The Influence of Predictive Models on V12 Engine Wear Assessment

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Wear Prediction Background

The V12 engine, renowned for its power and smoothness, has been a hallmark of high-performance vehicles for decades. As these engines continue to be utilized in luxury and sports cars, the need for accurate wear prediction has become increasingly crucial. Engine wear assessment plays a vital role in maintaining optimal performance, ensuring longevity, and preventing catastrophic failures.

Historically, engine wear prediction relied heavily on scheduled maintenance and periodic inspections. However, these methods often resulted in unnecessary servicing or missed critical wear issues. The advent of predictive models has revolutionized the approach to V12 engine wear assessment, offering a more proactive and data-driven methodology.

Predictive models for V12 engine wear incorporate various data sources, including real-time sensor readings, historical performance data, and environmental factors. These models utilize advanced algorithms and machine learning techniques to analyze complex patterns and correlations within the data. By doing so, they can forecast potential wear issues before they become critical, allowing for timely interventions and optimized maintenance schedules.

The development of predictive models for V12 engine wear has been driven by several factors. Firstly, the increasing complexity of modern V12 engines, with their intricate systems and components, necessitates more sophisticated monitoring techniques. Secondly, the high cost associated with V12 engine maintenance and repairs has created a strong economic incentive for more accurate wear prediction. Lastly, advancements in sensor technology and data analytics have made it possible to collect and process vast amounts of engine performance data in real-time.

The influence of predictive models on V12 engine wear assessment has been profound. These models have enabled a shift from reactive to proactive maintenance strategies, significantly reducing downtime and extending engine life. They have also improved the overall reliability of V12 engines, enhancing their appeal in high-end automotive applications.

Moreover, predictive models have contributed to the optimization of engine design and manufacturing processes. By providing insights into wear patterns and failure modes, these models have informed engineers about areas for improvement, leading to more durable and efficient V12 engines.

As we look towards the future, the role of predictive models in V12 engine wear assessment is expected to grow even further. With the integration of artificial intelligence and the Internet of Things (IoT), these models are becoming increasingly sophisticated and accurate. This evolution promises to bring about a new era of intelligent engine management, where wear prediction is seamlessly integrated into the overall vehicle health monitoring system.

Historically, engine wear prediction relied heavily on scheduled maintenance and periodic inspections. However, these methods often resulted in unnecessary servicing or missed critical wear issues. The advent of predictive models has revolutionized the approach to V12 engine wear assessment, offering a more proactive and data-driven methodology.

Predictive models for V12 engine wear incorporate various data sources, including real-time sensor readings, historical performance data, and environmental factors. These models utilize advanced algorithms and machine learning techniques to analyze complex patterns and correlations within the data. By doing so, they can forecast potential wear issues before they become critical, allowing for timely interventions and optimized maintenance schedules.

The development of predictive models for V12 engine wear has been driven by several factors. Firstly, the increasing complexity of modern V12 engines, with their intricate systems and components, necessitates more sophisticated monitoring techniques. Secondly, the high cost associated with V12 engine maintenance and repairs has created a strong economic incentive for more accurate wear prediction. Lastly, advancements in sensor technology and data analytics have made it possible to collect and process vast amounts of engine performance data in real-time.

The influence of predictive models on V12 engine wear assessment has been profound. These models have enabled a shift from reactive to proactive maintenance strategies, significantly reducing downtime and extending engine life. They have also improved the overall reliability of V12 engines, enhancing their appeal in high-end automotive applications.

Moreover, predictive models have contributed to the optimization of engine design and manufacturing processes. By providing insights into wear patterns and failure modes, these models have informed engineers about areas for improvement, leading to more durable and efficient V12 engines.

As we look towards the future, the role of predictive models in V12 engine wear assessment is expected to grow even further. With the integration of artificial intelligence and the Internet of Things (IoT), these models are becoming increasingly sophisticated and accurate. This evolution promises to bring about a new era of intelligent engine management, where wear prediction is seamlessly integrated into the overall vehicle health monitoring system.

