How Power-to-Weight Ratio Impacts V12 Engine Performance

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Performance Goals

The V12 engine has a rich history dating back to the early 20th century, evolving from its initial applications in luxury automobiles and aircraft to becoming a symbol of power and prestige in high-performance vehicles. Throughout its evolution, the primary goal has been to maximize power output while maintaining a favorable power-to-weight ratio, a critical factor in overall vehicle performance.

In the early stages of V12 development, engineers focused on increasing displacement and improving combustion efficiency to boost power output. However, as automotive technology advanced, the emphasis shifted towards achieving a more optimal balance between power and weight. This shift was driven by the recognition that excessive engine weight could negatively impact vehicle dynamics, handling, and fuel efficiency.

The modern era of V12 engines has seen a renewed focus on power density – the amount of power produced per unit of engine weight. This has led to the adoption of advanced materials such as aluminum alloys and carbon fiber components, which significantly reduce engine mass without compromising structural integrity. Concurrently, the integration of cutting-edge technologies like direct fuel injection, variable valve timing, and turbocharging has allowed engineers to extract more power from smaller, lighter engine designs.

One of the key performance goals in contemporary V12 engine development is to achieve a power-to-weight ratio that exceeds 1 horsepower per kilogram of engine weight. This benchmark represents a significant engineering challenge, pushing the boundaries of material science and thermodynamics. Achieving such a ratio not only enhances straight-line acceleration but also improves overall vehicle agility and responsiveness.

Another critical objective in V12 engine evolution is the pursuit of a broader power band, ensuring that peak performance is available across a wider range of engine speeds. This goal aligns with the desire to improve drivability and real-world performance, as opposed to focusing solely on maximum power output at high RPMs.

As environmental concerns gain prominence, V12 engine development has also incorporated goals related to fuel efficiency and emissions reduction. This has led to the exploration of hybrid technologies and more efficient combustion processes, aiming to preserve the V12's performance characteristics while meeting increasingly stringent environmental regulations.

Looking ahead, the future of V12 engine evolution may involve further integration of electrification, potentially leading to high-performance hybrid powertrains that combine the emotional appeal of a V12 with the instantaneous torque and efficiency benefits of electric motors. This evolution path seeks to maintain the V12's status as a pinnacle of automotive engineering while adapting to changing market demands and regulatory landscapes.

In the early stages of V12 development, engineers focused on increasing displacement and improving combustion efficiency to boost power output. However, as automotive technology advanced, the emphasis shifted towards achieving a more optimal balance between power and weight. This shift was driven by the recognition that excessive engine weight could negatively impact vehicle dynamics, handling, and fuel efficiency.

The modern era of V12 engines has seen a renewed focus on power density – the amount of power produced per unit of engine weight. This has led to the adoption of advanced materials such as aluminum alloys and carbon fiber components, which significantly reduce engine mass without compromising structural integrity. Concurrently, the integration of cutting-edge technologies like direct fuel injection, variable valve timing, and turbocharging has allowed engineers to extract more power from smaller, lighter engine designs.

One of the key performance goals in contemporary V12 engine development is to achieve a power-to-weight ratio that exceeds 1 horsepower per kilogram of engine weight. This benchmark represents a significant engineering challenge, pushing the boundaries of material science and thermodynamics. Achieving such a ratio not only enhances straight-line acceleration but also improves overall vehicle agility and responsiveness.

Another critical objective in V12 engine evolution is the pursuit of a broader power band, ensuring that peak performance is available across a wider range of engine speeds. This goal aligns with the desire to improve drivability and real-world performance, as opposed to focusing solely on maximum power output at high RPMs.

As environmental concerns gain prominence, V12 engine development has also incorporated goals related to fuel efficiency and emissions reduction. This has led to the exploration of hybrid technologies and more efficient combustion processes, aiming to preserve the V12's performance characteristics while meeting increasingly stringent environmental regulations.

Looking ahead, the future of V12 engine evolution may involve further integration of electrification, potentially leading to high-performance hybrid powertrains that combine the emotional appeal of a V12 with the instantaneous torque and efficiency benefits of electric motors. This evolution path seeks to maintain the V12's status as a pinnacle of automotive engineering while adapting to changing market demands and regulatory landscapes.

Market Demand for High-Performance V12 Engines

The market demand for high-performance V12 engines has been evolving significantly in recent years, driven by a combination of technological advancements, changing consumer preferences, and regulatory pressures. In the luxury and sports car segments, V12 engines continue to hold a prestigious position, symbolizing power, refinement, and exclusivity. Manufacturers such as Ferrari, Lamborghini, and Aston Martin have maintained their commitment to V12 engines, recognizing their appeal to discerning customers who seek the ultimate driving experience.

