V12 Engine Optimization for Fuel-Efficient Maritime Applications

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and aircraft, the V12 configuration has found its way into maritime applications due to its smooth operation and high power output. The evolution of V12 engines for maritime use has been driven by the need for increased efficiency, reduced emissions, and improved reliability.

In the 1950s and 1960s, V12 engines began to be widely adopted in large marine vessels, particularly in military and commercial ships. These early marine V12 engines were primarily focused on raw power output, often sacrificing fuel efficiency. As environmental concerns grew in the 1970s and 1980s, engine manufacturers started to shift their focus towards improving fuel economy and reducing emissions.

The 1990s saw a significant leap in V12 engine technology with the introduction of electronic fuel injection systems and advanced engine management computers. These innovations allowed for more precise control over fuel delivery and combustion timing, resulting in improved efficiency and reduced emissions. Additionally, the use of turbocharging and supercharging became more prevalent, enabling engines to produce more power from smaller displacements.

In the early 2000s, the development of common rail fuel injection systems marked another milestone in V12 engine evolution. This technology allowed for even greater control over fuel delivery, resulting in further improvements in efficiency and emissions reduction. Concurrently, advancements in materials science led to the use of lighter, stronger alloys in engine construction, reducing overall weight and improving power-to-weight ratios.

The past decade has seen a focus on integrating hybrid and electric technologies with V12 engines in maritime applications. This has led to the development of hybrid propulsion systems that combine the power of V12 engines with electric motors, offering improved fuel efficiency and reduced emissions during low-speed operations. Additionally, the use of alternative fuels such as liquefied natural gas (LNG) in V12 engines has gained traction, providing a cleaner-burning alternative to traditional marine diesel fuel.

Recent advancements in V12 engine optimization for maritime applications have centered around digital technologies and data analytics. The implementation of advanced sensors and real-time monitoring systems allows for predictive maintenance and performance optimization. Machine learning algorithms are being employed to analyze vast amounts of operational data, enabling continuous refinement of engine parameters for maximum efficiency across various operating conditions.

Looking forward, the evolution of V12 engines for maritime use is likely to continue focusing on further improvements in fuel efficiency and emissions reduction. Research into advanced combustion technologies, such as homogeneous charge compression ignition (HCCI), holds promise for significant efficiency gains. Additionally, the integration of artificial intelligence and autonomous systems may lead to self-optimizing engines capable of adapting to changing environmental and operational conditions in real-time.

In the 1950s and 1960s, V12 engines began to be widely adopted in large marine vessels, particularly in military and commercial ships. These early marine V12 engines were primarily focused on raw power output, often sacrificing fuel efficiency. As environmental concerns grew in the 1970s and 1980s, engine manufacturers started to shift their focus towards improving fuel economy and reducing emissions.

The 1990s saw a significant leap in V12 engine technology with the introduction of electronic fuel injection systems and advanced engine management computers. These innovations allowed for more precise control over fuel delivery and combustion timing, resulting in improved efficiency and reduced emissions. Additionally, the use of turbocharging and supercharging became more prevalent, enabling engines to produce more power from smaller displacements.

In the early 2000s, the development of common rail fuel injection systems marked another milestone in V12 engine evolution. This technology allowed for even greater control over fuel delivery, resulting in further improvements in efficiency and emissions reduction. Concurrently, advancements in materials science led to the use of lighter, stronger alloys in engine construction, reducing overall weight and improving power-to-weight ratios.

The past decade has seen a focus on integrating hybrid and electric technologies with V12 engines in maritime applications. This has led to the development of hybrid propulsion systems that combine the power of V12 engines with electric motors, offering improved fuel efficiency and reduced emissions during low-speed operations. Additionally, the use of alternative fuels such as liquefied natural gas (LNG) in V12 engines has gained traction, providing a cleaner-burning alternative to traditional marine diesel fuel.

Recent advancements in V12 engine optimization for maritime applications have centered around digital technologies and data analytics. The implementation of advanced sensors and real-time monitoring systems allows for predictive maintenance and performance optimization. Machine learning algorithms are being employed to analyze vast amounts of operational data, enabling continuous refinement of engine parameters for maximum efficiency across various operating conditions.

Looking forward, the evolution of V12 engines for maritime use is likely to continue focusing on further improvements in fuel efficiency and emissions reduction. Research into advanced combustion technologies, such as homogeneous charge compression ignition (HCCI), holds promise for significant efficiency gains. Additionally, the integration of artificial intelligence and autonomous systems may lead to self-optimizing engines capable of adapting to changing environmental and operational conditions in real-time.

