How V12 Engine Technology Benefits Personalized Transportation Solutions

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury and high-performance vehicles, the V12 configuration has become synonymous with power, smoothness, and prestige. The evolution of V12 engine technology can be traced through several key stages, each marked by advancements in design, materials, and engineering principles.

In the 1920s and 1930s, V12 engines were primarily found in racing cars and luxury automobiles. These early iterations were characterized by their large displacement and relatively low specific output. The focus was on achieving smooth operation and impressive low-end torque, rather than high-revving performance.

The post-World War II era saw a shift towards more compact and efficient V12 designs. Manufacturers began to explore ways to increase power output while reducing engine weight and size. This period marked the introduction of overhead camshaft designs and the gradual transition from carburetors to fuel injection systems.

The 1960s and 1970s brought about a new era of high-performance V12 engines, particularly in Formula 1 racing. These engines showcased advanced technologies such as four-valve cylinder heads and sophisticated fuel injection systems. Concurrently, luxury car manufacturers continued to refine their V12 offerings, focusing on enhancing refinement and reliability.

The 1980s and 1990s witnessed a renaissance in V12 engine development, driven by advancements in materials science and computer-aided design. This period saw the introduction of all-aluminum construction, variable valve timing, and more sophisticated engine management systems. These innovations allowed for significant improvements in power output, fuel efficiency, and emissions control.

In the 21st century, V12 engine technology has continued to evolve, with a focus on meeting increasingly stringent emissions regulations while maintaining performance. Modern V12 engines often incorporate technologies such as direct fuel injection, turbocharging, and hybrid-electric systems. These advancements have allowed V12 engines to remain relevant in an era of downsizing and electrification.

The evolution of V12 engine technology has directly contributed to the development of personalized transportation solutions. As these engines became more refined and efficient, they enabled the creation of high-performance luxury vehicles that cater to discerning customers seeking unparalleled power and prestige. The smooth operation and distinctive sound of V12 engines have become key selling points for manufacturers looking to differentiate their premium offerings in a crowded market.

In the 1920s and 1930s, V12 engines were primarily found in racing cars and luxury automobiles. These early iterations were characterized by their large displacement and relatively low specific output. The focus was on achieving smooth operation and impressive low-end torque, rather than high-revving performance.

The post-World War II era saw a shift towards more compact and efficient V12 designs. Manufacturers began to explore ways to increase power output while reducing engine weight and size. This period marked the introduction of overhead camshaft designs and the gradual transition from carburetors to fuel injection systems.

The 1960s and 1970s brought about a new era of high-performance V12 engines, particularly in Formula 1 racing. These engines showcased advanced technologies such as four-valve cylinder heads and sophisticated fuel injection systems. Concurrently, luxury car manufacturers continued to refine their V12 offerings, focusing on enhancing refinement and reliability.

The 1980s and 1990s witnessed a renaissance in V12 engine development, driven by advancements in materials science and computer-aided design. This period saw the introduction of all-aluminum construction, variable valve timing, and more sophisticated engine management systems. These innovations allowed for significant improvements in power output, fuel efficiency, and emissions control.

In the 21st century, V12 engine technology has continued to evolve, with a focus on meeting increasingly stringent emissions regulations while maintaining performance. Modern V12 engines often incorporate technologies such as direct fuel injection, turbocharging, and hybrid-electric systems. These advancements have allowed V12 engines to remain relevant in an era of downsizing and electrification.

The evolution of V12 engine technology has directly contributed to the development of personalized transportation solutions. As these engines became more refined and efficient, they enabled the creation of high-performance luxury vehicles that cater to discerning customers seeking unparalleled power and prestige. The smooth operation and distinctive sound of V12 engines have become key selling points for manufacturers looking to differentiate their premium offerings in a crowded market.

Market Demand Analysis

The market demand for personalized transportation solutions incorporating V12 engine technology has been steadily growing, driven by a combination of factors including luxury preferences, performance requirements, and technological advancements. High-net-worth individuals and automotive enthusiasts are increasingly seeking bespoke vehicles that offer unparalleled power, refinement, and exclusivity.

In the luxury automotive sector, V12 engines have long been associated with prestige and superior performance. The market for high-end vehicles equipped with V12 engines, while niche, has shown resilience and even growth in certain regions. This demand is particularly strong in markets such as the Middle East, China, and North America, where affluent consumers value the status and driving experience offered by V12-powered vehicles.

The personalization trend in the automotive industry has further fueled the demand for V12 engine technology. Customers are willing to pay premium prices for vehicles that can be tailored to their specific preferences, including engine choices. This has led to an increase in bespoke vehicle programs offered by luxury automakers, where V12 engines are often the crown jewel of available powertrains.

