Strategies in Long-Distance Transportation Using V12 Engines

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and aircraft, the V12 configuration has become synonymous with power, smoothness, and prestige in long-distance transportation.

In the 1920s and 1930s, V12 engines gained prominence in high-end automobiles, offering unparalleled refinement and performance. Manufacturers like Packard, Cadillac, and Lincoln led the way in V12 development for passenger cars. During this period, aircraft engines also adopted the V12 configuration, with notable examples including the Rolls-Royce Merlin used in World War II fighters.

The post-war era saw a decline in V12 usage for mainstream vehicles, but the configuration remained popular in racing and luxury applications. Ferrari, in particular, became closely associated with V12 engines, using them in their flagship models and Formula 1 cars. This period also saw advancements in materials and manufacturing techniques, allowing for higher-revving and more powerful V12 engines.

The 1980s and 1990s marked a resurgence of V12 engines in high-performance road cars. BMW introduced their first production V12 in the 750iL, while Mercedes-Benz developed a V12 for the S-Class. These engines set new standards for refinement and power in long-distance luxury transportation.

In recent decades, V12 engines have faced challenges due to increasing environmental regulations and a focus on fuel efficiency. However, manufacturers have responded with technological innovations. Direct fuel injection, variable valve timing, and cylinder deactivation have been implemented to improve efficiency while maintaining the V12's characteristic power and smoothness.

The advent of turbocharging and hybrid technologies has further transformed V12 engines. Bentley and Rolls-Royce have introduced twin-turbocharged V12s, offering immense power for long-distance cruising while improving fuel economy. Ferrari's LaFerrari showcased a hybrid V12 powertrain, demonstrating the potential for electrification to enhance V12 performance.

Looking towards the future, V12 engines in long-distance transportation face both challenges and opportunities. While stricter emissions standards may limit their use in mass-market vehicles, the configuration continues to evolve for specialized applications. Advancements in materials science, such as 3D-printed components and nano-engineered surfaces, promise to further enhance V12 efficiency and performance.

In the 1920s and 1930s, V12 engines gained prominence in high-end automobiles, offering unparalleled refinement and performance. Manufacturers like Packard, Cadillac, and Lincoln led the way in V12 development for passenger cars. During this period, aircraft engines also adopted the V12 configuration, with notable examples including the Rolls-Royce Merlin used in World War II fighters.

The post-war era saw a decline in V12 usage for mainstream vehicles, but the configuration remained popular in racing and luxury applications. Ferrari, in particular, became closely associated with V12 engines, using them in their flagship models and Formula 1 cars. This period also saw advancements in materials and manufacturing techniques, allowing for higher-revving and more powerful V12 engines.

The 1980s and 1990s marked a resurgence of V12 engines in high-performance road cars. BMW introduced their first production V12 in the 750iL, while Mercedes-Benz developed a V12 for the S-Class. These engines set new standards for refinement and power in long-distance luxury transportation.

In recent decades, V12 engines have faced challenges due to increasing environmental regulations and a focus on fuel efficiency. However, manufacturers have responded with technological innovations. Direct fuel injection, variable valve timing, and cylinder deactivation have been implemented to improve efficiency while maintaining the V12's characteristic power and smoothness.

The advent of turbocharging and hybrid technologies has further transformed V12 engines. Bentley and Rolls-Royce have introduced twin-turbocharged V12s, offering immense power for long-distance cruising while improving fuel economy. Ferrari's LaFerrari showcased a hybrid V12 powertrain, demonstrating the potential for electrification to enhance V12 performance.

Looking towards the future, V12 engines in long-distance transportation face both challenges and opportunities. While stricter emissions standards may limit their use in mass-market vehicles, the configuration continues to evolve for specialized applications. Advancements in materials science, such as 3D-printed components and nano-engineered surfaces, promise to further enhance V12 efficiency and performance.

