How Aerodynamics and V12 Engines Interact in Formula Racing

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

F1 Aerodynamics and V12 Evolution

The evolution of Formula 1 aerodynamics and V12 engines represents a fascinating journey of technological advancement and innovation in motorsport. The interplay between these two critical components has shaped the performance and design of racing cars over several decades.

In the early years of Formula 1, aerodynamics played a minimal role, with cars primarily relying on engine power for speed. The introduction of V12 engines in the 1960s marked a significant milestone, offering unprecedented power and performance. These engines, with their distinctive sound and smooth power delivery, quickly became synonymous with Formula 1 racing.

As the understanding of aerodynamics grew, teams began to experiment with wings and bodywork designs to generate downforce. This shift in focus led to a complex relationship between engine performance and aerodynamic efficiency. The powerful V12 engines, while providing excellent straight-line speed, posed challenges in terms of weight distribution and packaging within increasingly aerodynamic car designs.

The 1970s and 1980s saw rapid advancements in aerodynamic technology, with the introduction of ground effect and sophisticated wing designs. These developments allowed cars to generate massive amounts of downforce, dramatically improving cornering speeds. However, this also meant that engines needed to be more compact and efficient to accommodate the new aerodynamic requirements.

V12 engines reached their peak in Formula 1 during the 1990s. Teams like Ferrari and McLaren-Honda showcased the potential of these powerplants, combining raw power with advanced aerodynamics. The era saw a delicate balance between engine performance and aerodynamic efficiency, with teams constantly refining their designs to find the optimal compromise.

The turn of the millennium brought significant changes to Formula 1 regulations, gradually phasing out V12 engines in favor of smaller, more fuel-efficient powerplants. This shift coincided with further advancements in aerodynamics, including the use of computational fluid dynamics (CFD) and wind tunnel testing to optimize car designs.

Today, while V12 engines are no longer used in Formula 1, their legacy continues to influence the sport. The lessons learned from balancing powerful engines with aerodynamic efficiency have shaped modern racing car design. Current Formula 1 cars feature highly sophisticated aerodynamic packages working in harmony with turbocharged hybrid powertrains, showcasing the ongoing evolution of the relationship between power and aerodynamics in motorsport.

In the early years of Formula 1, aerodynamics played a minimal role, with cars primarily relying on engine power for speed. The introduction of V12 engines in the 1960s marked a significant milestone, offering unprecedented power and performance. These engines, with their distinctive sound and smooth power delivery, quickly became synonymous with Formula 1 racing.

As the understanding of aerodynamics grew, teams began to experiment with wings and bodywork designs to generate downforce. This shift in focus led to a complex relationship between engine performance and aerodynamic efficiency. The powerful V12 engines, while providing excellent straight-line speed, posed challenges in terms of weight distribution and packaging within increasingly aerodynamic car designs.

The 1970s and 1980s saw rapid advancements in aerodynamic technology, with the introduction of ground effect and sophisticated wing designs. These developments allowed cars to generate massive amounts of downforce, dramatically improving cornering speeds. However, this also meant that engines needed to be more compact and efficient to accommodate the new aerodynamic requirements.

V12 engines reached their peak in Formula 1 during the 1990s. Teams like Ferrari and McLaren-Honda showcased the potential of these powerplants, combining raw power with advanced aerodynamics. The era saw a delicate balance between engine performance and aerodynamic efficiency, with teams constantly refining their designs to find the optimal compromise.

The turn of the millennium brought significant changes to Formula 1 regulations, gradually phasing out V12 engines in favor of smaller, more fuel-efficient powerplants. This shift coincided with further advancements in aerodynamics, including the use of computational fluid dynamics (CFD) and wind tunnel testing to optimize car designs.

Today, while V12 engines are no longer used in Formula 1, their legacy continues to influence the sport. The lessons learned from balancing powerful engines with aerodynamic efficiency have shaped modern racing car design. Current Formula 1 cars feature highly sophisticated aerodynamic packages working in harmony with turbocharged hybrid powertrains, showcasing the ongoing evolution of the relationship between power and aerodynamics in motorsport.

Market Demand for High-Performance Racing

The market demand for high-performance racing, particularly in Formula 1, continues to grow steadily. This demand is driven by a combination of factors, including the sport's global appeal, technological advancements, and the increasing interest in sustainable high-performance solutions.

Formula 1 remains one of the most-watched sports globally, with a cumulative television audience of over 1.5 billion viewers annually. This widespread popularity translates into significant market demand for racing-related products and technologies. The interaction between aerodynamics and V12 engines in Formula racing is of particular interest to both enthusiasts and industry professionals.

The automotive industry's focus on performance and efficiency has led to increased demand for technologies developed in Formula racing. Aerodynamic innovations and engine advancements from the racing world often find their way into consumer vehicles, creating a lucrative market for technology transfer. This spillover effect amplifies the demand for high-performance racing research and development.

