Bioactive Glass Ceramics Derived from Borosilicate

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate BGC Background and Objectives

Bioactive glass ceramics (BGCs) derived from borosilicate have emerged as a promising class of biomaterials in recent decades. These materials combine the bioactive properties of traditional silicate-based bioactive glasses with the unique characteristics of boron-containing glasses. The evolution of borosilicate BGCs can be traced back to the 1960s when Larry Hench developed the first bioactive glass, 45S5 Bioglass®. This discovery sparked extensive research into bioactive materials, leading to the exploration of various glass compositions, including borosilicate systems.

The incorporation of boron into bioactive glasses has been driven by the need to enhance the biological performance and tailor the degradation rates of these materials. Boron, as a trace element, plays crucial roles in bone metabolism and wound healing. Its inclusion in BGCs has shown potential to improve osteogenesis, angiogenesis, and soft tissue regeneration. The development of borosilicate BGCs aims to address limitations of conventional silicate-based bioactive glasses, such as slow degradation rates and limited ion release profiles.

The primary objectives of research on borosilicate BGCs are multifaceted. Firstly, there is a focus on optimizing the composition and structure of these materials to achieve controlled degradation rates and ion release kinetics. This is crucial for matching the material's resorption with the rate of new tissue formation. Secondly, researchers aim to enhance the mechanical properties of borosilicate BGCs, particularly for load-bearing applications in orthopedics and dentistry. The goal is to develop materials that can provide adequate support while promoting tissue regeneration.

Another key objective is to understand and manipulate the biological interactions of borosilicate BGCs at the cellular and molecular levels. This includes investigating their effects on cell adhesion, proliferation, and differentiation, as well as their ability to stimulate angiogenesis and osteogenesis. Additionally, there is growing interest in exploring the antibacterial properties of boron-containing BGCs, which could be particularly beneficial in preventing implant-associated infections.

The development of borosilicate BGCs also aligns with broader trends in biomaterials research, such as the pursuit of multifunctional materials capable of drug delivery, gene therapy, and stimuli-responsive behavior. Researchers are exploring ways to incorporate these advanced functionalities into borosilicate BGCs, aiming to create smart biomaterials that can adapt to the physiological environment and provide targeted therapeutic effects.

As the field progresses, there is an increasing emphasis on translational research, focusing on bridging the gap between laboratory discoveries and clinical applications. This involves scaling up production processes, conducting comprehensive in vivo studies, and addressing regulatory challenges associated with novel biomaterials. The ultimate goal is to develop borosilicate BGCs that can be effectively used in a wide range of clinical applications, from bone grafts and dental implants to wound healing and soft tissue engineering.

The incorporation of boron into bioactive glasses has been driven by the need to enhance the biological performance and tailor the degradation rates of these materials. Boron, as a trace element, plays crucial roles in bone metabolism and wound healing. Its inclusion in BGCs has shown potential to improve osteogenesis, angiogenesis, and soft tissue regeneration. The development of borosilicate BGCs aims to address limitations of conventional silicate-based bioactive glasses, such as slow degradation rates and limited ion release profiles.

The primary objectives of research on borosilicate BGCs are multifaceted. Firstly, there is a focus on optimizing the composition and structure of these materials to achieve controlled degradation rates and ion release kinetics. This is crucial for matching the material's resorption with the rate of new tissue formation. Secondly, researchers aim to enhance the mechanical properties of borosilicate BGCs, particularly for load-bearing applications in orthopedics and dentistry. The goal is to develop materials that can provide adequate support while promoting tissue regeneration.

Another key objective is to understand and manipulate the biological interactions of borosilicate BGCs at the cellular and molecular levels. This includes investigating their effects on cell adhesion, proliferation, and differentiation, as well as their ability to stimulate angiogenesis and osteogenesis. Additionally, there is growing interest in exploring the antibacterial properties of boron-containing BGCs, which could be particularly beneficial in preventing implant-associated infections.

The development of borosilicate BGCs also aligns with broader trends in biomaterials research, such as the pursuit of multifunctional materials capable of drug delivery, gene therapy, and stimuli-responsive behavior. Researchers are exploring ways to incorporate these advanced functionalities into borosilicate BGCs, aiming to create smart biomaterials that can adapt to the physiological environment and provide targeted therapeutic effects.