Maritime Fuel Efficiency

Maritime fuel efficiency has become a critical focus in the shipping industry, driven by environmental concerns, regulatory pressures, and economic imperatives. The maritime sector accounts for approximately 3% of global greenhouse gas emissions, with a significant portion attributed to fuel consumption. As international regulations tighten and fuel costs fluctuate, ship operators are increasingly seeking ways to optimize their vessels' fuel efficiency.

The primary factors influencing maritime fuel efficiency include hull design, propulsion systems, operational practices, and environmental conditions. Advanced hull coatings and optimized hull shapes can reduce water resistance, while more efficient propellers and engine systems can improve overall propulsion efficiency. Operational strategies such as slow steaming, weather routing, and just-in-time arrival have also proven effective in reducing fuel consumption.

Recent technological advancements have introduced several innovative solutions to enhance maritime fuel efficiency. These include the use of alternative fuels like liquefied natural gas (LNG) and biofuels, which can significantly reduce emissions and, in some cases, offer cost savings. Hybrid and fully electric propulsion systems are gaining traction, particularly for short-sea shipping and port operations. Digital technologies, including AI-powered route optimization and real-time performance monitoring systems, are also playing a crucial role in maximizing fuel efficiency.

The economic benefits of improved maritime fuel efficiency are substantial. Fuel costs typically represent 50-60% of a vessel's operating expenses, making efficiency gains a direct contributor to profitability. Moreover, enhanced fuel efficiency aligns with the International Maritime Organization's (IMO) goal of reducing the carbon intensity of international shipping by at least 40% by 2030, compared to 2008 levels.

However, challenges remain in the pursuit of maritime fuel efficiency. The long lifespan of ships, typically 20-30 years, means that many vessels currently in operation were not designed with modern efficiency standards in mind. Retrofitting these ships can be costly and technically challenging. Additionally, the adoption of new technologies and alternative fuels often requires significant upfront investment and may face infrastructure limitations in ports worldwide.

Looking ahead, the maritime industry is likely to see continued innovation in fuel efficiency technologies. This includes further development of wind-assisted propulsion systems, advanced materials for lighter vessel construction, and the potential integration of fuel cells and hydrogen propulsion. As regulatory pressures increase and technology advances, the pursuit of maritime fuel efficiency will remain a key driver of change in the shipping industry, shaping vessel design, operational practices, and the broader maritime ecosystem.

The primary factors influencing maritime fuel efficiency include hull design, propulsion systems, operational practices, and environmental conditions. Advanced hull coatings and optimized hull shapes can reduce water resistance, while more efficient propellers and engine systems can improve overall propulsion efficiency. Operational strategies such as slow steaming, weather routing, and just-in-time arrival have also proven effective in reducing fuel consumption.

Recent technological advancements have introduced several innovative solutions to enhance maritime fuel efficiency. These include the use of alternative fuels like liquefied natural gas (LNG) and biofuels, which can significantly reduce emissions and, in some cases, offer cost savings. Hybrid and fully electric propulsion systems are gaining traction, particularly for short-sea shipping and port operations. Digital technologies, including AI-powered route optimization and real-time performance monitoring systems, are also playing a crucial role in maximizing fuel efficiency.

The economic benefits of improved maritime fuel efficiency are substantial. Fuel costs typically represent 50-60% of a vessel's operating expenses, making efficiency gains a direct contributor to profitability. Moreover, enhanced fuel efficiency aligns with the International Maritime Organization's (IMO) goal of reducing the carbon intensity of international shipping by at least 40% by 2030, compared to 2008 levels.

However, challenges remain in the pursuit of maritime fuel efficiency. The long lifespan of ships, typically 20-30 years, means that many vessels currently in operation were not designed with modern efficiency standards in mind. Retrofitting these ships can be costly and technically challenging. Additionally, the adoption of new technologies and alternative fuels often requires significant upfront investment and may face infrastructure limitations in ports worldwide.

Looking ahead, the maritime industry is likely to see continued innovation in fuel efficiency technologies. This includes further development of wind-assisted propulsion systems, advanced materials for lighter vessel construction, and the potential integration of fuel cells and hydrogen propulsion. As regulatory pressures increase and technology advances, the pursuit of maritime fuel efficiency will remain a key driver of change in the shipping industry, shaping vessel design, operational practices, and the broader maritime ecosystem.

V12 Engine Challenges

V12 engines, while renowned for their power and performance, face significant challenges in maritime applications, particularly when it comes to fuel efficiency. The primary obstacle lies in the inherent design of these large displacement engines, which typically consume substantial amounts of fuel to generate the required power output. This high fuel consumption not only increases operational costs but also contributes to environmental concerns in an era of increasing ecological awareness.

One of the key challenges is optimizing the combustion process within the V12 engine to maximize fuel efficiency without compromising power output. This involves fine-tuning the air-fuel mixture, improving ignition timing, and enhancing the overall combustion chamber design. Engineers must balance these factors to achieve optimal performance while reducing fuel consumption, a task that becomes increasingly complex as emission regulations tighten.

