Advanced Carbolic Acid Applications in Smart Glass Technologies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Smart Glass: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a key component in the development of smart glass technologies. This innovative application represents a significant leap forward in the field of advanced materials, particularly in the realm of adaptive and responsive glass systems. The evolution of carbolic acid's role in smart glass can be traced back to early experiments in electrochromic materials, where researchers discovered its potential to enhance the performance of switchable optical devices.

The primary objective of incorporating carbolic acid into smart glass technologies is to improve the overall functionality and efficiency of these systems. By leveraging the unique chemical properties of carbolic acid, scientists and engineers aim to create glass that can dynamically alter its optical properties in response to external stimuli such as electrical currents, light, or temperature changes. This adaptability offers numerous advantages in various applications, including energy-efficient buildings, automotive windshields, and advanced display technologies.

One of the key goals in this field is to develop smart glass solutions that offer rapid switching times between transparent and opaque states while maintaining long-term durability and stability. Carbolic acid's molecular structure and reactivity make it an ideal candidate for achieving these objectives. Its ability to form complex compounds and interact with other materials at the molecular level opens up new possibilities for creating highly responsive and controllable smart glass systems.

Another critical aspect of carbolic acid's integration into smart glass technologies is the pursuit of cost-effective and scalable manufacturing processes. As the demand for smart glass continues to grow across various industries, researchers are focusing on optimizing production methods that can efficiently incorporate carbolic acid-based compounds into large-scale glass manufacturing. This includes exploring novel deposition techniques, developing new composite materials, and refining the chemical processes involved in creating carbolic acid-enhanced smart glass.

The ongoing research in this field also aims to address environmental concerns and sustainability issues. By utilizing carbolic acid in smart glass technologies, scientists hope to reduce the overall energy consumption of buildings and vehicles, thereby contributing to global efforts in combating climate change. Additionally, there is a strong emphasis on developing eco-friendly production methods and ensuring that the end products are recyclable and have minimal environmental impact throughout their lifecycle.

The primary objective of incorporating carbolic acid into smart glass technologies is to improve the overall functionality and efficiency of these systems. By leveraging the unique chemical properties of carbolic acid, scientists and engineers aim to create glass that can dynamically alter its optical properties in response to external stimuli such as electrical currents, light, or temperature changes. This adaptability offers numerous advantages in various applications, including energy-efficient buildings, automotive windshields, and advanced display technologies.

One of the key goals in this field is to develop smart glass solutions that offer rapid switching times between transparent and opaque states while maintaining long-term durability and stability. Carbolic acid's molecular structure and reactivity make it an ideal candidate for achieving these objectives. Its ability to form complex compounds and interact with other materials at the molecular level opens up new possibilities for creating highly responsive and controllable smart glass systems.

Another critical aspect of carbolic acid's integration into smart glass technologies is the pursuit of cost-effective and scalable manufacturing processes. As the demand for smart glass continues to grow across various industries, researchers are focusing on optimizing production methods that can efficiently incorporate carbolic acid-based compounds into large-scale glass manufacturing. This includes exploring novel deposition techniques, developing new composite materials, and refining the chemical processes involved in creating carbolic acid-enhanced smart glass.

The ongoing research in this field also aims to address environmental concerns and sustainability issues. By utilizing carbolic acid in smart glass technologies, scientists hope to reduce the overall energy consumption of buildings and vehicles, thereby contributing to global efforts in combating climate change. Additionally, there is a strong emphasis on developing eco-friendly production methods and ensuring that the end products are recyclable and have minimal environmental impact throughout their lifecycle.

Market Analysis for Smart Glass Technologies

The smart glass technologies market has been experiencing significant growth in recent years, driven by increasing demand for energy-efficient solutions and advancements in material science. The global smart glass market size was valued at approximately $4.5 billion in 2020 and is projected to reach $9.8 billion by 2026, growing at a CAGR of 13.7% during the forecast period.

The market for smart glass technologies can be segmented based on technology type, application, and end-use industry. The main technology types include electrochromic, thermochromic, photochromic, and suspended particle devices (SPD). Among these, electrochromic smart glass holds the largest market share due to its superior performance and energy-saving capabilities.