As the field progresses, there is an increasing emphasis on translational research, focusing on bridging the gap between laboratory discoveries and clinical applications. This involves scaling up production processes, conducting comprehensive in vivo studies, and addressing regulatory challenges associated with novel biomaterials. The ultimate goal is to develop borosilicate BGCs that can be effectively used in a wide range of clinical applications, from bone grafts and dental implants to wound healing and soft tissue engineering.

Market Analysis for Bioactive Glass Ceramics

The market for bioactive glass ceramics derived from borosilicate has shown significant growth potential in recent years, driven by increasing applications in healthcare and biomedicine. These materials offer unique properties that make them highly suitable for bone regeneration, dental applications, and wound healing.

In the healthcare sector, the rising prevalence of bone-related disorders and the aging population have created a substantial demand for bioactive materials. Bioactive glass ceramics derived from borosilicate have gained traction due to their ability to bond with living tissues and promote bone growth. The global bone graft substitute market, where these materials play a crucial role, is experiencing steady growth.

The dental industry represents another key market for bioactive glass ceramics. With the increasing focus on aesthetic dentistry and the growing number of dental procedures worldwide, the demand for biocompatible and bioactive materials has surged. Bioactive glass ceramics are being increasingly used in dental implants, fillings, and restorative procedures.

In the wound care segment, bioactive glass ceramics have shown promise in accelerating wound healing and reducing infection risks. This application is particularly relevant in treating chronic wounds, burns, and diabetic ulcers. The global wound care market's expansion further supports the growth prospects for these materials.

The market for bioactive glass ceramics is also benefiting from advancements in material science and manufacturing technologies. Improved production techniques have led to enhanced material properties and reduced costs, making these ceramics more accessible for various applications.

Geographically, North America and Europe currently dominate the market due to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing healthcare expenditure, growing awareness, and improving medical facilities.

Despite the positive outlook, the market faces challenges such as high production costs and stringent regulatory requirements for medical-grade materials. These factors may impact market growth and adoption rates, particularly in emerging economies.

Looking ahead, the market for bioactive glass ceramics derived from borosilicate is projected to continue its growth trajectory. Factors such as ongoing research and development activities, expanding applications in tissue engineering, and the shift towards personalized medicine are expected to create new opportunities in this market.

In the healthcare sector, the rising prevalence of bone-related disorders and the aging population have created a substantial demand for bioactive materials. Bioactive glass ceramics derived from borosilicate have gained traction due to their ability to bond with living tissues and promote bone growth. The global bone graft substitute market, where these materials play a crucial role, is experiencing steady growth.

The dental industry represents another key market for bioactive glass ceramics. With the increasing focus on aesthetic dentistry and the growing number of dental procedures worldwide, the demand for biocompatible and bioactive materials has surged. Bioactive glass ceramics are being increasingly used in dental implants, fillings, and restorative procedures.

In the wound care segment, bioactive glass ceramics have shown promise in accelerating wound healing and reducing infection risks. This application is particularly relevant in treating chronic wounds, burns, and diabetic ulcers. The global wound care market's expansion further supports the growth prospects for these materials.

The market for bioactive glass ceramics is also benefiting from advancements in material science and manufacturing technologies. Improved production techniques have led to enhanced material properties and reduced costs, making these ceramics more accessible for various applications.

Geographically, North America and Europe currently dominate the market due to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing healthcare expenditure, growing awareness, and improving medical facilities.

Despite the positive outlook, the market faces challenges such as high production costs and stringent regulatory requirements for medical-grade materials. These factors may impact market growth and adoption rates, particularly in emerging economies.

Looking ahead, the market for bioactive glass ceramics derived from borosilicate is projected to continue its growth trajectory. Factors such as ongoing research and development activities, expanding applications in tissue engineering, and the shift towards personalized medicine are expected to create new opportunities in this market.

Current Challenges in Borosilicate BGC Development

The development of borosilicate bioactive glass ceramics (BGCs) faces several significant challenges that hinder their widespread application in biomedical fields. One of the primary obstacles is achieving optimal bioactivity while maintaining mechanical strength. Borosilicate BGCs often exhibit enhanced bioactivity compared to traditional silicate-based BGCs, but this comes at the cost of reduced mechanical properties, limiting their use in load-bearing applications.

