Role of Treating Agents in V12 Engine Fuel Systems

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Fuel System Evolution and Objectives

The evolution of V12 engine fuel systems has been a journey of continuous innovation and refinement, driven by the pursuit of enhanced performance, efficiency, and environmental sustainability. From the early days of carburetors to modern direct injection systems, the fuel delivery mechanisms in V12 engines have undergone significant transformations.

Initially, V12 engines relied on simple mechanical fuel delivery systems, which were prone to inefficiencies and inconsistencies. As technology progressed, electronic fuel injection systems were introduced, marking a significant leap in precision and control. This transition allowed for more accurate fuel metering and improved engine response across various operating conditions.

The advent of high-pressure common rail systems represented another milestone in V12 engine fuel system development. These systems enabled finer atomization of fuel, resulting in more complete combustion and reduced emissions. Concurrently, the role of treating agents in fuel systems began to gain prominence, as engineers recognized their potential to address various challenges inherent in high-performance engines.

Treating agents, such as detergents, corrosion inhibitors, and lubricity enhancers, were introduced to combat issues like deposit formation, fuel system wear, and corrosion. These additives played a crucial role in maintaining the integrity and efficiency of increasingly complex fuel systems, particularly as engines were pushed to higher levels of performance and durability.

The objectives of modern V12 engine fuel systems have evolved to encompass a broader range of priorities. While maximizing power output remains a key goal, there is now an equal emphasis on optimizing fuel efficiency, reducing emissions, and ensuring long-term reliability. Treating agents have become instrumental in achieving these objectives, helping to keep fuel systems clean, protected, and operating at peak efficiency.

As environmental regulations have become more stringent, the focus has shifted towards developing fuel systems that can accommodate alternative fuels and hybrid technologies. This has led to the exploration of new treating agent formulations capable of addressing the unique challenges posed by biofuels and synthetic fuels, while still maintaining compatibility with traditional petroleum-based fuels.

Looking ahead, the evolution of V12 engine fuel systems is likely to continue, with treating agents playing an increasingly vital role. Future developments may include smart fuel systems that can adapt to different fuel compositions in real-time, with treating agents dynamically adjusted to optimize performance and protect engine components under varying conditions.

Initially, V12 engines relied on simple mechanical fuel delivery systems, which were prone to inefficiencies and inconsistencies. As technology progressed, electronic fuel injection systems were introduced, marking a significant leap in precision and control. This transition allowed for more accurate fuel metering and improved engine response across various operating conditions.

The advent of high-pressure common rail systems represented another milestone in V12 engine fuel system development. These systems enabled finer atomization of fuel, resulting in more complete combustion and reduced emissions. Concurrently, the role of treating agents in fuel systems began to gain prominence, as engineers recognized their potential to address various challenges inherent in high-performance engines.

Treating agents, such as detergents, corrosion inhibitors, and lubricity enhancers, were introduced to combat issues like deposit formation, fuel system wear, and corrosion. These additives played a crucial role in maintaining the integrity and efficiency of increasingly complex fuel systems, particularly as engines were pushed to higher levels of performance and durability.

The objectives of modern V12 engine fuel systems have evolved to encompass a broader range of priorities. While maximizing power output remains a key goal, there is now an equal emphasis on optimizing fuel efficiency, reducing emissions, and ensuring long-term reliability. Treating agents have become instrumental in achieving these objectives, helping to keep fuel systems clean, protected, and operating at peak efficiency.

As environmental regulations have become more stringent, the focus has shifted towards developing fuel systems that can accommodate alternative fuels and hybrid technologies. This has led to the exploration of new treating agent formulations capable of addressing the unique challenges posed by biofuels and synthetic fuels, while still maintaining compatibility with traditional petroleum-based fuels.

Looking ahead, the evolution of V12 engine fuel systems is likely to continue, with treating agents playing an increasingly vital role. Future developments may include smart fuel systems that can adapt to different fuel compositions in real-time, with treating agents dynamically adjusted to optimize performance and protect engine components under varying conditions.

