Advanced Studies on Borosilicate Glass Durability

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Evolution and Research Objectives

Borosilicate glass has been a cornerstone material in various industries for over a century, with its development tracing back to the late 19th century. The evolution of this versatile material has been driven by the need for glass with superior thermal and chemical resistance properties. Initially developed for laboratory glassware, borosilicate glass quickly found applications in a wide range of fields, from cookware to industrial processes and even space exploration.

The primary objective of advanced studies on borosilicate glass durability is to enhance its longevity and performance under extreme conditions. This research aims to push the boundaries of what is possible with glass materials, focusing on improving resistance to thermal shock, chemical corrosion, and mechanical stress. By understanding the fundamental mechanisms that govern the durability of borosilicate glass, researchers seek to develop new compositions and manufacturing techniques that can yield even more resilient products.

One of the key areas of focus is the glass's behavior in high-radiation environments, particularly for nuclear waste containment. The goal is to create borosilicate glass formulations that can safely encapsulate radioactive waste for thousands of years without degradation. This research has far-reaching implications for environmental protection and the sustainable management of nuclear materials.

Another critical objective is to improve the glass's resistance to weathering and chemical attack in various industrial applications. This includes developing coatings or surface treatments that can further enhance the inherent durability of borosilicate glass, extending its service life in harsh chemical environments and reducing the need for frequent replacements.

Researchers are also exploring the potential of borosilicate glass in advanced optical applications, aiming to combine its durability with precise optical properties. This could lead to breakthroughs in fields such as high-power lasers, telecommunications, and advanced imaging systems.

The evolution of borosilicate glass technology is closely tied to advancements in material science and nanotechnology. By incorporating nanostructures or manipulating the glass at the atomic level, scientists hope to create "smart" borosilicate glasses that can adapt to their environment or serve multiple functions simultaneously.

As we look to the future, the research objectives for borosilicate glass durability are becoming increasingly ambitious. The ultimate goal is to develop a new generation of borosilicate glasses that not only meet current industrial and scientific needs but also anticipate future challenges in emerging technologies and environmental concerns.

The primary objective of advanced studies on borosilicate glass durability is to enhance its longevity and performance under extreme conditions. This research aims to push the boundaries of what is possible with glass materials, focusing on improving resistance to thermal shock, chemical corrosion, and mechanical stress. By understanding the fundamental mechanisms that govern the durability of borosilicate glass, researchers seek to develop new compositions and manufacturing techniques that can yield even more resilient products.

One of the key areas of focus is the glass's behavior in high-radiation environments, particularly for nuclear waste containment. The goal is to create borosilicate glass formulations that can safely encapsulate radioactive waste for thousands of years without degradation. This research has far-reaching implications for environmental protection and the sustainable management of nuclear materials.

Another critical objective is to improve the glass's resistance to weathering and chemical attack in various industrial applications. This includes developing coatings or surface treatments that can further enhance the inherent durability of borosilicate glass, extending its service life in harsh chemical environments and reducing the need for frequent replacements.

Researchers are also exploring the potential of borosilicate glass in advanced optical applications, aiming to combine its durability with precise optical properties. This could lead to breakthroughs in fields such as high-power lasers, telecommunications, and advanced imaging systems.

The evolution of borosilicate glass technology is closely tied to advancements in material science and nanotechnology. By incorporating nanostructures or manipulating the glass at the atomic level, scientists hope to create "smart" borosilicate glasses that can adapt to their environment or serve multiple functions simultaneously.

As we look to the future, the research objectives for borosilicate glass durability are becoming increasingly ambitious. The ultimate goal is to develop a new generation of borosilicate glasses that not only meet current industrial and scientific needs but also anticipate future challenges in emerging technologies and environmental concerns.

Market Analysis for Durable Glass Applications

The market for durable glass applications, particularly those utilizing borosilicate glass, has shown significant growth and potential in recent years. This trend is driven by increasing demand across various industries, including laboratory equipment, pharmaceutical packaging, and high-performance consumer products. The global borosilicate glass market was valued at approximately $1.3 billion in 2020 and is projected to reach $2.1 billion by 2027, growing at a CAGR of around 5.8% during this period.