Market Demand Analysis

The market demand for predictive models in V12 engine wear assessment has been steadily increasing over the past decade. This growth is primarily driven by the automotive and aerospace industries, where high-performance V12 engines are commonly used in luxury vehicles, racing cars, and certain aircraft. The need for accurate wear prediction models stems from the high costs associated with engine maintenance, repair, and potential failures.

In the automotive sector, luxury car manufacturers are particularly interested in these predictive models. Brands like Ferrari, Lamborghini, and Aston Martin, which frequently use V12 engines in their high-end models, are investing heavily in predictive maintenance technologies. These companies aim to enhance customer satisfaction by reducing unexpected breakdowns and optimizing service intervals.

The racing industry also shows significant demand for V12 engine wear assessment models. Formula 1 and endurance racing teams are constantly seeking ways to maximize engine performance while minimizing wear. Predictive models allow them to push their engines to the limit without risking catastrophic failures during races.

In the aerospace sector, although V12 engines are less common, there is still a niche market for wear assessment models in certain private jets and military aircraft. The high stakes involved in aviation make predictive maintenance a critical factor in ensuring safety and operational efficiency.

The market for these predictive models is not limited to end-users of V12 engines. Engine manufacturers, automotive suppliers, and maintenance service providers are also key players in driving demand. These companies are looking to integrate advanced wear prediction capabilities into their products and services to gain a competitive edge.

There is a growing trend towards the integration of artificial intelligence and machine learning techniques in engine wear prediction. This has opened up new market opportunities for software companies and data analytics firms specializing in AI-driven predictive maintenance solutions.

The global predictive maintenance market, which includes engine wear assessment, is expected to see significant growth in the coming years. While specific figures for V12 engine wear models are not readily available, the overall predictive maintenance market is projected to expand at a compound annual growth rate of over 25% through 2026.

Factors contributing to this market growth include the increasing adoption of Industrial Internet of Things (IIoT) technologies, the rising focus on reducing operational costs, and the growing awareness of the benefits of predictive maintenance in extending equipment lifespan.

However, challenges such as the high initial investment costs for implementing predictive models and the need for specialized expertise in data analysis may slow down market penetration, particularly among smaller companies and in developing economies.

In the automotive sector, luxury car manufacturers are particularly interested in these predictive models. Brands like Ferrari, Lamborghini, and Aston Martin, which frequently use V12 engines in their high-end models, are investing heavily in predictive maintenance technologies. These companies aim to enhance customer satisfaction by reducing unexpected breakdowns and optimizing service intervals.

The racing industry also shows significant demand for V12 engine wear assessment models. Formula 1 and endurance racing teams are constantly seeking ways to maximize engine performance while minimizing wear. Predictive models allow them to push their engines to the limit without risking catastrophic failures during races.

In the aerospace sector, although V12 engines are less common, there is still a niche market for wear assessment models in certain private jets and military aircraft. The high stakes involved in aviation make predictive maintenance a critical factor in ensuring safety and operational efficiency.

The market for these predictive models is not limited to end-users of V12 engines. Engine manufacturers, automotive suppliers, and maintenance service providers are also key players in driving demand. These companies are looking to integrate advanced wear prediction capabilities into their products and services to gain a competitive edge.

There is a growing trend towards the integration of artificial intelligence and machine learning techniques in engine wear prediction. This has opened up new market opportunities for software companies and data analytics firms specializing in AI-driven predictive maintenance solutions.

The global predictive maintenance market, which includes engine wear assessment, is expected to see significant growth in the coming years. While specific figures for V12 engine wear models are not readily available, the overall predictive maintenance market is projected to expand at a compound annual growth rate of over 25% through 2026.

Factors contributing to this market growth include the increasing adoption of Industrial Internet of Things (IIoT) technologies, the rising focus on reducing operational costs, and the growing awareness of the benefits of predictive maintenance in extending equipment lifespan.

However, challenges such as the high initial investment costs for implementing predictive models and the need for specialized expertise in data analysis may slow down market penetration, particularly among smaller companies and in developing economies.

Current Challenges in Engine Wear Assessment

Engine wear assessment in V12 engines faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of wear patterns in these high-performance engines. V12 engines, with their intricate design and multiple moving parts, exhibit wear in various components simultaneously, making it difficult to isolate and accurately assess individual wear factors.

