Advances in Air-Fuel Mixture Optimization for V12 Engines

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Optimization Goals

The V12 engine has a rich history dating back to the early 20th century, evolving from luxury and racing applications to become a symbol of power and prestige in high-performance vehicles. Initially developed for aircraft and marine use, V12 engines found their way into automobiles, offering unparalleled smoothness and power delivery. Over the decades, V12 engines have undergone significant transformations, adapting to changing market demands, environmental regulations, and technological advancements.

The evolution of V12 engines has been marked by continuous improvements in power output, fuel efficiency, and emissions control. Early V12 engines were known for their large displacement and relatively low specific output. However, as technology progressed, manufacturers began implementing advanced materials, precision engineering, and innovative design techniques to extract more power from smaller displacements while improving overall efficiency.

In recent years, the focus on V12 engine development has shifted towards optimizing the air-fuel mixture to meet increasingly stringent emissions standards without compromising performance. This has led to the integration of cutting-edge technologies such as direct fuel injection, variable valve timing, and advanced engine management systems. These innovations have allowed V12 engines to maintain their position at the pinnacle of automotive engineering while adapting to modern environmental concerns.

The primary optimization goals for V12 engines in the context of air-fuel mixture advancement include maximizing power output, improving fuel efficiency, reducing emissions, and enhancing overall engine responsiveness. Engineers are striving to achieve a perfect balance between these often conflicting objectives, pushing the boundaries of what is possible with internal combustion technology.

One key area of focus is the development of more precise fuel delivery systems that can adapt to varying engine loads and operating conditions in real-time. This includes the refinement of multi-stage injection systems and the exploration of new injector designs capable of producing finer fuel atomization for more complete combustion.

Another critical optimization goal is the improvement of air management within the combustion chamber. This involves enhancing intake and exhaust flow dynamics, optimizing valve timing and lift profiles, and developing more efficient turbocharging and supercharging systems. The aim is to ensure optimal air-fuel ratios across the entire operating range of the engine, from idle to full throttle.

As the automotive industry moves towards electrification, the future of V12 engines faces new challenges and opportunities. Optimization efforts are now also focused on integrating hybrid technologies to complement the V12's performance characteristics while meeting future emissions targets. This includes the development of mild hybrid systems and the exploration of synthetic fuels as potential pathways to extend the viability of V12 engines in an increasingly eco-conscious market.

The evolution of V12 engines has been marked by continuous improvements in power output, fuel efficiency, and emissions control. Early V12 engines were known for their large displacement and relatively low specific output. However, as technology progressed, manufacturers began implementing advanced materials, precision engineering, and innovative design techniques to extract more power from smaller displacements while improving overall efficiency.

In recent years, the focus on V12 engine development has shifted towards optimizing the air-fuel mixture to meet increasingly stringent emissions standards without compromising performance. This has led to the integration of cutting-edge technologies such as direct fuel injection, variable valve timing, and advanced engine management systems. These innovations have allowed V12 engines to maintain their position at the pinnacle of automotive engineering while adapting to modern environmental concerns.

The primary optimization goals for V12 engines in the context of air-fuel mixture advancement include maximizing power output, improving fuel efficiency, reducing emissions, and enhancing overall engine responsiveness. Engineers are striving to achieve a perfect balance between these often conflicting objectives, pushing the boundaries of what is possible with internal combustion technology.

One key area of focus is the development of more precise fuel delivery systems that can adapt to varying engine loads and operating conditions in real-time. This includes the refinement of multi-stage injection systems and the exploration of new injector designs capable of producing finer fuel atomization for more complete combustion.

Another critical optimization goal is the improvement of air management within the combustion chamber. This involves enhancing intake and exhaust flow dynamics, optimizing valve timing and lift profiles, and developing more efficient turbocharging and supercharging systems. The aim is to ensure optimal air-fuel ratios across the entire operating range of the engine, from idle to full throttle.