In the laboratory and scientific equipment sector, borosilicate glass remains the material of choice due to its exceptional chemical resistance and thermal stability. The ongoing expansion of research and development activities in pharmaceuticals, biotechnology, and academic institutions is fueling the demand for high-quality laboratory glassware. This segment accounts for a substantial portion of the overall market share and is expected to maintain steady growth.

The pharmaceutical packaging industry represents another significant market for durable borosilicate glass. With increasing concerns over drug stability and shelf life, pharmaceutical companies are increasingly opting for borosilicate glass vials and containers. This trend is particularly evident in the packaging of sensitive biologics and vaccines, where material compatibility and long-term stability are crucial. The COVID-19 pandemic has further accelerated this demand, with borosilicate glass playing a critical role in vaccine distribution.

In the consumer goods sector, there is a growing preference for durable and eco-friendly materials. Borosilicate glass is gaining popularity in kitchenware, food storage containers, and reusable beverage bottles. This shift is driven by consumer awareness of environmental issues and the desire for products with longer lifespans. The market for borosilicate glass in this segment is expected to grow at a higher rate compared to traditional soda-lime glass alternatives.

The automotive and aerospace industries are also exploring advanced applications of durable glass. Borosilicate glass is being considered for specialized components such as high-temperature sensors, lighting systems, and display panels. While this segment currently represents a smaller portion of the market, it shows promising growth potential as manufacturers seek materials that can withstand extreme conditions.

Geographically, North America and Europe dominate the market for durable glass applications, owing to their well-established research infrastructure and stringent quality standards in pharmaceutical and laboratory sectors. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, healthcare investments, and adoption of advanced materials in manufacturing.

In the laboratory and scientific equipment sector, borosilicate glass remains the material of choice due to its exceptional chemical resistance and thermal stability. The ongoing expansion of research and development activities in pharmaceuticals, biotechnology, and academic institutions is fueling the demand for high-quality laboratory glassware. This segment accounts for a substantial portion of the overall market share and is expected to maintain steady growth.

The pharmaceutical packaging industry represents another significant market for durable borosilicate glass. With increasing concerns over drug stability and shelf life, pharmaceutical companies are increasingly opting for borosilicate glass vials and containers. This trend is particularly evident in the packaging of sensitive biologics and vaccines, where material compatibility and long-term stability are crucial. The COVID-19 pandemic has further accelerated this demand, with borosilicate glass playing a critical role in vaccine distribution.

In the consumer goods sector, there is a growing preference for durable and eco-friendly materials. Borosilicate glass is gaining popularity in kitchenware, food storage containers, and reusable beverage bottles. This shift is driven by consumer awareness of environmental issues and the desire for products with longer lifespans. The market for borosilicate glass in this segment is expected to grow at a higher rate compared to traditional soda-lime glass alternatives.

The automotive and aerospace industries are also exploring advanced applications of durable glass. Borosilicate glass is being considered for specialized components such as high-temperature sensors, lighting systems, and display panels. While this segment currently represents a smaller portion of the market, it shows promising growth potential as manufacturers seek materials that can withstand extreme conditions.

Geographically, North America and Europe dominate the market for durable glass applications, owing to their well-established research infrastructure and stringent quality standards in pharmaceutical and laboratory sectors. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, healthcare investments, and adoption of advanced materials in manufacturing.

Current Challenges in Borosilicate Glass Durability

Despite significant advancements in borosilicate glass technology, several challenges persist in ensuring its long-term durability. One of the primary concerns is the glass's susceptibility to chemical corrosion, particularly in high-pH environments. This corrosion can lead to the formation of surface layers that alter the glass's properties and potentially compromise its structural integrity over time.