Environmental concerns and sustainability initiatives are reshaping the racing industry. There is a growing demand for more fuel-efficient and environmentally friendly high-performance solutions. This shift has led to increased interest in how aerodynamics can be optimized to work in harmony with powerful engines like the V12, potentially reducing fuel consumption without sacrificing performance.

The luxury and supercar markets also contribute to the demand for high-performance racing technologies. Manufacturers of high-end vehicles often incorporate Formula 1-inspired aerodynamic features and engine technologies to appeal to discerning customers who value both performance and prestige.

Racing simulators and video games represent another significant market segment. The demand for accurate representations of aerodynamics and engine performance in virtual environments drives ongoing research and development in these areas. This digital market helps to broaden the appeal of high-performance racing beyond traditional audiences.

The interaction between aerodynamics and V12 engines in Formula racing also fuels demand in the aftermarket and tuning industry. Enthusiasts and smaller racing teams seek to apply these advanced technologies to their own vehicles, creating a substantial market for specialized parts and expertise.

In conclusion, the market demand for high-performance racing, particularly concerning the interaction of aerodynamics and V12 engines, remains robust and multifaceted. It spans from the professional racing circuit to consumer applications, digital entertainment, and the aftermarket industry, underscoring the wide-reaching impact and continued relevance of these technologies.

Formula 1 remains one of the most-watched sports globally, with a cumulative television audience of over 1.5 billion viewers annually. This widespread popularity translates into significant market demand for racing-related products and technologies. The interaction between aerodynamics and V12 engines in Formula racing is of particular interest to both enthusiasts and industry professionals.

The automotive industry's focus on performance and efficiency has led to increased demand for technologies developed in Formula racing. Aerodynamic innovations and engine advancements from the racing world often find their way into consumer vehicles, creating a lucrative market for technology transfer. This spillover effect amplifies the demand for high-performance racing research and development.

Environmental concerns and sustainability initiatives are reshaping the racing industry. There is a growing demand for more fuel-efficient and environmentally friendly high-performance solutions. This shift has led to increased interest in how aerodynamics can be optimized to work in harmony with powerful engines like the V12, potentially reducing fuel consumption without sacrificing performance.

The luxury and supercar markets also contribute to the demand for high-performance racing technologies. Manufacturers of high-end vehicles often incorporate Formula 1-inspired aerodynamic features and engine technologies to appeal to discerning customers who value both performance and prestige.

Racing simulators and video games represent another significant market segment. The demand for accurate representations of aerodynamics and engine performance in virtual environments drives ongoing research and development in these areas. This digital market helps to broaden the appeal of high-performance racing beyond traditional audiences.

The interaction between aerodynamics and V12 engines in Formula racing also fuels demand in the aftermarket and tuning industry. Enthusiasts and smaller racing teams seek to apply these advanced technologies to their own vehicles, creating a substantial market for specialized parts and expertise.

In conclusion, the market demand for high-performance racing, particularly concerning the interaction of aerodynamics and V12 engines, remains robust and multifaceted. It spans from the professional racing circuit to consumer applications, digital entertainment, and the aftermarket industry, underscoring the wide-reaching impact and continued relevance of these technologies.

Current Challenges in F1 Aerodynamics and V12 Integration

Formula 1 racing faces significant challenges in integrating V12 engines with advanced aerodynamics, primarily due to the sport's current regulations and the inherent characteristics of these powerful powerplants. The FIA's strict limitations on engine specifications, aimed at reducing costs and promoting sustainability, have effectively eliminated V12 engines from modern F1 competition. This regulatory environment poses a fundamental obstacle to any potential reintroduction of V12 engines.

The sheer size and weight of V12 engines present substantial aerodynamic challenges. These larger powerplants require more space within the car's chassis, potentially compromising the sleek, aerodynamic profiles that are crucial for optimal performance. The increased weight of V12 engines also affects the car's center of gravity and weight distribution, factors that are meticulously optimized in F1 car design to enhance cornering ability and overall handling.

Heat management is another critical issue. V12 engines generate significant heat, necessitating more extensive cooling systems. These additional cooling requirements often result in larger air intakes and vents, which can disrupt the carefully crafted aerodynamic surfaces of the car. The challenge lies in balancing the need for efficient cooling with the imperative to maintain aerodynamic efficiency.

Fuel consumption presents a further complication. V12 engines typically consume more fuel than their smaller counterparts, which conflicts with F1's push towards fuel efficiency and reduced emissions. This higher fuel consumption necessitates larger fuel tanks, again impacting the car's weight distribution and aerodynamic design.

The interaction between engine exhaust gases and aerodynamics is another area of complexity. In modern F1 cars, exhaust gases are often strategically directed to enhance aerodynamic performance. The different exhaust configuration of a V12 engine would require a complete redesign of these systems, potentially altering the car's aerodynamic characteristics.