Thermal management presents another significant hurdle in V12 engine optimization. The large number of cylinders generates substantial heat, which must be efficiently dissipated to maintain engine performance and longevity. Developing advanced cooling systems that can handle the heat load without adding excessive weight or complexity to the engine is a critical challenge.

Weight reduction is also a crucial factor in improving fuel efficiency. V12 engines are inherently heavy, and reducing their mass without compromising structural integrity or performance is a complex engineering task. This challenge extends to the materials used in engine construction, with a need for lightweight yet durable components that can withstand the harsh maritime environment.

Friction reduction within the engine is another area of focus. With twelve cylinders and numerous moving parts, minimizing internal friction is essential for improving overall efficiency. This includes developing advanced lubricants, improving surface finishes, and optimizing component designs to reduce energy losses due to friction.

Adapting V12 engines to alternative fuels or hybrid systems presents additional challenges. As the maritime industry explores cleaner energy options, integrating these large engines with new fuel technologies or electric propulsion systems requires significant re-engineering and innovation.

Lastly, the challenge of meeting increasingly stringent emission regulations while maintaining the power and reliability expected from V12 engines is paramount. This involves developing advanced aftertreatment systems, improving fuel injection technologies, and potentially exploring new combustion strategies to reduce harmful emissions without sacrificing engine performance.

One of the key challenges is optimizing the combustion process within the V12 engine to maximize fuel efficiency without compromising power output. This involves fine-tuning the air-fuel mixture, improving ignition timing, and enhancing the overall combustion chamber design. Engineers must balance these factors to achieve optimal performance while reducing fuel consumption, a task that becomes increasingly complex as emission regulations tighten.

Thermal management presents another significant hurdle in V12 engine optimization. The large number of cylinders generates substantial heat, which must be efficiently dissipated to maintain engine performance and longevity. Developing advanced cooling systems that can handle the heat load without adding excessive weight or complexity to the engine is a critical challenge.

Weight reduction is also a crucial factor in improving fuel efficiency. V12 engines are inherently heavy, and reducing their mass without compromising structural integrity or performance is a complex engineering task. This challenge extends to the materials used in engine construction, with a need for lightweight yet durable components that can withstand the harsh maritime environment.

Friction reduction within the engine is another area of focus. With twelve cylinders and numerous moving parts, minimizing internal friction is essential for improving overall efficiency. This includes developing advanced lubricants, improving surface finishes, and optimizing component designs to reduce energy losses due to friction.

Adapting V12 engines to alternative fuels or hybrid systems presents additional challenges. As the maritime industry explores cleaner energy options, integrating these large engines with new fuel technologies or electric propulsion systems requires significant re-engineering and innovation.

Lastly, the challenge of meeting increasingly stringent emission regulations while maintaining the power and reliability expected from V12 engines is paramount. This involves developing advanced aftertreatment systems, improving fuel injection technologies, and potentially exploring new combustion strategies to reduce harmful emissions without sacrificing engine performance.

Current V12 Solutions

01 Engine control strategies for improved fuel efficiency

Various control strategies can be implemented in V12 engines to optimize fuel efficiency. These may include advanced fuel injection timing, variable valve timing, and cylinder deactivation technologies. Such strategies aim to improve combustion efficiency, reduce pumping losses, and adapt engine operation to varying load conditions.- Engine control systems for improved fuel efficiency: Advanced engine control systems are implemented to optimize fuel efficiency in V12 engines. These systems may include electronic control units that manage various engine parameters such as fuel injection timing, valve timing, and air-fuel mixture ratios. By precisely controlling these factors, the engine can operate at peak efficiency across different driving conditions.

- Cylinder deactivation technology: Cylinder deactivation technology is employed to improve fuel efficiency in V12 engines. This system allows the engine to selectively shut down a portion of its cylinders during low-load conditions, effectively reducing fuel consumption without compromising performance when full power is needed.

- Advanced fuel injection systems: Innovative fuel injection systems are developed to enhance fuel efficiency in V12 engines. These may include direct injection technology, high-pressure fuel delivery systems, and precise fuel metering capabilities. Such advancements allow for more efficient combustion and reduced fuel waste.

- Turbocharging and supercharging technologies: Forced induction systems, such as turbochargers and superchargers, are utilized to improve the power output and fuel efficiency of V12 engines. These technologies allow for downsizing of the engine while maintaining performance, resulting in better fuel economy.

- Lightweight materials and design optimization: The use of lightweight materials and optimized engine designs contributes to improved fuel efficiency in V12 engines. This includes the application of advanced alloys, composite materials, and innovative manufacturing techniques to reduce engine weight and friction, leading to better overall fuel economy.