Long-Distance Transport Demand

The demand for long-distance transportation using V12 engines has been steadily increasing in recent years, driven by several key factors. Firstly, the global economy's continued growth has led to an expansion of international trade, necessitating more efficient and powerful long-haul transportation solutions. V12 engines, known for their superior performance and reliability, have become increasingly attractive for this purpose.

In the commercial sector, the rise of e-commerce and just-in-time delivery systems has created a need for faster, more reliable long-distance freight transportation. This has led to a growing demand for trucks and other heavy vehicles equipped with V12 engines, capable of maintaining high speeds over extended periods while carrying substantial loads.

The luxury travel market has also contributed significantly to the demand for V12-powered vehicles in long-distance transportation. High-end automobiles and private jets, often favored by business executives and affluent travelers, frequently utilize V12 engines for their smooth operation and impressive power output. This segment of the market continues to grow as global wealth increases and more individuals seek premium travel experiences.

In the maritime industry, large cruise ships and cargo vessels have been adopting V12 engines for their main propulsion systems. The need for fuel-efficient yet powerful engines capable of traversing vast oceanic distances has made V12 engines an attractive option for shipbuilders and operators alike.

The aviation sector, particularly in the realm of business and private jets, has seen a surge in demand for V12-powered aircraft. These engines offer the perfect balance of power, efficiency, and reliability required for long-distance flights, making them ideal for transcontinental and intercontinental travel.

However, it's important to note that the demand for V12 engines in long-distance transportation is not without challenges. Environmental concerns and stricter emissions regulations have prompted manufacturers to invest heavily in developing cleaner and more fuel-efficient V12 engines. This has led to innovations in engine design and the integration of hybrid technologies to meet both performance requirements and environmental standards.

The ongoing shift towards electric and hydrogen-powered vehicles in some transportation sectors may impact the future demand for V12 engines. However, for the foreseeable future, V12 engines are expected to maintain a significant market share in long-distance transportation, particularly in applications where high power output and long-range capabilities are crucial.

In the commercial sector, the rise of e-commerce and just-in-time delivery systems has created a need for faster, more reliable long-distance freight transportation. This has led to a growing demand for trucks and other heavy vehicles equipped with V12 engines, capable of maintaining high speeds over extended periods while carrying substantial loads.

The luxury travel market has also contributed significantly to the demand for V12-powered vehicles in long-distance transportation. High-end automobiles and private jets, often favored by business executives and affluent travelers, frequently utilize V12 engines for their smooth operation and impressive power output. This segment of the market continues to grow as global wealth increases and more individuals seek premium travel experiences.

In the maritime industry, large cruise ships and cargo vessels have been adopting V12 engines for their main propulsion systems. The need for fuel-efficient yet powerful engines capable of traversing vast oceanic distances has made V12 engines an attractive option for shipbuilders and operators alike.

The aviation sector, particularly in the realm of business and private jets, has seen a surge in demand for V12-powered aircraft. These engines offer the perfect balance of power, efficiency, and reliability required for long-distance flights, making them ideal for transcontinental and intercontinental travel.

However, it's important to note that the demand for V12 engines in long-distance transportation is not without challenges. Environmental concerns and stricter emissions regulations have prompted manufacturers to invest heavily in developing cleaner and more fuel-efficient V12 engines. This has led to innovations in engine design and the integration of hybrid technologies to meet both performance requirements and environmental standards.

The ongoing shift towards electric and hydrogen-powered vehicles in some transportation sectors may impact the future demand for V12 engines. However, for the foreseeable future, V12 engines are expected to maintain a significant market share in long-distance transportation, particularly in applications where high power output and long-range capabilities are crucial.

V12 Engine Challenges

V12 engines, renowned for their power and prestige, face significant challenges in long-distance transportation applications. One of the primary issues is their high fuel consumption, which can make them economically unfeasible for extended journeys. The complex design of V12 engines, with their large number of cylinders and moving parts, leads to increased maintenance requirements and potential reliability concerns over long distances.