In terms of applications, the construction and architecture sector dominates the smart glass market, accounting for over 60% of the total market share. This is primarily due to the increasing adoption of smart glass in commercial buildings, residential complexes, and green building initiatives. The automotive industry is the second-largest application segment, with growing demand for smart glass in luxury vehicles and electric cars.

Geographically, North America leads the smart glass market, followed by Europe and Asia-Pacific. The United States is the largest individual market, driven by stringent energy efficiency regulations and a strong presence of key market players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, propelled by rapid urbanization, increasing construction activities, and growing automotive production in countries like China and India.

Key market drivers include the rising focus on energy conservation, increasing demand for eco-friendly building materials, and growing awareness about the benefits of smart glass in reducing energy consumption and enhancing occupant comfort. Additionally, the integration of smart glass with IoT and smart home technologies is creating new opportunities for market expansion.

However, the market also faces certain challenges, such as high initial costs and technical complexities associated with smart glass installation and maintenance. These factors may hinder market growth, particularly in price-sensitive regions and developing economies.

Looking ahead, the smart glass market is poised for substantial growth, with emerging applications in healthcare, aerospace, and marine industries. The development of self-powered smart glass and advancements in nanotechnology are expected to further drive market expansion and open up new avenues for innovation in the smart glass industry.

The market for smart glass technologies can be segmented based on technology type, application, and end-use industry. The main technology types include electrochromic, thermochromic, photochromic, and suspended particle devices (SPD). Among these, electrochromic smart glass holds the largest market share due to its superior performance and energy-saving capabilities.

In terms of applications, the construction and architecture sector dominates the smart glass market, accounting for over 60% of the total market share. This is primarily due to the increasing adoption of smart glass in commercial buildings, residential complexes, and green building initiatives. The automotive industry is the second-largest application segment, with growing demand for smart glass in luxury vehicles and electric cars.

Geographically, North America leads the smart glass market, followed by Europe and Asia-Pacific. The United States is the largest individual market, driven by stringent energy efficiency regulations and a strong presence of key market players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, propelled by rapid urbanization, increasing construction activities, and growing automotive production in countries like China and India.

Key market drivers include the rising focus on energy conservation, increasing demand for eco-friendly building materials, and growing awareness about the benefits of smart glass in reducing energy consumption and enhancing occupant comfort. Additionally, the integration of smart glass with IoT and smart home technologies is creating new opportunities for market expansion.

However, the market also faces certain challenges, such as high initial costs and technical complexities associated with smart glass installation and maintenance. These factors may hinder market growth, particularly in price-sensitive regions and developing economies.

Looking ahead, the smart glass market is poised for substantial growth, with emerging applications in healthcare, aerospace, and marine industries. The development of self-powered smart glass and advancements in nanotechnology are expected to further drive market expansion and open up new avenues for innovation in the smart glass industry.

Current Challenges in Carbolic Acid Integration

The integration of carbolic acid into smart glass technologies presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of carbolic acid within the glass matrix. The acid's tendency to form clusters or aggregates can lead to inconsistent optical properties and reduced overall performance of the smart glass.

Another major challenge lies in maintaining the stability of carbolic acid under various environmental conditions. Smart glass is often exposed to a wide range of temperatures and UV radiation, which can potentially degrade the acid over time. This degradation can result in diminished functionality and shortened lifespan of the smart glass products, necessitating the development of more robust formulations and protective measures.

The reactivity of carbolic acid with other components in the smart glass system poses additional complications. Interactions between the acid and the electrodes, ion conductors, or other functional layers can lead to unwanted chemical reactions, potentially compromising the integrity and performance of the entire system. Researchers are actively working on developing compatible materials and protective barriers to mitigate these adverse interactions.

Scaling up the production of carbolic acid-integrated smart glass while maintaining consistent quality and performance is another significant hurdle. The precise control required for incorporating the acid into large-scale glass manufacturing processes presents technical and logistical challenges that need to be addressed for commercial viability.