As the automotive industry moves towards electrification, the future of V12 engines faces new challenges and opportunities. Optimization efforts are now also focused on integrating hybrid technologies to complement the V12's performance characteristics while meeting future emissions targets. This includes the development of mild hybrid systems and the exploration of synthetic fuels as potential pathways to extend the viability of V12 engines in an increasingly eco-conscious market.

Market Demand for High-Performance V12 Engines

The market demand for high-performance V12 engines has been evolving significantly in recent years, driven by a combination of technological advancements, changing consumer preferences, and regulatory pressures. Despite the overall trend towards downsizing and electrification in the automotive industry, there remains a niche but passionate market for V12-powered vehicles, particularly in the ultra-luxury and high-performance segments.

In the luxury car market, brands like Rolls-Royce, Ferrari, and Lamborghini continue to offer V12 engines in their flagship models, catering to discerning customers who value the prestige, smoothness, and power delivery characteristics unique to V12 configurations. These engines are often seen as the pinnacle of internal combustion technology, offering unparalleled refinement and performance.

The motorsport sector also contributes to the demand for high-performance V12 engines, especially in endurance racing categories. While many racing series have moved to smaller displacement engines, some classes still allow or require V12 powerplants, maintaining a market for advanced V12 technology development.

However, the market faces significant challenges. Stringent emissions regulations worldwide are putting pressure on manufacturers to improve the efficiency and reduce the environmental impact of V12 engines. This has led to increased investment in technologies such as direct injection, variable valve timing, and cylinder deactivation to enhance fuel economy without compromising performance.

The advent of high-performance electric vehicles has also impacted the V12 market. Electric powertrains can now deliver instant torque and acceleration that rival or surpass traditional V12 engines, challenging the performance supremacy of these large displacement engines.

Despite these challenges, market analysis indicates a steady, albeit limited, demand for V12 engines. Luxury car manufacturers are adapting by developing hybrid V12 powertrains, combining the emotional appeal of the V12 with improved efficiency and performance through electrification. This approach aims to extend the viability of V12 engines in the face of tightening regulations.

The potential market size for high-performance V12 engines remains relatively small but lucrative. While exact figures are challenging to determine due to the niche nature of the market, industry reports suggest that annual production of V12-powered vehicles is in the low thousands globally, with each engine commanding a premium price point.

Looking ahead, the market for high-performance V12 engines is expected to become increasingly specialized. As mainstream manufacturers move away from large displacement engines, the V12 may become even more exclusive, potentially increasing its appeal among collectors and enthusiasts. This could lead to a scenario where V12 engines are produced in limited numbers for special edition models or bespoke creations, maintaining their status as the ultimate expression of automotive engineering prowess.

In the luxury car market, brands like Rolls-Royce, Ferrari, and Lamborghini continue to offer V12 engines in their flagship models, catering to discerning customers who value the prestige, smoothness, and power delivery characteristics unique to V12 configurations. These engines are often seen as the pinnacle of internal combustion technology, offering unparalleled refinement and performance.

The motorsport sector also contributes to the demand for high-performance V12 engines, especially in endurance racing categories. While many racing series have moved to smaller displacement engines, some classes still allow or require V12 powerplants, maintaining a market for advanced V12 technology development.

However, the market faces significant challenges. Stringent emissions regulations worldwide are putting pressure on manufacturers to improve the efficiency and reduce the environmental impact of V12 engines. This has led to increased investment in technologies such as direct injection, variable valve timing, and cylinder deactivation to enhance fuel economy without compromising performance.

The advent of high-performance electric vehicles has also impacted the V12 market. Electric powertrains can now deliver instant torque and acceleration that rival or surpass traditional V12 engines, challenging the performance supremacy of these large displacement engines.