Another challenge lies in the glass's resistance to radiation damage, especially in nuclear waste storage applications. While borosilicate glass has shown remarkable stability, prolonged exposure to high-energy radiation can induce structural changes at the atomic level, potentially affecting its containment properties.

The heterogeneity of borosilicate glass compositions presents a significant hurdle in predicting long-term behavior. Variations in elemental ratios and the presence of minor components can dramatically influence the glass's durability, making it difficult to establish universal models for degradation processes.

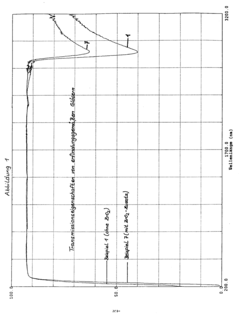

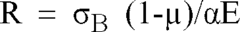

Mechanical stress and thermal cycling pose additional challenges to borosilicate glass durability. In industrial applications, where the glass is subjected to repeated temperature fluctuations or mechanical loads, microcracks can develop and propagate, potentially leading to catastrophic failure over time.

The interaction between borosilicate glass and its environment, particularly in the presence of water or humid conditions, remains a complex issue. The leaching of alkali and boron from the glass network can create altered surface layers, which may either protect the underlying glass or accelerate its degradation, depending on the specific environmental conditions.

Researchers are also grappling with the challenge of accurately predicting the long-term behavior of borosilicate glass over geological timescales, particularly for nuclear waste storage. Current accelerated testing methods may not fully capture the nuanced degradation mechanisms that occur over thousands of years.

Furthermore, the development of advanced characterization techniques to detect and quantify subtle changes in glass structure and composition remains an ongoing challenge. Improved analytical methods are crucial for understanding the early stages of glass degradation and for validating predictive models of long-term durability.

Another challenge lies in the glass's resistance to radiation damage, especially in nuclear waste storage applications. While borosilicate glass has shown remarkable stability, prolonged exposure to high-energy radiation can induce structural changes at the atomic level, potentially affecting its containment properties.

The heterogeneity of borosilicate glass compositions presents a significant hurdle in predicting long-term behavior. Variations in elemental ratios and the presence of minor components can dramatically influence the glass's durability, making it difficult to establish universal models for degradation processes.

Mechanical stress and thermal cycling pose additional challenges to borosilicate glass durability. In industrial applications, where the glass is subjected to repeated temperature fluctuations or mechanical loads, microcracks can develop and propagate, potentially leading to catastrophic failure over time.

The interaction between borosilicate glass and its environment, particularly in the presence of water or humid conditions, remains a complex issue. The leaching of alkali and boron from the glass network can create altered surface layers, which may either protect the underlying glass or accelerate its degradation, depending on the specific environmental conditions.

Researchers are also grappling with the challenge of accurately predicting the long-term behavior of borosilicate glass over geological timescales, particularly for nuclear waste storage. Current accelerated testing methods may not fully capture the nuanced degradation mechanisms that occur over thousands of years.

Furthermore, the development of advanced characterization techniques to detect and quantify subtle changes in glass structure and composition remains an ongoing challenge. Improved analytical methods are crucial for understanding the early stages of glass degradation and for validating predictive models of long-term durability.

Existing Durability Enhancement Techniques

01 Chemical composition optimization

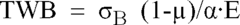

Improving the durability of borosilicate glass by optimizing its chemical composition. This involves adjusting the ratios of silica, boron oxide, and other components to enhance the glass's resistance to thermal shock, chemical corrosion, and mechanical stress. The optimized composition can lead to increased strength and longevity of the glass.- Chemical composition for improved durability: Borosilicate glass durability can be enhanced by optimizing its chemical composition. This involves adjusting the ratios of silica, boron oxide, and other elements to create a more resistant structure. The improved composition leads to better thermal shock resistance, chemical durability, and mechanical strength.

- Surface treatment techniques: Various surface treatment methods can be applied to borosilicate glass to improve its durability. These techniques may include ion exchange, chemical tempering, or the application of protective coatings. Such treatments can enhance scratch resistance, impact strength, and overall longevity of the glass.