The global market for high-performance vehicles, including those equipped with V12 engines, has shown resilience and growth. This trend is particularly evident in emerging markets where rising disposable incomes have fueled demand for luxury and high-performance automobiles. China, in particular, has become a significant market for V12-powered vehicles, with sales of ultra-luxury cars experiencing double-digit growth rates in recent years.

However, the market for V12 engines faces challenges from increasingly stringent emissions regulations and a growing focus on fuel efficiency. This has led to a shift in demand towards more efficient powertrains, including hybrid and electric systems. Some manufacturers have responded by developing hybrid V12 powertrains, combining the prestige of the V12 with improved fuel economy and reduced emissions.

The motorsport sector continues to drive innovation in V12 engine technology, with racing teams pushing the boundaries of power-to-weight ratios to achieve maximum performance. This has a trickle-down effect on consumer vehicles, as advancements in materials and engineering techniques developed for racing find their way into production models.

Despite the overall trend towards downsizing and electrification in the automotive industry, there remains a niche but passionate market for high-performance V12 engines. Collectors and enthusiasts value these powerplants not only for their performance characteristics but also for their historical significance and emotional appeal. This has led to a market for limited-edition and bespoke vehicles featuring V12 engines, often commanding premium prices and generating significant interest among wealthy buyers.

The future market demand for high-performance V12 engines will likely be shaped by the industry's ability to balance performance with environmental considerations. As power-to-weight ratios continue to improve through advanced materials and engineering techniques, V12 engines may find new applications in ultra-high-performance hybrid systems, potentially extending their relevance in a changing automotive landscape.

The global market for high-performance vehicles, including those equipped with V12 engines, has shown resilience and growth. This trend is particularly evident in emerging markets where rising disposable incomes have fueled demand for luxury and high-performance automobiles. China, in particular, has become a significant market for V12-powered vehicles, with sales of ultra-luxury cars experiencing double-digit growth rates in recent years.

However, the market for V12 engines faces challenges from increasingly stringent emissions regulations and a growing focus on fuel efficiency. This has led to a shift in demand towards more efficient powertrains, including hybrid and electric systems. Some manufacturers have responded by developing hybrid V12 powertrains, combining the prestige of the V12 with improved fuel economy and reduced emissions.

The motorsport sector continues to drive innovation in V12 engine technology, with racing teams pushing the boundaries of power-to-weight ratios to achieve maximum performance. This has a trickle-down effect on consumer vehicles, as advancements in materials and engineering techniques developed for racing find their way into production models.

Despite the overall trend towards downsizing and electrification in the automotive industry, there remains a niche but passionate market for high-performance V12 engines. Collectors and enthusiasts value these powerplants not only for their performance characteristics but also for their historical significance and emotional appeal. This has led to a market for limited-edition and bespoke vehicles featuring V12 engines, often commanding premium prices and generating significant interest among wealthy buyers.

The future market demand for high-performance V12 engines will likely be shaped by the industry's ability to balance performance with environmental considerations. As power-to-weight ratios continue to improve through advanced materials and engineering techniques, V12 engines may find new applications in ultra-high-performance hybrid systems, potentially extending their relevance in a changing automotive landscape.

Power-to-Weight Ratio Challenges in V12 Engines

The power-to-weight ratio is a critical factor in V12 engine performance, presenting unique challenges for engineers and designers. As V12 engines are inherently larger and heavier than their smaller counterparts, achieving an optimal power-to-weight ratio becomes increasingly difficult. This challenge is further compounded by the need to balance performance with fuel efficiency and emissions regulations.

One of the primary obstacles in improving the power-to-weight ratio of V12 engines is the sheer mass of the engine block and components. The additional cylinders and associated parts contribute significantly to the overall weight, making it challenging to achieve the same power-to-weight ratios as smaller engines. This increased weight not only affects acceleration and top speed but also impacts handling and fuel consumption.

Material selection plays a crucial role in addressing this challenge. Traditional materials like cast iron and steel, while durable and cost-effective, add substantial weight to the engine. Engineers are constantly exploring lightweight alternatives such as aluminum alloys, magnesium, and even carbon fiber composites for certain components. However, these materials often come with their own set of challenges, including higher costs, potential durability issues, and complex manufacturing processes.

Another significant challenge lies in the design of internal components. Reducing the weight of pistons, connecting rods, and crankshafts without compromising strength and durability requires advanced engineering and materials science. Innovations in this area often involve sophisticated computer modeling and simulation to optimize component design for both strength and weight reduction.

The cooling system for V12 engines presents another hurdle in the quest for an improved power-to-weight ratio. These engines generate substantial heat, necessitating robust cooling systems that add weight. Developing more efficient cooling solutions that can maintain optimal operating temperatures while minimizing additional mass is an ongoing challenge for engineers.