Market Analysis for V12 Engine Fuel Treatments

The market for V12 engine fuel treatments has shown significant growth in recent years, driven by the increasing demand for high-performance luxury vehicles and the need for enhanced engine efficiency. V12 engines, known for their power and smoothness, are primarily used in premium automobiles and high-end sports cars, creating a niche but lucrative market for specialized fuel treatments.

The global market size for V12 engine fuel treatments is closely tied to the production and sales of V12-powered vehicles. While these engines represent a small fraction of the overall automotive market, they command a premium price point and require specialized maintenance products. This has led to the development of a range of fuel treatments specifically formulated to address the unique needs of V12 engines.

Key market drivers include the growing emphasis on engine longevity, performance optimization, and emission reduction. As V12 engines are often found in luxury and collector vehicles, owners are willing to invest in high-quality fuel treatments to protect their valuable assets. Additionally, stringent environmental regulations have pushed manufacturers to develop fuel treatments that can help reduce emissions without compromising engine performance.

The market is segmented based on product types, including fuel system cleaners, octane boosters, and fuel stabilizers. Each segment addresses specific issues related to V12 engine operation, such as carbon deposit buildup, fuel efficiency, and storage stability for vehicles that may not be driven regularly.

Geographically, the market for V12 engine fuel treatments is concentrated in regions with high luxury car ownership rates. North America and Europe dominate the market, with emerging economies in Asia-Pacific showing rapid growth potential as wealth accumulation leads to increased demand for luxury vehicles.

Competition in this market is characterized by a mix of established automotive chemical companies and specialized boutique brands. Major players have been investing in research and development to create advanced formulations that cater to the specific requirements of V12 engines, including compatibility with high-performance fuels and materials used in modern engine designs.

Consumer trends indicate a growing awareness of the benefits of regular fuel system maintenance among V12 engine owners. This has led to increased adoption of preventive maintenance practices, including the use of specialized fuel treatments. Marketing strategies in this sector often emphasize product quality, performance benefits, and the prestige associated with maintaining high-end vehicles.

Looking ahead, the market for V12 engine fuel treatments is expected to continue its growth trajectory, albeit at a moderate pace. Factors such as the gradual shift towards electrification in the automotive industry may present challenges, but the enduring appeal of V12 engines in certain market segments suggests a sustained demand for specialized fuel treatments in the foreseeable future.

The global market size for V12 engine fuel treatments is closely tied to the production and sales of V12-powered vehicles. While these engines represent a small fraction of the overall automotive market, they command a premium price point and require specialized maintenance products. This has led to the development of a range of fuel treatments specifically formulated to address the unique needs of V12 engines.

Key market drivers include the growing emphasis on engine longevity, performance optimization, and emission reduction. As V12 engines are often found in luxury and collector vehicles, owners are willing to invest in high-quality fuel treatments to protect their valuable assets. Additionally, stringent environmental regulations have pushed manufacturers to develop fuel treatments that can help reduce emissions without compromising engine performance.

The market is segmented based on product types, including fuel system cleaners, octane boosters, and fuel stabilizers. Each segment addresses specific issues related to V12 engine operation, such as carbon deposit buildup, fuel efficiency, and storage stability for vehicles that may not be driven regularly.

Geographically, the market for V12 engine fuel treatments is concentrated in regions with high luxury car ownership rates. North America and Europe dominate the market, with emerging economies in Asia-Pacific showing rapid growth potential as wealth accumulation leads to increased demand for luxury vehicles.

Competition in this market is characterized by a mix of established automotive chemical companies and specialized boutique brands. Major players have been investing in research and development to create advanced formulations that cater to the specific requirements of V12 engines, including compatibility with high-performance fuels and materials used in modern engine designs.