- Thermal processing for durability enhancement: Specific thermal processing techniques can be employed to improve the durability of borosilicate glass. These may include controlled cooling rates, annealing processes, or heat strengthening. Such thermal treatments can reduce internal stresses and improve the glass's resistance to thermal shock and mechanical stress.

- Nanostructure modification: Incorporating nanostructures or nanoparticles into borosilicate glass can significantly enhance its durability. This approach can improve mechanical properties, increase scratch resistance, and enhance chemical durability. The nanostructures can be added during the glass formation process or through post-processing techniques.

- Composite materials and reinforcement: Combining borosilicate glass with other materials to create composites or reinforced structures can greatly improve durability. This may involve laminating the glass with polymers, incorporating fiber reinforcements, or creating glass-ceramic composites. Such approaches can enhance impact resistance, flexural strength, and overall toughness of the material.

02 Surface treatment techniques

Enhancing the durability of borosilicate glass through various surface treatment methods. These techniques may include ion exchange, chemical tempering, or application of protective coatings. Such treatments can improve scratch resistance, increase overall strength, and extend the lifespan of the glass products.Expand Specific Solutions03 Thermal processing methods

Utilizing specific thermal processing methods to enhance the durability of borosilicate glass. This may involve controlled cooling rates, annealing processes, or tempering techniques. These methods can reduce internal stresses, improve impact resistance, and increase the overall durability of the glass.Expand Specific Solutions04 Nanostructure incorporation

Incorporating nanostructures or nanoparticles into borosilicate glass to enhance its durability. This approach can involve adding specific nanoparticles during the glass formation process or creating nanostructured surfaces. These modifications can improve mechanical strength, scratch resistance, and overall durability of the glass.Expand Specific Solutions05 Composite material development

Developing composite materials that combine borosilicate glass with other materials to enhance durability. This may include creating layered structures, embedding reinforcing materials, or developing glass-ceramic composites. These composite approaches can significantly improve the overall durability and performance of borosilicate glass products.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The advanced studies on borosilicate glass durability are taking place in a mature yet evolving industry. The market for borosilicate glass is substantial, driven by its wide-ranging applications in pharmaceuticals, electronics, and laboratory equipment. Key players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. are at the forefront of technological advancements. These companies, along with emerging players such as Hunan Kibing Pharmaceutical Material Technology Co., Ltd., are investing heavily in R&D to improve glass durability and expand applications. The competitive landscape is characterized by a mix of established global leaders and innovative regional manufacturers, all striving to enhance product performance and capture market share in this high-tech materials sector.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions with enhanced durability. Their research focuses on improving chemical resistance and mechanical strength through optimized glass formulations. SCHOTT's borosilicate glasses demonstrate superior resistance to thermal shock, acids, and alkalis[1]. They have implemented ion-exchange processes to create chemically strengthened borosilicate glass, significantly increasing surface compression and overall durability[2]. SCHOTT also utilizes advanced melting techniques to reduce defects and improve homogeneity, resulting in glasses with enhanced longevity and performance in demanding applications[3].

Strengths: Extensive experience in specialty glass manufacturing, strong R&D capabilities, and a wide range of applications. Weaknesses: Higher production costs compared to standard glass, limited flexibility in customization for specific applications.

Corning, Inc.

Technical Solution: Corning's approach to borosilicate glass durability involves innovative composition adjustments and surface treatments. They have developed a proprietary process to incorporate alumina into the glass network, enhancing chemical durability and scratch resistance[4]. Corning's research also includes the development of ion-exchange techniques specific to borosilicate compositions, creating a compressive stress layer that significantly improves mechanical strength[5]. Additionally, they have explored the use of nano-scale phase separation to create borosilicate glasses with improved thermal shock resistance and overall durability[6].

Strengths: Strong patent portfolio, cutting-edge research facilities, and a history of successful commercialization of advanced glass technologies. Weaknesses: High R&D costs and potential challenges in scaling up new technologies for mass production.