Balancing performance enhancements with weight reduction is a delicate task. While forced induction systems like turbochargers and superchargers can significantly boost power output, they also add weight to the engine. Engineers must carefully consider the trade-offs between power gains and weight increases to achieve the best overall performance.

Emissions regulations and fuel efficiency standards further complicate the power-to-weight ratio equation. Technologies required to meet these standards, such as catalytic converters and particulate filters, add weight to the engine system. Finding ways to integrate these necessary components while minimizing their impact on the overall weight of the engine is a constant challenge for automotive engineers.

One of the primary obstacles in improving the power-to-weight ratio of V12 engines is the sheer mass of the engine block and components. The additional cylinders and associated parts contribute significantly to the overall weight, making it challenging to achieve the same power-to-weight ratios as smaller engines. This increased weight not only affects acceleration and top speed but also impacts handling and fuel consumption.

Material selection plays a crucial role in addressing this challenge. Traditional materials like cast iron and steel, while durable and cost-effective, add substantial weight to the engine. Engineers are constantly exploring lightweight alternatives such as aluminum alloys, magnesium, and even carbon fiber composites for certain components. However, these materials often come with their own set of challenges, including higher costs, potential durability issues, and complex manufacturing processes.

Another significant challenge lies in the design of internal components. Reducing the weight of pistons, connecting rods, and crankshafts without compromising strength and durability requires advanced engineering and materials science. Innovations in this area often involve sophisticated computer modeling and simulation to optimize component design for both strength and weight reduction.

The cooling system for V12 engines presents another hurdle in the quest for an improved power-to-weight ratio. These engines generate substantial heat, necessitating robust cooling systems that add weight. Developing more efficient cooling solutions that can maintain optimal operating temperatures while minimizing additional mass is an ongoing challenge for engineers.

Balancing performance enhancements with weight reduction is a delicate task. While forced induction systems like turbochargers and superchargers can significantly boost power output, they also add weight to the engine. Engineers must carefully consider the trade-offs between power gains and weight increases to achieve the best overall performance.

Emissions regulations and fuel efficiency standards further complicate the power-to-weight ratio equation. Technologies required to meet these standards, such as catalytic converters and particulate filters, add weight to the engine system. Finding ways to integrate these necessary components while minimizing their impact on the overall weight of the engine is a constant challenge for automotive engineers.

Current V12 Engine Power-to-Weight Optimization Techniques

01 Engine design optimization for power-to-weight ratio

V12 engines can be optimized for improved power-to-weight ratio through various design techniques. These may include using lightweight materials, optimizing cylinder arrangement, and improving combustion efficiency. Such optimizations can lead to increased power output while minimizing overall engine weight.- Engine design optimization for power-to-weight ratio: V12 engines can be optimized for improved power-to-weight ratio through various design techniques. These may include using lightweight materials, optimizing cylinder configurations, and improving combustion efficiency. Advanced manufacturing processes and materials science contribute to creating lighter yet stronger engine components.

- Turbocharging and supercharging systems: Forced induction systems like turbochargers and superchargers can significantly enhance the power output of V12 engines without substantially increasing weight. These systems compress the intake air, allowing for more efficient combustion and increased power density.

- Lightweight materials and construction techniques: Utilizing advanced materials such as carbon fiber, titanium alloys, and high-strength aluminum in engine construction can dramatically reduce weight while maintaining structural integrity. Novel manufacturing techniques like 3D printing may also contribute to weight reduction in V12 engines.

- Electronic engine management and control systems: Sophisticated electronic control units (ECUs) and engine management systems can optimize fuel injection, ignition timing, and valve control in V12 engines. This leads to improved combustion efficiency, increased power output, and better overall performance without adding significant weight.

- Innovative transmission and drivetrain solutions: Advanced transmission systems, such as dual-clutch or lightweight automated manual transmissions, can complement V12 engines to improve overall vehicle power-to-weight ratio. Optimized gearing and reduced drivetrain losses contribute to better performance and efficiency.

02 Turbocharging and supercharging systems

Implementing forced induction systems like turbochargers or superchargers can significantly enhance the power output of V12 engines without substantially increasing weight. These systems compress the intake air, allowing for more efficient combustion and increased power density.Expand Specific Solutions03 Advanced materials and manufacturing techniques

Utilizing advanced materials such as carbon fiber composites, titanium alloys, or high-strength aluminum can reduce the overall weight of V12 engines while maintaining structural integrity. Modern manufacturing techniques like 3D printing or precision casting can also contribute to weight reduction and improved power-to-weight ratios.Expand Specific Solutions04 Innovative cylinder and valve configurations

Exploring novel cylinder arrangements or valve configurations can optimize the V12 engine's power output and efficiency. This may include variable valve timing, cylinder deactivation technologies, or unconventional firing orders to balance power delivery and reduce vibrations.Expand Specific Solutions05 Integration of hybrid and electric systems