Despite these challenges, market analysis indicates a steady, albeit limited, demand for V12 engines. Luxury car manufacturers are adapting by developing hybrid V12 powertrains, combining the emotional appeal of the V12 with improved efficiency and performance through electrification. This approach aims to extend the viability of V12 engines in the face of tightening regulations.

The potential market size for high-performance V12 engines remains relatively small but lucrative. While exact figures are challenging to determine due to the niche nature of the market, industry reports suggest that annual production of V12-powered vehicles is in the low thousands globally, with each engine commanding a premium price point.

Looking ahead, the market for high-performance V12 engines is expected to become increasingly specialized. As mainstream manufacturers move away from large displacement engines, the V12 may become even more exclusive, potentially increasing its appeal among collectors and enthusiasts. This could lead to a scenario where V12 engines are produced in limited numbers for special edition models or bespoke creations, maintaining their status as the ultimate expression of automotive engineering prowess.

Current Air-Fuel Mixture Challenges in V12 Engines

V12 engines, renowned for their power and smoothness, face significant challenges in optimizing air-fuel mixture for peak performance and efficiency. The primary hurdle lies in achieving uniform fuel distribution across all twelve cylinders, especially given the engine's complex geometry and high-speed operation.

One of the key issues is fuel atomization. At high engine speeds, there's limited time for fuel to vaporize and mix with air properly. This can lead to incomplete combustion, reduced power output, and increased emissions. Advanced fuel injection systems and optimized intake manifold designs are being explored to address this challenge, but further refinements are needed.

Another critical challenge is maintaining the ideal air-fuel ratio across all operating conditions. V12 engines often experience variations in cylinder-to-cylinder air-fuel ratios due to uneven air distribution in the intake manifold. This imbalance can result in some cylinders running too rich or too lean, compromising overall engine performance and efficiency.

The complexity of the V12 engine layout also presents challenges in terms of exhaust gas recirculation (EGR) and variable valve timing implementation. These technologies, crucial for emissions control and performance optimization, are more difficult to apply effectively across all cylinders in a V12 configuration compared to smaller engines.

Thermal management is another significant concern. The compact nature of V12 engines, combined with their high power output, creates substantial heat generation. This heat can affect the air-fuel mixture quality, potentially leading to pre-ignition or knock, especially in high-performance applications.

Furthermore, the pursuit of higher specific power outputs in modern V12 engines has led to increased boost pressures in turbocharged variants. This presents challenges in maintaining optimal air-fuel ratios under varying boost conditions and preventing charge air temperature issues that can affect mixture quality.

Lastly, the integration of advanced sensors and control systems for real-time air-fuel mixture optimization remains a challenge. While individual cylinder control is theoretically possible, implementing such systems in a cost-effective and reliable manner for V12 engines is still an area of ongoing development.

These challenges collectively highlight the complexity of air-fuel mixture optimization in V12 engines, underscoring the need for innovative solutions to enhance performance, efficiency, and emissions compliance in these high-performance powerplants.

One of the key issues is fuel atomization. At high engine speeds, there's limited time for fuel to vaporize and mix with air properly. This can lead to incomplete combustion, reduced power output, and increased emissions. Advanced fuel injection systems and optimized intake manifold designs are being explored to address this challenge, but further refinements are needed.

Another critical challenge is maintaining the ideal air-fuel ratio across all operating conditions. V12 engines often experience variations in cylinder-to-cylinder air-fuel ratios due to uneven air distribution in the intake manifold. This imbalance can result in some cylinders running too rich or too lean, compromising overall engine performance and efficiency.

The complexity of the V12 engine layout also presents challenges in terms of exhaust gas recirculation (EGR) and variable valve timing implementation. These technologies, crucial for emissions control and performance optimization, are more difficult to apply effectively across all cylinders in a V12 configuration compared to smaller engines.

Thermal management is another significant concern. The compact nature of V12 engines, combined with their high power output, creates substantial heat generation. This heat can affect the air-fuel mixture quality, potentially leading to pre-ignition or knock, especially in high-performance applications.