02 Turbocharging and supercharging systems

Forced induction systems, such as turbochargers and superchargers, can be employed to enhance the power output and fuel efficiency of V12 engines. These systems increase air intake, allowing for more efficient combustion and improved overall engine performance.Expand Specific Solutions03 Lightweight materials and design optimization

The use of lightweight materials and optimized engine designs can significantly improve the fuel efficiency of V12 engines. This includes the application of advanced alloys, composite materials, and innovative structural designs to reduce overall engine weight while maintaining strength and performance.Expand Specific Solutions04 Advanced lubrication and cooling systems

Implementing sophisticated lubrication and cooling systems can enhance the fuel efficiency of V12 engines by reducing friction and maintaining optimal operating temperatures. This may involve the use of low-viscosity oils, precision oil delivery systems, and advanced thermal management techniques.Expand Specific Solutions05 Integration of hybrid and electric technologies

Incorporating hybrid or electric technologies into V12 engine systems can significantly improve overall fuel efficiency. This may include the integration of electric motors, regenerative braking systems, and advanced energy storage solutions to complement the traditional V12 engine.Expand Specific Solutions

Marine Engine Players

The V12 engine optimization for fuel-efficient maritime applications is in a mature development stage, with significant market potential due to increasing demand for eco-friendly maritime solutions. The market size is substantial, driven by global shipping industry needs and environmental regulations. Technologically, the field is advanced, with companies like ExxonMobil Technology & Engineering Co., Japan Engine Corp., and Mitsubishi Heavy Industries leading innovation. Academic institutions such as Dalian Maritime University and Harbin Engineering University contribute to research and development. The competitive landscape includes established players and emerging companies, reflecting a dynamic and evolving sector focused on improving maritime engine efficiency and reducing environmental impact.

Dalian Shipbuilding Industry Co., Ltd.

Technical Solution: Dalian Shipbuilding Industry Co., Ltd. has developed a comprehensive V12 engine optimization package for fuel-efficient maritime applications. Their solution incorporates an intelligent combustion control system that utilizes real-time monitoring of cylinder pressure and temperature to optimize fuel injection parameters[7]. The company has also implemented an advanced turbocharger matching technology, which ensures optimal air supply across various engine loads and speeds. Dalian Shipbuilding's system includes a dynamic cylinder oil feed rate control, which adjusts lubrication based on engine operating conditions, reducing oil consumption and wear[8]. Additionally, they have integrated a fuel emulsion technology that improves combustion efficiency and reduces particulate matter emissions[9].

Strengths: Intelligent combustion control system and advanced turbocharger matching contribute to improved fuel efficiency. The dynamic cylinder oil feed rate control and fuel emulsion technology offer additional benefits in terms of reduced maintenance and emissions. Weaknesses: The system's complexity may require extensive crew training and potentially higher initial investment.

Japan Engine Corp.

Technical Solution: Japan Engine Corp. has developed a cutting-edge V12 engine optimization solution for maritime applications, focusing on fuel efficiency and emissions reduction. Their approach includes an advanced electronic control system that precisely manages fuel injection, valve timing, and turbocharger operation[2]. The company has implemented a variable valve timing mechanism that optimizes air intake and exhaust flow across different engine loads. Japan Engine Corp. has also integrated a low-temperature exhaust gas recirculation (EGR) system, which significantly reduces NOx emissions while maintaining fuel efficiency[4]. Furthermore, they have developed a unique cylinder lubrication system that minimizes oil consumption and reduces friction losses, contributing to overall engine efficiency[6].

Strengths: Advanced electronic control system, variable valve timing, and low-temperature EGR technology contribute to both fuel efficiency and emissions reduction. The innovative cylinder lubrication system further enhances efficiency. Weaknesses: The sophisticated technology may require specialized training for operation and maintenance, potentially increasing operational costs.