Vibration and harmonics from V12 engines also pose unique challenges. These vibrations can affect the stability of aerodynamic components, particularly at high speeds. Engineers would need to develop new methods to dampen these vibrations without adding significant weight or compromising aerodynamic efficiency.

Lastly, the power delivery characteristics of V12 engines differ from current F1 power units. This would necessitate a reevaluation of traction control systems and overall chassis design to effectively harness the engine's power while maintaining aerodynamic stability, especially during acceleration and cornering.

The sheer size and weight of V12 engines present substantial aerodynamic challenges. These larger powerplants require more space within the car's chassis, potentially compromising the sleek, aerodynamic profiles that are crucial for optimal performance. The increased weight of V12 engines also affects the car's center of gravity and weight distribution, factors that are meticulously optimized in F1 car design to enhance cornering ability and overall handling.

Heat management is another critical issue. V12 engines generate significant heat, necessitating more extensive cooling systems. These additional cooling requirements often result in larger air intakes and vents, which can disrupt the carefully crafted aerodynamic surfaces of the car. The challenge lies in balancing the need for efficient cooling with the imperative to maintain aerodynamic efficiency.

Fuel consumption presents a further complication. V12 engines typically consume more fuel than their smaller counterparts, which conflicts with F1's push towards fuel efficiency and reduced emissions. This higher fuel consumption necessitates larger fuel tanks, again impacting the car's weight distribution and aerodynamic design.

The interaction between engine exhaust gases and aerodynamics is another area of complexity. In modern F1 cars, exhaust gases are often strategically directed to enhance aerodynamic performance. The different exhaust configuration of a V12 engine would require a complete redesign of these systems, potentially altering the car's aerodynamic characteristics.

Vibration and harmonics from V12 engines also pose unique challenges. These vibrations can affect the stability of aerodynamic components, particularly at high speeds. Engineers would need to develop new methods to dampen these vibrations without adding significant weight or compromising aerodynamic efficiency.

Lastly, the power delivery characteristics of V12 engines differ from current F1 power units. This would necessitate a reevaluation of traction control systems and overall chassis design to effectively harness the engine's power while maintaining aerodynamic stability, especially during acceleration and cornering.

Current Aerodynamic and V12 Engine Solutions in F1

01 Aerodynamic design for V12 engines

Optimizing the aerodynamic design of vehicles equipped with V12 engines to reduce drag and improve fuel efficiency. This includes streamlining the body shape, implementing active aerodynamic elements, and enhancing underbody airflow management to maximize performance while minimizing air resistance.- Aerodynamic design for V12 engine vehicles: Aerodynamic designs are crucial for vehicles with V12 engines to optimize performance and fuel efficiency. These designs focus on reducing drag and improving airflow around the vehicle body, particularly in high-performance and luxury automobiles where V12 engines are commonly used. Advanced computational fluid dynamics and wind tunnel testing are employed to refine the vehicle's shape and features for optimal aerodynamic performance.

- Engine cooling systems for V12 engines: Efficient cooling systems are essential for V12 engines due to their high power output and heat generation. These systems often incorporate advanced radiator designs, multiple cooling circuits, and aerodynamically optimized air intakes to ensure proper heat dissipation. The integration of cooling systems with the overall aerodynamic design of the vehicle is crucial for maintaining engine performance and longevity.

- Exhaust system design for V12 engines: Exhaust systems for V12 engines are designed to optimize engine performance while meeting noise and emissions regulations. These systems often feature complex geometries and multiple catalytic converters to handle the high exhaust flow rates. The design also considers the aerodynamic impact of exhaust placement and flow, aiming to minimize drag and maximize engine efficiency.

- Aerodynamic features for engine air intake: Air intake systems for V12 engines are designed to maximize airflow while minimizing aerodynamic drag. This involves careful placement and shaping of air intakes, often incorporating active aerodynamic elements that can adjust based on vehicle speed and engine demand. The goal is to ensure sufficient air supply to the engine while maintaining overall vehicle aerodynamics.

- Aerodynamic integration of powertrain components: The integration of V12 engine components with the vehicle's aerodynamic design is crucial for overall performance. This includes the positioning of the engine, transmission, and associated systems to optimize weight distribution and minimize aerodynamic disturbances. Advanced packaging techniques are used to create a sleek underbody and manage airflow around critical powertrain components.