Consumer trends indicate a growing awareness of the benefits of regular fuel system maintenance among V12 engine owners. This has led to increased adoption of preventive maintenance practices, including the use of specialized fuel treatments. Marketing strategies in this sector often emphasize product quality, performance benefits, and the prestige associated with maintaining high-end vehicles.

Looking ahead, the market for V12 engine fuel treatments is expected to continue its growth trajectory, albeit at a moderate pace. Factors such as the gradual shift towards electrification in the automotive industry may present challenges, but the enduring appeal of V12 engines in certain market segments suggests a sustained demand for specialized fuel treatments in the foreseeable future.

Current Challenges in V12 Fuel System Maintenance

The maintenance of V12 engine fuel systems presents several significant challenges that require careful attention and specialized solutions. One of the primary issues is the complexity of these high-performance engines, which demand precise fuel delivery and optimal combustion efficiency. The intricate design of V12 fuel systems, with their multiple cylinders and advanced fuel injection technologies, makes them particularly susceptible to performance degradation due to fuel contamination and deposit formation.

Fuel quality is a critical factor in V12 engine maintenance. These engines are often used in luxury and high-performance vehicles, which require premium-grade fuels. However, even high-quality fuels can lead to the accumulation of deposits in the fuel system over time. These deposits can form in various components, including fuel injectors, intake valves, and combustion chambers, potentially leading to reduced engine performance, increased fuel consumption, and higher emissions.

Another challenge is the sensitivity of V12 engines to fuel system imbalances. Any inconsistency in fuel delivery across the twelve cylinders can result in uneven combustion, leading to power loss, rough idling, and increased wear on engine components. Maintaining proper fuel pressure and ensuring equal distribution to all cylinders is crucial but can be difficult due to the engine's layout and the potential for variations in fuel system components over time.

The high operating temperatures of V12 engines also contribute to maintenance challenges. These temperatures can accelerate the breakdown of fuel and oil, leading to the formation of varnish and sludge within the fuel system. This thermal stress can affect fuel lines, seals, and other components, potentially causing leaks or fuel degradation.

Furthermore, the advanced electronic control systems in modern V12 engines add another layer of complexity to fuel system maintenance. These systems rely on numerous sensors and actuators to optimize fuel delivery and engine performance. Any malfunction in these electronic components can lead to fuel system inefficiencies and may be challenging to diagnose without specialized diagnostic equipment.

Lastly, the infrequent use of some V12-equipped vehicles, particularly in luxury or collector car applications, can lead to fuel system issues. Extended periods of inactivity can result in fuel degradation, corrosion of metal components, and the formation of deposits, all of which can compromise the fuel system's integrity and performance when the vehicle is eventually used.

Fuel quality is a critical factor in V12 engine maintenance. These engines are often used in luxury and high-performance vehicles, which require premium-grade fuels. However, even high-quality fuels can lead to the accumulation of deposits in the fuel system over time. These deposits can form in various components, including fuel injectors, intake valves, and combustion chambers, potentially leading to reduced engine performance, increased fuel consumption, and higher emissions.

Another challenge is the sensitivity of V12 engines to fuel system imbalances. Any inconsistency in fuel delivery across the twelve cylinders can result in uneven combustion, leading to power loss, rough idling, and increased wear on engine components. Maintaining proper fuel pressure and ensuring equal distribution to all cylinders is crucial but can be difficult due to the engine's layout and the potential for variations in fuel system components over time.

The high operating temperatures of V12 engines also contribute to maintenance challenges. These temperatures can accelerate the breakdown of fuel and oil, leading to the formation of varnish and sludge within the fuel system. This thermal stress can affect fuel lines, seals, and other components, potentially causing leaks or fuel degradation.

Furthermore, the advanced electronic control systems in modern V12 engines add another layer of complexity to fuel system maintenance. These systems rely on numerous sensors and actuators to optimize fuel delivery and engine performance. Any malfunction in these electronic components can lead to fuel system inefficiencies and may be challenging to diagnose without specialized diagnostic equipment.