Performance-oriented buyers, including collectors and motorsport enthusiasts, continue to drive demand for V12 engines due to their unique characteristics. The smooth power delivery, distinctive sound, and heritage associated with V12 engines make them highly desirable for high-performance applications and limited-edition models.

However, the market for V12 engines faces challenges from increasingly stringent emissions regulations and a global shift towards electrification. This has led to a bifurcation in the market, with some manufacturers phasing out V12 engines while others are investing in hybrid V12 powertrains to meet both performance demands and environmental standards.

The integration of V12 engine technology with advanced personalization features is opening new market opportunities. This includes the development of customizable engine management systems, bespoke exhaust systems, and personalized driving modes that leverage the V12's capabilities. Such innovations are attracting a new generation of tech-savvy luxury car buyers who seek both traditional engineering excellence and cutting-edge technology.

As the automotive industry evolves, the market for V12-powered personalized transportation solutions is expected to remain robust among a select clientele. The combination of heritage, performance, and exclusivity continues to command a premium, ensuring that V12 engines will maintain their position at the pinnacle of personalized automotive offerings for the foreseeable future.

In the luxury automotive sector, V12 engines have long been associated with prestige and superior performance. The market for high-end vehicles equipped with V12 engines, while niche, has shown resilience and even growth in certain regions. This demand is particularly strong in markets such as the Middle East, China, and North America, where affluent consumers value the status and driving experience offered by V12-powered vehicles.

The personalization trend in the automotive industry has further fueled the demand for V12 engine technology. Customers are willing to pay premium prices for vehicles that can be tailored to their specific preferences, including engine choices. This has led to an increase in bespoke vehicle programs offered by luxury automakers, where V12 engines are often the crown jewel of available powertrains.

Performance-oriented buyers, including collectors and motorsport enthusiasts, continue to drive demand for V12 engines due to their unique characteristics. The smooth power delivery, distinctive sound, and heritage associated with V12 engines make them highly desirable for high-performance applications and limited-edition models.

However, the market for V12 engines faces challenges from increasingly stringent emissions regulations and a global shift towards electrification. This has led to a bifurcation in the market, with some manufacturers phasing out V12 engines while others are investing in hybrid V12 powertrains to meet both performance demands and environmental standards.

The integration of V12 engine technology with advanced personalization features is opening new market opportunities. This includes the development of customizable engine management systems, bespoke exhaust systems, and personalized driving modes that leverage the V12's capabilities. Such innovations are attracting a new generation of tech-savvy luxury car buyers who seek both traditional engineering excellence and cutting-edge technology.

As the automotive industry evolves, the market for V12-powered personalized transportation solutions is expected to remain robust among a select clientele. The combination of heritage, performance, and exclusivity continues to command a premium, ensuring that V12 engines will maintain their position at the pinnacle of personalized automotive offerings for the foreseeable future.

Technical Challenges

The implementation of V12 engine technology in personalized transportation solutions faces several significant technical challenges. One of the primary hurdles is the inherent complexity of the V12 engine design. With twelve cylinders arranged in a V-configuration, these engines require intricate engineering to ensure optimal performance, fuel efficiency, and reliability.

Balancing power output and fuel consumption presents another major challenge. V12 engines are known for their impressive power delivery, but this often comes at the cost of increased fuel consumption. Engineers must develop innovative solutions to improve fuel efficiency without compromising the engine's performance characteristics, which is particularly crucial in an era of increasing environmental concerns and stringent emissions regulations.

The integration of V12 engines into personalized transportation platforms poses unique packaging challenges. These large, heavy powerplants require substantial space within the vehicle's architecture, which can impact overall vehicle design, weight distribution, and handling characteristics. Designers must find creative ways to accommodate the engine while maintaining optimal vehicle dynamics and passenger comfort.

Heat management is another critical issue facing V12 engine implementation. The high power output generates significant heat, necessitating advanced cooling systems to maintain optimal operating temperatures. This challenge is further compounded in personalized transportation applications, where vehicle designs may prioritize aesthetics or aerodynamics over traditional cooling solutions.

Noise, vibration, and harshness (NVH) control presents yet another technical hurdle. While the distinctive sound of a V12 engine is often desirable, excessive noise and vibration can detract from the overall driving experience, particularly in luxury or comfort-oriented personalized transportation solutions. Engineers must develop sophisticated NVH mitigation strategies to ensure a refined and comfortable ride.

The complexity of V12 engines also leads to increased manufacturing costs and maintenance requirements. This poses challenges in terms of scalability and long-term viability for personalized transportation solutions, particularly in markets where cost-effectiveness is a key consideration. Manufacturers must explore ways to streamline production processes and improve serviceability to make V12-powered vehicles more accessible and sustainable.