02 Engine cooling and airflow management

Developing advanced cooling systems and airflow management techniques specifically for V12 engines to maintain optimal operating temperatures and enhance overall performance. This involves designing efficient air intakes, implementing advanced heat exchangers, and optimizing the placement of cooling components.Expand Specific Solutions03 Aerodynamic integration of exhaust systems

Integrating exhaust systems into the overall aerodynamic design of vehicles with V12 engines to minimize drag and optimize performance. This includes designing aerodynamically efficient exhaust outlets, implementing active exhaust flaps, and utilizing the exhaust flow to enhance vehicle stability and downforce.Expand Specific Solutions04 Aerodynamic enhancements for high-performance vehicles

Implementing advanced aerodynamic features specifically designed for high-performance vehicles equipped with V12 engines. This includes active aerodynamic elements, such as adjustable spoilers and diffusers, as well as innovative body designs to optimize downforce and reduce lift at high speeds.Expand Specific Solutions05 Computational fluid dynamics for V12 engine optimization

Utilizing computational fluid dynamics (CFD) simulations to optimize the aerodynamic performance of vehicles with V12 engines. This involves analyzing airflow patterns around the vehicle and within the engine bay to identify areas for improvement and develop innovative solutions for enhanced aerodynamic efficiency.Expand Specific Solutions

Key F1 Teams and Engine Manufacturers

The aerodynamics and V12 engine interaction in Formula Racing represents a highly competitive and technologically advanced field. The industry is in a mature stage, with continuous innovation driving performance improvements. The global Formula 1 market size exceeds $1 billion annually, attracting significant investment. Technological maturity is high, with companies like Ferrari, Mercedes-AMG, and Renault leading engine development. Other players like GM Global Technology Operations, Ford Global Technologies, and Toyota Motor Corp. contribute advanced aerodynamic solutions. The interplay between aerodynamics and powertrain efficiency remains a critical focus for teams and manufacturers, driving ongoing research and development in this high-stakes racing environment.

Ford Global Technologies LLC

Technical Solution: Ford has a rich history in motorsports, particularly with their GT40 program that featured V12 engines. In modern Formula Racing, Ford has developed advanced aerodynamic packages that work in tandem with high-performance engines. Their research focuses on creating a synergy between engine placement, exhaust flow, and overall car aerodynamics. Ford's engineers use sophisticated CFD simulations to optimize the interaction between the V12 engine's heat dissipation and the car's aerodynamic surfaces[10]. They have also developed innovative cooling solutions that integrate seamlessly with the aerodynamic package, ensuring optimal engine performance without compromising drag coefficients. Ford's EcoBoost technology principles have been adapted to racing applications, focusing on efficiency and power density, which complements their aerodynamic developments[11].

Strengths: Extensive motorsport experience; integrated approach to engine and aerodynamics development; advanced simulation capabilities. Weaknesses: Recent focus on smaller displacement engines may limit V12-specific expertise; balancing road car and racing technology transfer.

Toyota Motor Corp.

Technical Solution: Toyota's involvement in Formula Racing has led to significant advancements in the integration of aerodynamics and V12 engine technology. Their approach focuses on holistic vehicle design, where the engine and aerodynamic package are developed as a single unit. Toyota has pioneered the use of artificial intelligence in CFD simulations to predict and optimize the complex airflow patterns around a V12 engine and its impact on overall car aerodynamics[12]. They have also developed advanced thermal management systems that work in conjunction with the aerodynamic surfaces to efficiently channel heat away from the V12 engine, maintaining optimal operating temperatures while minimizing aerodynamic disruption. Toyota's expertise in hybrid powertrains has influenced their V12 engine designs, incorporating energy recovery systems that complement the aerodynamic package for improved overall efficiency[13].

Strengths: Comprehensive approach to vehicle dynamics; advanced AI-driven simulation techniques; expertise in thermal management. Weaknesses: Primary focus on hybrid technologies may limit pure V12 development; balancing road car technology transfer with specialized racing applications.