Weight is another critical factor. V12 engines are inherently heavier than their smaller counterparts, which can impact vehicle dynamics and fuel efficiency, especially in long-haul scenarios. This weight penalty becomes more pronounced when considering the additional fuel required for extended trips, further compromising overall efficiency.

Heat management presents a substantial challenge for V12 engines in long-distance transportation. The engine's high power output generates significant heat, which must be effectively dissipated to prevent overheating and ensure optimal performance. This necessitates sophisticated cooling systems, adding complexity and weight to the vehicle.

Emissions regulations pose a growing challenge for V12 engines. As environmental standards become increasingly stringent, manufacturers must invest heavily in advanced technologies to reduce emissions without compromising performance. This balancing act is particularly difficult for large displacement engines like V12s, which inherently produce higher levels of emissions.

The cost factor cannot be overlooked. V12 engines are expensive to produce and maintain, which can be a significant barrier to their widespread adoption in long-distance transportation fleets. The initial investment and ongoing operational costs may outweigh the benefits for many operators, especially when compared to more economical engine options.

Packaging constraints also present challenges. The size and configuration of V12 engines can limit their application in certain vehicle designs, particularly those optimized for aerodynamics and cargo capacity. This can result in compromises in vehicle layout and overall efficiency.

Lastly, the advent of alternative powertrains, such as electric and hydrogen fuel cell technologies, poses an existential challenge to V12 engines in long-distance transportation. As these newer technologies improve in range and performance, they may increasingly displace traditional combustion engines, including V12s, in various transportation sectors.

Weight is another critical factor. V12 engines are inherently heavier than their smaller counterparts, which can impact vehicle dynamics and fuel efficiency, especially in long-haul scenarios. This weight penalty becomes more pronounced when considering the additional fuel required for extended trips, further compromising overall efficiency.

Heat management presents a substantial challenge for V12 engines in long-distance transportation. The engine's high power output generates significant heat, which must be effectively dissipated to prevent overheating and ensure optimal performance. This necessitates sophisticated cooling systems, adding complexity and weight to the vehicle.

Emissions regulations pose a growing challenge for V12 engines. As environmental standards become increasingly stringent, manufacturers must invest heavily in advanced technologies to reduce emissions without compromising performance. This balancing act is particularly difficult for large displacement engines like V12s, which inherently produce higher levels of emissions.

The cost factor cannot be overlooked. V12 engines are expensive to produce and maintain, which can be a significant barrier to their widespread adoption in long-distance transportation fleets. The initial investment and ongoing operational costs may outweigh the benefits for many operators, especially when compared to more economical engine options.

Packaging constraints also present challenges. The size and configuration of V12 engines can limit their application in certain vehicle designs, particularly those optimized for aerodynamics and cargo capacity. This can result in compromises in vehicle layout and overall efficiency.

Lastly, the advent of alternative powertrains, such as electric and hydrogen fuel cell technologies, poses an existential challenge to V12 engines in long-distance transportation. As these newer technologies improve in range and performance, they may increasingly displace traditional combustion engines, including V12s, in various transportation sectors.

Current V12 Transport Solutions

01 V12 Engine Design and Configuration

V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design offers a balance of power, smoothness, and compact packaging. The V12 layout allows for high power output while maintaining relatively compact dimensions, making it suitable for high-performance and luxury vehicles.- V12 Engine Design and Configuration: V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design offers a balance of power, smoothness, and compact packaging. The V12 layout allows for high power output while maintaining relatively compact dimensions, making it suitable for high-performance and luxury vehicles.

- Engine Control Systems for V12 Engines: Advanced control systems are crucial for optimizing the performance and efficiency of V12 engines. These systems manage fuel injection, ignition timing, and other parameters to ensure smooth operation across various driving conditions. Modern V12 engines often incorporate sophisticated electronic control units (ECUs) to fine-tune engine performance and meet emissions standards.