Lastly, the integration of modern technologies such as hybrid systems, advanced driver assistance features, and connectivity solutions with V12 engines presents significant engineering challenges. Balancing the traditional mechanical prowess of the V12 with cutting-edge electronic systems requires careful design considerations and extensive testing to ensure seamless operation and optimal performance across all vehicle systems.

Balancing power output and fuel consumption presents another major challenge. V12 engines are known for their impressive power delivery, but this often comes at the cost of increased fuel consumption. Engineers must develop innovative solutions to improve fuel efficiency without compromising the engine's performance characteristics, which is particularly crucial in an era of increasing environmental concerns and stringent emissions regulations.

The integration of V12 engines into personalized transportation platforms poses unique packaging challenges. These large, heavy powerplants require substantial space within the vehicle's architecture, which can impact overall vehicle design, weight distribution, and handling characteristics. Designers must find creative ways to accommodate the engine while maintaining optimal vehicle dynamics and passenger comfort.

Heat management is another critical issue facing V12 engine implementation. The high power output generates significant heat, necessitating advanced cooling systems to maintain optimal operating temperatures. This challenge is further compounded in personalized transportation applications, where vehicle designs may prioritize aesthetics or aerodynamics over traditional cooling solutions.

Noise, vibration, and harshness (NVH) control presents yet another technical hurdle. While the distinctive sound of a V12 engine is often desirable, excessive noise and vibration can detract from the overall driving experience, particularly in luxury or comfort-oriented personalized transportation solutions. Engineers must develop sophisticated NVH mitigation strategies to ensure a refined and comfortable ride.

The complexity of V12 engines also leads to increased manufacturing costs and maintenance requirements. This poses challenges in terms of scalability and long-term viability for personalized transportation solutions, particularly in markets where cost-effectiveness is a key consideration. Manufacturers must explore ways to streamline production processes and improve serviceability to make V12-powered vehicles more accessible and sustainable.

Lastly, the integration of modern technologies such as hybrid systems, advanced driver assistance features, and connectivity solutions with V12 engines presents significant engineering challenges. Balancing the traditional mechanical prowess of the V12 with cutting-edge electronic systems requires careful design considerations and extensive testing to ensure seamless operation and optimal performance across all vehicle systems.

Current V12 Solutions

01 V12 Engine Design and Configuration

V12 engines are designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine layout while providing high power output and smooth operation. Advancements in V12 engine technology focus on optimizing cylinder arrangement, improving combustion efficiency, and reducing overall engine weight.- V12 Engine Design and Configuration: V12 engines are designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine layout while providing high power output and smooth operation. The design often incorporates advanced materials and manufacturing techniques to optimize performance and efficiency.

- Fuel Injection and Combustion Technology: Modern V12 engines utilize sophisticated fuel injection systems and combustion technologies to enhance performance and reduce emissions. This includes direct injection, variable valve timing, and advanced engine management systems to optimize fuel delivery and combustion processes.

- Turbocharging and Supercharging: To further increase power output and efficiency, many V12 engines incorporate forced induction systems such as turbochargers or superchargers. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher power output from a given engine displacement.

