Nanotechnology Integration with Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology and Borosilicate Glass Integration Objectives

The integration of nanotechnology with borosilicate glass represents a cutting-edge research area with immense potential for technological advancement. This fusion aims to enhance the inherent properties of borosilicate glass, known for its thermal resistance and chemical durability, by incorporating nanoscale materials and structures. The primary objective is to develop novel materials with superior characteristics, combining the best attributes of both nanotechnology and borosilicate glass.

One key goal is to improve the mechanical strength of borosilicate glass through nanostructuring. By introducing nanoparticles or creating nanoscale surface patterns, researchers aim to enhance the glass's resistance to fracture and scratching. This could lead to more durable and longer-lasting glass products for various applications, from laboratory equipment to consumer electronics.

Another critical objective is to enhance the optical properties of borosilicate glass. Nanotechnology integration can potentially modify the refractive index, increase light transmission, or create specific light-scattering effects. These improvements could revolutionize applications in optics, photonics, and solar energy harvesting.

The research also focuses on developing smart glass capabilities. By incorporating responsive nanomaterials, the goal is to create borosilicate glass that can change its properties in response to external stimuli such as light, temperature, or electrical signals. This could lead to applications in smart windows, adaptive optics, and advanced sensing devices.

Enhancing the chemical resistance of borosilicate glass is another important objective. Nanotechnology could be used to create protective coatings or modify the glass surface at the nanoscale, potentially expanding its use in harsh chemical environments or improving its performance in pharmaceutical and biotechnology applications.

Researchers are also exploring ways to impart new functionalities to borosilicate glass. This includes developing self-cleaning surfaces, antimicrobial properties, or even electrical conductivity while maintaining the glass's transparency. Such advancements could open up new applications in fields like healthcare, electronics, and energy storage.

The ultimate aim of this research is to push the boundaries of material science, creating a new class of advanced glass materials that combine the best properties of nanotechnology and borosilicate glass. This could lead to transformative innovations across multiple industries, from advanced manufacturing to renewable energy technologies, and contribute to solving some of the most pressing technological challenges of our time.

One key goal is to improve the mechanical strength of borosilicate glass through nanostructuring. By introducing nanoparticles or creating nanoscale surface patterns, researchers aim to enhance the glass's resistance to fracture and scratching. This could lead to more durable and longer-lasting glass products for various applications, from laboratory equipment to consumer electronics.

Another critical objective is to enhance the optical properties of borosilicate glass. Nanotechnology integration can potentially modify the refractive index, increase light transmission, or create specific light-scattering effects. These improvements could revolutionize applications in optics, photonics, and solar energy harvesting.

The research also focuses on developing smart glass capabilities. By incorporating responsive nanomaterials, the goal is to create borosilicate glass that can change its properties in response to external stimuli such as light, temperature, or electrical signals. This could lead to applications in smart windows, adaptive optics, and advanced sensing devices.

Enhancing the chemical resistance of borosilicate glass is another important objective. Nanotechnology could be used to create protective coatings or modify the glass surface at the nanoscale, potentially expanding its use in harsh chemical environments or improving its performance in pharmaceutical and biotechnology applications.

Researchers are also exploring ways to impart new functionalities to borosilicate glass. This includes developing self-cleaning surfaces, antimicrobial properties, or even electrical conductivity while maintaining the glass's transparency. Such advancements could open up new applications in fields like healthcare, electronics, and energy storage.

The ultimate aim of this research is to push the boundaries of material science, creating a new class of advanced glass materials that combine the best properties of nanotechnology and borosilicate glass. This could lead to transformative innovations across multiple industries, from advanced manufacturing to renewable energy technologies, and contribute to solving some of the most pressing technological challenges of our time.

Market Analysis for Nano-Enhanced Borosilicate Products

The integration of nanotechnology with borosilicate glass has opened up new avenues for product innovation and market expansion. The global market for nano-enhanced borosilicate products is experiencing significant growth, driven by increasing demand across various industries such as healthcare, electronics, and energy.