Lastly, the infrequent use of some V12-equipped vehicles, particularly in luxury or collector car applications, can lead to fuel system issues. Extended periods of inactivity can result in fuel degradation, corrosion of metal components, and the formation of deposits, all of which can compromise the fuel system's integrity and performance when the vehicle is eventually used.

Existing Treating Agent Solutions for V12 Engines

01 Chemical treatment agents for water and wastewater

Various chemical agents are used for treating water and wastewater. These agents can include coagulants, flocculants, disinfectants, and pH adjusters. They help in removing contaminants, improving water quality, and ensuring safe drinking water. The treatment process may involve multiple stages and combinations of different agents to achieve desired results.- Chemical treatment agents for water and wastewater: Various chemical agents are used for treating water and wastewater, including coagulants, flocculants, and disinfectants. These agents help in removing contaminants, improving water quality, and ensuring safe drinking water. The treatment processes may involve oxidation, precipitation, and filtration techniques to remove pollutants and pathogens.

- Biological treatment agents for environmental remediation: Biological agents, such as microorganisms and enzymes, are employed in environmental remediation processes. These agents can break down pollutants, treat contaminated soil and water, and assist in the biodegradation of organic compounds. Bioremediation techniques using these agents are often more environmentally friendly and cost-effective compared to traditional chemical treatments.

- Surface treatment agents for materials and coatings: Various agents are used for surface treatment of materials, including metals, plastics, and textiles. These agents can improve adhesion, corrosion resistance, and other surface properties. Treatment processes may involve chemical etching, plasma treatment, or the application of specialized coatings to enhance material performance and durability.

- Medical and pharmaceutical treating agents: Treating agents in the medical and pharmaceutical fields include various drugs, therapeutic compounds, and diagnostic agents. These agents are used for treating diseases, managing symptoms, and improving patient outcomes. The development of new treating agents often involves extensive research, clinical trials, and regulatory approval processes.

- Industrial process treating agents: Various agents are used in industrial processes for treating raw materials, intermediates, and finished products. These agents can include catalysts, stabilizers, and additives that enhance product quality, improve process efficiency, or modify material properties. The selection and application of these agents are crucial for optimizing industrial production and ensuring product consistency.

02 Biological treatment agents for environmental remediation

Biological agents, such as microorganisms and enzymes, are employed in environmental remediation processes. These agents can break down pollutants, treat contaminated soil and water, and assist in bioremediation efforts. They offer eco-friendly alternatives to chemical treatments and can be effective in addressing various types of environmental contamination.Expand Specific Solutions03 Surface treatment agents for materials and coatings

Surface treatment agents are used to modify the properties of materials and coatings. These agents can enhance adhesion, improve corrosion resistance, alter surface energy, or provide specific functionalities. They find applications in industries such as automotive, aerospace, and electronics, where surface properties play a crucial role in product performance.Expand Specific Solutions04 Medical treatment agents for therapeutic applications

Various agents are developed and used for medical treatments. These can include pharmaceuticals, biologics, and gene therapies. They are designed to target specific diseases, conditions, or physiological processes. The development of these agents involves extensive research, clinical trials, and regulatory approvals to ensure safety and efficacy.Expand Specific Solutions05 Industrial process treatment agents

Treatment agents are used in various industrial processes to improve efficiency, product quality, or process outcomes. These can include catalysts, separation agents, anti-fouling agents, and process enhancers. They play critical roles in industries such as oil and gas, chemical manufacturing, and food processing, helping to optimize operations and reduce environmental impact.Expand Specific Solutions

Key Players in V12 Engine Fuel Additives

The competitive landscape for treating agents in V12 engine fuel systems is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by the automotive industry's demand for high-performance engines. Key players like Afton Chemical Corp., China Petroleum & Chemical Corp., and Toyota Motor Corp. are at the forefront of innovation, leveraging their extensive research capabilities and global presence. The technology's maturity is evident, with companies like Tenneco Automotive Operating Co. and GM Global Technology Operations LLC continuously refining their offerings. However, emerging trends in fuel efficiency and emissions reduction are pushing for further advancements, creating opportunities for both incumbents and new entrants in this specialized field.