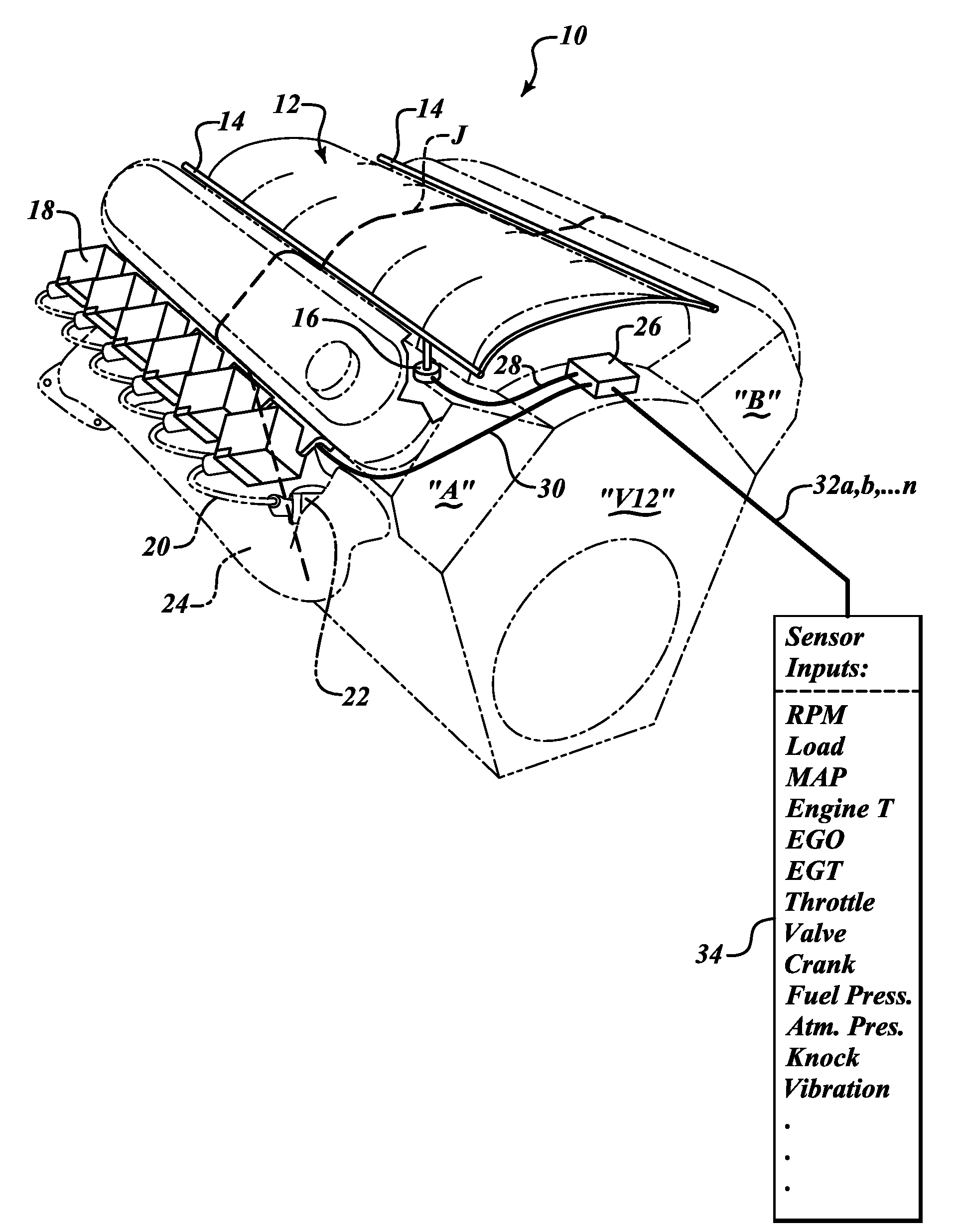

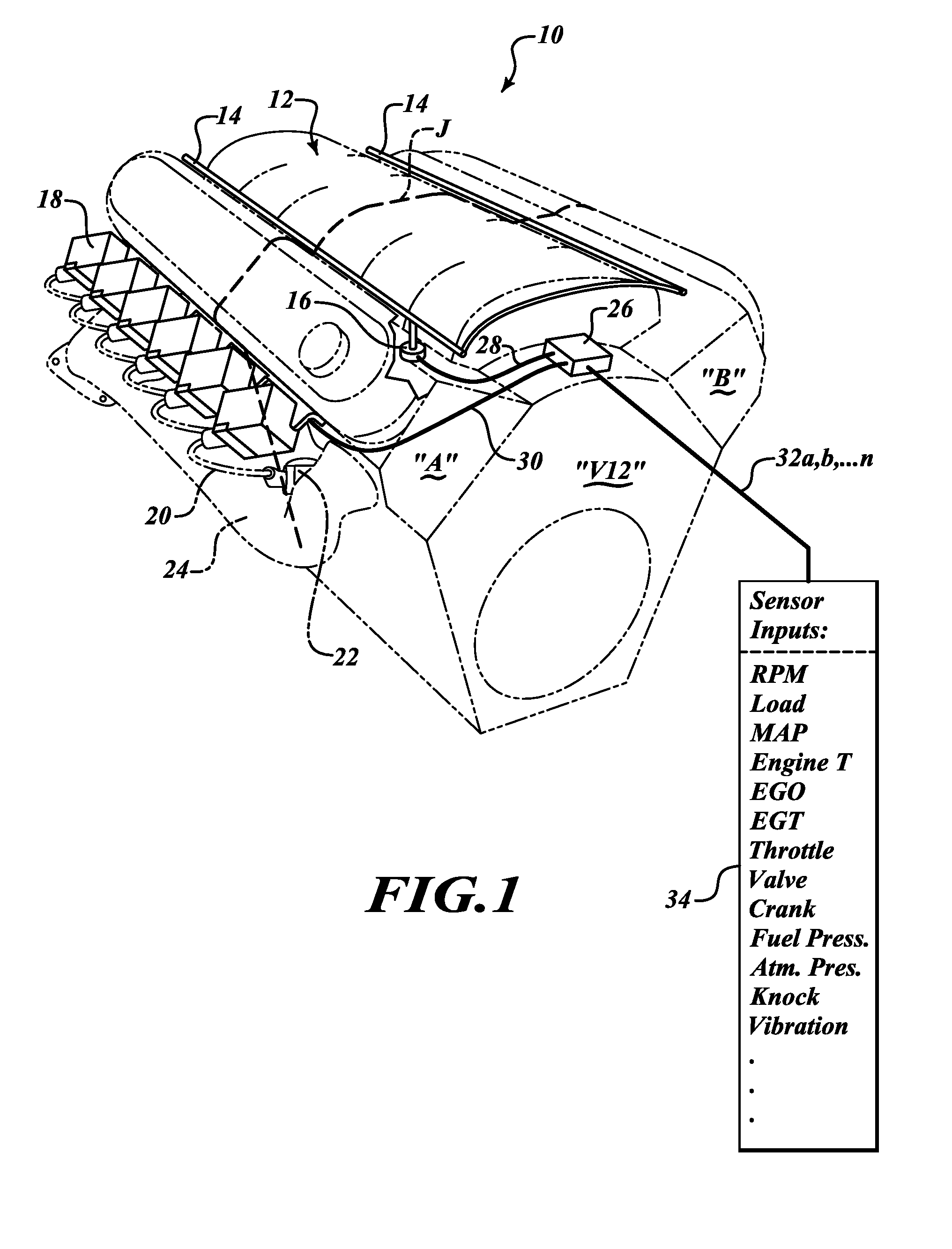

- Engine Control and Management Systems: Advanced electronic control units (ECUs) and engine management systems are crucial for optimizing V12 engine performance. These systems monitor and adjust various parameters in real-time, including fuel injection, ignition timing, and valve operation, to maximize efficiency and power output while meeting emissions standards.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are essential for V12 engines due to their high power output and complex design. Advanced cooling technologies and oil circulation systems are employed to maintain optimal operating temperatures and ensure proper lubrication of all moving parts, enhancing engine longevity and performance.

02 Fuel Efficiency and Emissions Control

Modern V12 engine technology incorporates advanced fuel injection systems, variable valve timing, and exhaust gas recirculation to improve fuel efficiency and reduce emissions. These innovations help V12 engines meet stringent environmental regulations while maintaining high performance characteristics.Expand Specific Solutions03 Engine Management and Control Systems

Sophisticated electronic control units (ECUs) and sensors are utilized in V12 engines to optimize performance, fuel consumption, and emissions. These systems monitor various engine parameters in real-time and adjust operating conditions accordingly, ensuring optimal engine performance across different driving scenarios.Expand Specific Solutions04 Materials and Manufacturing Techniques

Advanced materials such as lightweight alloys and composites are employed in V12 engine construction to reduce weight and improve heat dissipation. Cutting-edge manufacturing techniques, including 3D printing and precision machining, are used to produce complex engine components with tight tolerances.Expand Specific Solutions05 Hybridization and Electrification