In the healthcare sector, nano-enhanced borosilicate glass is finding applications in advanced drug delivery systems, biosensors, and medical implants. The improved biocompatibility and controlled release properties offered by these materials are attracting substantial investment from pharmaceutical companies and medical device manufacturers.

The electronics industry is another key market for nano-enhanced borosilicate products. With the miniaturization trend in electronic devices, there is a growing need for materials that can provide enhanced thermal and electrical properties while maintaining transparency. Nano-enhanced borosilicate glass meets these requirements, making it an attractive option for manufacturers of displays, touchscreens, and other electronic components.

Energy sector applications, particularly in solar energy and battery technologies, are also driving market growth. Nano-enhanced borosilicate glass offers improved efficiency in solar panels and enhanced performance in battery separators, contributing to the development of more sustainable energy solutions.

The market for nano-enhanced borosilicate products is geographically diverse, with significant demand in North America, Europe, and Asia-Pacific regions. The Asia-Pacific market, in particular, is expected to show the highest growth rate due to rapid industrialization and increasing investment in research and development activities.

Key market players include established glass manufacturers who have invested in nanotechnology research, as well as specialized nanotechnology firms collaborating with glass producers. These companies are focusing on developing proprietary nano-enhancement techniques to differentiate their products and gain a competitive edge.

Consumer trends indicate a growing preference for high-performance materials with multifunctional properties. This aligns well with the capabilities of nano-enhanced borosilicate glass, which can offer combinations of strength, thermal resistance, and specialized surface properties tailored to specific applications.

Regulatory considerations play a crucial role in market development, particularly in sectors like healthcare and food packaging. As nanotechnology evolves, regulatory bodies are developing new guidelines for the use of nanomaterials, which may impact market growth and product development strategies.

In the healthcare sector, nano-enhanced borosilicate glass is finding applications in advanced drug delivery systems, biosensors, and medical implants. The improved biocompatibility and controlled release properties offered by these materials are attracting substantial investment from pharmaceutical companies and medical device manufacturers.

The electronics industry is another key market for nano-enhanced borosilicate products. With the miniaturization trend in electronic devices, there is a growing need for materials that can provide enhanced thermal and electrical properties while maintaining transparency. Nano-enhanced borosilicate glass meets these requirements, making it an attractive option for manufacturers of displays, touchscreens, and other electronic components.

Energy sector applications, particularly in solar energy and battery technologies, are also driving market growth. Nano-enhanced borosilicate glass offers improved efficiency in solar panels and enhanced performance in battery separators, contributing to the development of more sustainable energy solutions.

The market for nano-enhanced borosilicate products is geographically diverse, with significant demand in North America, Europe, and Asia-Pacific regions. The Asia-Pacific market, in particular, is expected to show the highest growth rate due to rapid industrialization and increasing investment in research and development activities.

Key market players include established glass manufacturers who have invested in nanotechnology research, as well as specialized nanotechnology firms collaborating with glass producers. These companies are focusing on developing proprietary nano-enhancement techniques to differentiate their products and gain a competitive edge.

Consumer trends indicate a growing preference for high-performance materials with multifunctional properties. This aligns well with the capabilities of nano-enhanced borosilicate glass, which can offer combinations of strength, thermal resistance, and specialized surface properties tailored to specific applications.

Regulatory considerations play a crucial role in market development, particularly in sectors like healthcare and food packaging. As nanotechnology evolves, regulatory bodies are developing new guidelines for the use of nanomaterials, which may impact market growth and product development strategies.

Current Challenges in Nano-Borosilicate Integration

The integration of nanotechnology with borosilicate glass presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of nanoparticles within the glass matrix. The tendency of nanoparticles to agglomerate due to their high surface energy can lead to inhomogeneous distribution, compromising the desired properties of the nano-enhanced glass.