Another challenge lies in controlling the degradation rate of borosilicate BGCs. While faster dissolution can promote rapid bone formation, it may also lead to premature loss of structural integrity. Balancing the degradation kinetics with the rate of new tissue formation remains a complex task, requiring precise tailoring of glass composition and microstructure.

The incorporation of therapeutic ions into borosilicate BGCs presents both opportunities and challenges. While these ions can enhance biological responses, their release profiles must be carefully controlled to avoid potential cytotoxicity or undesired systemic effects. Achieving a sustained and controlled release of therapeutic ions over extended periods is an ongoing area of research.

Manufacturing processes for borosilicate BGCs also pose significant challenges. Traditional melting techniques may lead to the volatilization of boron, altering the final composition and properties of the material. Alternative synthesis methods, such as sol-gel processing, require careful optimization to ensure homogeneity and reproducibility of the final product.

The long-term in vivo behavior of borosilicate BGCs remains an area of uncertainty. While short-term studies have shown promising results, comprehensive long-term evaluations are needed to fully understand their degradation patterns, tissue interactions, and potential adverse effects over extended periods.

Scalability and cost-effectiveness present additional hurdles in the commercialization of borosilicate BGCs. Developing economically viable production methods that can meet the stringent quality requirements for medical-grade materials is crucial for their widespread adoption in clinical applications.

Lastly, regulatory challenges persist in the approval process for novel borosilicate BGC-based medical devices. The unique composition and behavior of these materials may require extensive safety and efficacy studies to meet regulatory standards, potentially prolonging the time-to-market for innovative products in this field.

Another challenge lies in controlling the degradation rate of borosilicate BGCs. While faster dissolution can promote rapid bone formation, it may also lead to premature loss of structural integrity. Balancing the degradation kinetics with the rate of new tissue formation remains a complex task, requiring precise tailoring of glass composition and microstructure.

The incorporation of therapeutic ions into borosilicate BGCs presents both opportunities and challenges. While these ions can enhance biological responses, their release profiles must be carefully controlled to avoid potential cytotoxicity or undesired systemic effects. Achieving a sustained and controlled release of therapeutic ions over extended periods is an ongoing area of research.

Manufacturing processes for borosilicate BGCs also pose significant challenges. Traditional melting techniques may lead to the volatilization of boron, altering the final composition and properties of the material. Alternative synthesis methods, such as sol-gel processing, require careful optimization to ensure homogeneity and reproducibility of the final product.

The long-term in vivo behavior of borosilicate BGCs remains an area of uncertainty. While short-term studies have shown promising results, comprehensive long-term evaluations are needed to fully understand their degradation patterns, tissue interactions, and potential adverse effects over extended periods.

Scalability and cost-effectiveness present additional hurdles in the commercialization of borosilicate BGCs. Developing economically viable production methods that can meet the stringent quality requirements for medical-grade materials is crucial for their widespread adoption in clinical applications.

Lastly, regulatory challenges persist in the approval process for novel borosilicate BGC-based medical devices. The unique composition and behavior of these materials may require extensive safety and efficacy studies to meet regulatory standards, potentially prolonging the time-to-market for innovative products in this field.

Existing Borosilicate BGC Synthesis Methods

01 Composition and preparation of bioactive glass ceramics

Bioactive glass ceramics are composed of specific materials and prepared through various methods to achieve desired properties. These materials often include silica, calcium oxide, and phosphorus pentoxide in specific ratios. The preparation process may involve melting, quenching, and heat treatment to control crystallization and bioactivity.- Composition and preparation of bioactive glass ceramics: Bioactive glass ceramics are composed of specific materials and prepared through various methods to achieve desired properties. These materials often include silica, calcium oxide, and phosphorus pentoxide in specific ratios. The preparation process may involve melting, quenching, and heat treatment to control crystallization and bioactivity.

- Applications in bone tissue engineering and regeneration: Bioactive glass ceramics are widely used in bone tissue engineering and regeneration due to their ability to bond with living bone tissue. They can be used as scaffolds, coatings, or fillers to promote bone growth and repair. These materials stimulate osteoblast proliferation and differentiation, enhancing bone formation.

- Drug delivery systems using bioactive glass ceramics: Bioactive glass ceramics can be used as carriers for drug delivery systems. Their porous structure and controlled dissolution rate allow for the incorporation and release of various therapeutic agents. This application is particularly useful in treating bone-related diseases and infections.