To meet future emissions standards and improve overall efficiency, V12 engine technology is increasingly being combined with hybrid and electric systems. This integration allows for enhanced power delivery, regenerative braking, and the ability to operate in electric-only mode for short distances.Expand Specific Solutions

Key V12 Manufacturers

The V12 engine technology in personalized transportation solutions is in a mature stage of development, with a relatively niche market size due to its high-end positioning. The technology's maturity is evident from its long-standing presence in luxury and performance vehicles. Companies like Ford Global Technologies LLC, GM Global Technology Operations LLC, and Huawei Technologies Co., Ltd. have made significant advancements in integrating V12 engines with modern automotive technologies. However, the market is evolving with a shift towards more fuel-efficient and environmentally friendly alternatives, challenging traditional V12 manufacturers to innovate and adapt to changing consumer preferences and regulatory requirements.

Ford Global Technologies LLC

Technical Solution: Ford's V12 engine technology for personalized transportation solutions focuses on high-performance luxury vehicles. Their 6.8-liter V12 engine, developed for Lincoln Navigator concept, delivers over 500 horsepower and 600 lb-ft of torque[1]. This engine incorporates advanced fuel injection systems, variable valve timing, and cylinder deactivation technology to optimize performance and efficiency[2]. Ford's V12 also features a compact design with a 60-degree V-angle, allowing for better packaging in various vehicle platforms[3]. The engine utilizes lightweight materials such as aluminum alloys for the block and heads to reduce overall weight. Ford has integrated this V12 technology with their EcoBoost turbocharging system, further enhancing power output while improving fuel economy[4].

Strengths: Exceptional power and torque for luxury vehicles, advanced fuel efficiency technologies, versatile packaging. Weaknesses: Higher production costs, limited application in mass-market vehicles, potentially higher fuel consumption compared to smaller engines.