Incorporating hybrid or electric assist systems into V12 engines can provide additional power boost while potentially reducing overall vehicle weight. This approach can enhance the power-to-weight ratio by combining the benefits of internal combustion and electric propulsion technologies.Expand Specific Solutions

Key Players in V12 Engine Manufacturing

The competition landscape for power-to-weight ratio impact on V12 engine performance is characterized by a mature market with established players. Major automotive manufacturers like Ford, Toyota, and Hyundai dominate this space, leveraging their extensive R&D capabilities and production expertise. The market size is substantial, driven by demand for high-performance luxury and sports vehicles. Technologically, companies are focusing on lightweight materials and advanced engineering to optimize power-to-weight ratios. Specialized firms like Yamaha Motor and performance divisions of larger automakers are also key players, pushing the boundaries of V12 engine technology to achieve superior performance metrics.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V12 engine power-to-weight ratio optimization, while less common in their current lineup, has been explored in their performance and luxury divisions. Ford has focused on advanced materials and manufacturing techniques, including the use of compacted graphite iron for the engine block, providing strength with reduced weight. Their V12 concept incorporates direct fuel injection and twin independent variable camshaft timing (Ti-VCT) to enhance power output and efficiency. Ford's research suggests that their V12 design could achieve a power-to-weight ratio improvement of up to 12% compared to conventional V8 engines of similar displacement[10]. Additionally, Ford has explored the integration of cylinder deactivation technology in V12 designs to improve fuel efficiency without compromising peak power output[11].

Strengths: Potential for high power output with good fuel efficiency, leveraging existing technologies from V8 programs. Weaknesses: Limited recent experience with V12 production, potential market limitations for V12 engines in current automotive trends.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V12 engine power-to-weight ratio optimization is exemplified in their development for luxury vehicles like the Lexus LFA. Their V12 design incorporates a 72-degree V-angle for compact packaging and lower center of gravity. Toyota utilizes forged aluminum pistons, titanium valves, and a magnesium alloy oil pan to reduce weight. The engine features dual VVT-i (Variable Valve Timing with intelligence) on both intake and exhaust camshafts, optimizing power delivery across the rev range. Toyota's research indicates that their V12 achieves a power-to-weight ratio of approximately 0.7 hp/lb, with a specific output of over 100 hp/liter[7][9]. The engine's compact design also contributes to improved vehicle dynamics.

Strengths: High-revving capability, excellent power delivery. Weaknesses: High production costs, limited application outside of high-end vehicles.