Another major challenge lies in maintaining the transparency of borosilicate glass while incorporating nanoparticles. The introduction of nanoparticles can cause light scattering, potentially reducing the optical clarity that is a key characteristic of borosilicate glass. Balancing the concentration of nanoparticles to achieve desired functional properties without significantly impacting transparency remains a complex task.

The thermal stability of nanoparticles during the glass melting and forming processes poses yet another hurdle. Many nanoparticles can degrade or lose their unique properties at the high temperatures required for glass production. This necessitates the development of thermally stable nanoparticles or alternative incorporation methods that do not compromise the integrity of the nanostructures.

Interface compatibility between the nanoparticles and the glass matrix is crucial for ensuring the longevity and performance of nano-enhanced borosilicate glass. Poor interfacial bonding can lead to particle detachment, compromising the mechanical and functional properties of the composite material. Developing surface modification techniques to improve nanoparticle-glass interactions remains an active area of research.

The potential for nanoparticle leaching from the glass matrix, especially in applications involving contact with liquids or harsh environments, is a significant concern. Ensuring the long-term stability and containment of nanoparticles within the glass structure is essential for both performance and safety considerations.

Scalability and cost-effectiveness of nano-borosilicate integration processes present additional challenges. While laboratory-scale production may yield promising results, translating these techniques to industrial-scale manufacturing while maintaining quality and economic viability remains a substantial hurdle.

Lastly, the characterization and quality control of nano-enhanced borosilicate glass products pose unique challenges. Developing reliable and efficient methods to assess the distribution, size, and properties of nanoparticles within the glass matrix, as well as the overall performance of the composite material, is crucial for advancing this technology towards practical applications.

Another major challenge lies in maintaining the transparency of borosilicate glass while incorporating nanoparticles. The introduction of nanoparticles can cause light scattering, potentially reducing the optical clarity that is a key characteristic of borosilicate glass. Balancing the concentration of nanoparticles to achieve desired functional properties without significantly impacting transparency remains a complex task.

The thermal stability of nanoparticles during the glass melting and forming processes poses yet another hurdle. Many nanoparticles can degrade or lose their unique properties at the high temperatures required for glass production. This necessitates the development of thermally stable nanoparticles or alternative incorporation methods that do not compromise the integrity of the nanostructures.

Interface compatibility between the nanoparticles and the glass matrix is crucial for ensuring the longevity and performance of nano-enhanced borosilicate glass. Poor interfacial bonding can lead to particle detachment, compromising the mechanical and functional properties of the composite material. Developing surface modification techniques to improve nanoparticle-glass interactions remains an active area of research.

The potential for nanoparticle leaching from the glass matrix, especially in applications involving contact with liquids or harsh environments, is a significant concern. Ensuring the long-term stability and containment of nanoparticles within the glass structure is essential for both performance and safety considerations.

Scalability and cost-effectiveness of nano-borosilicate integration processes present additional challenges. While laboratory-scale production may yield promising results, translating these techniques to industrial-scale manufacturing while maintaining quality and economic viability remains a substantial hurdle.

Lastly, the characterization and quality control of nano-enhanced borosilicate glass products pose unique challenges. Developing reliable and efficient methods to assess the distribution, size, and properties of nanoparticles within the glass matrix, as well as the overall performance of the composite material, is crucial for advancing this technology towards practical applications.

Existing Nano-Integration Methods for Borosilicate

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and flasks, due to its chemical resistance and thermal stability. It is also utilized in industrial applications, including sight glasses, process vessels, and piping systems. The material's durability and transparency make it ideal for these demanding environments.

- Borosilicate glass in consumer products: Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and home appliances. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The material's clarity and ability to withstand temperature changes also make it popular in lighting fixtures and decorative items.