The integration of predictive models into wear assessment processes has introduced new challenges. While these models offer the potential for more accurate and proactive maintenance, they also require vast amounts of high-quality data to function effectively. Collecting and managing this data, especially in real-time operating conditions, poses significant technical and logistical hurdles.

Another challenge lies in the variability of operating conditions for V12 engines. These engines are often used in diverse applications, from high-performance sports cars to luxury vehicles and even some industrial applications. Each use case presents unique wear patterns and stress factors, making it difficult to develop universally applicable predictive models.

The rapid pace of technological advancement in engine design and materials science further complicates wear assessment. As new materials and manufacturing techniques are introduced, existing wear models may become obsolete or require significant recalibration. This constant evolution necessitates ongoing research and development to keep predictive models relevant and accurate.

Sensor technology, while advancing, still presents limitations in accurately measuring all relevant parameters for wear assessment. Some critical wear indicators may occur in areas that are difficult to monitor continuously, leading to potential gaps in data collection and analysis.

The interpretation of data from predictive models poses another significant challenge. Translating complex model outputs into actionable maintenance decisions requires a high level of expertise and can be prone to human error. There is an ongoing need for more intuitive and user-friendly interfaces that can bridge the gap between sophisticated predictive algorithms and practical maintenance applications.

Lastly, the cost-effectiveness of implementing advanced predictive wear assessment systems remains a challenge, particularly for smaller-scale operations or individual vehicle owners. Balancing the benefits of predictive maintenance against the investment required for sophisticated monitoring and analysis systems is an ongoing consideration in the industry.

The integration of predictive models into wear assessment processes has introduced new challenges. While these models offer the potential for more accurate and proactive maintenance, they also require vast amounts of high-quality data to function effectively. Collecting and managing this data, especially in real-time operating conditions, poses significant technical and logistical hurdles.

Another challenge lies in the variability of operating conditions for V12 engines. These engines are often used in diverse applications, from high-performance sports cars to luxury vehicles and even some industrial applications. Each use case presents unique wear patterns and stress factors, making it difficult to develop universally applicable predictive models.

The rapid pace of technological advancement in engine design and materials science further complicates wear assessment. As new materials and manufacturing techniques are introduced, existing wear models may become obsolete or require significant recalibration. This constant evolution necessitates ongoing research and development to keep predictive models relevant and accurate.

Sensor technology, while advancing, still presents limitations in accurately measuring all relevant parameters for wear assessment. Some critical wear indicators may occur in areas that are difficult to monitor continuously, leading to potential gaps in data collection and analysis.

The interpretation of data from predictive models poses another significant challenge. Translating complex model outputs into actionable maintenance decisions requires a high level of expertise and can be prone to human error. There is an ongoing need for more intuitive and user-friendly interfaces that can bridge the gap between sophisticated predictive algorithms and practical maintenance applications.

Lastly, the cost-effectiveness of implementing advanced predictive wear assessment systems remains a challenge, particularly for smaller-scale operations or individual vehicle owners. Balancing the benefits of predictive maintenance against the investment required for sophisticated monitoring and analysis systems is an ongoing consideration in the industry.

Existing Predictive Solutions

01 Machine learning models for engine wear prediction

Advanced machine learning algorithms are employed to create predictive models for engine wear. These models analyze various data inputs such as operational parameters, sensor readings, and historical maintenance records to forecast potential wear and tear on engine components. This approach enables proactive maintenance scheduling and helps optimize engine performance.- Machine learning models for engine wear prediction: Advanced machine learning algorithms are employed to create predictive models for engine wear. These models analyze various engine parameters and historical data to forecast potential wear and tear, enabling proactive maintenance and optimizing engine performance.

- Sensor-based data collection for wear analysis: Sophisticated sensor systems are integrated into engines to collect real-time data on various operational parameters. This data is then used to feed predictive models, providing accurate and timely information on engine wear patterns and potential failures.