Innovative Materials and Design in V12 Engines

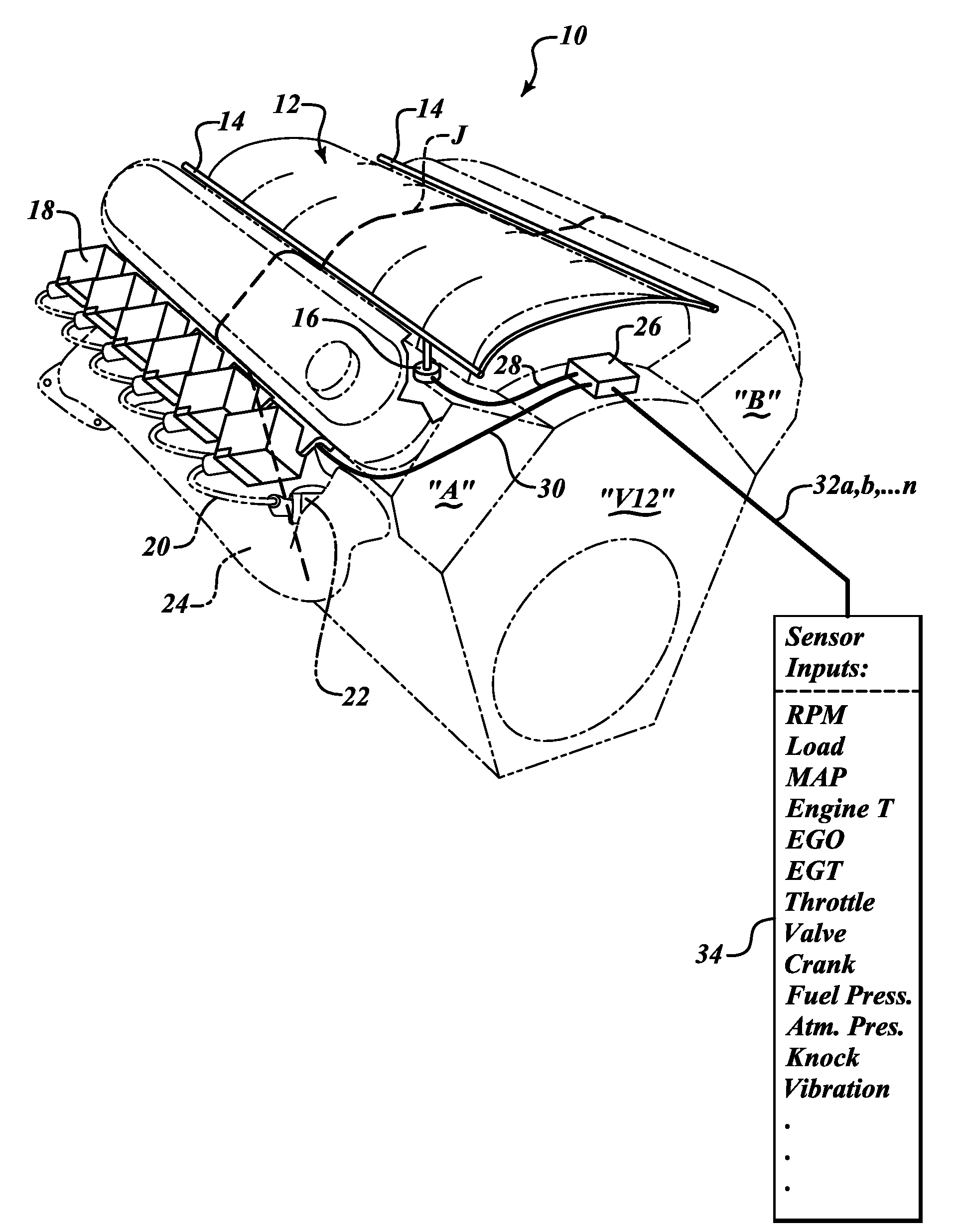

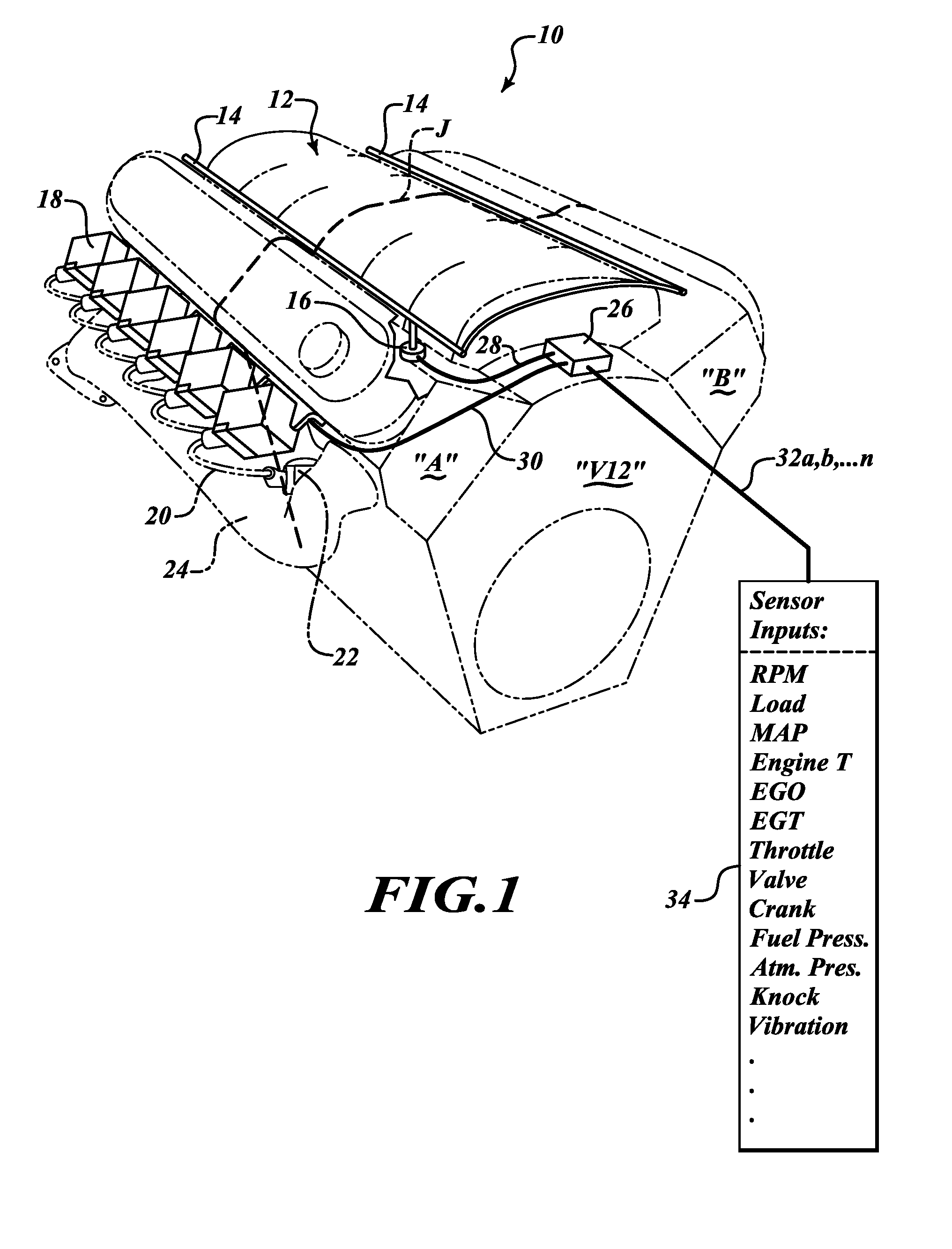

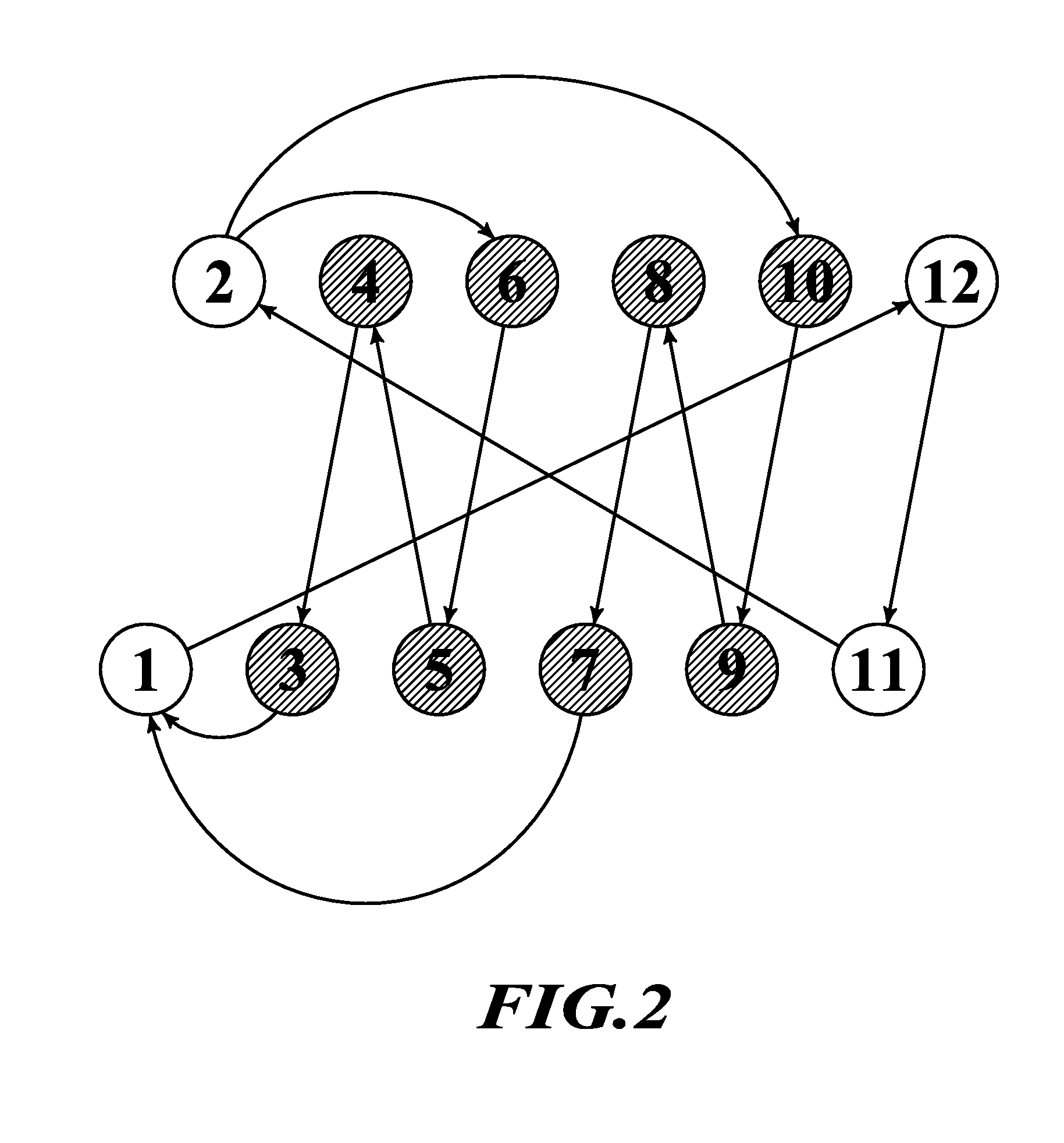

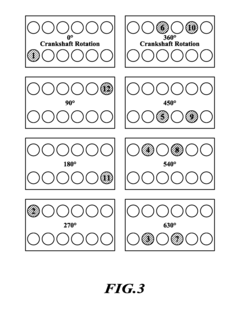

Even fire 90a°v12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/p technology and IFR compensation by fuel feed control