- Fuel Efficiency Improvements in V12 Engines: Despite their high power output, modern V12 engines incorporate various technologies to improve fuel efficiency. These may include direct fuel injection, variable valve timing, and cylinder deactivation systems. Such advancements help reduce fuel consumption and emissions while maintaining the performance characteristics expected from a V12 engine.

- Historical Development of V12 Engines: The development of V12 engines has a rich history dating back to the early 20th century. Early designs were often used in luxury automobiles and aircraft. Over time, V12 engines have evolved significantly, incorporating new materials, manufacturing techniques, and technologies to improve performance, reliability, and efficiency.

- Applications of V12 Engines: V12 engines find applications in various high-performance and luxury vehicles, including sports cars, luxury sedans, and racing cars. They are also used in some marine applications and specialized industrial equipment where high power output and smooth operation are required. The unique characteristics of V12 engines make them suitable for applications demanding both power and refinement.

02 Engine Management Systems for V12 Engines

Advanced engine management systems are crucial for optimizing the performance and efficiency of V12 engines. These systems control various aspects such as fuel injection, ignition timing, and valve timing to ensure optimal power output, fuel economy, and emissions control. Modern V12 engines often incorporate sophisticated electronic control units to manage these complex systems.Expand Specific Solutions03 Fuel Efficiency Improvements in V12 Engines

Despite their high power output, modern V12 engines incorporate various technologies to improve fuel efficiency. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced materials to reduce weight. Such innovations help to balance the power demands of V12 engines with increasing environmental and efficiency requirements.Expand Specific Solutions04 Historical Development of V12 Engines

The development of V12 engines has a rich history dating back to the early 20th century. Early designs were often used in luxury automobiles and aircraft. Over time, V12 engines have evolved significantly, incorporating technological advancements in materials, manufacturing processes, and engine management systems to improve performance, reliability, and efficiency.Expand Specific Solutions05 Applications of V12 Engines

V12 engines find applications in various high-performance and luxury vehicles, including sports cars, luxury sedans, and some racing cars. They are also used in certain marine applications and have historically been employed in aircraft. The smooth power delivery and prestigious status associated with V12 engines make them particularly popular in the luxury automotive sector.Expand Specific Solutions

Key V12 Engine Manufacturers

The long-distance transportation sector utilizing V12 engines is in a mature stage, with a substantial market size driven by demand for high-performance vehicles and heavy-duty applications. The technology is well-established, with key players like Volvo Lastvagnar AB, GM Global Technology Operations LLC, and Caterpillar, Inc. leading innovation. These companies have extensive experience in developing and refining V12 engine technology, focusing on improving fuel efficiency, reducing emissions, and enhancing overall performance. The competitive landscape is characterized by ongoing research and development efforts to meet stringent environmental regulations while maintaining power output and reliability for long-distance transportation applications.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks, while not primarily focused on V12 engines for long-distance transportation, has developed strategies applicable to large displacement engines. Their approach includes the use of advanced turbocharging technologies, such as turbo-compound systems, which recover exhaust energy to improve overall engine efficiency[7]. Volvo has also implemented I-See predictive cruise control, which uses topographical data to optimize gear shifting and speed, significantly reducing fuel consumption in long-haul operations[8]. Additionally, Volvo's engine management systems incorporate advanced software algorithms to balance performance, fuel efficiency, and emissions control. The company has invested heavily in alternative powertrains, including electric and hydrogen fuel cell technologies, which may eventually complement or replace traditional large displacement engines in long-distance transportation[9].

Strengths: Advanced predictive technologies for optimizing fuel efficiency, strong focus on alternative powertrains for future long-distance transportation. Weaknesses: Limited direct experience with V12 engines in commercial vehicles, potential challenges in transitioning from smaller displacement engines to larger ones if market demands shift.