Afton Chemical Corp.

Technical Solution: Afton Chemical Corp. has developed a specialized line of fuel treating agents for V12 engine fuel systems, focusing on performance enhancement and emissions reduction. Their approach involves a multi-functional additive package that addresses several key aspects of fuel quality and engine protection. Afton's treating agents incorporate advanced detergents that prevent and remove deposits from fuel injectors, intake valves, and combustion chambers[10]. The company has also developed a proprietary friction modifier that reduces internal engine friction, improving fuel efficiency and power output. Afton's fuel treatment system includes stability improvers that extend the shelf life of fuel and prevent oxidation, which is particularly important for high-performance V12 engines that may experience periods of inactivity[12]. Additionally, their treating agents feature corrosion inhibitors specifically designed to protect the complex fuel systems of V12 engines from moisture-related damage.

Strengths: Comprehensive fuel quality improvement, tailored for high-performance engines, proven track record in motorsports applications. Weaknesses: May require more frequent application compared to some competitors, potentially higher cost due to specialized formulations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced treating agents for V12 engine fuel systems. Their approach involves using multi-functional additives that combine detergents, corrosion inhibitors, and friction modifiers. These additives are designed to clean and protect fuel injectors, valves, and combustion chambers in high-performance V12 engines. Sinopec's treating agents utilize nano-scale particles to enhance fuel atomization and combustion efficiency[1]. The company has also implemented a proprietary blending technology that ensures uniform distribution of the treating agents in the fuel, maintaining consistent performance across varying operating conditions[3].

Strengths: Comprehensive protection for engine components, improved fuel efficiency, and reduced emissions. Weaknesses: Potentially higher cost compared to standard fuel additives, may require more frequent replenishment.

Innovative Fuel Treatment Technologies

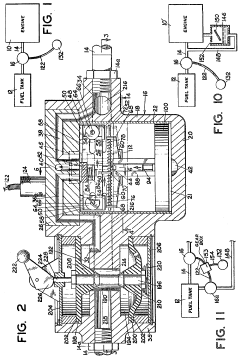

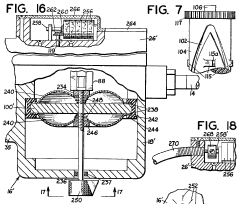

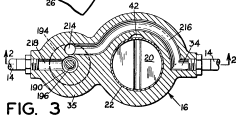

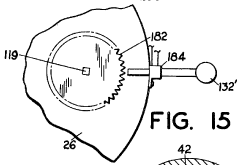

Temperature controlled fuel systems for engines

PatentInactiveUS4098113A

Innovation

- A direct-reading fuel flow meter that compensates for temperature variations, featuring a bypass valve and adjustable mechanisms to ensure accurate fuel usage measurement, integrated with a tachometer-like instrument for remote indication and recording of fuel consumption rates.

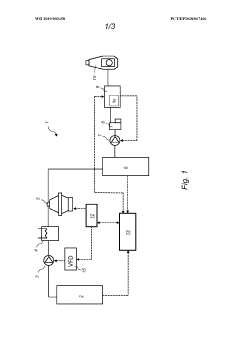

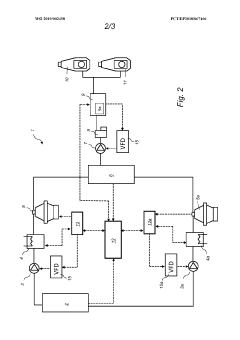

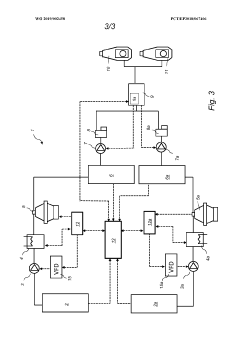

Fuel treatment system for an engine and a method using the system

PatentWO2019002458A1

Innovation

- A fuel treatment system comprising multiple centrifugal separators with variable feed pumps and control units that optimize flow rates and operational efficiency, including a system control unit that coordinates the operation of separators and feed pumps based on real-time data from downstream units, ensuring energy efficiency and effective separation of fuel components.