Innovative Approaches in Glass Strengthening

Low boric acid borosilicate glass and its use

PatentInactiveEP0699636A1

Innovation

- Developing new borosilicate glass compositions with specific ratios of SiO2, B2O3, Al2O3, Li2O, Na2O, K2O, MgO, CaO, BaO, ZnO, ZrO2, and other oxides, ensuring high alkali resistance (LBK 1), low thermal expansion (4.0-5.3 x 10^-6 K^-1), and high UV transmission, while maintaining mechanical and thermal strength through chemical and thermal toughening.

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of borosilicate glass durability are crucial aspects in the advanced studies of this material. Borosilicate glass, known for its exceptional chemical and thermal resistance, plays a significant role in various industries, including laboratory equipment, pharmaceutical packaging, and nuclear waste containment. Its durability directly influences its environmental footprint and long-term sustainability.

One of the primary environmental benefits of borosilicate glass is its recyclability. Unlike many other materials, borosilicate glass can be recycled indefinitely without loss of quality or purity. This characteristic significantly reduces the demand for raw materials and energy in glass production, thereby minimizing the overall environmental impact. However, the recycling process for borosilicate glass requires specialized facilities due to its higher melting point compared to soda-lime glass, which can pose challenges in some regions.

The durability of borosilicate glass also contributes to its sustainability profile. Its resistance to chemical corrosion and thermal shock means that products made from this material have longer lifespans, reducing the need for frequent replacements. This longevity translates to less waste generation and lower resource consumption over time. In applications such as laboratory glassware, the extended lifespan of borosilicate glass products significantly reduces the environmental burden associated with manufacturing and disposal.

In the context of nuclear waste storage, the durability of borosilicate glass is of paramount importance. The material's ability to immobilize radioactive waste for extended periods minimizes the risk of environmental contamination. Ongoing research focuses on enhancing the long-term stability of borosilicate glass in geological disposal conditions, aiming to ensure environmental safety for thousands of years.

However, the production of borosilicate glass does have environmental considerations. The manufacturing process requires high temperatures, resulting in significant energy consumption and associated carbon emissions. Efforts to improve the sustainability of borosilicate glass production include exploring renewable energy sources for furnaces and optimizing the melting process to reduce energy requirements.

The raw materials used in borosilicate glass production, particularly boron, also have environmental implications. Boron mining can impact local ecosystems, and its extraction and processing contribute to the overall environmental footprint of the glass. Sustainable sourcing practices and the development of alternative boron sources are areas of ongoing research to mitigate these impacts.

In conclusion, while borosilicate glass offers significant environmental benefits through its durability and recyclability, there are still challenges to address in terms of production energy intensity and raw material sourcing. Advancing studies on borosilicate glass durability not only focus on improving its performance but also on enhancing its overall sustainability profile, balancing its exceptional properties with environmental responsibility.

One of the primary environmental benefits of borosilicate glass is its recyclability. Unlike many other materials, borosilicate glass can be recycled indefinitely without loss of quality or purity. This characteristic significantly reduces the demand for raw materials and energy in glass production, thereby minimizing the overall environmental impact. However, the recycling process for borosilicate glass requires specialized facilities due to its higher melting point compared to soda-lime glass, which can pose challenges in some regions.

The durability of borosilicate glass also contributes to its sustainability profile. Its resistance to chemical corrosion and thermal shock means that products made from this material have longer lifespans, reducing the need for frequent replacements. This longevity translates to less waste generation and lower resource consumption over time. In applications such as laboratory glassware, the extended lifespan of borosilicate glass products significantly reduces the environmental burden associated with manufacturing and disposal.

In the context of nuclear waste storage, the durability of borosilicate glass is of paramount importance. The material's ability to immobilize radioactive waste for extended periods minimizes the risk of environmental contamination. Ongoing research focuses on enhancing the long-term stability of borosilicate glass in geological disposal conditions, aiming to ensure environmental safety for thousands of years.