GM Global Technology Operations LLC

Technical Solution: General Motors, through its GM Global Technology Operations, has developed strategies for long-distance transportation that, while not specifically focused on V12 engines, are applicable to large displacement powertrains. GM's approach includes the development of Dynamic Fuel Management (DFM) technology, which can deactivate cylinders in various combinations to optimize fuel efficiency under different load conditions[10]. This technology could be adapted for V12 engines to improve fuel economy in long-haul applications. GM has also invested in advanced materials and manufacturing techniques to reduce engine weight and improve thermal efficiency. Their latest generation of engines incorporates stop-start technology and advanced thermal management systems to further enhance fuel efficiency[11]. Additionally, GM has been exploring the integration of electrification in large engines, potentially leading to hybrid powertrains for long-distance transportation that could complement V12 engines[12].

Strengths: Innovative cylinder deactivation technology, advanced materials science for engine weight reduction, and progress in electrification of powertrains. Weaknesses: Limited recent experience with V12 engines in production vehicles, potential challenges in scaling technologies developed for smaller engines to V12 applications.

V12 Efficiency Innovations

High-speed transport system

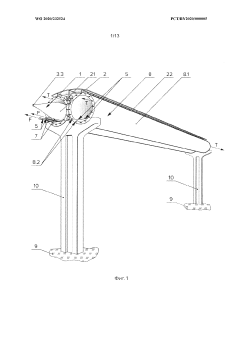

PatentWO2020232524A1

Innovation

- The Yunitsky hyper-high-speed transport complex employs a self-propelled wheeled vehicle with a hydrogen engine and a pre-stressed tensile track structure in a sealed tunnel, utilizing hydrogen as both fuel and oxidizer, with a tunnel design that includes a circular cross-section, cone-shaped vehicle profile, and optimized aerodynamics to reduce drag and energy consumption.

A method for operating an automatic or semi-automatic manual transmission of a heavy vehicle when in idle-driving mode

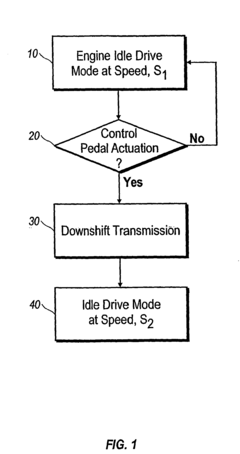

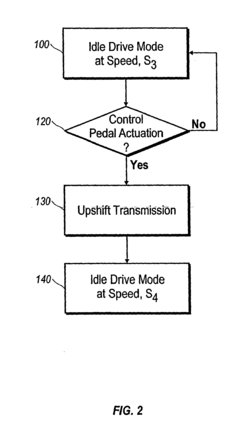

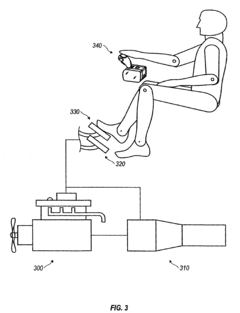

PatentActiveEP1929187B1

Innovation

- A method for operating semi-automatic or automatic transmissions in heavy vehicles that allows for semi-automated gear selection and shifting by using pedal bump-depression to downshift or upshift gears without engaging brakes, enabling the vehicle to maintain a desired speed using engine-idle power, with computer-controlled systems coordinating engine and transmission for improved fuel economy and driver comfort.

Fuel Efficiency Regulations

Fuel efficiency regulations have become increasingly stringent in recent years, significantly impacting the long-distance transportation sector, particularly for vehicles equipped with V12 engines. These regulations aim to reduce greenhouse gas emissions and promote sustainable transportation practices, presenting both challenges and opportunities for manufacturers and operators of V12-powered vehicles.

The European Union has been at the forefront of implementing strict fuel efficiency standards. The Euro 6 emission standards, introduced in 2014, set limits on carbon dioxide emissions for heavy-duty vehicles, including those with V12 engines. These standards have been progressively tightened, with the latest Euro 6d-TEMP regulations requiring even lower emission levels. In the United States, the Corporate Average Fuel Economy (CAFE) standards have similarly evolved, pushing manufacturers to improve fuel efficiency across their vehicle fleets.