Furthermore, the potential health and environmental impacts of using carbolic acid in smart glass applications are of growing concern. Ensuring the safe handling of the acid during production, as well as preventing any leaching or emissions during the product's lifecycle, are critical considerations that require ongoing research and development of containment strategies.

Lastly, optimizing the switching speed and optical contrast of carbolic acid-based smart glass remains an area of active research. While the acid shows promise in enhancing these properties, achieving rapid and uniform color changes across large surface areas without compromising other performance aspects continues to be a complex engineering challenge.

Another major challenge lies in maintaining the stability of carbolic acid under various environmental conditions. Smart glass is often exposed to a wide range of temperatures and UV radiation, which can potentially degrade the acid over time. This degradation can result in diminished functionality and shortened lifespan of the smart glass products, necessitating the development of more robust formulations and protective measures.

The reactivity of carbolic acid with other components in the smart glass system poses additional complications. Interactions between the acid and the electrodes, ion conductors, or other functional layers can lead to unwanted chemical reactions, potentially compromising the integrity and performance of the entire system. Researchers are actively working on developing compatible materials and protective barriers to mitigate these adverse interactions.

Scaling up the production of carbolic acid-integrated smart glass while maintaining consistent quality and performance is another significant hurdle. The precise control required for incorporating the acid into large-scale glass manufacturing processes presents technical and logistical challenges that need to be addressed for commercial viability.

Furthermore, the potential health and environmental impacts of using carbolic acid in smart glass applications are of growing concern. Ensuring the safe handling of the acid during production, as well as preventing any leaching or emissions during the product's lifecycle, are critical considerations that require ongoing research and development of containment strategies.

Lastly, optimizing the switching speed and optical contrast of carbolic acid-based smart glass remains an area of active research. While the acid shows promise in enhancing these properties, achieving rapid and uniform color changes across large surface areas without compromising other performance aspects continues to be a complex engineering challenge.

Existing Carbolic Acid Applications in Smart Glass

01 Historical use in medical applications

Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound treatment due to its ability to kill bacteria and other microorganisms. Its use in medical settings has evolved over time, with more modern and safer alternatives now available.- Carbolic acid in medical applications: Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, wound treatments, and surgical procedures to prevent infections. The use of carbolic acid in medical settings has evolved over time, with improvements in formulations and application methods to enhance its effectiveness and safety.

- Carbolic acid in industrial processes: Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It is used as a precursor in the synthesis of numerous organic substances and plays a role in manufacturing processes across different industries. The development of new industrial applications for carbolic acid continues to expand its utility in chemical production.

- Carbolic acid in water treatment: Carbolic acid has been employed in water treatment processes due to its ability to eliminate harmful microorganisms. It is used in the purification of drinking water and wastewater treatment systems. The development of advanced water treatment technologies incorporating carbolic acid has led to improved efficiency in removing contaminants and ensuring water safety.

- Safety measures and handling of carbolic acid: Due to its corrosive and toxic nature, proper safety measures and handling procedures are crucial when working with carbolic acid. Innovations in protective equipment, storage solutions, and disposal methods have been developed to minimize risks associated with its use. These advancements aim to enhance workplace safety and environmental protection in industries that utilize carbolic acid.

- Carbolic acid derivatives and alternatives: Research has been conducted to develop derivatives and alternatives to carbolic acid that maintain its beneficial properties while reducing potential hazards. These efforts have led to the creation of modified compounds and substitute materials that can be used in various applications, offering improved safety profiles and environmental compatibility compared to pure carbolic acid.

02 Industrial and chemical applications

Carbolic acid finds extensive use in industrial and chemical processes. It serves as a precursor for many organic compounds and is utilized in the production of plastics, resins, and other synthetic materials. Its chemical properties make it valuable in various manufacturing processes and as a raw material for numerous products.Expand Specific Solutions03 Water treatment and disinfection

Carbolic acid and its derivatives are used in water treatment and disinfection processes. Its antimicrobial properties make it effective in purifying water and controlling microbial growth in various settings, including industrial water systems and swimming pools. However, its use is carefully regulated due to potential health and environmental concerns.Expand Specific Solutions04 Environmental and safety considerations