However, the production of borosilicate glass does have environmental considerations. The manufacturing process requires high temperatures, resulting in significant energy consumption and associated carbon emissions. Efforts to improve the sustainability of borosilicate glass production include exploring renewable energy sources for furnaces and optimizing the melting process to reduce energy requirements.

The raw materials used in borosilicate glass production, particularly boron, also have environmental implications. Boron mining can impact local ecosystems, and its extraction and processing contribute to the overall environmental footprint of the glass. Sustainable sourcing practices and the development of alternative boron sources are areas of ongoing research to mitigate these impacts.

In conclusion, while borosilicate glass offers significant environmental benefits through its durability and recyclability, there are still challenges to address in terms of production energy intensity and raw material sourcing. Advancing studies on borosilicate glass durability not only focus on improving its performance but also on enhancing its overall sustainability profile, balancing its exceptional properties with environmental responsibility.

Regulatory Framework for Advanced Glass Materials

The regulatory framework for advanced glass materials, particularly in the context of borosilicate glass durability, is a complex and evolving landscape. Governments and international organizations have established various standards and guidelines to ensure the safety, quality, and performance of these materials across different applications.

In the United States, the Nuclear Regulatory Commission (NRC) plays a crucial role in setting standards for borosilicate glass used in nuclear waste containment. The NRC's regulations focus on the long-term durability of glass materials under various environmental conditions, including exposure to radiation and chemical interactions. These regulations are continuously updated based on advanced studies and new findings in glass durability.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which impacts the production and use of borosilicate glass. This comprehensive framework requires manufacturers to assess and manage the risks associated with the chemicals used in glass production, including those that may affect its durability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and evaluating the durability of borosilicate glass. These standards provide uniform methods for assessing chemical resistance, thermal shock resistance, and mechanical strength, which are critical aspects of glass durability.

In the medical and pharmaceutical sectors, regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established guidelines for borosilicate glass used in packaging and delivery systems. These regulations focus on ensuring the glass's compatibility with various drugs and its ability to maintain product integrity over time.

The construction industry also has specific regulations governing the use of advanced glass materials. Building codes in many countries now include provisions for the use of high-performance glass, including requirements for durability under various environmental conditions and safety standards for impact resistance.

As research in borosilicate glass durability advances, regulatory frameworks are expected to evolve. There is a growing emphasis on lifecycle assessments and sustainability considerations, which may lead to new regulations addressing the environmental impact of glass production and disposal. Additionally, emerging applications in fields such as energy storage and advanced electronics may necessitate the development of new regulatory standards tailored to these specific uses.

In the United States, the Nuclear Regulatory Commission (NRC) plays a crucial role in setting standards for borosilicate glass used in nuclear waste containment. The NRC's regulations focus on the long-term durability of glass materials under various environmental conditions, including exposure to radiation and chemical interactions. These regulations are continuously updated based on advanced studies and new findings in glass durability.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which impacts the production and use of borosilicate glass. This comprehensive framework requires manufacturers to assess and manage the risks associated with the chemicals used in glass production, including those that may affect its durability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and evaluating the durability of borosilicate glass. These standards provide uniform methods for assessing chemical resistance, thermal shock resistance, and mechanical strength, which are critical aspects of glass durability.

In the medical and pharmaceutical sectors, regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established guidelines for borosilicate glass used in packaging and delivery systems. These regulations focus on ensuring the glass's compatibility with various drugs and its ability to maintain product integrity over time.

The construction industry also has specific regulations governing the use of advanced glass materials. Building codes in many countries now include provisions for the use of high-performance glass, including requirements for durability under various environmental conditions and safety standards for impact resistance.

As research in borosilicate glass durability advances, regulatory frameworks are expected to evolve. There is a growing emphasis on lifecycle assessments and sustainability considerations, which may lead to new regulations addressing the environmental impact of glass production and disposal. Additionally, emerging applications in fields such as energy storage and advanced electronics may necessitate the development of new regulatory standards tailored to these specific uses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!