Environmental Impact of Fuel Treating Agents

The environmental impact of fuel treating agents used in V12 engine fuel systems is a critical consideration in the automotive industry. These agents, while essential for maintaining engine performance and efficiency, can have significant effects on the environment throughout their lifecycle.

Fuel treating agents typically contain a variety of chemical compounds, including detergents, corrosion inhibitors, and stabilizers. When these agents are introduced into the fuel system, a portion of them may be released into the environment through exhaust emissions. The combustion process can alter the chemical structure of these agents, potentially creating new compounds with unknown environmental consequences.

One of the primary environmental concerns is the potential for these agents to contribute to air pollution. Some treating agents may increase the emission of volatile organic compounds (VOCs) or particulate matter, which can have adverse effects on air quality and human health. Additionally, certain compounds in fuel treating agents may react with other pollutants in the atmosphere, contributing to the formation of ground-level ozone or smog.

Water pollution is another significant environmental risk associated with fuel treating agents. When vehicles are washed or exposed to rain, residual agents on the engine or fuel system components can be washed away and enter water systems. This runoff can contaminate surface water and groundwater, potentially harming aquatic ecosystems and affecting drinking water sources.

The production and disposal of fuel treating agents also present environmental challenges. The manufacturing process often involves energy-intensive operations and the use of potentially hazardous chemicals. Improper disposal of unused or expired treating agents can lead to soil contamination and further water pollution if not managed correctly.

However, it is important to note that fuel treating agents can also have positive environmental impacts. By improving engine efficiency and reducing carbon deposits, these agents can help reduce overall fuel consumption and decrease harmful emissions. This dual nature of fuel treating agents highlights the need for a balanced approach in their development and use.

Research into more environmentally friendly fuel treating agents is ongoing. Efforts are being made to develop biodegradable alternatives and formulations that minimize harmful emissions while maintaining or improving engine performance. Additionally, advancements in engine technology and fuel system design are aimed at reducing the reliance on treating agents altogether.

As environmental regulations become increasingly stringent, manufacturers of V12 engines and fuel treating agents must continue to innovate and adapt. The challenge lies in finding solutions that balance the need for high-performance engines with the imperative of environmental protection.

Fuel treating agents typically contain a variety of chemical compounds, including detergents, corrosion inhibitors, and stabilizers. When these agents are introduced into the fuel system, a portion of them may be released into the environment through exhaust emissions. The combustion process can alter the chemical structure of these agents, potentially creating new compounds with unknown environmental consequences.

One of the primary environmental concerns is the potential for these agents to contribute to air pollution. Some treating agents may increase the emission of volatile organic compounds (VOCs) or particulate matter, which can have adverse effects on air quality and human health. Additionally, certain compounds in fuel treating agents may react with other pollutants in the atmosphere, contributing to the formation of ground-level ozone or smog.

Water pollution is another significant environmental risk associated with fuel treating agents. When vehicles are washed or exposed to rain, residual agents on the engine or fuel system components can be washed away and enter water systems. This runoff can contaminate surface water and groundwater, potentially harming aquatic ecosystems and affecting drinking water sources.

The production and disposal of fuel treating agents also present environmental challenges. The manufacturing process often involves energy-intensive operations and the use of potentially hazardous chemicals. Improper disposal of unused or expired treating agents can lead to soil contamination and further water pollution if not managed correctly.