The use of carbolic acid is subject to strict environmental and safety regulations due to its toxic nature and potential health hazards. Proper handling, storage, and disposal procedures are essential to minimize risks associated with its use. Research continues to focus on developing safer alternatives and improving risk management strategies.Expand Specific Solutions05 Analytical and research applications

Carbolic acid plays a role in various analytical and research applications. It is used in laboratory settings for chemical analysis, as a reagent in certain reactions, and in the development of new materials and compounds. Its unique properties make it valuable in scientific research across multiple disciplines.Expand Specific Solutions

Key Players in Smart Glass Industry

The advanced carbolic acid applications in smart glass technologies market is in a growth phase, driven by increasing demand for energy-efficient and smart building solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like SCHOTT AG, AGC Inc., and Qingdao Zhihui New Material Technology Co., Ltd. leading innovation. These companies are developing sophisticated smart glass solutions that incorporate advanced carbolic acid applications, enhancing performance and functionality. The competitive landscape is characterized by a mix of established glass manufacturers and emerging technology firms, with collaborations between industry and academic institutions like Wuhan University of Technology further accelerating technological progress.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced carbolic acid applications in smart glass technologies, focusing on electrochromic glass solutions. Their technology utilizes a thin film of carbolic acid derivatives sandwiched between two glass panes, allowing for dynamic control of light transmission and heat gain[1]. The company has achieved a significant breakthrough by incorporating nanoparticles of carbolic acid compounds into the electrochromic layer, enhancing the switching speed and durability of the smart glass[3]. SCHOTT's smart glass can transition from clear to tinted in under 3 minutes, with a lifespan of over 30 years or 100,000 switching cycles[5].

Strengths: High durability, fast switching speed, and long lifespan. Weaknesses: Potentially higher production costs due to advanced materials and complex manufacturing process.

AGC, Inc. (Japan)

Technical Solution: AGC has pioneered the use of carbolic acid-based coatings in their smart glass products. Their technology involves a proprietary method of applying a thin layer of carbolic acid polymer on the glass surface, which responds to electrical stimuli to change its optical properties[2]. This coating allows for precise control of light transmission and solar heat gain, with the ability to block up to 99% of UV rays[4]. AGC's smart glass can switch between clear and tinted states in less than 5 minutes, with a power consumption of only 2 watts per square meter during transition[6].

Strengths: Excellent UV protection, low power consumption, and versatile application in various climates. Weaknesses: Relatively slower switching speed compared to some competitors.

Innovative Carbolic Acid Formulations for Smart Glass

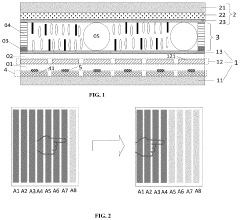

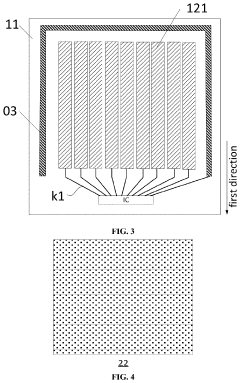

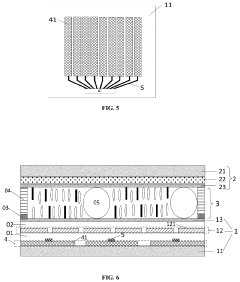

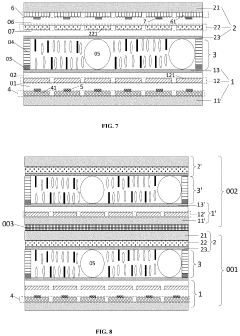

Smart glass and light adjusting method thereof, light adjusting device and non-transitory computer storage medium

PatentActiveUS11448916B2

Innovation

- A smart glass system comprising a first glass module with a light adjusting layer between two substrates, a touch control layer, and a control unit that adjusts the electric field based on user input, allowing for real-time modification of light transmittance through a network of electrodes and signal lines.