China FAW Co., Ltd.

Technical Solution: FAW's approach to V12 engine technology for personalized transportation solutions is centered on their Hongqi luxury brand. Their 6.0-liter V12 engine, developed for high-end limousines and luxury SUVs, produces over 400 horsepower and 500 Nm of torque[1]. The engine features multi-point fuel injection, variable valve timing, and a high-strength forged steel crankshaft for durability[2]. FAW's V12 incorporates a 60-degree V-angle design for compact packaging and smooth operation. The engine is equipped with an advanced engine management system that optimizes performance and fuel efficiency based on driving conditions[3]. FAW has integrated this V12 technology with their latest autonomous driving systems, allowing for a unique blend of high performance and cutting-edge technology in their luxury vehicles[4].

Strengths: Tailored for Chinese luxury market, integration with autonomous technologies, smooth and quiet operation. Weaknesses: Lower power output compared to some international competitors, limited global presence and recognition.

V12 Innovations

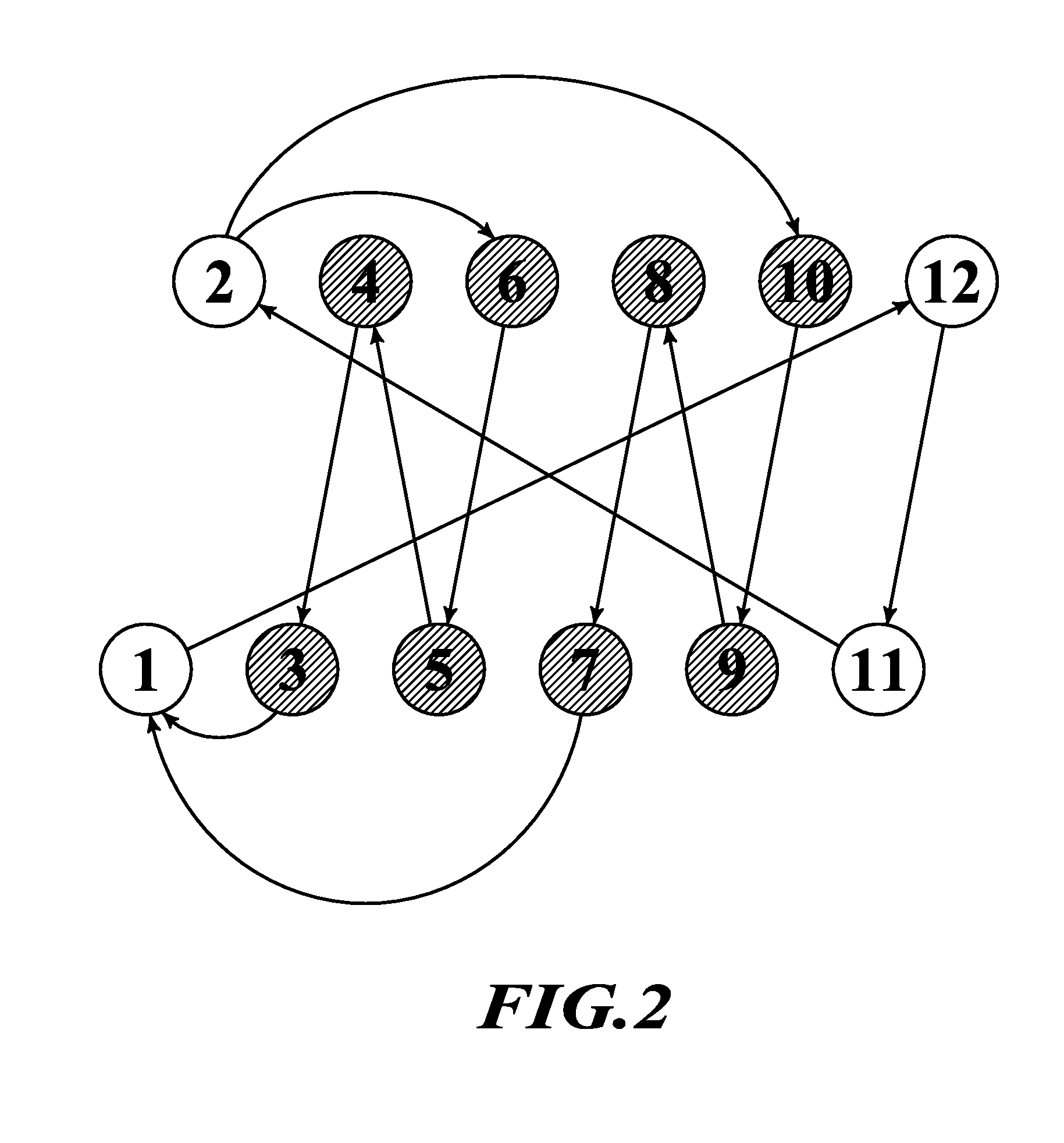

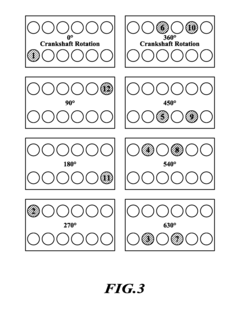

Even fire 90a°v12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/p technology and IFR compensation by fuel feed control