- AI-powered predictive maintenance strategies: Artificial Intelligence is utilized to develop advanced predictive maintenance strategies. These AI systems analyze complex patterns in engine data to predict wear-related issues before they occur, allowing for timely interventions and reducing downtime.

- Digital twin technology for engine wear simulation: Digital twin technology is employed to create virtual replicas of physical engines. These digital models simulate various wear scenarios, allowing for accurate predictions of engine lifespan and optimization of maintenance schedules without risking actual hardware.

- Integration of historical and real-time data for wear forecasting: Predictive models combine historical engine performance data with real-time operational data to create more accurate wear forecasts. This integrated approach allows for dynamic adjustments to predictions based on current engine conditions and past wear patterns.

02 Real-time monitoring and analysis of engine data

Systems are developed to continuously monitor and analyze engine performance data in real-time. These systems utilize sensors and data processing techniques to collect and interpret information on engine operating conditions, temperature, pressure, and other relevant parameters. The real-time analysis helps in early detection of potential wear issues and allows for timely interventions.Expand Specific Solutions03 Integration of historical data and predictive analytics

Predictive models for engine wear incorporate historical maintenance data and operational records. By analyzing past patterns and trends, these models can more accurately predict future wear scenarios. This integration of historical data with advanced analytics techniques enhances the reliability and accuracy of wear predictions.Expand Specific Solutions04 AI-driven optimization of engine maintenance schedules

Artificial intelligence algorithms are used to optimize engine maintenance schedules based on predicted wear patterns. These AI systems consider multiple factors such as operational demands, component lifespans, and predicted failure rates to generate efficient maintenance plans. This approach helps in reducing downtime and extending engine life while minimizing unnecessary maintenance.Expand Specific Solutions05 Predictive modeling for specific engine components

Specialized predictive models are developed for individual engine components such as pistons, valves, and bearings. These models focus on the unique wear characteristics and failure modes of each component, allowing for more targeted and accurate predictions. By addressing component-specific wear patterns, maintenance efforts can be more effectively prioritized and executed.Expand Specific Solutions

Key Players in Engine Diagnostics

The predictive modeling of V12 engine wear assessment is in a nascent stage, with the market still developing and technology maturity varying across players. Industry leaders like Cummins, Pratt & Whitney Canada, and Safran Aircraft Engines are at the forefront, leveraging their extensive experience in engine manufacturing. The market size is growing, driven by the increasing demand for high-performance engines in luxury vehicles and aviation. Tech giants like Google and Oracle are also entering the space, bringing advanced AI and data analytics capabilities. Universities and research institutions, such as Guangxi University and Civil Aviation University of China, are contributing to the field's academic advancement, indicating a collaborative ecosystem for innovation in this domain.

Cummins, Inc.

Technical Solution: Cummins has developed a robust predictive model for V12 engine wear assessment, leveraging their extensive experience in engine manufacturing and maintenance. Their approach combines traditional reliability engineering principles with advanced data analytics and machine learning techniques. Cummins' model utilizes a vast array of sensors to monitor key engine parameters, including oil pressure, fuel efficiency, and exhaust gas composition. The collected data is processed through a sophisticated algorithm that incorporates both physics-based models and data-driven predictions[7]. Cummins has also implemented edge computing solutions to enable real-time analysis and rapid response to potential wear issues, even in remote or offline environments[8].

Strengths: Combines traditional engineering knowledge with advanced analytics, robust performance in various operating conditions, and edge computing capabilities. Weaknesses: May be more focused on heavy-duty applications and less adaptable to high-performance V12 engines in luxury vehicles.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed a cutting-edge predictive model for V12 engine wear assessment, drawing on their extensive experience in aircraft engine manufacturing. Their approach focuses on high-precision wear prediction in extreme operating conditions. The model utilizes advanced materials science and tribology principles, combined with machine learning algorithms, to predict wear patterns at the microscopic level. Pratt & Whitney's system incorporates real-time monitoring of engine performance parameters, including thrust, fuel consumption, and thermal efficiency. The predictive model also takes into account environmental factors such as altitude, temperature, and humidity to provide context-specific wear assessments[9]. Additionally, the company has implemented a cloud-based analytics platform that allows for continuous improvement of the model through aggregated data from multiple engines across their fleet[10].