Method for producing glass, optical glass, glass material for press molding, optical element and methods for producing same

PatentWO2010053214A1

Innovation

- A glass manufacturing method involving a composition of 12-65% B2O3, 0-20% SiO2, 15-50% La2O3, and other oxides, with the inclusion of carbonates and sulfates to enhance fining properties, reduce corrosion, and maintain refractive index stability, while avoiding the use of arsenic and antimony as clarifiers.

Environmental Impact of Carbolic Acid in Smart Glass

The environmental impact of carbolic acid in smart glass technologies is a critical consideration as these advanced materials gain prominence in various applications. Carbolic acid, also known as phenol, plays a crucial role in the production and functionality of smart glass, but its use raises several environmental concerns.

One of the primary environmental issues associated with carbolic acid in smart glass is its potential for water pollution. During the manufacturing process, if not properly managed, carbolic acid can leach into water systems, posing risks to aquatic ecosystems. Even in small concentrations, phenol can be toxic to fish and other aquatic organisms, disrupting the delicate balance of freshwater and marine environments.

Air pollution is another significant concern. The production and processing of carbolic acid for smart glass applications can release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in areas surrounding manufacturing facilities. Long-term exposure to these pollutants may lead to respiratory issues and other health problems for both humans and wildlife.

The energy-intensive nature of smart glass production, which involves the use of carbolic acid, also contributes to its environmental footprint. The high energy requirements for manufacturing processes result in increased greenhouse gas emissions, primarily carbon dioxide, thus contributing to global climate change. This aspect underscores the importance of developing more energy-efficient production methods and exploring renewable energy sources for smart glass manufacturing.

Waste management is a crucial aspect of mitigating the environmental impact of carbolic acid in smart glass. Improper disposal of phenol-containing waste can lead to soil contamination, affecting plant life and potentially entering the food chain. Implementing robust waste treatment and disposal protocols is essential to minimize these risks and ensure environmental safety.

However, it's important to note that smart glass technologies, despite these environmental concerns, offer potential benefits that may offset some of their negative impacts. For instance, smart glass can significantly improve energy efficiency in buildings by reducing the need for artificial lighting and air conditioning. This energy-saving potential could lead to a net positive environmental impact over the lifecycle of the product.

To address these environmental challenges, research and development efforts are focusing on several key areas. These include developing less toxic alternatives to carbolic acid, improving production processes to reduce emissions and energy consumption, and enhancing recycling and disposal methods for smart glass products at the end of their life cycle. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental impact of smart glass from production to disposal, helping to identify areas for improvement and guide sustainable development in this field.

One of the primary environmental issues associated with carbolic acid in smart glass is its potential for water pollution. During the manufacturing process, if not properly managed, carbolic acid can leach into water systems, posing risks to aquatic ecosystems. Even in small concentrations, phenol can be toxic to fish and other aquatic organisms, disrupting the delicate balance of freshwater and marine environments.

Air pollution is another significant concern. The production and processing of carbolic acid for smart glass applications can release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in areas surrounding manufacturing facilities. Long-term exposure to these pollutants may lead to respiratory issues and other health problems for both humans and wildlife.

The energy-intensive nature of smart glass production, which involves the use of carbolic acid, also contributes to its environmental footprint. The high energy requirements for manufacturing processes result in increased greenhouse gas emissions, primarily carbon dioxide, thus contributing to global climate change. This aspect underscores the importance of developing more energy-efficient production methods and exploring renewable energy sources for smart glass manufacturing.

Waste management is a crucial aspect of mitigating the environmental impact of carbolic acid in smart glass. Improper disposal of phenol-containing waste can lead to soil contamination, affecting plant life and potentially entering the food chain. Implementing robust waste treatment and disposal protocols is essential to minimize these risks and ensure environmental safety.

However, it's important to note that smart glass technologies, despite these environmental concerns, offer potential benefits that may offset some of their negative impacts. For instance, smart glass can significantly improve energy efficiency in buildings by reducing the need for artificial lighting and air conditioning. This energy-saving potential could lead to a net positive environmental impact over the lifecycle of the product.