However, it is important to note that fuel treating agents can also have positive environmental impacts. By improving engine efficiency and reducing carbon deposits, these agents can help reduce overall fuel consumption and decrease harmful emissions. This dual nature of fuel treating agents highlights the need for a balanced approach in their development and use.

Research into more environmentally friendly fuel treating agents is ongoing. Efforts are being made to develop biodegradable alternatives and formulations that minimize harmful emissions while maintaining or improving engine performance. Additionally, advancements in engine technology and fuel system design are aimed at reducing the reliance on treating agents altogether.

As environmental regulations become increasingly stringent, manufacturers of V12 engines and fuel treating agents must continue to innovate and adapt. The challenge lies in finding solutions that balance the need for high-performance engines with the imperative of environmental protection.

Regulatory Framework for Fuel Additives

The regulatory framework for fuel additives plays a crucial role in ensuring the safety, performance, and environmental impact of treating agents used in V12 engine fuel systems. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing fuel additives through the Clean Air Act and its amendments. The EPA requires manufacturers to register fuel additives before they can be introduced into commerce, providing detailed information on their chemical composition and potential health and environmental effects.

The European Union has established similar regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program, which aims to protect human health and the environment from risks posed by chemicals, including fuel additives. Under REACH, manufacturers must register their substances and provide safety data to the European Chemicals Agency (ECHA).

In addition to these overarching regulatory frameworks, specific standards have been developed to address the unique requirements of V12 engine fuel systems. The Society of Automotive Engineers (SAE) has published several standards, such as SAE J1681, which provides guidelines for deposit control additives in gasoline fuel injection systems. These standards help ensure that treating agents used in V12 engines meet performance and compatibility requirements.

Regulatory bodies also focus on the environmental impact of fuel additives. For instance, the California Air Resources Board (CARB) has implemented stringent regulations on fuel composition and additives to reduce air pollution. These regulations have influenced the development of treating agents that not only enhance engine performance but also minimize harmful emissions.

The regulatory landscape for fuel additives is continually evolving, with increasing emphasis on reducing greenhouse gas emissions and promoting sustainable fuel technologies. This has led to the development of new standards and regulations for alternative fuels and their additives, which may impact the future use of treating agents in V12 engine fuel systems.

Compliance with these regulations requires extensive testing and documentation. Manufacturers must conduct thorough evaluations of their additives, including long-term stability tests, compatibility assessments with engine materials, and emissions impact studies. This rigorous process ensures that only safe and effective treating agents are approved for use in V12 engine fuel systems.

The European Union has established similar regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program, which aims to protect human health and the environment from risks posed by chemicals, including fuel additives. Under REACH, manufacturers must register their substances and provide safety data to the European Chemicals Agency (ECHA).

In addition to these overarching regulatory frameworks, specific standards have been developed to address the unique requirements of V12 engine fuel systems. The Society of Automotive Engineers (SAE) has published several standards, such as SAE J1681, which provides guidelines for deposit control additives in gasoline fuel injection systems. These standards help ensure that treating agents used in V12 engines meet performance and compatibility requirements.

Regulatory bodies also focus on the environmental impact of fuel additives. For instance, the California Air Resources Board (CARB) has implemented stringent regulations on fuel composition and additives to reduce air pollution. These regulations have influenced the development of treating agents that not only enhance engine performance but also minimize harmful emissions.

The regulatory landscape for fuel additives is continually evolving, with increasing emphasis on reducing greenhouse gas emissions and promoting sustainable fuel technologies. This has led to the development of new standards and regulations for alternative fuels and their additives, which may impact the future use of treating agents in V12 engine fuel systems.

Compliance with these regulations requires extensive testing and documentation. Manufacturers must conduct thorough evaluations of their additives, including long-term stability tests, compatibility assessments with engine materials, and emissions impact studies. This rigorous process ensures that only safe and effective treating agents are approved for use in V12 engine fuel systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!