Key V12 Innovations

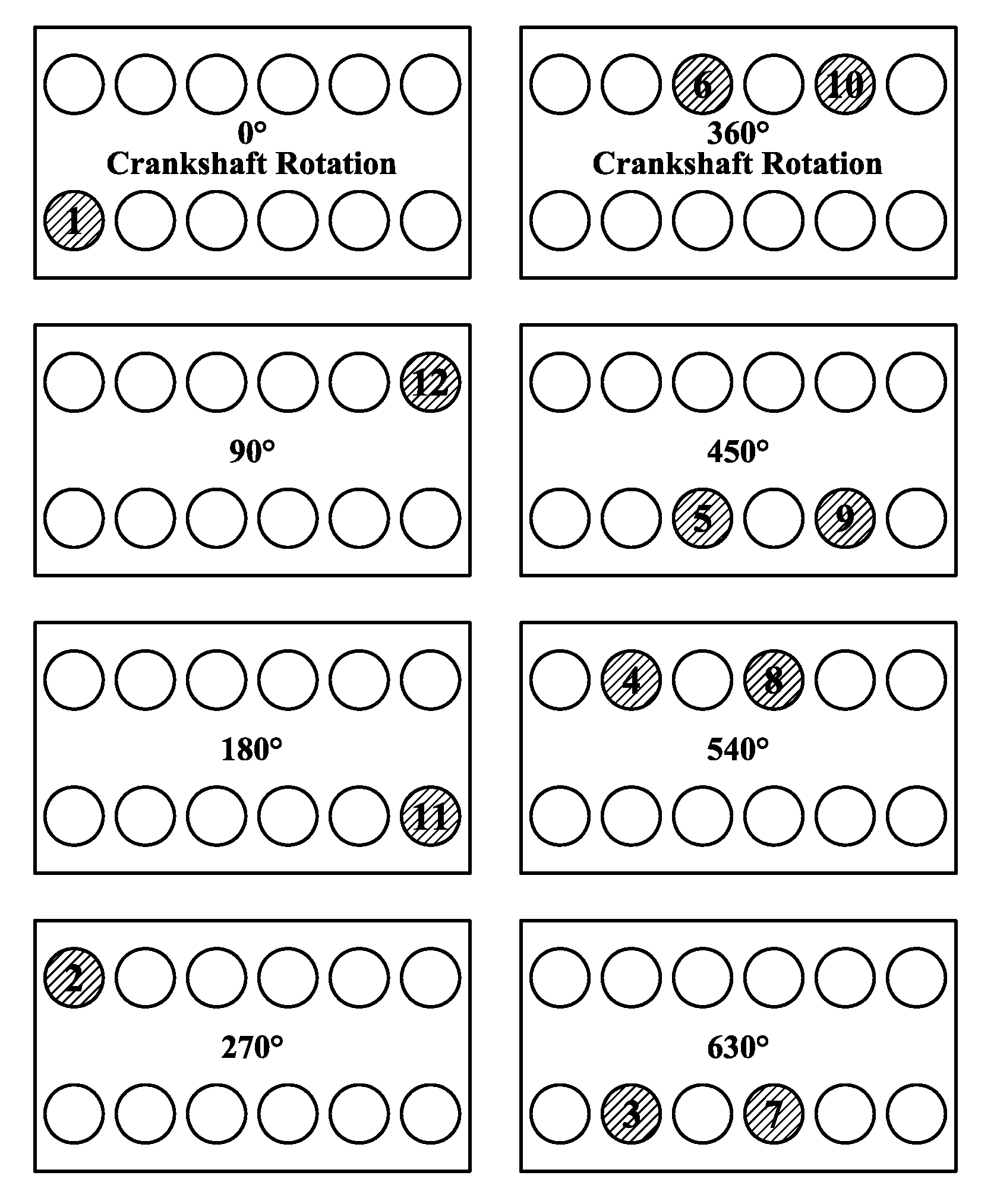

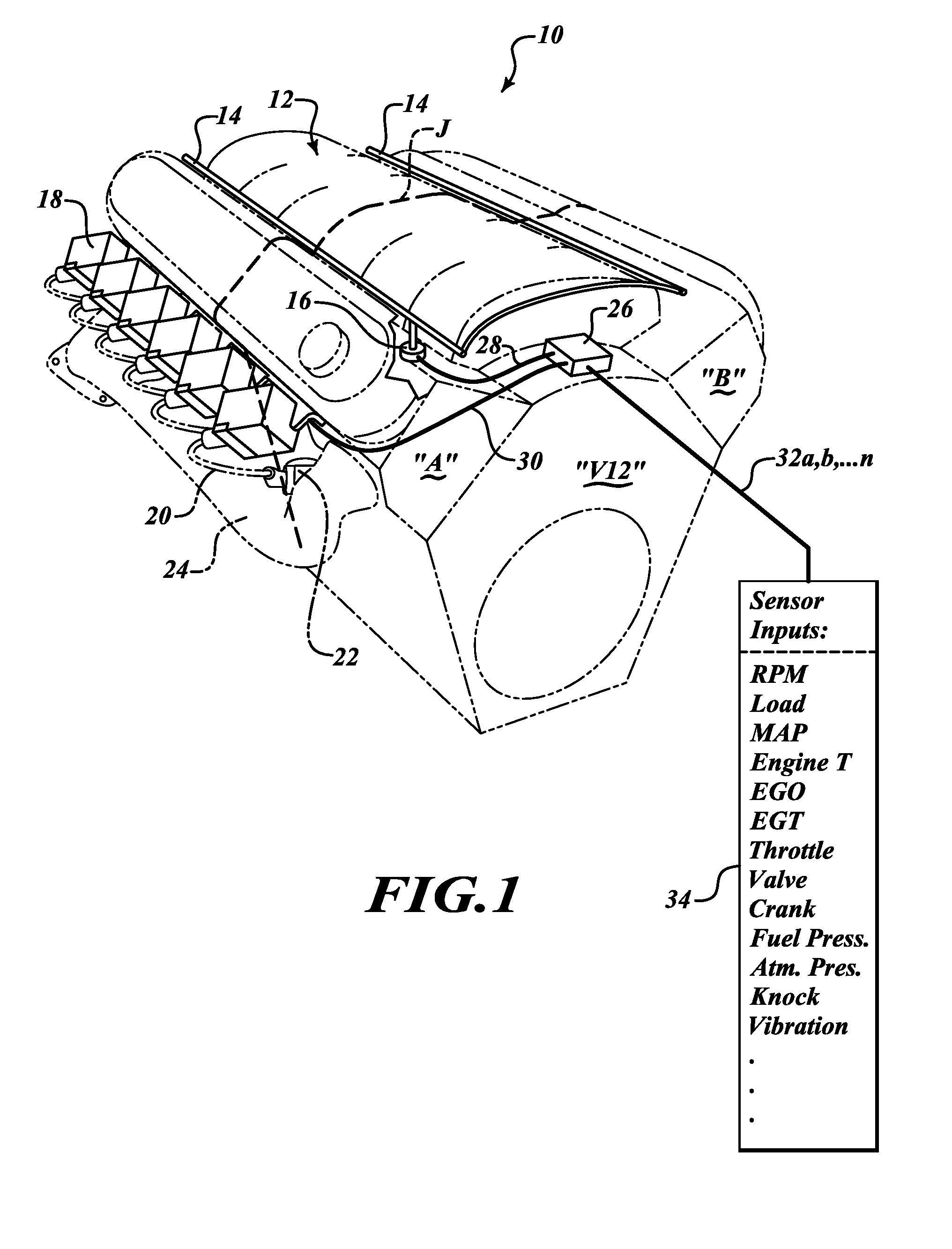

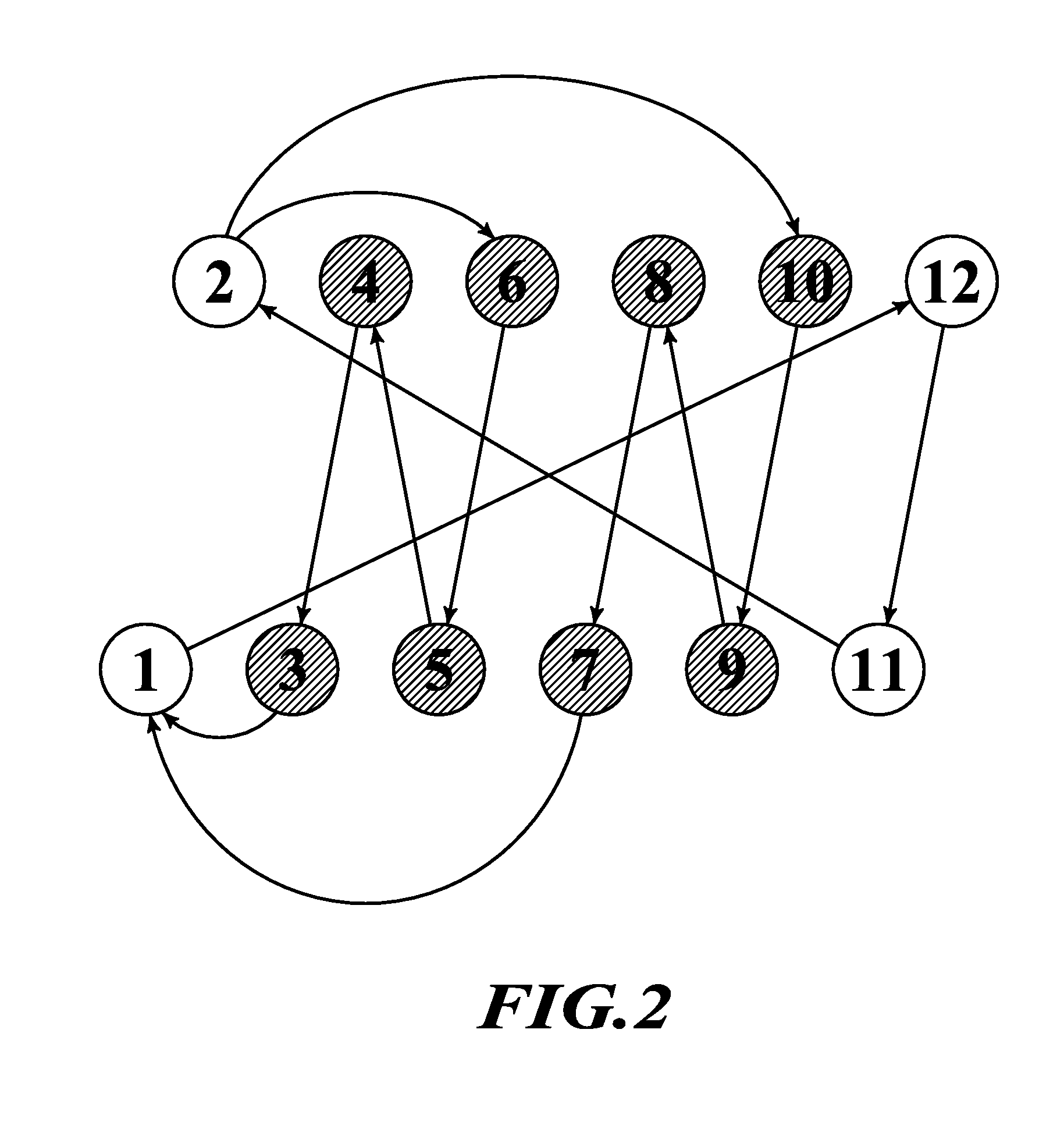

Even fire 90°V12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/P technology and IFR compensation by fuel feed control

PatentInactiveUS7979193B2

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence controlled by a Powertrain Control Module (PCM) that allows all cylinders in a 90°V12 to operate in Even Fire mode, with Dynamic Fuel Balancing and IFR Compensation by selectively reducing fuel to specific cylinders during imbalance frequencies, effectively converting the engine's operation to a balanced V8 mode during peak vibrations.

Emission Regulations

Emission regulations for maritime applications have become increasingly stringent in recent years, driven by global efforts to reduce environmental impact and improve air quality. The International Maritime Organization (IMO) has been at the forefront of these regulations, implementing progressively stricter standards for ship emissions, particularly focusing on sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM).

The IMO's MARPOL Annex VI, which came into force in 2005, has been the primary framework for addressing ship emissions. In 2020, a significant milestone was reached with the global sulfur cap, reducing the allowable sulfur content in marine fuels from 3.5% to 0.5%. This regulation has had a profound impact on the maritime industry, forcing ship operators to either switch to low-sulfur fuels or install exhaust gas cleaning systems (scrubbers).