To comply with these regulations, manufacturers of V12 engines have had to implement various technological advancements. Engine management systems have been optimized to enhance fuel combustion efficiency, while advanced turbocharging and supercharging technologies have been employed to extract maximum power from smaller fuel inputs. Additionally, the integration of start-stop systems and regenerative braking has helped reduce fuel consumption during idle periods and deceleration.

The impact of these regulations on long-distance transportation strategies has been significant. Fleet operators have had to reassess their vehicle choices, often opting for more fuel-efficient alternatives to traditional V12-powered trucks. This has led to a shift towards smaller displacement engines with comparable power outputs, achieved through advanced engineering and forced induction technologies.

However, the unique characteristics of V12 engines, such as their smooth operation and high power output, continue to make them attractive for certain long-distance transportation applications. Manufacturers have responded by developing hybrid V12 powertrains, combining the traditional engine with electric motors to improve overall efficiency while maintaining performance.

Looking ahead, the regulatory landscape is set to become even more challenging. The European Commission has proposed new CO2 emission standards for heavy-duty vehicles, aiming for a 15% reduction by 2025 and a 30% reduction by 2030, compared to 2019 levels. Similarly, the United States Environmental Protection Agency has announced plans to tighten fuel efficiency standards for heavy-duty trucks in the coming years.

These evolving regulations are driving innovation in the transportation sector, pushing manufacturers to explore alternative fuel technologies and advanced powertrain solutions. While the future of V12 engines in long-distance transportation may be uncertain, the ongoing technological advancements suggest that there may still be a place for these powerful engines in specialized applications, provided they can meet increasingly stringent efficiency requirements.

The European Union has been at the forefront of implementing strict fuel efficiency standards. The Euro 6 emission standards, introduced in 2014, set limits on carbon dioxide emissions for heavy-duty vehicles, including those with V12 engines. These standards have been progressively tightened, with the latest Euro 6d-TEMP regulations requiring even lower emission levels. In the United States, the Corporate Average Fuel Economy (CAFE) standards have similarly evolved, pushing manufacturers to improve fuel efficiency across their vehicle fleets.

To comply with these regulations, manufacturers of V12 engines have had to implement various technological advancements. Engine management systems have been optimized to enhance fuel combustion efficiency, while advanced turbocharging and supercharging technologies have been employed to extract maximum power from smaller fuel inputs. Additionally, the integration of start-stop systems and regenerative braking has helped reduce fuel consumption during idle periods and deceleration.

The impact of these regulations on long-distance transportation strategies has been significant. Fleet operators have had to reassess their vehicle choices, often opting for more fuel-efficient alternatives to traditional V12-powered trucks. This has led to a shift towards smaller displacement engines with comparable power outputs, achieved through advanced engineering and forced induction technologies.

However, the unique characteristics of V12 engines, such as their smooth operation and high power output, continue to make them attractive for certain long-distance transportation applications. Manufacturers have responded by developing hybrid V12 powertrains, combining the traditional engine with electric motors to improve overall efficiency while maintaining performance.

Looking ahead, the regulatory landscape is set to become even more challenging. The European Commission has proposed new CO2 emission standards for heavy-duty vehicles, aiming for a 15% reduction by 2025 and a 30% reduction by 2030, compared to 2019 levels. Similarly, the United States Environmental Protection Agency has announced plans to tighten fuel efficiency standards for heavy-duty trucks in the coming years.

These evolving regulations are driving innovation in the transportation sector, pushing manufacturers to explore alternative fuel technologies and advanced powertrain solutions. While the future of V12 engines in long-distance transportation may be uncertain, the ongoing technological advancements suggest that there may still be a place for these powerful engines in specialized applications, provided they can meet increasingly stringent efficiency requirements.