- Surface modifications and coatings: The surface of bioactive glass ceramics can be modified or coated to enhance their properties and performance. These modifications may include the addition of functional groups, incorporation of nanoparticles, or application of bioactive coatings. Such treatments can improve biocompatibility, mechanical strength, and specific biological responses.

- Novel compositions and manufacturing processes: Ongoing research focuses on developing novel compositions and manufacturing processes for bioactive glass ceramics. These innovations aim to improve mechanical properties, bioactivity, and processability. New techniques may include sol-gel methods, 3D printing, or the incorporation of novel elements to enhance specific properties.

02 Applications in bone tissue engineering and regeneration

Bioactive glass ceramics are widely used in bone tissue engineering and regeneration due to their ability to bond with living bone tissue. They can be used as scaffolds, coatings, or fillers to promote bone growth and repair. These materials stimulate osteoblast proliferation and differentiation, enhancing bone formation.Expand Specific Solutions03 Drug delivery systems using bioactive glass ceramics

Bioactive glass ceramics can be used as carriers for drug delivery systems. Their porous structure and controlled dissolution rate allow for the incorporation and release of various therapeutic agents. This application is particularly useful in treating bone-related diseases and infections.Expand Specific Solutions04 Surface modifications and coatings

The surface of bioactive glass ceramics can be modified or coated to enhance their properties and performance. These modifications can improve biocompatibility, mechanical strength, or specific biological responses. Techniques such as ion implantation, plasma spraying, or chemical treatments are used to achieve desired surface characteristics.Expand Specific Solutions05 Composite materials with bioactive glass ceramics

Bioactive glass ceramics can be combined with other materials to create composites with enhanced properties. These composites may incorporate polymers, metals, or other ceramics to improve mechanical strength, flexibility, or specific biological responses. Such composites find applications in various biomedical fields, including orthopedics and dentistry.Expand Specific Solutions

Key Players in BGC Research and Production

The research on bioactive glass ceramics derived from borosilicate is in a growth phase, with increasing market potential and technological advancements. The global bioactive glass market is expanding, driven by applications in orthopedics, dentistry, and tissue engineering. While the technology is maturing, there's still room for innovation. Key players like Corning, Inc., SCHOTT AG, and NovaBone Products LLC are leading the field, leveraging their expertise in glass and biomaterials. Academic institutions such as Tongji University and Sichuan University are contributing to research and development, fostering industry-academia collaborations. The competitive landscape is diverse, with both established companies and emerging startups vying for market share and technological breakthroughs.

Corning, Inc.

Technical Solution: Corning has developed advanced borosilicate glass ceramics for biomedical applications. Their research focuses on tailoring the composition and microstructure to enhance bioactivity and mechanical properties. They have successfully created bioactive glass ceramics with controlled porosity and degradation rates, suitable for bone tissue engineering[1]. Corning's approach involves a two-step heat treatment process to achieve optimal crystallization and bioactive phase formation. Their materials demonstrate excellent osteoconductivity and the ability to form a hydroxyapatite layer when exposed to simulated body fluid[3]. Recent developments include incorporating therapeutic ions like strontium and zinc to enhance bone regeneration capabilities[5].

Strengths: Extensive experience in glass manufacturing, strong R&D capabilities, and established market presence. Weaknesses: Potential high production costs and regulatory hurdles for medical-grade materials.

SCHOTT AG

Technical Solution: SCHOTT AG has made significant strides in bioactive glass ceramics derived from borosilicate. Their research focuses on developing materials with controlled ion release profiles for enhanced bioactivity. SCHOTT's approach involves precise control of glass composition and heat treatment processes to achieve desired crystallization and bioactive properties[2]. They have successfully created bioactive glass ceramics with tailored degradation rates and mechanical strengths suitable for various biomedical applications, including dental and orthopedic implants[4]. SCHOTT's materials demonstrate excellent biocompatibility and the ability to stimulate bone cell proliferation and differentiation[6]. Recent innovations include the development of bioactive glass ceramics with antimicrobial properties through the incorporation of silver ions[8].

Strengths: Strong expertise in specialty glass and glass-ceramics, global presence, and established relationships with medical device manufacturers. Weaknesses: Potential challenges in scaling up production for specialized biomedical applications.