- Innovations and modifications in borosilicate glass: Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to tailor the glass for specific uses.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, level gauges, and process vessels, where its durability and transparency are advantageous.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in cookware and bakeware. Its low thermal expansion makes it resistant to thermal shock, allowing for use in both hot and cold temperatures. Additionally, it is utilized in high-end drinkware, storage containers, and even smartphone screen protectors due to its durability and scratch resistance.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to tailor the glass for specific uses.Expand Specific Solutions

Key Players in Nano-Glass Research and Development

The integration of nanotechnology with borosilicate glass is an emerging field in the advanced materials sector, currently in its early development stage. The market size is growing but still relatively small, with potential applications across various industries including pharmaceuticals, electronics, and optics. The technology's maturity is progressing, with key players like SCHOTT AG, Corning, Inc., and AGC, Inc. leading research and development efforts. These companies are leveraging their expertise in specialty glass to explore nano-scale modifications and enhancements. Academic institutions such as Wuhan University of Technology and research organizations like the Council of Scientific & Industrial Research are also contributing to advancements in this field, indicating a collaborative approach to innovation. As the technology evolves, we can expect increased commercial applications and market expansion in the coming years.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced nanotechnology integration with borosilicate glass, focusing on enhancing material properties and functionalities. Their approach involves incorporating nanoparticles into the glass matrix during the melting process, resulting in nanocomposite materials with improved mechanical, optical, and chemical properties[1]. SCHOTT has successfully implemented nano-coatings on borosilicate glass surfaces, enhancing scratch resistance and anti-reflective properties[2]. They have also explored the use of nanostructured borosilicate glass for biomedical applications, such as drug delivery systems and tissue engineering scaffolds[3]. SCHOTT's research extends to developing smart glass solutions by integrating nanoelectronics within borosilicate glass substrates, enabling applications in display technologies and sensors[4].

Strengths: Extensive experience in glass manufacturing, strong R&D capabilities, and a wide range of applications. Weaknesses: High production costs and potential scalability issues for some nano-integrated products.

Corning, Inc.

Technical Solution: Corning has made significant strides in nanotechnology integration with borosilicate glass, focusing on enhancing material properties and developing novel applications. Their approach involves the use of nanoparticle doping and surface modification techniques to create advanced glass composites[1]. Corning has developed nano-engineered borosilicate glass with improved thermal and mechanical properties, suitable for high-performance applications in electronics and aerospace industries[2]. They have also explored the integration of nanostructures within borosilicate glass to create photonic devices and optical waveguides[3]. Corning's research extends to the development of nanoporosity in borosilicate glass, enabling applications in filtration, catalysis, and energy storage[4]. Additionally, they have investigated the use of nanotechnology to enhance the chemical durability and biocompatibility of borosilicate glass for pharmaceutical packaging and biomedical devices[5].

Strengths: Strong research capabilities, diverse product portfolio, and established market presence. Weaknesses: High R&D costs and potential regulatory challenges for some nano-integrated products.

Breakthrough Nanotech Innovations for Borosilicate

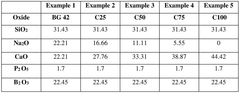

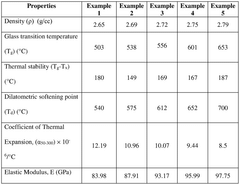

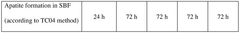

Novel borosilicate based bioactive glass for coating on ti-6al-4v implants and its process thereof

PatentWO2025083707A1

Innovation

- Development of novel borosilicate bioactive glass compositions with a thermal expansion coefficient matching that of Ti-6A1-4V, high thermal stability to prevent devitrification, and fast in vitro bioactivity, applied via a simple cold spraying and sintering process.

Method for the production of borosilicate glass with a surface suitable for modification, glass obtained according to said method and the use thereof

PatentWO2003045862A2

Innovation

- Introducing water into molten borosilicate glass, particularly using water of crystallization and gaseous water in a high-water-content atmosphere, to create a glass with a high concentration of reactive SiOH groups, enhancing surface reactivity and reducing fluorescence.