Strengths: High-precision wear prediction, expertise in extreme operating conditions, and continuous improvement through cloud-based analytics. Weaknesses: May be overly specialized for aviation applications and could require significant adaptation for automotive V12 engines.

Core Innovations in Wear Prediction

Method and system for wear estimation

PatentActiveUS20210123376A1

Innovation

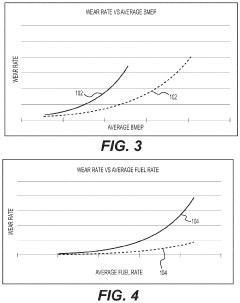

- A system that utilizes sensors and a controller to estimate wear by monitoring fuel injection and engine operation data, calculating incremental wear, and providing notifications based on cumulative wear thresholds, allowing for more precise timing of maintenance.

Method and device for predictive wear analysis with regard to a component of a motor vehicle

PatentWO2022263056A1

Innovation

- A method and device for predictive wear analysis using sensor data to determine current and remaining wear of motor vehicle components by comparing instantaneous wear with maximum permissible wear, employing models and direct measurements to calculate wear based on temperature, torque, and stress changes, and providing a warning system for unusual wear behavior.

Regulatory Framework

The regulatory framework surrounding predictive models for V12 engine wear assessment is complex and multifaceted, encompassing various standards, guidelines, and legal requirements. At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards like ISO 13379-1:2015, which provides guidelines for data interpretation and diagnostics of machines. This standard is particularly relevant to the application of predictive models in engine wear assessment.

In the automotive industry, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) in Europe play crucial roles in setting safety standards that indirectly influence the development and implementation of predictive models for engine wear. These agencies often require manufacturers to demonstrate the reliability and accuracy of their predictive maintenance systems as part of overall vehicle safety assessments.

Environmental regulations also significantly impact the development of predictive models for V12 engine wear. For instance, the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe have established strict emissions standards that necessitate advanced monitoring and prediction of engine performance. These regulations drive the need for more sophisticated predictive models that can accurately assess engine wear and its impact on emissions.

In the context of data protection and privacy, regulations such as the General Data Protection Regulation (GDPR) in the European Union and the California Consumer Privacy Act (CCPA) in the United States have implications for the collection, processing, and storage of data used in predictive models. These regulations require manufacturers and service providers to ensure the security and proper handling of data collected from V12 engines for wear assessment purposes.

Furthermore, industry-specific standards set by organizations like the Society of Automotive Engineers (SAE) provide guidelines for the development and implementation of predictive maintenance systems in vehicles. These standards often address issues such as data quality, model validation, and system integration, which are critical for ensuring the reliability and effectiveness of predictive models in assessing V12 engine wear.

As the field of predictive modeling continues to evolve, regulatory frameworks are likely to adapt and expand. This may include the development of new standards specifically tailored to AI-driven predictive maintenance systems, as well as updates to existing regulations to address emerging technologies and methodologies in engine wear assessment.

In the automotive industry, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) in Europe play crucial roles in setting safety standards that indirectly influence the development and implementation of predictive models for engine wear. These agencies often require manufacturers to demonstrate the reliability and accuracy of their predictive maintenance systems as part of overall vehicle safety assessments.

Environmental regulations also significantly impact the development of predictive models for V12 engine wear. For instance, the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe have established strict emissions standards that necessitate advanced monitoring and prediction of engine performance. These regulations drive the need for more sophisticated predictive models that can accurately assess engine wear and its impact on emissions.

In the context of data protection and privacy, regulations such as the General Data Protection Regulation (GDPR) in the European Union and the California Consumer Privacy Act (CCPA) in the United States have implications for the collection, processing, and storage of data used in predictive models. These regulations require manufacturers and service providers to ensure the security and proper handling of data collected from V12 engines for wear assessment purposes.

Furthermore, industry-specific standards set by organizations like the Society of Automotive Engineers (SAE) provide guidelines for the development and implementation of predictive maintenance systems in vehicles. These standards often address issues such as data quality, model validation, and system integration, which are critical for ensuring the reliability and effectiveness of predictive models in assessing V12 engine wear.