Innovative Aerodynamic and V12 Engine Technologies

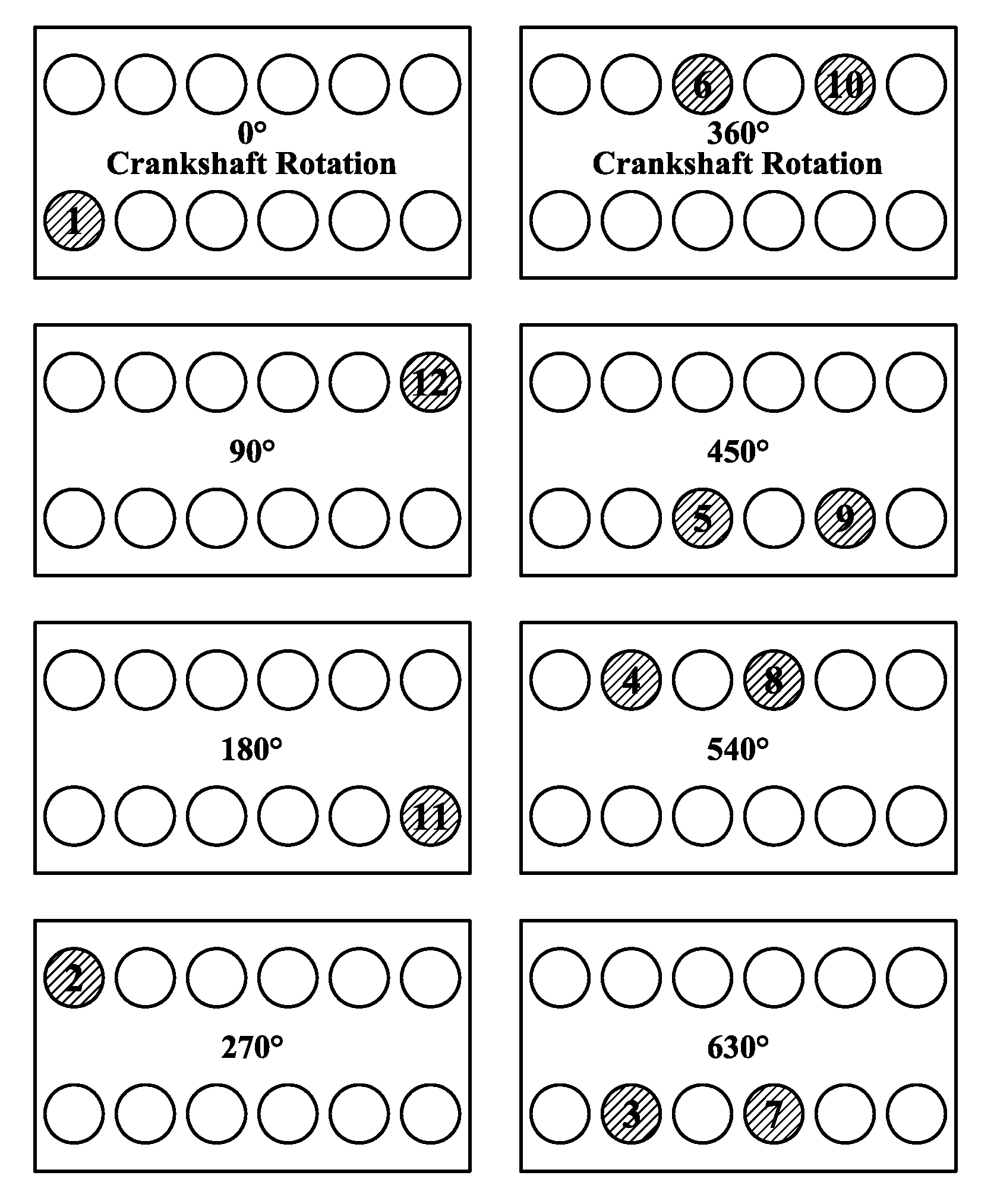

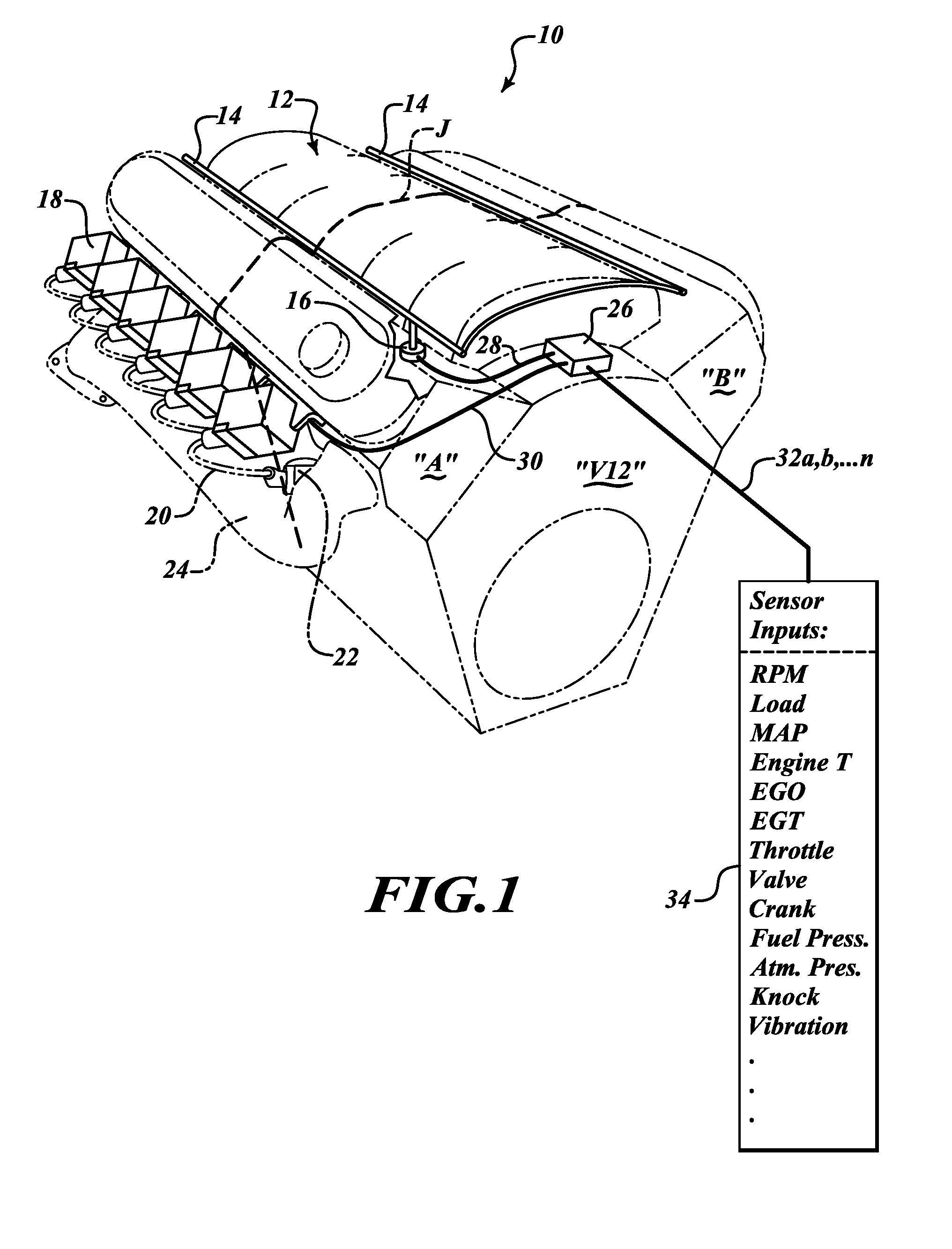

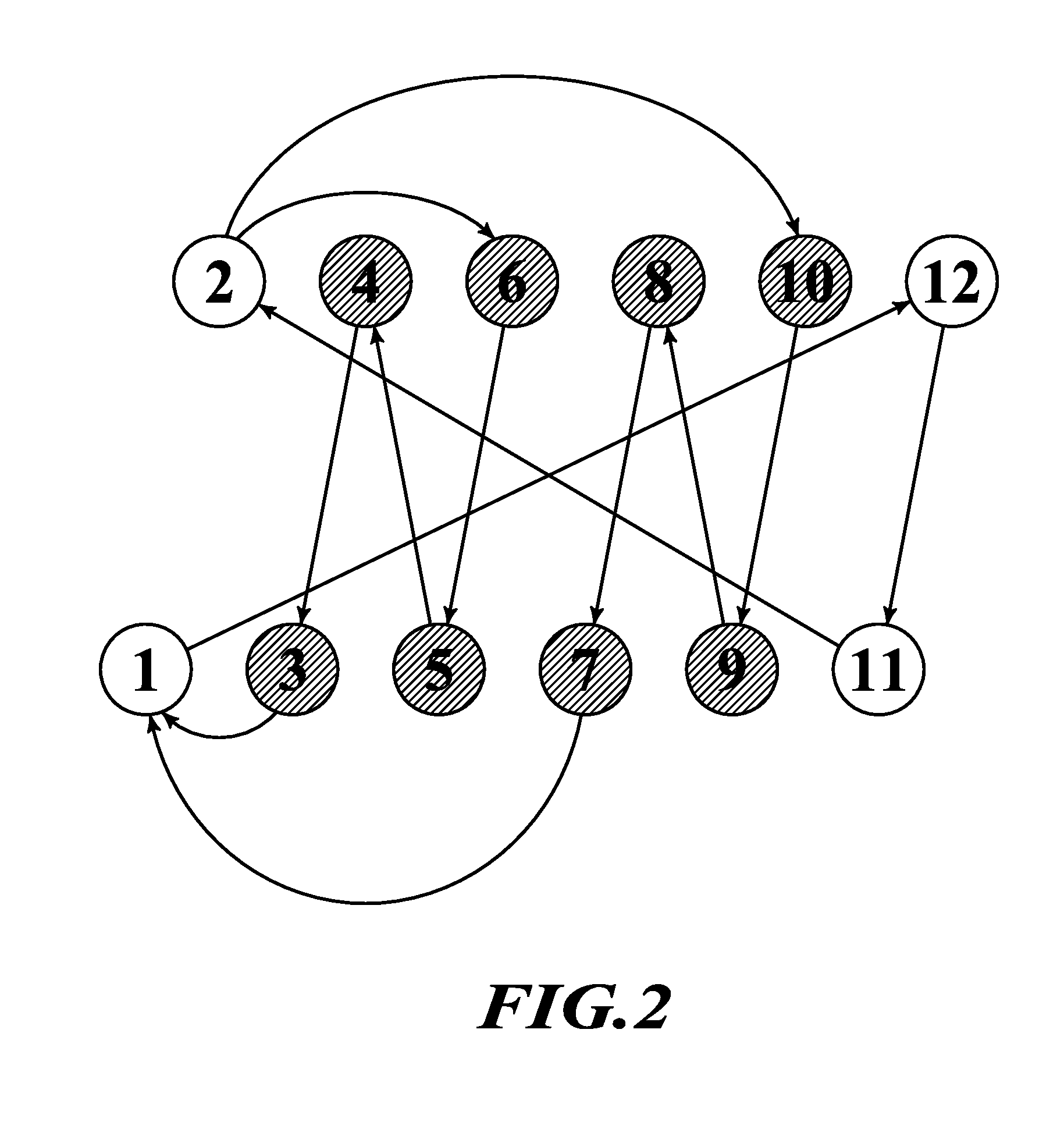

Even fire 90°V12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/P technology and IFR compensation by fuel feed control

PatentInactiveUS7979193B2

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence controlled by a Powertrain Control Module (PCM) that allows all cylinders in a 90°V12 to operate in Even Fire mode, with Dynamic Fuel Balancing and IFR Compensation by selectively reducing fuel to specific cylinders during imbalance frequencies, effectively converting the engine's operation to a balanced V8 mode during peak vibrations.

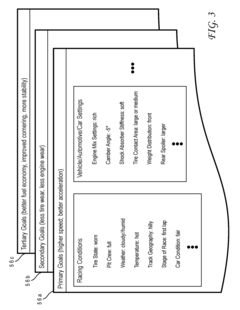

Using cognitive analysis with pattern templates to compose engine mapping mix settings

PatentActiveUS20180119632A1

Innovation

- A cognitive analysis system that uses pattern templates and natural language processing to analyze historical racing data, suggesting optimal engine mix settings and other automotive configurations based on current racing conditions and goals, allowing for real-time adjustments and optimization.

Environmental Impact of F1 Racing Technologies

Formula 1 racing, while renowned for its technological advancements and thrilling spectacles, has faced increasing scrutiny regarding its environmental impact. The interaction between aerodynamics and V12 engines in Formula racing has significant implications for the sport's ecological footprint. As F1 continues to evolve, balancing performance with sustainability has become a critical challenge.