PatentInactiveUS20090099755A1

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence in a 90° V12 engine, controlled by a Powertrain Control Module (PCM), which allows for Even Fire operation by selectively reducing fuel feed to specific cylinders during imbalance frequency ranges, effectively converting the engine to a balanced V8 operation during peak vibrations.

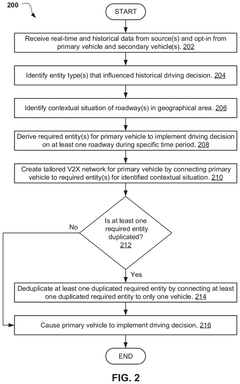

Optimal entity connectivity for tailored vehicle-to-everything network

PatentPendingUS20240355194A1

Innovation

- A system that receives real-time and historical data to identify required entities for a primary vehicle, creating a tailored V2X network by connecting the vehicle to only the necessary entities for a specific contextual situation, optimizing the network by reducing data volume and processing.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of V12 engine technology in personalized transportation solutions. As governments worldwide strive to reduce carbon emissions and combat climate change, stringent regulations have been imposed on vehicle manufacturers, particularly targeting high-performance engines like the V12.

In recent years, many countries have introduced increasingly strict emissions standards, such as the Euro 6 in Europe and Tier 3 in the United States. These regulations set limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For V12 engines, which are known for their power and performance, meeting these standards has become a significant challenge.

To comply with emissions regulations, V12 engine manufacturers have implemented various technological advancements. One key approach is the integration of advanced fuel injection systems, such as direct injection, which improves fuel efficiency and reduces emissions. Additionally, the use of turbocharging and supercharging technologies has allowed V12 engines to maintain their power output while reducing displacement and fuel consumption.

Another important development is the implementation of advanced exhaust after-treatment systems. These include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems, which work together to reduce harmful emissions. Some V12 engines now incorporate cylinder deactivation technology, allowing them to operate on fewer cylinders during low-load conditions, further improving fuel efficiency and reducing emissions.

The push for cleaner engines has also led to the exploration of alternative fuels and hybrid powertrains in V12 configurations. Some manufacturers have begun developing V12 engines that can run on biofuels or synthetic fuels, which have a lower carbon footprint compared to traditional fossil fuels. Furthermore, hybrid V12 powertrains, combining electric motors with the internal combustion engine, have emerged as a promising solution to meet emissions targets while preserving the unique characteristics of V12 engines.

Despite these advancements, the future of V12 engines in personalized transportation solutions remains uncertain. As emissions regulations continue to tighten, some automakers are considering phasing out V12 engines in favor of smaller, more efficient powertrains. However, for luxury and high-performance vehicle segments, where V12 engines are most prevalent, manufacturers are investing heavily in research and development to ensure compliance with current and future emissions standards.

The impact of emissions regulations on V12 engine technology extends beyond the engines themselves. Vehicle aerodynamics, weight reduction, and overall design are being optimized to complement engine efficiency and reduce overall vehicle emissions. This holistic approach to emissions reduction is essential for the continued viability of V12 engines in personalized transportation solutions.

In recent years, many countries have introduced increasingly strict emissions standards, such as the Euro 6 in Europe and Tier 3 in the United States. These regulations set limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For V12 engines, which are known for their power and performance, meeting these standards has become a significant challenge.

To comply with emissions regulations, V12 engine manufacturers have implemented various technological advancements. One key approach is the integration of advanced fuel injection systems, such as direct injection, which improves fuel efficiency and reduces emissions. Additionally, the use of turbocharging and supercharging technologies has allowed V12 engines to maintain their power output while reducing displacement and fuel consumption.

Another important development is the implementation of advanced exhaust after-treatment systems. These include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems, which work together to reduce harmful emissions. Some V12 engines now incorporate cylinder deactivation technology, allowing them to operate on fewer cylinders during low-load conditions, further improving fuel efficiency and reducing emissions.