For V12 engines used in maritime applications, these regulations have necessitated substantial modifications and optimizations. Engine manufacturers have had to develop new technologies and strategies to meet emission standards while maintaining performance and fuel efficiency. This has led to the adoption of advanced fuel injection systems, exhaust gas recirculation (EGR), and selective catalytic reduction (SCR) technologies.

The NOx emission limits, defined in the IMO Tier III standards, have been particularly challenging for large marine engines. These standards require a reduction of NOx emissions by approximately 80% compared to the Tier I levels. For V12 engines, this has prompted the development of innovative combustion strategies and aftertreatment systems.

Looking ahead, the IMO has set ambitious targets for reducing greenhouse gas emissions from international shipping. The initial strategy aims to reduce CO2 emissions per transport work by at least 40% by 2030, and 70% by 2050, compared to 2008 levels. This long-term goal is driving research and development in alternative fuels and propulsion technologies, which will likely impact the future design and optimization of V12 engines for maritime use.

As emission regulations continue to evolve, engine manufacturers and ship operators must stay ahead of the curve. This involves not only complying with current standards but also anticipating future regulations and investing in technologies that will ensure long-term compliance and operational efficiency. The optimization of V12 engines for fuel-efficient maritime applications must, therefore, balance the demands of emission reduction with the need for reliable and economical operation in challenging marine environments.

The IMO's MARPOL Annex VI, which came into force in 2005, has been the primary framework for addressing ship emissions. In 2020, a significant milestone was reached with the global sulfur cap, reducing the allowable sulfur content in marine fuels from 3.5% to 0.5%. This regulation has had a profound impact on the maritime industry, forcing ship operators to either switch to low-sulfur fuels or install exhaust gas cleaning systems (scrubbers).

For V12 engines used in maritime applications, these regulations have necessitated substantial modifications and optimizations. Engine manufacturers have had to develop new technologies and strategies to meet emission standards while maintaining performance and fuel efficiency. This has led to the adoption of advanced fuel injection systems, exhaust gas recirculation (EGR), and selective catalytic reduction (SCR) technologies.

The NOx emission limits, defined in the IMO Tier III standards, have been particularly challenging for large marine engines. These standards require a reduction of NOx emissions by approximately 80% compared to the Tier I levels. For V12 engines, this has prompted the development of innovative combustion strategies and aftertreatment systems.