Furthermore, the pursuit of higher specific power outputs in modern V12 engines has led to increased boost pressures in turbocharged variants. This presents challenges in maintaining optimal air-fuel ratios under varying boost conditions and preventing charge air temperature issues that can affect mixture quality.

Lastly, the integration of advanced sensors and control systems for real-time air-fuel mixture optimization remains a challenge. While individual cylinder control is theoretically possible, implementing such systems in a cost-effective and reliable manner for V12 engines is still an area of ongoing development.

These challenges collectively highlight the complexity of air-fuel mixture optimization in V12 engines, underscoring the need for innovative solutions to enhance performance, efficiency, and emissions compliance in these high-performance powerplants.

Modern Air-Fuel Mixture Control Solutions

01 Fuel injection systems for V12 engines

Advanced fuel injection systems are utilized in V12 engines to precisely control the air-fuel mixture. These systems employ electronic control units and high-pressure injectors to optimize fuel delivery, ensuring efficient combustion and improved performance across various operating conditions.- Fuel injection systems for V12 engines: Advanced fuel injection systems are utilized in V12 engines to optimize the air-fuel mixture. These systems precisely control the amount and timing of fuel delivery, ensuring efficient combustion and improved performance. Electronic fuel injection systems can adapt to various operating conditions, enhancing the overall engine efficiency and power output.

- Air intake and distribution optimization: V12 engines employ sophisticated air intake and distribution systems to ensure optimal air-fuel mixture across all cylinders. This includes the use of advanced intake manifold designs, variable intake systems, and air flow management techniques to improve volumetric efficiency and ensure uniform air distribution to each cylinder.

- Combustion chamber design for efficient mixture formation: The design of combustion chambers in V12 engines plays a crucial role in air-fuel mixture formation and combustion efficiency. Optimized chamber geometries, piston crown designs, and valve configurations contribute to better fuel atomization, mixture distribution, and flame propagation, resulting in improved engine performance and reduced emissions.

- Engine management systems for mixture control: Advanced engine management systems are employed in V12 engines to continuously monitor and adjust the air-fuel mixture. These systems utilize various sensors and sophisticated algorithms to optimize the mixture ratio based on factors such as engine load, speed, and environmental conditions, ensuring optimal performance and fuel efficiency across different operating ranges.

- Turbocharging and supercharging for mixture enhancement: V12 engines often incorporate turbocharging or supercharging technologies to enhance the air-fuel mixture. These forced induction systems increase the amount of air entering the combustion chambers, allowing for more fuel to be injected and burned efficiently. This results in increased power output and improved overall engine performance.

02 Air-fuel mixture control for improved efficiency

Sophisticated air-fuel mixture control strategies are implemented in V12 engines to enhance efficiency and reduce emissions. These methods involve real-time adjustments based on engine load, speed, and environmental factors, often utilizing advanced sensors and adaptive algorithms.Expand Specific Solutions03 Carburetor designs for V12 engines

Specialized carburetor designs are developed for V12 engines to ensure proper air-fuel mixture distribution across all cylinders. These carburetors often feature multiple barrels or stages to accommodate the high air flow requirements of V12 engines while maintaining optimal fuel atomization.Expand Specific Solutions04 Turbocharging and supercharging systems

Forced induction systems, such as turbochargers and superchargers, are employed in V12 engines to increase air intake and allow for precise control of the air-fuel mixture. These systems enable higher power output and improved fuel efficiency by optimizing the combustion process.Expand Specific Solutions05 Variable valve timing for mixture control

Variable valve timing mechanisms are integrated into V12 engines to dynamically adjust the air-fuel mixture. By altering valve opening and closing times, these systems can optimize engine breathing, improve fuel economy, and enhance performance across a wide range of operating conditions.Expand Specific Solutions