PatentInactiveUS20090099755A1

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence in a 90° V12 engine, controlled by a Powertrain Control Module (PCM), which allows for Even Fire operation by selectively reducing fuel feed to specific cylinders during imbalance frequency ranges, effectively converting the engine to a balanced V8 operation during peak vibrations.

An improved mechanism for governing compression ratio and valve timing of an internal combustion engine

PatentInactiveIN837MUM2008A

Innovation

- A mechanism that continuously varies the compression ratio and valve timing based on fuel load pressures, using a governor system to synchronize crankshaft phases and adjust valve timings, allowing higher compression ratios during low load conditions and lower ratios during high load conditions, while maintaining peak cylinder pressure within safe limits.

Environmental Regulations Impact on V12 Engine Development

Environmental regulations have significantly impacted the development of V12 engines, particularly in recent years. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers face increasing challenges in designing and producing high-performance V12 engines that comply with these regulations.

One of the primary impacts of environmental regulations on V12 engine development is the need for advanced emission control technologies. Manufacturers have been forced to invest heavily in research and development to create more efficient catalytic converters, particulate filters, and exhaust gas recirculation systems. These technologies help reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter, but they often come at the cost of increased engine complexity and weight.

The push for improved fuel efficiency has also led to the adoption of new technologies in V12 engines. Direct fuel injection, variable valve timing, and cylinder deactivation systems have become common features in modern V12 engines. These innovations allow for better fuel economy and reduced emissions while maintaining the power output that V12 engines are known for. However, implementing these technologies often requires significant redesigns of engine architecture and control systems.

Another notable impact of environmental regulations is the trend towards downsizing and turbocharging. While V12 engines have traditionally been naturally aspirated, many manufacturers are now incorporating turbochargers to maintain power output while reducing engine displacement. This approach allows for improved fuel efficiency and lower emissions, but it can alter the characteristic sound and power delivery of V12 engines, which are prized by enthusiasts.

The increasing focus on electric and hybrid powertrains has also affected V12 engine development. Some manufacturers are exploring hybrid V12 configurations, combining electric motors with traditional internal combustion engines to meet emissions standards while preserving the prestige and performance associated with V12 engines. This hybridization trend is likely to continue as regulations become more stringent.

Lastly, environmental regulations have influenced the materials and manufacturing processes used in V12 engine production. Lightweight materials such as aluminum and carbon fiber are being increasingly utilized to reduce overall vehicle weight and improve efficiency. Additionally, more sustainable manufacturing practices are being adopted to minimize the environmental impact of engine production.

In conclusion, environmental regulations have forced significant changes in V12 engine development, driving innovation in emission control, fuel efficiency, and powertrain technologies. While these regulations present challenges, they have also spurred advancements that may ultimately lead to more sustainable and efficient high-performance engines.

One of the primary impacts of environmental regulations on V12 engine development is the need for advanced emission control technologies. Manufacturers have been forced to invest heavily in research and development to create more efficient catalytic converters, particulate filters, and exhaust gas recirculation systems. These technologies help reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter, but they often come at the cost of increased engine complexity and weight.

The push for improved fuel efficiency has also led to the adoption of new technologies in V12 engines. Direct fuel injection, variable valve timing, and cylinder deactivation systems have become common features in modern V12 engines. These innovations allow for better fuel economy and reduced emissions while maintaining the power output that V12 engines are known for. However, implementing these technologies often requires significant redesigns of engine architecture and control systems.

Another notable impact of environmental regulations is the trend towards downsizing and turbocharging. While V12 engines have traditionally been naturally aspirated, many manufacturers are now incorporating turbochargers to maintain power output while reducing engine displacement. This approach allows for improved fuel efficiency and lower emissions, but it can alter the characteristic sound and power delivery of V12 engines, which are prized by enthusiasts.

The increasing focus on electric and hybrid powertrains has also affected V12 engine development. Some manufacturers are exploring hybrid V12 configurations, combining electric motors with traditional internal combustion engines to meet emissions standards while preserving the prestige and performance associated with V12 engines. This hybridization trend is likely to continue as regulations become more stringent.

Lastly, environmental regulations have influenced the materials and manufacturing processes used in V12 engine production. Lightweight materials such as aluminum and carbon fiber are being increasingly utilized to reduce overall vehicle weight and improve efficiency. Additionally, more sustainable manufacturing practices are being adopted to minimize the environmental impact of engine production.