Innovations in Borosilicate-derived BGC

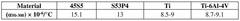

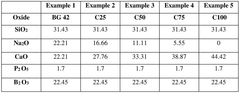

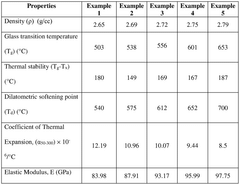

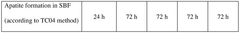

Novel borosilicate based bioactive glass for coating on ti-6al-4v implants and its process thereof

PatentWO2025083707A1

Innovation

- Development of novel borosilicate bioactive glass compositions with a thermal expansion coefficient matching that of Ti-6A1-4V, high thermal stability to prevent devitrification, and fast in vitro bioactivity, applied via a simple cold spraying and sintering process.

Medical and Dental Bioceramic Composition for Temporary Use

PatentPendingUS20220202659A1

Innovation

- A bioceramic composition comprising a complexing resin derived from salicylic acid ester and a metal ions source, which forms a cationic complex upon contact with a saline solution, providing controlled release of metal ions and hydroxyl ions, promoting bioactive, antimicrobial, and anti-inflammatory properties without setting, suitable for temporary intracanal use.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development and application of bioactive glass ceramics derived from borosilicate. These materials, designed for use in medical and dental applications, must undergo rigorous testing to ensure their safety and efficacy in biological environments.

One of the primary concerns in biocompatibility is the potential for adverse reactions when the material comes into contact with living tissues. Borosilicate-derived bioactive glass ceramics have shown promising results in this regard, with studies indicating minimal inflammatory responses and good integration with surrounding tissues. The controlled release of ions, such as calcium and silicon, from these materials can promote bone formation and tissue regeneration without causing toxicity.

However, the long-term effects of these materials on the body must be carefully evaluated. This includes assessing the potential for degradation products to accumulate in organs or tissues over time. Researchers have focused on optimizing the composition and structure of bioactive glass ceramics to ensure controlled dissolution rates that match the pace of tissue regeneration.

The safety profile of borosilicate-derived bioactive glass ceramics extends beyond biocompatibility to include mechanical stability and structural integrity. These materials must maintain their properties under physiological conditions without compromising their function or releasing harmful particles. Extensive in vitro and in vivo studies have been conducted to evaluate the mechanical behavior and degradation characteristics of these materials in simulated biological environments.

Another critical aspect of safety considerations is the sterilization process. Bioactive glass ceramics must be able to withstand standard sterilization methods without altering their physical, chemical, or biological properties. Research has shown that these materials generally maintain their bioactivity and structural integrity after common sterilization techniques such as autoclaving or gamma irradiation.

The potential for bacterial adhesion and biofilm formation on the surface of bioactive glass ceramics is also a significant safety concern. Studies have investigated the antimicrobial properties of these materials, with some compositions showing inherent ability to inhibit bacterial growth. This characteristic could be particularly beneficial in reducing the risk of implant-associated infections.

Regulatory compliance is a crucial component of safety considerations for bioactive glass ceramics. Manufacturers must adhere to strict guidelines set by regulatory bodies such as the FDA and EMA, which require comprehensive documentation of safety and efficacy data. This includes detailed information on material composition, manufacturing processes, and quality control measures.

One of the primary concerns in biocompatibility is the potential for adverse reactions when the material comes into contact with living tissues. Borosilicate-derived bioactive glass ceramics have shown promising results in this regard, with studies indicating minimal inflammatory responses and good integration with surrounding tissues. The controlled release of ions, such as calcium and silicon, from these materials can promote bone formation and tissue regeneration without causing toxicity.

However, the long-term effects of these materials on the body must be carefully evaluated. This includes assessing the potential for degradation products to accumulate in organs or tissues over time. Researchers have focused on optimizing the composition and structure of bioactive glass ceramics to ensure controlled dissolution rates that match the pace of tissue regeneration.

The safety profile of borosilicate-derived bioactive glass ceramics extends beyond biocompatibility to include mechanical stability and structural integrity. These materials must maintain their properties under physiological conditions without compromising their function or releasing harmful particles. Extensive in vitro and in vivo studies have been conducted to evaluate the mechanical behavior and degradation characteristics of these materials in simulated biological environments.

Another critical aspect of safety considerations is the sterilization process. Bioactive glass ceramics must be able to withstand standard sterilization methods without altering their physical, chemical, or biological properties. Research has shown that these materials generally maintain their bioactivity and structural integrity after common sterilization techniques such as autoclaving or gamma irradiation.