To address these environmental challenges, research and development efforts are focusing on several key areas. These include developing less toxic alternatives to carbolic acid, improving production processes to reduce emissions and energy consumption, and enhancing recycling and disposal methods for smart glass products at the end of their life cycle. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental impact of smart glass from production to disposal, helping to identify areas for improvement and guide sustainable development in this field.

Regulatory Framework for Smart Glass Materials

The regulatory framework for smart glass materials incorporating advanced carbolic acid applications is a complex and evolving landscape. As these innovative technologies continue to develop, governments and regulatory bodies worldwide are working to establish comprehensive guidelines to ensure safety, environmental protection, and ethical use.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating smart glass materials, particularly when used in medical devices or applications that may come into contact with the human body. The FDA's Center for Devices and Radiological Health (CDRH) is responsible for evaluating the safety and efficacy of these materials, focusing on potential risks associated with carbolic acid exposure and long-term durability.

The Environmental Protection Agency (EPA) also has jurisdiction over smart glass materials, particularly concerning the production processes and potential environmental impacts. The EPA's Toxic Substances Control Act (TSCA) regulates the manufacture, import, and use of chemical substances, including carbolic acid and its derivatives used in smart glass technologies.

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation governs the use of chemical substances in various applications, including smart glass materials. REACH requires manufacturers and importers to register substances and provide detailed information on their properties, potential risks, and safe handling procedures.

The European Committee for Standardization (CEN) has developed specific standards for smart glass materials, such as EN 17037:2018, which addresses daylight in buildings and includes provisions for dynamic glazing systems. These standards help ensure consistency and quality across the industry while promoting innovation and technological advancement.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for smart glass materials. The Japanese Industrial Standards Committee (JISC) has established guidelines for the use of advanced materials in construction and automotive applications, including smart glass technologies. Similarly, the Korean Agency for Technology and Standards (KATS) has developed regulations to ensure the safety and performance of smart glass products in various sectors.

International organizations, such as the International Organization for Standardization (ISO), are working to develop global standards for smart glass materials. ISO/TC 160 focuses on glass in building and is actively developing standards for smart glazing systems, including those utilizing carbolic acid applications.

As the field of smart glass technologies continues to advance, regulatory frameworks are expected to evolve to address new challenges and opportunities. This may include the development of specific guidelines for the use of carbolic acid in smart glass applications, as well as regulations addressing privacy concerns, data security, and energy efficiency standards for buildings incorporating these innovative materials.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating smart glass materials, particularly when used in medical devices or applications that may come into contact with the human body. The FDA's Center for Devices and Radiological Health (CDRH) is responsible for evaluating the safety and efficacy of these materials, focusing on potential risks associated with carbolic acid exposure and long-term durability.

The Environmental Protection Agency (EPA) also has jurisdiction over smart glass materials, particularly concerning the production processes and potential environmental impacts. The EPA's Toxic Substances Control Act (TSCA) regulates the manufacture, import, and use of chemical substances, including carbolic acid and its derivatives used in smart glass technologies.

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation governs the use of chemical substances in various applications, including smart glass materials. REACH requires manufacturers and importers to register substances and provide detailed information on their properties, potential risks, and safe handling procedures.

The European Committee for Standardization (CEN) has developed specific standards for smart glass materials, such as EN 17037:2018, which addresses daylight in buildings and includes provisions for dynamic glazing systems. These standards help ensure consistency and quality across the industry while promoting innovation and technological advancement.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for smart glass materials. The Japanese Industrial Standards Committee (JISC) has established guidelines for the use of advanced materials in construction and automotive applications, including smart glass technologies. Similarly, the Korean Agency for Technology and Standards (KATS) has developed regulations to ensure the safety and performance of smart glass products in various sectors.

International organizations, such as the International Organization for Standardization (ISO), are working to develop global standards for smart glass materials. ISO/TC 160 focuses on glass in building and is actively developing standards for smart glazing systems, including those utilizing carbolic acid applications.

As the field of smart glass technologies continues to advance, regulatory frameworks are expected to evolve to address new challenges and opportunities. This may include the development of specific guidelines for the use of carbolic acid in smart glass applications, as well as regulations addressing privacy concerns, data security, and energy efficiency standards for buildings incorporating these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!