Environmental Impact Assessment

The environmental impact of long-distance transportation using V12 engines is a critical consideration in the modern era of increasing environmental awareness. These powerful engines, while offering superior performance and reliability for heavy-duty vehicles, also contribute significantly to greenhouse gas emissions and air pollution. The carbon footprint of V12 engines is substantial, with higher fuel consumption rates compared to smaller engine configurations.

One of the primary environmental concerns is the emission of carbon dioxide (CO2), a major contributor to global warming. V12 engines, due to their larger displacement and higher fuel consumption, produce more CO2 per kilometer traveled than smaller engines. This increased carbon output has direct implications for climate change and the transportation sector's overall environmental impact.

In addition to CO2, V12 engines also emit other pollutants such as nitrogen oxides (NOx), particulate matter, and volatile organic compounds (VOCs). These emissions contribute to air quality degradation, particularly in urban areas and along major transportation corridors. The health implications of these pollutants include respiratory issues, cardiovascular problems, and increased risks of certain cancers.

The noise pollution generated by V12 engines is another environmental factor to consider. The high-powered nature of these engines often results in increased noise levels, which can have detrimental effects on wildlife habitats and human communities along transportation routes. This acoustic pollution can disrupt ecosystems and affect the quality of life for residents in affected areas.

However, it's important to note that advancements in engine technology have led to improvements in the environmental performance of V12 engines. Modern V12 engines often incorporate advanced emission control systems, such as catalytic converters and particulate filters, which significantly reduce harmful emissions. Additionally, the development of more efficient fuel injection systems and engine management technologies has helped to optimize fuel consumption and reduce overall emissions.

The use of alternative fuels and hybrid technologies in V12 engines is an emerging trend that could potentially mitigate some of the environmental impacts. Biodiesel blends and synthetic fuels can reduce the carbon intensity of these engines, while hybrid systems that combine V12 engines with electric motors can improve overall efficiency and reduce emissions in certain operating conditions.

In conclusion, while V12 engines offer significant advantages in terms of power and performance for long-distance transportation, their environmental impact remains a concern. Balancing the need for robust transportation solutions with environmental sustainability will require ongoing technological innovation and strategic implementation of cleaner technologies in the V12 engine segment.

One of the primary environmental concerns is the emission of carbon dioxide (CO2), a major contributor to global warming. V12 engines, due to their larger displacement and higher fuel consumption, produce more CO2 per kilometer traveled than smaller engines. This increased carbon output has direct implications for climate change and the transportation sector's overall environmental impact.

In addition to CO2, V12 engines also emit other pollutants such as nitrogen oxides (NOx), particulate matter, and volatile organic compounds (VOCs). These emissions contribute to air quality degradation, particularly in urban areas and along major transportation corridors. The health implications of these pollutants include respiratory issues, cardiovascular problems, and increased risks of certain cancers.

The noise pollution generated by V12 engines is another environmental factor to consider. The high-powered nature of these engines often results in increased noise levels, which can have detrimental effects on wildlife habitats and human communities along transportation routes. This acoustic pollution can disrupt ecosystems and affect the quality of life for residents in affected areas.

However, it's important to note that advancements in engine technology have led to improvements in the environmental performance of V12 engines. Modern V12 engines often incorporate advanced emission control systems, such as catalytic converters and particulate filters, which significantly reduce harmful emissions. Additionally, the development of more efficient fuel injection systems and engine management technologies has helped to optimize fuel consumption and reduce overall emissions.

The use of alternative fuels and hybrid technologies in V12 engines is an emerging trend that could potentially mitigate some of the environmental impacts. Biodiesel blends and synthetic fuels can reduce the carbon intensity of these engines, while hybrid systems that combine V12 engines with electric motors can improve overall efficiency and reduce emissions in certain operating conditions.

In conclusion, while V12 engines offer significant advantages in terms of power and performance for long-distance transportation, their environmental impact remains a concern. Balancing the need for robust transportation solutions with environmental sustainability will require ongoing technological innovation and strategic implementation of cleaner technologies in the V12 engine segment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!