As the field of predictive modeling continues to evolve, regulatory frameworks are likely to adapt and expand. This may include the development of new standards specifically tailored to AI-driven predictive maintenance systems, as well as updates to existing regulations to address emerging technologies and methodologies in engine wear assessment.

Environmental Impact Assessment

The environmental impact of predictive models on V12 engine wear assessment is a crucial aspect to consider in the automotive industry's pursuit of sustainability. These models, while primarily aimed at optimizing engine performance and longevity, have significant indirect effects on the environment.

Predictive models for V12 engine wear assessment contribute to reduced environmental impact through improved engine efficiency and extended lifespan. By accurately predicting wear patterns, these models enable proactive maintenance, preventing catastrophic failures that could lead to increased emissions or oil leaks. This preventive approach reduces the frequency of major repairs, thereby minimizing the consumption of replacement parts and the associated environmental costs of manufacturing and disposing of these components.

Furthermore, these models facilitate the optimization of engine operating parameters, leading to improved fuel efficiency. By fine-tuning engine performance based on wear predictions, fuel consumption can be reduced, directly translating to lower greenhouse gas emissions. This is particularly significant for V12 engines, which are typically high-performance units with substantial fuel requirements.

The implementation of predictive models also supports the development of more durable engine components. By identifying wear-prone areas and understanding the factors contributing to wear, engineers can design more resilient parts. This results in engines with longer operational lifespans, reducing the overall environmental impact associated with manufacturing and disposing of entire engine units.

However, it is important to note that the use of predictive models may indirectly lead to increased computational requirements. The complex algorithms and data processing involved in these models demand significant computing power, potentially increasing energy consumption and associated carbon emissions from data centers and cloud computing services.

Additionally, the accuracy of these predictive models often relies on extensive data collection from operational engines. This data gathering process may involve additional sensors and monitoring equipment, which have their own environmental footprint in terms of production, energy consumption, and eventual disposal.

On balance, the environmental benefits of implementing predictive models for V12 engine wear assessment outweigh the potential negative impacts. The reduction in fuel consumption, extension of engine lifespan, and optimization of maintenance schedules contribute significantly to lowering the overall environmental footprint of V12 engines. As these models continue to evolve, their integration with broader sustainability initiatives in the automotive industry will likely further enhance their positive environmental impact.

Predictive models for V12 engine wear assessment contribute to reduced environmental impact through improved engine efficiency and extended lifespan. By accurately predicting wear patterns, these models enable proactive maintenance, preventing catastrophic failures that could lead to increased emissions or oil leaks. This preventive approach reduces the frequency of major repairs, thereby minimizing the consumption of replacement parts and the associated environmental costs of manufacturing and disposing of these components.

Furthermore, these models facilitate the optimization of engine operating parameters, leading to improved fuel efficiency. By fine-tuning engine performance based on wear predictions, fuel consumption can be reduced, directly translating to lower greenhouse gas emissions. This is particularly significant for V12 engines, which are typically high-performance units with substantial fuel requirements.

The implementation of predictive models also supports the development of more durable engine components. By identifying wear-prone areas and understanding the factors contributing to wear, engineers can design more resilient parts. This results in engines with longer operational lifespans, reducing the overall environmental impact associated with manufacturing and disposing of entire engine units.

However, it is important to note that the use of predictive models may indirectly lead to increased computational requirements. The complex algorithms and data processing involved in these models demand significant computing power, potentially increasing energy consumption and associated carbon emissions from data centers and cloud computing services.

Additionally, the accuracy of these predictive models often relies on extensive data collection from operational engines. This data gathering process may involve additional sensors and monitoring equipment, which have their own environmental footprint in terms of production, energy consumption, and eventual disposal.

On balance, the environmental benefits of implementing predictive models for V12 engine wear assessment outweigh the potential negative impacts. The reduction in fuel consumption, extension of engine lifespan, and optimization of maintenance schedules contribute significantly to lowering the overall environmental footprint of V12 engines. As these models continue to evolve, their integration with broader sustainability initiatives in the automotive industry will likely further enhance their positive environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!