Key V12 Engine Manufacturers and Suppliers

The field of air-fuel mixture optimization for V12 engines is in a mature stage of development, with ongoing advancements driven by environmental regulations and performance demands. The market size is significant, given the application in high-end automotive and aerospace sectors. Technologically, the field is well-established but continues to evolve, with companies like Afton Chemical Corp., Shell Oil Co., and Woodward, Inc. leading in fuel additive and engine control innovations. Major automotive players such as Ford Global Technologies LLC, GM Global Technology Operations LLC, and Mitsubishi Motors Corp. are actively pursuing advancements in this area, while aerospace giants like RTX Corp. and Rolls-Royce Plc contribute to the technology's progression in aviation applications.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced air-fuel mixture optimization system for V12 engines, focusing on precise fuel injection and air intake control. Their system utilizes high-pressure direct injection technology combined with variable valve timing to achieve optimal air-fuel ratios across different engine loads and speeds. Ford's approach incorporates real-time sensors and adaptive algorithms to continuously adjust the mixture based on driving conditions and environmental factors. The system also integrates exhaust gas recirculation (EGR) to further optimize combustion efficiency and reduce emissions[1][3]. Additionally, Ford has implemented a twin-turbocharging system specifically designed for V12 engines, which allows for better air management and improved power delivery across the entire RPM range[5].

Strengths: Precise control over air-fuel mixture, improved fuel efficiency, and reduced emissions. Weaknesses: Complexity of the system may lead to higher manufacturing and maintenance costs.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated air-fuel mixture optimization system for V12 engines, focusing on advanced combustion strategies and intelligent control systems. Their approach utilizes a combination of port and direct fuel injection, allowing for greater flexibility in fuel delivery and mixture formation. GM's system incorporates cylinder deactivation technology, which can selectively shut down cylinders under light load conditions to improve fuel efficiency[2]. The company has also implemented a dynamic skip fire system that can rapidly activate and deactivate individual cylinders based on power demand, further optimizing the air-fuel mixture[4]. Additionally, GM's V12 engines feature a variable geometry intake manifold that adjusts airflow characteristics to match engine speed and load, ensuring optimal air-fuel mixture across various operating conditions[6].

Strengths: Highly adaptable system that can optimize performance and efficiency across a wide range of driving conditions. Weaknesses: The complexity of the system may result in higher initial costs and potential reliability concerns.

Innovative Air-Fuel Optimization Patents

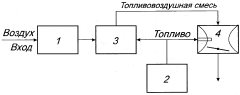

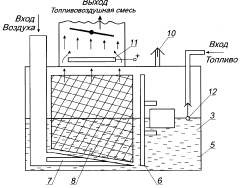

Air-fuel mixture producing method and a device for carrying out said method

PatentWO2008121089A1

Innovation

- The method involves replacing air or fuel heating with cold boiling and evaporation in an additional float chamber, utilizing a sealed container with a partition, float assembly, metal mesh, and electric heating elements to homogenize the mixture before it enters the combustion chamber, along with a safety valve and a round damper for controlled mixture regulation.

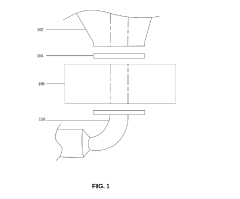

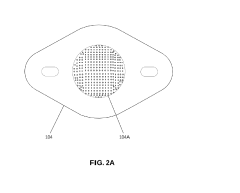

Optimized air-fuel mixing & filtering device(AFMFD) for enhanced fuel efficiency in spark ignition engines

PatentPendingIN202311051115A

Innovation

- An optimized Air-Fuel Mixing & Filtering Device (AFMFD) with a disk having predefined holes forms a mesh structure that ensures air and fuel mix optimally and convert to a gaseous state before entering the engine, preventing entry without proper mixing and pressure, and allows for adjustable mesh density to adapt to engine and environmental conditions.