The aerodynamic design of F1 cars, aimed at maximizing downforce and minimizing drag, contributes to increased fuel consumption. Complex aerodynamic features, such as wings, diffusers, and bargeboards, create turbulent air flow, requiring more engine power to overcome air resistance. This demand for power historically led to the development of high-performance V12 engines, known for their impressive output but also for their substantial fuel consumption and emissions.

V12 engines, with their larger displacement and higher cylinder count, inherently consume more fuel than smaller engine configurations. The interaction between these powerful engines and advanced aerodynamics results in a compounded effect on fuel efficiency. As cars achieve higher speeds due to aerodynamic improvements, the engines must work harder to maintain those speeds, leading to increased fuel burn and, consequently, higher carbon emissions.

The environmental impact extends beyond direct emissions. The manufacturing processes for both aerodynamic components and V12 engines involve energy-intensive procedures and the use of specialized materials. Carbon fiber, widely used in F1 for its strength-to-weight ratio, has a significant carbon footprint in its production. Similarly, the precision engineering required for V12 engines demands substantial resources and energy.

In recent years, F1 has recognized the need to address these environmental concerns. The sport has implemented various initiatives to reduce its carbon footprint, including the transition to hybrid power units and the exploration of sustainable fuels. These efforts aim to maintain the high performance standards of F1 while mitigating the environmental impact of the sport's cutting-edge technologies.

