollutants such as nitrogen oxides (NOx) and particulate matter. These regulations have forced manufacturers to invest heavily in advanced emission control technologies or consider alternative powertrains.

To comply with these regulations, manufacturers are exploring various strategies. Some are implementing advanced technologies such as cylinder deactivation, direct injection, and improved thermal management to enhance the efficiency of V12 engines. Others are turning to hybridization, combining V12 engines with electric motors to reduce overall emissions while maintaining performance.

However, the long-term viability of V12 engines in the face of tightening emissions regulations remains uncertain. Many automakers are shifting their focus towards smaller, turbocharged engines or fully electric powertrains. This shift is driven not only by regulatory pressures but also by changing consumer preferences and the need to future-proof their product lines.

As emissions regulations continue to evolve, the future of V12 engines will likely depend on technological advancements and the ability of manufacturers to balance performance with environmental compliance. While some niche markets may continue to support V12 engines, their widespread use in mainstream vehicles is likely to diminish as the automotive industry transitions towards more sustainable mobility solutions.

Electrification Impact

The electrification of the automotive industry is undoubtedly one of the most significant trends shaping the future of mobility. This shift towards electric powertrains has profound implications for traditional internal combustion engines, particularly high-performance V12 engines. As governments worldwide implement stricter emissions regulations and automakers commit to electrification targets, the landscape for V12 engines is rapidly changing.

The impact of electrification on V12 engines is multifaceted. Firstly, the increasing adoption of hybrid powertrains has allowed some manufacturers to maintain V12 engines in their lineups while improving fuel efficiency and reducing emissions. This approach combines the prestige and performance of V12 engines with the benefits of electric assistance, potentially extending their viability in the short to medium term.

However, the long-term outlook for V12 engines in a fully electrified future is challenging. As battery technology advances and electric motors become more powerful and efficient, the performance advantages of V12 engines are being eroded. Electric vehicles can now match or exceed the acceleration and top speeds of V12-powered cars while offering instant torque and smoother power delivery.

The shift towards electrification is also influencing consumer preferences and market demand. As environmental consciousness grows, luxury and performance car buyers are increasingly considering electric alternatives. This trend is putting pressure on manufacturers to justify the continued development and production of V12 engines, which are inherently less efficient and more emissions-intensive than their electric counterparts.

From a manufacturing perspective, the transition to electrification is prompting automakers to reallocate resources and investment away from internal combustion engine development, including V12 engines. This shift in focus is likely to accelerate the decline of V12 engines as companies prioritize electric powertrain technologies to meet future market demands and regulatory requirements.

Nevertheless, the emotional appeal and brand heritage associated with V12 engines should not be underestimated. Some manufacturers may choose to preserve V12 engines in limited production runs or special editions, leveraging their iconic status to create exclusive, high-value products. These engines could become even more prized by enthusiasts and collectors as they become increasingly rare in the electrified automotive landscape.

In conclusion, while electrification poses significant challenges to the future of V12 engines, it may also create opportunities for innovation and differentiation in the high-end automotive market. The ultimate fate of V12 engines will depend on how manufacturers balance tradition, performance, and sustainability in an increasingly electrified world.

The impact of electrification on V12 engines is multifaceted. Firstly, the increasing adoption of hybrid powertrains has allowed some manufacturers to maintain V12 engines in their lineups while improving fuel efficiency and reducing emissions. This approach combines the prestige and performance of V12 engines with the benefits of electric assistance, potentially extending their viability in the short to medium term.

However, the long-term outlook for V12 engines in a fully electrified future is challenging. As battery technology advances and electric motors become more powerful and efficient, the performance advantages of V12 engines are being eroded. Electric vehicles can now match or exceed the acceleration and top speeds of V12-powered cars while offering instant torque and smoother power delivery.

The shift towards electrification is also influencing consumer preferences and market demand. As environmental consciousness grows, luxury and performance car buyers are increasingly considering electric alternatives. This trend is putting pressure on manufacturers to justify the continued development and production of V12 engines, which are inherently less efficient and more emissions-intensive than their electric counterparts.

From a manufacturing perspective, the transition to electrification is prompting automakers to reallocate resources and investment away from internal combustion engine development, including V12 engines. This shift in focus is likely to accelerate the decline of V12 engines as companies prioritize electric powertrain technologies to meet future market demands and regulatory requirements.

Nevertheless, the emotional appeal and brand heritage associated with V12 engines should not be underestimated. Some manufacturers may choose to preserve V12 engines in limited production runs or special editions, leveraging their iconic status to create exclusive, high-value products. These engines could become even more prized by enthusiasts and collectors as they become increasingly rare in the electrified automotive landscape.

In conclusion, while electrification poses significant challenges to the future of V12 engines, it may also create opportunities for innovation and differentiation in the high-end automotive market. The ultimate fate of V12 engines will depend on how manufacturers balance tradition, performance, and sustainability in an increasingly electrified world.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!