Emissions Regulations Impact on V12 Engines

The impact of emissions regulations on V12 engines has been profound and far-reaching, significantly shaping the development and future of these high-performance powerplants. As global environmental concerns have intensified, regulatory bodies worldwide have implemented increasingly stringent emissions standards, posing substantial challenges for V12 engine manufacturers.

These regulations have primarily targeted the reduction of harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For V12 engines, which are known for their power output and fuel consumption, meeting these standards has necessitated substantial technological advancements and design modifications.

One of the most significant impacts has been the shift towards more efficient combustion processes. Manufacturers have been compelled to optimize air-fuel mixture ratios, improve fuel injection systems, and enhance engine management software to achieve cleaner burning and reduced emissions. This has led to the widespread adoption of direct injection technology and variable valve timing in V12 engines, allowing for more precise control over the combustion process.

Turbocharging and supercharging have also become more prevalent in V12 engines as a means to maintain power output while reducing engine displacement and improving fuel efficiency. These forced induction systems enable engines to produce comparable power to larger naturally aspirated units while consuming less fuel and producing fewer emissions.

The integration of hybrid technology has emerged as another strategy to meet emissions regulations. Some manufacturers have incorporated electric motors into their V12 powertrains, creating hybrid systems that can significantly reduce overall emissions, particularly in urban driving scenarios.

Exhaust after-treatment systems have also seen substantial development. Advanced catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems have been engineered specifically for V12 engines to further reduce emissions at the tailpipe.

However, these technological advancements come at a cost. The complexity of V12 engines has increased dramatically, leading to higher production costs and potentially reduced reliability. This has prompted some manufacturers to reconsider the viability of V12 engines in their product lineups, with some opting to discontinue V12 models in favor of smaller, more efficient engine configurations.

The future of V12 engines in light of ever-tightening emissions regulations remains uncertain. While technological innovations continue to push the boundaries of what's possible in terms of emissions reduction, the long-term sustainability of these large displacement engines in a world increasingly focused on environmental protection is a subject of ongoing debate within the automotive industry.

These regulations have primarily targeted the reduction of harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. For V12 engines, which are known for their power output and fuel consumption, meeting these standards has necessitated substantial technological advancements and design modifications.

One of the most significant impacts has been the shift towards more efficient combustion processes. Manufacturers have been compelled to optimize air-fuel mixture ratios, improve fuel injection systems, and enhance engine management software to achieve cleaner burning and reduced emissions. This has led to the widespread adoption of direct injection technology and variable valve timing in V12 engines, allowing for more precise control over the combustion process.

Turbocharging and supercharging have also become more prevalent in V12 engines as a means to maintain power output while reducing engine displacement and improving fuel efficiency. These forced induction systems enable engines to produce comparable power to larger naturally aspirated units while consuming less fuel and producing fewer emissions.

The integration of hybrid technology has emerged as another strategy to meet emissions regulations. Some manufacturers have incorporated electric motors into their V12 powertrains, creating hybrid systems that can significantly reduce overall emissions, particularly in urban driving scenarios.

Exhaust after-treatment systems have also seen substantial development. Advanced catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems have been engineered specifically for V12 engines to further reduce emissions at the tailpipe.

However, these technological advancements come at a cost. The complexity of V12 engines has increased dramatically, leading to higher production costs and potentially reduced reliability. This has prompted some manufacturers to reconsider the viability of V12 engines in their product lineups, with some opting to discontinue V12 models in favor of smaller, more efficient engine configurations.

The future of V12 engines in light of ever-tightening emissions regulations remains uncertain. While technological innovations continue to push the boundaries of what's possible in terms of emissions reduction, the long-term sustainability of these large displacement engines in a world increasingly focused on environmental protection is a subject of ongoing debate within the automotive industry.

V12 Engine Efficiency Benchmarking

Benchmarking the efficiency of V12 engines is a critical process in evaluating the advancements in air-fuel mixture optimization. This analysis provides valuable insights into the performance characteristics and fuel economy of these high-performance powerplants across various manufacturers and applications.