Looking ahead, the IMO has set ambitious targets for reducing greenhouse gas emissions from international shipping. The initial strategy aims to reduce CO2 emissions per transport work by at least 40% by 2030, and 70% by 2050, compared to 2008 levels. This long-term goal is driving research and development in alternative fuels and propulsion technologies, which will likely impact the future design and optimization of V12 engines for maritime use.

As emission regulations continue to evolve, engine manufacturers and ship operators must stay ahead of the curve. This involves not only complying with current standards but also anticipating future regulations and investing in technologies that will ensure long-term compliance and operational efficiency. The optimization of V12 engines for fuel-efficient maritime applications must, therefore, balance the demands of emission reduction with the need for reliable and economical operation in challenging marine environments.

Alternative Fuels

Alternative fuels are becoming increasingly important in the maritime industry as a means to reduce emissions and improve fuel efficiency. In the context of V12 engine optimization for fuel-efficient maritime applications, several alternative fuel options are being explored and implemented.

Liquefied Natural Gas (LNG) has emerged as a promising alternative fuel for maritime applications. LNG offers significant reductions in emissions, particularly sulfur oxides and particulate matter. When used in V12 engines, LNG can provide comparable power output to traditional marine diesel while reducing greenhouse gas emissions by up to 25%. However, the adoption of LNG requires significant infrastructure investments and modifications to existing engine designs.

Biodiesel blends are another alternative fuel option being considered for V12 marine engines. These blends, typically consisting of a mixture of conventional diesel and biodiesel derived from renewable sources, can be used in existing engines with minimal modifications. Biodiesel blends can reduce emissions of particulate matter and carbon monoxide, although their impact on nitrogen oxide emissions varies depending on the blend ratio.

Hydrogen fuel cells are gaining attention as a zero-emission alternative for maritime propulsion. While not directly applicable to V12 engines, hydrogen fuel cell technology could potentially replace traditional combustion engines in certain maritime applications. The main challenges for hydrogen adoption include high production costs, storage difficulties, and the need for extensive infrastructure development.

Methanol is emerging as another alternative fuel option for maritime use. It can be produced from renewable sources and offers lower emissions compared to conventional marine fuels. Methanol can be used in modified V12 engines, providing a pathway for existing vessels to transition to cleaner fuel options. However, methanol has a lower energy density compared to diesel, which may impact vessel range and performance.

Ammonia is being investigated as a potential carbon-free fuel for maritime applications. It can be produced using renewable energy sources and offers zero carbon emissions when burned. However, the use of ammonia in V12 engines presents significant technical challenges, including corrosion issues and the need for specialized fuel storage and handling systems.

As the maritime industry continues to seek ways to reduce its environmental impact, the development and optimization of V12 engines to accommodate these alternative fuels will play a crucial role. Engine manufacturers and researchers are focusing on improving combustion efficiency, reducing emissions, and enhancing overall performance when using these alternative fuels in V12 marine engines.

Liquefied Natural Gas (LNG) has emerged as a promising alternative fuel for maritime applications. LNG offers significant reductions in emissions, particularly sulfur oxides and particulate matter. When used in V12 engines, LNG can provide comparable power output to traditional marine diesel while reducing greenhouse gas emissions by up to 25%. However, the adoption of LNG requires significant infrastructure investments and modifications to existing engine designs.

Biodiesel blends are another alternative fuel option being considered for V12 marine engines. These blends, typically consisting of a mixture of conventional diesel and biodiesel derived from renewable sources, can be used in existing engines with minimal modifications. Biodiesel blends can reduce emissions of particulate matter and carbon monoxide, although their impact on nitrogen oxide emissions varies depending on the blend ratio.

Hydrogen fuel cells are gaining attention as a zero-emission alternative for maritime propulsion. While not directly applicable to V12 engines, hydrogen fuel cell technology could potentially replace traditional combustion engines in certain maritime applications. The main challenges for hydrogen adoption include high production costs, storage difficulties, and the need for extensive infrastructure development.

Methanol is emerging as another alternative fuel option for maritime use. It can be produced from renewable sources and offers lower emissions compared to conventional marine fuels. Methanol can be used in modified V12 engines, providing a pathway for existing vessels to transition to cleaner fuel options. However, methanol has a lower energy density compared to diesel, which may impact vessel range and performance.

Ammonia is being investigated as a potential carbon-free fuel for maritime applications. It can be produced using renewable energy sources and offers zero carbon emissions when burned. However, the use of ammonia in V12 engines presents significant technical challenges, including corrosion issues and the need for specialized fuel storage and handling systems.

As the maritime industry continues to seek ways to reduce its environmental impact, the development and optimization of V12 engines to accommodate these alternative fuels will play a crucial role. Engine manufacturers and researchers are focusing on improving combustion efficiency, reducing emissions, and enhancing overall performance when using these alternative fuels in V12 marine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!