Environmental Impact of Nano-Enhanced Glass Production

The integration of nanotechnology with borosilicate glass production presents both opportunities and challenges from an environmental perspective. While nano-enhanced glass offers potential benefits in terms of improved performance and durability, the production process and end-of-life disposal raise important environmental considerations.

One of the primary environmental concerns is the increased energy consumption during the manufacturing process. The incorporation of nanoparticles into borosilicate glass often requires higher melting temperatures and longer processing times, leading to greater energy usage and associated greenhouse gas emissions. This increased energy demand may partially offset the environmental benefits gained from the enhanced properties of the final product.

The use of nanomaterials in glass production also introduces potential risks of nanoparticle release into the environment. During manufacturing, there is a possibility of nanoparticle emissions through air or water discharges. Proper filtration and containment systems are crucial to minimize these releases and protect both workers and the surrounding ecosystem.

Water usage and contamination are additional environmental factors to consider. The production of nano-enhanced borosilicate glass may require more water for cooling and cleaning processes. Furthermore, the presence of nanoparticles in wastewater can complicate treatment procedures and potentially impact aquatic ecosystems if not properly managed.

End-of-life disposal of nano-enhanced glass products poses unique challenges. While traditional borosilicate glass is highly recyclable, the presence of nanoparticles may complicate recycling processes or render the material unsuitable for conventional recycling methods. This could lead to increased landfill disposal or the need for specialized recycling facilities, potentially increasing the environmental footprint of these products.

On the positive side, the enhanced properties of nano-enhanced borosilicate glass can contribute to environmental benefits in certain applications. For instance, improved thermal insulation properties in windows can lead to reduced energy consumption in buildings. Similarly, increased durability and scratch resistance may extend the lifespan of glass products, reducing the need for frequent replacements and associated resource consumption.

The production of nanomaterials used in glass enhancement also warrants environmental scrutiny. The extraction and processing of raw materials for nanoparticle production can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. A comprehensive life cycle assessment is necessary to fully understand the environmental implications of nano-enhanced glass production.

One of the primary environmental concerns is the increased energy consumption during the manufacturing process. The incorporation of nanoparticles into borosilicate glass often requires higher melting temperatures and longer processing times, leading to greater energy usage and associated greenhouse gas emissions. This increased energy demand may partially offset the environmental benefits gained from the enhanced properties of the final product.

The use of nanomaterials in glass production also introduces potential risks of nanoparticle release into the environment. During manufacturing, there is a possibility of nanoparticle emissions through air or water discharges. Proper filtration and containment systems are crucial to minimize these releases and protect both workers and the surrounding ecosystem.

Water usage and contamination are additional environmental factors to consider. The production of nano-enhanced borosilicate glass may require more water for cooling and cleaning processes. Furthermore, the presence of nanoparticles in wastewater can complicate treatment procedures and potentially impact aquatic ecosystems if not properly managed.

End-of-life disposal of nano-enhanced glass products poses unique challenges. While traditional borosilicate glass is highly recyclable, the presence of nanoparticles may complicate recycling processes or render the material unsuitable for conventional recycling methods. This could lead to increased landfill disposal or the need for specialized recycling facilities, potentially increasing the environmental footprint of these products.

On the positive side, the enhanced properties of nano-enhanced borosilicate glass can contribute to environmental benefits in certain applications. For instance, improved thermal insulation properties in windows can lead to reduced energy consumption in buildings. Similarly, increased durability and scratch resistance may extend the lifespan of glass products, reducing the need for frequent replacements and associated resource consumption.

The production of nanomaterials used in glass enhancement also warrants environmental scrutiny. The extraction and processing of raw materials for nanoparticle production can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. A comprehensive life cycle assessment is necessary to fully understand the environmental implications of nano-enhanced glass production.

Intellectual Property Landscape in Nano-Glass Technology

The intellectual property landscape in nano-glass technology is rapidly evolving, reflecting the growing interest and investment in this innovative field. Patents related to nanotechnology integration with borosilicate glass have seen a significant increase over the past decade, with major players from both academia and industry contributing to the expanding knowledge base.