V12 engines, known for their smooth operation and high power output, have been a staple in luxury vehicles, high-performance sports cars, and marine applications. However, they face increasing scrutiny due to their traditionally high fuel consumption and emissions. Recent advancements in air-fuel mixture optimization have aimed to address these concerns while maintaining the desirable attributes of V12 engines.

To establish a comprehensive benchmark, it is essential to consider a range of parameters. These include specific fuel consumption (g/kWh), thermal efficiency, power-to-weight ratio, and emissions levels. Additionally, factors such as throttle response, power delivery across the RPM range, and overall drivability must be taken into account to provide a holistic view of engine performance.

Several leading manufacturers have made significant strides in V12 engine efficiency. For instance, Ferrari's latest V12 engines incorporate advanced direct injection systems and variable valve timing, resulting in improved fuel economy without sacrificing power output. Similarly, Aston Martin has implemented cylinder deactivation technology in their V12 engines, allowing for reduced fuel consumption during low-load conditions.

Comparative analysis of these engines reveals interesting trends. Modern V12 engines are achieving thermal efficiencies approaching 40%, a marked improvement over earlier generations. This has been accomplished through a combination of technologies, including high-precision fuel injection, advanced combustion chamber designs, and sophisticated engine management systems.

Emissions performance is another crucial aspect of V12 engine benchmarking. With increasingly stringent regulations worldwide, manufacturers have had to innovate to meet these standards. The implementation of particulate filters, advanced catalytic converters, and optimized exhaust gas recirculation systems has resulted in significant reductions in harmful emissions.

When comparing V12 engines to their smaller counterparts, such as V8 or inline-six configurations, it becomes evident that the efficiency gap has narrowed considerably. While V12 engines still tend to consume more fuel overall, the difference in specific fuel consumption (g/kWh) has decreased, particularly at higher power outputs where V12 engines can operate more efficiently within their optimal range.

V12 engines, known for their smooth operation and high power output, have been a staple in luxury vehicles, high-performance sports cars, and marine applications. However, they face increasing scrutiny due to their traditionally high fuel consumption and emissions. Recent advancements in air-fuel mixture optimization have aimed to address these concerns while maintaining the desirable attributes of V12 engines.

To establish a comprehensive benchmark, it is essential to consider a range of parameters. These include specific fuel consumption (g/kWh), thermal efficiency, power-to-weight ratio, and emissions levels. Additionally, factors such as throttle response, power delivery across the RPM range, and overall drivability must be taken into account to provide a holistic view of engine performance.

Several leading manufacturers have made significant strides in V12 engine efficiency. For instance, Ferrari's latest V12 engines incorporate advanced direct injection systems and variable valve timing, resulting in improved fuel economy without sacrificing power output. Similarly, Aston Martin has implemented cylinder deactivation technology in their V12 engines, allowing for reduced fuel consumption during low-load conditions.

Comparative analysis of these engines reveals interesting trends. Modern V12 engines are achieving thermal efficiencies approaching 40%, a marked improvement over earlier generations. This has been accomplished through a combination of technologies, including high-precision fuel injection, advanced combustion chamber designs, and sophisticated engine management systems.

Emissions performance is another crucial aspect of V12 engine benchmarking. With increasingly stringent regulations worldwide, manufacturers have had to innovate to meet these standards. The implementation of particulate filters, advanced catalytic converters, and optimized exhaust gas recirculation systems has resulted in significant reductions in harmful emissions.

When comparing V12 engines to their smaller counterparts, such as V8 or inline-six configurations, it becomes evident that the efficiency gap has narrowed considerably. While V12 engines still tend to consume more fuel overall, the difference in specific fuel consumption (g/kWh) has decreased, particularly at higher power outputs where V12 engines can operate more efficiently within their optimal range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!