The push for sustainability has led to innovations that have potential applications beyond the racetrack. Advancements in aerodynamics have contributed to more efficient designs in road cars, while engine technologies developed for F1 have influenced the development of more fuel-efficient powertrains for consumer vehicles. This transfer of technology demonstrates how F1's environmental challenges can drive broader automotive industry innovations.

As Formula 1 continues to evolve, the balance between performance and environmental responsibility remains a key focus. The sport's commitment to achieving net-zero carbon emissions by 2030 is driving further research into sustainable technologies, potentially reshaping the future of both racing and automotive engineering.

The aerodynamic design of F1 cars, aimed at maximizing downforce and minimizing drag, contributes to increased fuel consumption. Complex aerodynamic features, such as wings, diffusers, and bargeboards, create turbulent air flow, requiring more engine power to overcome air resistance. This demand for power historically led to the development of high-performance V12 engines, known for their impressive output but also for their substantial fuel consumption and emissions.

V12 engines, with their larger displacement and higher cylinder count, inherently consume more fuel than smaller engine configurations. The interaction between these powerful engines and advanced aerodynamics results in a compounded effect on fuel efficiency. As cars achieve higher speeds due to aerodynamic improvements, the engines must work harder to maintain those speeds, leading to increased fuel burn and, consequently, higher carbon emissions.