Key patent holders in this domain include multinational corporations such as Corning, Schott, and AGC, who have established strong portfolios covering various aspects of nano-glass technology. These companies have filed patents on methods for incorporating nanoparticles into borosilicate glass matrices, techniques for enhancing mechanical and optical properties, and processes for creating nanostructured surfaces on glass substrates.

Universities and research institutions have also made substantial contributions to the patent landscape. Notable examples include MIT, Stanford University, and the Max Planck Institute, which have patented novel approaches to synthesizing nanocomposite glasses and controlling their properties at the nanoscale.

The geographical distribution of patents reveals a concentration in developed countries, with the United States, Japan, and Germany leading in terms of patent filings. However, emerging economies such as China and South Korea are rapidly increasing their patent activities in this field, indicating a shift in the global innovation landscape.

Patent trends show a focus on several key areas within nano-glass technology. These include methods for improving the durability and scratch resistance of borosilicate glass through nanoparticle incorporation, techniques for enhancing the optical properties of glass for advanced display applications, and processes for creating self-cleaning and anti-fogging surfaces using nanostructured coatings.

Recent patent filings have also highlighted growing interest in the development of smart glass technologies that integrate nanomaterials for dynamic control of optical and thermal properties. Additionally, there is an increasing emphasis on environmentally friendly manufacturing processes and the use of sustainable nanomaterials in glass production.

The patent landscape also reveals potential areas for future innovation. These include the development of multifunctional nano-glass composites that combine multiple enhanced properties, such as improved mechanical strength, optical clarity, and chemical resistance. Another emerging trend is the integration of nano-glass technologies with other advanced materials and systems, such as flexible electronics and energy harvesting devices.

As the field continues to advance, it is likely that the intellectual property landscape will become increasingly complex, with a growing number of cross-licensing agreements and potential patent disputes. This underscores the importance of comprehensive patent strategies for companies and research institutions operating in the nano-glass technology space.

Key patent holders in this domain include multinational corporations such as Corning, Schott, and AGC, who have established strong portfolios covering various aspects of nano-glass technology. These companies have filed patents on methods for incorporating nanoparticles into borosilicate glass matrices, techniques for enhancing mechanical and optical properties, and processes for creating nanostructured surfaces on glass substrates.

Universities and research institutions have also made substantial contributions to the patent landscape. Notable examples include MIT, Stanford University, and the Max Planck Institute, which have patented novel approaches to synthesizing nanocomposite glasses and controlling their properties at the nanoscale.

The geographical distribution of patents reveals a concentration in developed countries, with the United States, Japan, and Germany leading in terms of patent filings. However, emerging economies such as China and South Korea are rapidly increasing their patent activities in this field, indicating a shift in the global innovation landscape.

Patent trends show a focus on several key areas within nano-glass technology. These include methods for improving the durability and scratch resistance of borosilicate glass through nanoparticle incorporation, techniques for enhancing the optical properties of glass for advanced display applications, and processes for creating self-cleaning and anti-fogging surfaces using nanostructured coatings.

Recent patent filings have also highlighted growing interest in the development of smart glass technologies that integrate nanomaterials for dynamic control of optical and thermal properties. Additionally, there is an increasing emphasis on environmentally friendly manufacturing processes and the use of sustainable nanomaterials in glass production.

The patent landscape also reveals potential areas for future innovation. These include the development of multifunctional nano-glass composites that combine multiple enhanced properties, such as improved mechanical strength, optical clarity, and chemical resistance. Another emerging trend is the integration of nano-glass technologies with other advanced materials and systems, such as flexible electronics and energy harvesting devices.

As the field continues to advance, it is likely that the intellectual property landscape will become increasingly complex, with a growing number of cross-licensing agreements and potential patent disputes. This underscores the importance of comprehensive patent strategies for companies and research institutions operating in the nano-glass technology space.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!