The push for cleaner engines has also led to the exploration of alternative fuels and hybrid powertrains in V12 configurations. Some manufacturers have begun developing V12 engines that can run on biofuels or synthetic fuels, which have a lower carbon footprint compared to traditional fossil fuels. Furthermore, hybrid V12 powertrains, combining electric motors with the internal combustion engine, have emerged as a promising solution to meet emissions targets while preserving the unique characteristics of V12 engines.

Despite these advancements, the future of V12 engines in personalized transportation solutions remains uncertain. As emissions regulations continue to tighten, some automakers are considering phasing out V12 engines in favor of smaller, more efficient powertrains. However, for luxury and high-performance vehicle segments, where V12 engines are most prevalent, manufacturers are investing heavily in research and development to ensure compliance with current and future emissions standards.

The impact of emissions regulations on V12 engine technology extends beyond the engines themselves. Vehicle aerodynamics, weight reduction, and overall design are being optimized to complement engine efficiency and reduce overall vehicle emissions. This holistic approach to emissions reduction is essential for the continued viability of V12 engines in personalized transportation solutions.

Luxury Vehicle Trends

The luxury vehicle market has been experiencing significant shifts in recent years, driven by changing consumer preferences and technological advancements. One notable trend is the increasing demand for personalized transportation solutions, particularly in high-end vehicles. This trend has led to a renewed interest in V12 engine technology, which offers unique benefits for luxury car manufacturers and discerning customers alike.

V12 engines have long been associated with prestige and performance in the automotive world. Their smooth operation, impressive power output, and distinctive sound make them ideal for luxury vehicles. As the market for personalized transportation solutions grows, V12 engines are finding new applications in bespoke and limited-edition models, catering to customers who seek the ultimate in exclusivity and performance.

Another emerging trend in the luxury vehicle segment is the integration of advanced materials and manufacturing techniques. Carbon fiber, for instance, is being used more extensively in body panels and structural components, reducing weight while maintaining strength. This aligns well with V12 engine technology, as the reduced overall vehicle weight helps offset the engine's inherent mass, resulting in improved performance and handling characteristics.

Sustainability is also becoming a key focus in the luxury vehicle market. While V12 engines are not typically associated with eco-friendliness, manufacturers are exploring ways to make these powerplants more efficient and environmentally responsible. This includes the development of hybrid V12 systems, which combine the traditional engine with electric motors to reduce emissions and improve fuel economy without sacrificing the unique driving experience that V12 engines provide.

The rise of autonomous driving technology is another trend shaping the luxury vehicle landscape. While this may seem at odds with the driver-focused nature of V12-powered cars, manufacturers are finding ways to integrate these technologies in a manner that enhances rather than detracts from the driving experience. For example, advanced driver assistance systems can be tailored to provide a more relaxed cruising experience when desired, while still allowing for spirited driving when the owner takes full control.

In conclusion, the luxury vehicle market is evolving to meet the demands of a new generation of affluent consumers who value personalization, performance, and cutting-edge technology. V12 engine technology continues to play a significant role in this segment, adapting to new trends and requirements while maintaining its status as a symbol of automotive excellence and exclusivity.

V12 engines have long been associated with prestige and performance in the automotive world. Their smooth operation, impressive power output, and distinctive sound make them ideal for luxury vehicles. As the market for personalized transportation solutions grows, V12 engines are finding new applications in bespoke and limited-edition models, catering to customers who seek the ultimate in exclusivity and performance.

Another emerging trend in the luxury vehicle segment is the integration of advanced materials and manufacturing techniques. Carbon fiber, for instance, is being used more extensively in body panels and structural components, reducing weight while maintaining strength. This aligns well with V12 engine technology, as the reduced overall vehicle weight helps offset the engine's inherent mass, resulting in improved performance and handling characteristics.

Sustainability is also becoming a key focus in the luxury vehicle market. While V12 engines are not typically associated with eco-friendliness, manufacturers are exploring ways to make these powerplants more efficient and environmentally responsible. This includes the development of hybrid V12 systems, which combine the traditional engine with electric motors to reduce emissions and improve fuel economy without sacrificing the unique driving experience that V12 engines provide.

The rise of autonomous driving technology is another trend shaping the luxury vehicle landscape. While this may seem at odds with the driver-focused nature of V12-powered cars, manufacturers are finding ways to integrate these technologies in a manner that enhances rather than detracts from the driving experience. For example, advanced driver assistance systems can be tailored to provide a more relaxed cruising experience when desired, while still allowing for spirited driving when the owner takes full control.

In conclusion, the luxury vehicle market is evolving to meet the demands of a new generation of affluent consumers who value personalization, performance, and cutting-edge technology. V12 engine technology continues to play a significant role in this segment, adapting to new trends and requirements while maintaining its status as a symbol of automotive excellence and exclusivity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!