The environmental impact extends beyond direct emissions. The manufacturing processes for both aerodynamic components and V12 engines involve energy-intensive procedures and the use of specialized materials. Carbon fiber, widely used in F1 for its strength-to-weight ratio, has a significant carbon footprint in its production. Similarly, the precision engineering required for V12 engines demands substantial resources and energy.

In recent years, F1 has recognized the need to address these environmental concerns. The sport has implemented various initiatives to reduce its carbon footprint, including the transition to hybrid power units and the exploration of sustainable fuels. These efforts aim to maintain the high performance standards of F1 while mitigating the environmental impact of the sport's cutting-edge technologies.

The push for sustainability has led to innovations that have potential applications beyond the racetrack. Advancements in aerodynamics have contributed to more efficient designs in road cars, while engine technologies developed for F1 have influenced the development of more fuel-efficient powertrains for consumer vehicles. This transfer of technology demonstrates how F1's environmental challenges can drive broader automotive industry innovations.

As Formula 1 continues to evolve, the balance between performance and environmental responsibility remains a key focus. The sport's commitment to achieving net-zero carbon emissions by 2030 is driving further research into sustainable technologies, potentially reshaping the future of both racing and automotive engineering.

F1 Regulations and Technical Specifications

Formula 1 (F1) racing is governed by a comprehensive set of regulations and technical specifications that define the parameters within which teams must operate. These rules are designed to ensure fair competition, promote safety, and drive technological innovation. The Fédération Internationale de l'Automobile (FIA) is responsible for setting and enforcing these regulations, which are regularly updated to address emerging challenges and maintain the sport's competitive balance.

The technical specifications for F1 cars are highly detailed and cover every aspect of the vehicle's design and performance. Engine regulations are particularly stringent, with current rules mandating the use of 1.6-liter V6 turbo-hybrid power units. These engines are limited to a maximum of 15,000 rpm and must adhere to strict fuel flow limits. The energy recovery system (ERS) is an integral part of the power unit, allowing for the harvesting and deployment of electrical energy to boost performance.

Aerodynamic regulations are equally complex and have a significant impact on car design. The FIA specifies maximum dimensions for various components, including the front and rear wings, diffuser, and floor. Teams must also comply with regulations regarding the overall shape of the car, including minimum weight requirements and specific crash structure designs to enhance driver safety.

The interaction between aerodynamics and engine performance is a critical consideration in F1 car design. Teams must balance the need for aerodynamic efficiency with the cooling requirements of the power unit. This often involves intricate packaging solutions to minimize drag while ensuring adequate airflow to critical components.

Regulations also extend to the materials and manufacturing processes used in car construction. There are restrictions on the use of exotic materials and advanced manufacturing techniques to control costs and maintain a level playing field. Additionally, the FIA imposes limits on testing and development activities, including wind tunnel time and computational fluid dynamics (CFD) usage, to prevent larger teams from gaining an insurmountable advantage through superior resources.

The regulatory framework in F1 is dynamic, with changes introduced periodically to address emerging issues or to steer the sport in a particular direction. For instance, recent regulations have focused on promoting sustainability, with increased emphasis on hybrid technology and plans for carbon-neutral fuels. These evolving regulations continually challenge teams to innovate within defined parameters, driving the technological advancements that often find their way into road cars.

The technical specifications for F1 cars are highly detailed and cover every aspect of the vehicle's design and performance. Engine regulations are particularly stringent, with current rules mandating the use of 1.6-liter V6 turbo-hybrid power units. These engines are limited to a maximum of 15,000 rpm and must adhere to strict fuel flow limits. The energy recovery system (ERS) is an integral part of the power unit, allowing for the harvesting and deployment of electrical energy to boost performance.

Aerodynamic regulations are equally complex and have a significant impact on car design. The FIA specifies maximum dimensions for various components, including the front and rear wings, diffuser, and floor. Teams must also comply with regulations regarding the overall shape of the car, including minimum weight requirements and specific crash structure designs to enhance driver safety.

The interaction between aerodynamics and engine performance is a critical consideration in F1 car design. Teams must balance the need for aerodynamic efficiency with the cooling requirements of the power unit. This often involves intricate packaging solutions to minimize drag while ensuring adequate airflow to critical components.

Regulations also extend to the materials and manufacturing processes used in car construction. There are restrictions on the use of exotic materials and advanced manufacturing techniques to control costs and maintain a level playing field. Additionally, the FIA imposes limits on testing and development activities, including wind tunnel time and computational fluid dynamics (CFD) usage, to prevent larger teams from gaining an insurmountable advantage through superior resources.

The regulatory framework in F1 is dynamic, with changes introduced periodically to address emerging issues or to steer the sport in a particular direction. For instance, recent regulations have focused on promoting sustainability, with increased emphasis on hybrid technology and plans for carbon-neutral fuels. These evolving regulations continually challenge teams to innovate within defined parameters, driving the technological advancements that often find their way into road cars.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!