The potential for bacterial adhesion and biofilm formation on the surface of bioactive glass ceramics is also a significant safety concern. Studies have investigated the antimicrobial properties of these materials, with some compositions showing inherent ability to inhibit bacterial growth. This characteristic could be particularly beneficial in reducing the risk of implant-associated infections.

Regulatory compliance is a crucial component of safety considerations for bioactive glass ceramics. Manufacturers must adhere to strict guidelines set by regulatory bodies such as the FDA and EMA, which require comprehensive documentation of safety and efficacy data. This includes detailed information on material composition, manufacturing processes, and quality control measures.

Environmental Impact of BGC Production

The production of bioactive glass ceramics (BGCs) derived from borosilicate has significant environmental implications that warrant careful consideration. The manufacturing process of BGCs involves high-temperature melting and subsequent heat treatments, which consume substantial amounts of energy. This energy-intensive production contributes to greenhouse gas emissions and carbon footprint, particularly when non-renewable energy sources are utilized.

Raw material extraction for BGCs, including boron and silica, can lead to habitat disruption and soil erosion in mining areas. However, the use of recycled glass as a precursor material for BGCs offers a promising avenue for reducing the environmental impact associated with raw material procurement. This approach not only minimizes waste but also decreases the demand for virgin resources.

Water consumption during the production of BGCs is another environmental concern. The cooling processes and cleaning of equipment require significant water usage, potentially straining local water resources. Implementing closed-loop water systems and water-efficient technologies can help mitigate this impact.

The release of particulate matter and volatile compounds during BGC production may contribute to air pollution if not properly controlled. Advanced filtration systems and emission control technologies are essential to minimize these environmental hazards and ensure compliance with air quality regulations.

On a positive note, the biocompatibility and biodegradability of BGCs contribute to their environmental friendliness in medical applications. Unlike some synthetic materials, BGCs can be safely absorbed by the body over time, reducing long-term environmental impact from medical waste.

The production of BGCs also generates waste materials, including off-specification products and processing residues. Developing efficient recycling methods for these waste products within the manufacturing process can significantly reduce the overall environmental footprint of BGC production.

As the demand for BGCs in medical and dental applications grows, scaling up production while minimizing environmental impact becomes crucial. Research into more energy-efficient melting techniques, such as sol-gel processes or microwave-assisted sintering, shows promise in reducing the energy intensity of BGC manufacturing.

In conclusion, while the production of bioactive glass ceramics from borosilicate presents several environmental challenges, ongoing research and technological advancements offer opportunities to mitigate these impacts. Balancing the medical benefits of BGCs with sustainable production practices remains a key focus for the industry's future development.

Raw material extraction for BGCs, including boron and silica, can lead to habitat disruption and soil erosion in mining areas. However, the use of recycled glass as a precursor material for BGCs offers a promising avenue for reducing the environmental impact associated with raw material procurement. This approach not only minimizes waste but also decreases the demand for virgin resources.

Water consumption during the production of BGCs is another environmental concern. The cooling processes and cleaning of equipment require significant water usage, potentially straining local water resources. Implementing closed-loop water systems and water-efficient technologies can help mitigate this impact.

The release of particulate matter and volatile compounds during BGC production may contribute to air pollution if not properly controlled. Advanced filtration systems and emission control technologies are essential to minimize these environmental hazards and ensure compliance with air quality regulations.

On a positive note, the biocompatibility and biodegradability of BGCs contribute to their environmental friendliness in medical applications. Unlike some synthetic materials, BGCs can be safely absorbed by the body over time, reducing long-term environmental impact from medical waste.

The production of BGCs also generates waste materials, including off-specification products and processing residues. Developing efficient recycling methods for these waste products within the manufacturing process can significantly reduce the overall environmental footprint of BGC production.

As the demand for BGCs in medical and dental applications grows, scaling up production while minimizing environmental impact becomes crucial. Research into more energy-efficient melting techniques, such as sol-gel processes or microwave-assisted sintering, shows promise in reducing the energy intensity of BGC manufacturing.

In conclusion, while the production of bioactive glass ceramics from borosilicate presents several environmental challenges, ongoing research and technological advancements offer opportunities to mitigate these impacts. Balancing the medical benefits of BGCs with sustainable production practices remains a key focus for the industry's future development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!