In conclusion, environmental regulations have forced significant changes in V12 engine development, driving innovation in emission control, fuel efficiency, and powertrain technologies. While these regulations present challenges, they have also spurred advancements that may ultimately lead to more sustainable and efficient high-performance engines.

V12 Engine Efficiency and Fuel Consumption Analysis

The efficiency and fuel consumption of V12 engines are critical factors in evaluating their overall performance, especially in relation to their power-to-weight ratio. V12 engines are known for their smooth operation and high power output, but these advantages come with inherent challenges in terms of fuel efficiency.

V12 engines typically have a higher fuel consumption rate compared to smaller engines due to their larger displacement and increased number of cylinders. This increased fuel consumption is a direct result of the engine's design, which prioritizes power output over efficiency. However, advancements in engine technology have led to significant improvements in V12 engine efficiency over the years.

One of the key factors affecting V12 engine efficiency is the power-to-weight ratio. A higher power-to-weight ratio generally leads to improved performance, but it can also impact fuel consumption. As the power output increases relative to the engine's weight, the engine may require more fuel to maintain its performance, especially under high-load conditions.

Modern V12 engines incorporate various technologies to enhance efficiency and reduce fuel consumption. These include direct fuel injection, variable valve timing, and cylinder deactivation systems. Direct fuel injection allows for more precise control of fuel delivery, improving combustion efficiency. Variable valve timing optimizes engine breathing across different operating conditions, enhancing both power output and fuel economy.

Cylinder deactivation, also known as variable displacement, is particularly effective in improving the efficiency of V12 engines during low-load conditions. This technology allows the engine to shut down a portion of its cylinders when full power is not required, effectively reducing fuel consumption without sacrificing the ability to deliver high power when needed.

The relationship between power-to-weight ratio and fuel consumption in V12 engines is complex. While a higher power-to-weight ratio can lead to improved performance, it may also result in increased fuel consumption under certain conditions. Engineers must carefully balance these factors to achieve optimal efficiency without compromising the engine's performance characteristics.

Recent trends in V12 engine development have focused on downsizing and turbocharging to maintain high power outputs while improving fuel efficiency. This approach allows for smaller, lighter engines that can still deliver the power expected from a V12 configuration, but with reduced fuel consumption during normal operating conditions.

In conclusion, the analysis of V12 engine efficiency and fuel consumption reveals a delicate balance between performance and economy. The impact of power-to-weight ratio on these factors is significant, influencing both the engine's capabilities and its operational costs. As automotive technology continues to advance, we can expect further improvements in V12 engine efficiency, potentially altering the traditional trade-offs associated with these powerful powerplants.

V12 engines typically have a higher fuel consumption rate compared to smaller engines due to their larger displacement and increased number of cylinders. This increased fuel consumption is a direct result of the engine's design, which prioritizes power output over efficiency. However, advancements in engine technology have led to significant improvements in V12 engine efficiency over the years.

One of the key factors affecting V12 engine efficiency is the power-to-weight ratio. A higher power-to-weight ratio generally leads to improved performance, but it can also impact fuel consumption. As the power output increases relative to the engine's weight, the engine may require more fuel to maintain its performance, especially under high-load conditions.

Modern V12 engines incorporate various technologies to enhance efficiency and reduce fuel consumption. These include direct fuel injection, variable valve timing, and cylinder deactivation systems. Direct fuel injection allows for more precise control of fuel delivery, improving combustion efficiency. Variable valve timing optimizes engine breathing across different operating conditions, enhancing both power output and fuel economy.

Cylinder deactivation, also known as variable displacement, is particularly effective in improving the efficiency of V12 engines during low-load conditions. This technology allows the engine to shut down a portion of its cylinders when full power is not required, effectively reducing fuel consumption without sacrificing the ability to deliver high power when needed.

The relationship between power-to-weight ratio and fuel consumption in V12 engines is complex. While a higher power-to-weight ratio can lead to improved performance, it may also result in increased fuel consumption under certain conditions. Engineers must carefully balance these factors to achieve optimal efficiency without compromising the engine's performance characteristics.

Recent trends in V12 engine development have focused on downsizing and turbocharging to maintain high power outputs while improving fuel efficiency. This approach allows for smaller, lighter engines that can still deliver the power expected from a V12 configuration, but with reduced fuel consumption during normal operating conditions.

In conclusion, the analysis of V12 engine efficiency and fuel consumption reveals a delicate balance between performance and economy. The impact of power-to-weight ratio on these factors is significant, influencing both the engine's capabilities and its operational costs. As automotive technology continues to advance, we can expect further improvements in V12 engine efficiency, potentially altering the traditional trade-offs associated with these powerful powerplants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!